Refine search

Actions for selected content:

106116 results in Materials Science

Fabrication of amorphous Co–Cr–B and catalytic sodium borohydride hydrolysis for hydrogen generation

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 3 / 14 February 2020

- Published online by Cambridge University Press:

- 17 January 2020, pp. 281-288

- Print publication:

- 14 February 2020

-

- Article

- Export citation

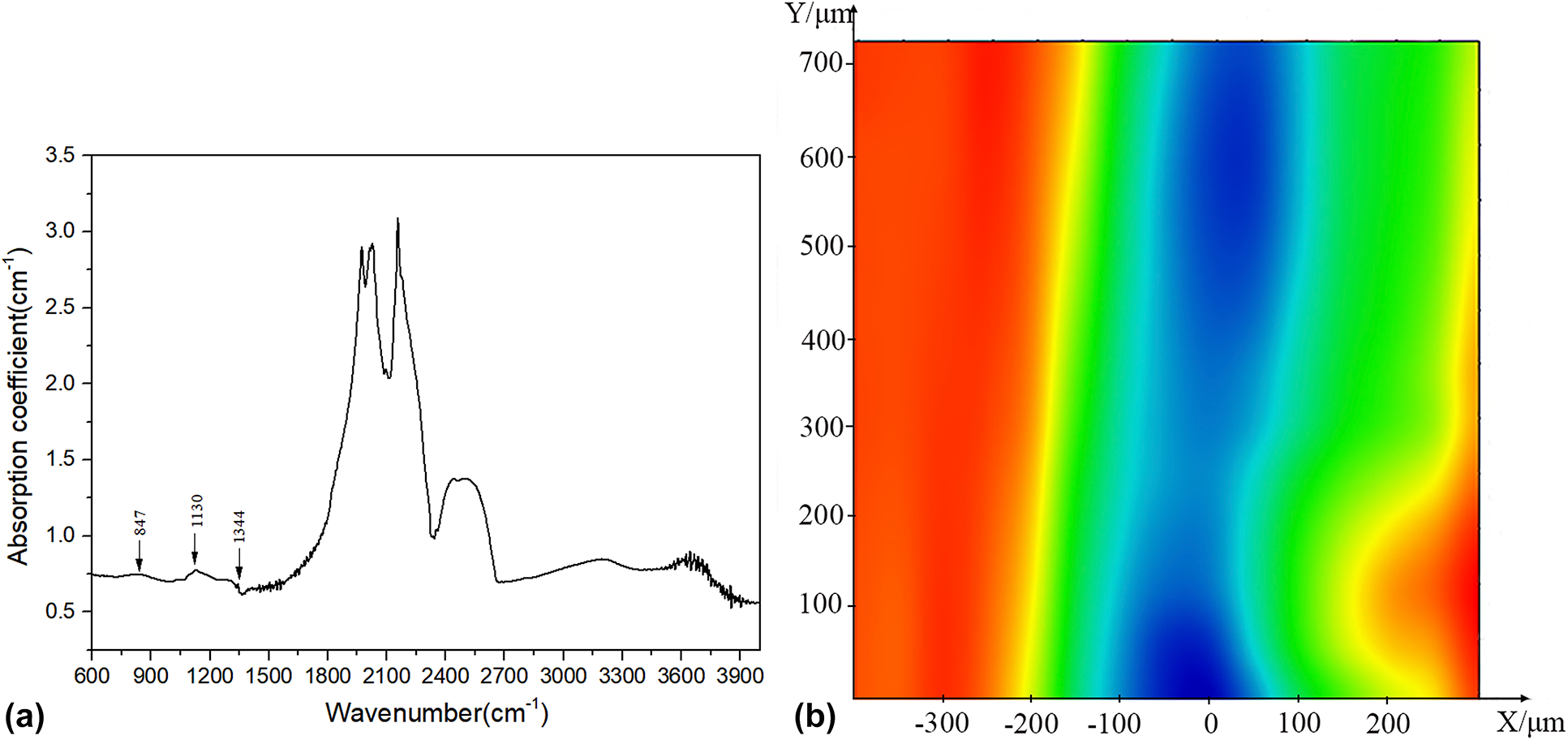

Effect of LPHT annealing on interface characteristics between HPHT Ib diamond substrates and homoepitaxial CVD diamond layers

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 5 / 16 March 2020

- Published online by Cambridge University Press:

- 17 January 2020, pp. 527-536

- Print publication:

- 16 March 2020

-

- Article

- Export citation

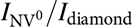

Controllable atomic layer deposition coatings to boost the performance of LiMnxCoyNi1−x−yO2 in lithium-ion batteries: A review

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 7 / 14 April 2020

- Published online by Cambridge University Press:

- 17 January 2020, pp. 762-774

- Print publication:

- 14 April 2020

-

- Article

-

- You have access

- HTML

- Export citation

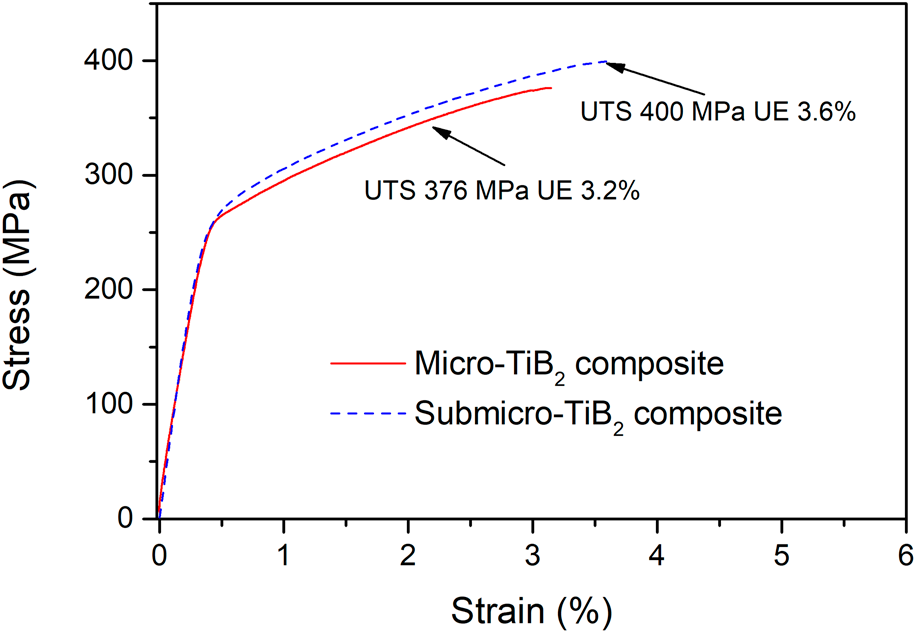

Effect of ceramic particle size on densification behavior, microstructure formation, and performance of TiB2-reinforced Al-based composites prepared by selective laser melting

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 6 / 30 March 2020

- Published online by Cambridge University Press:

- 17 January 2020, pp. 559-570

- Print publication:

- 30 March 2020

-

- Article

- Export citation

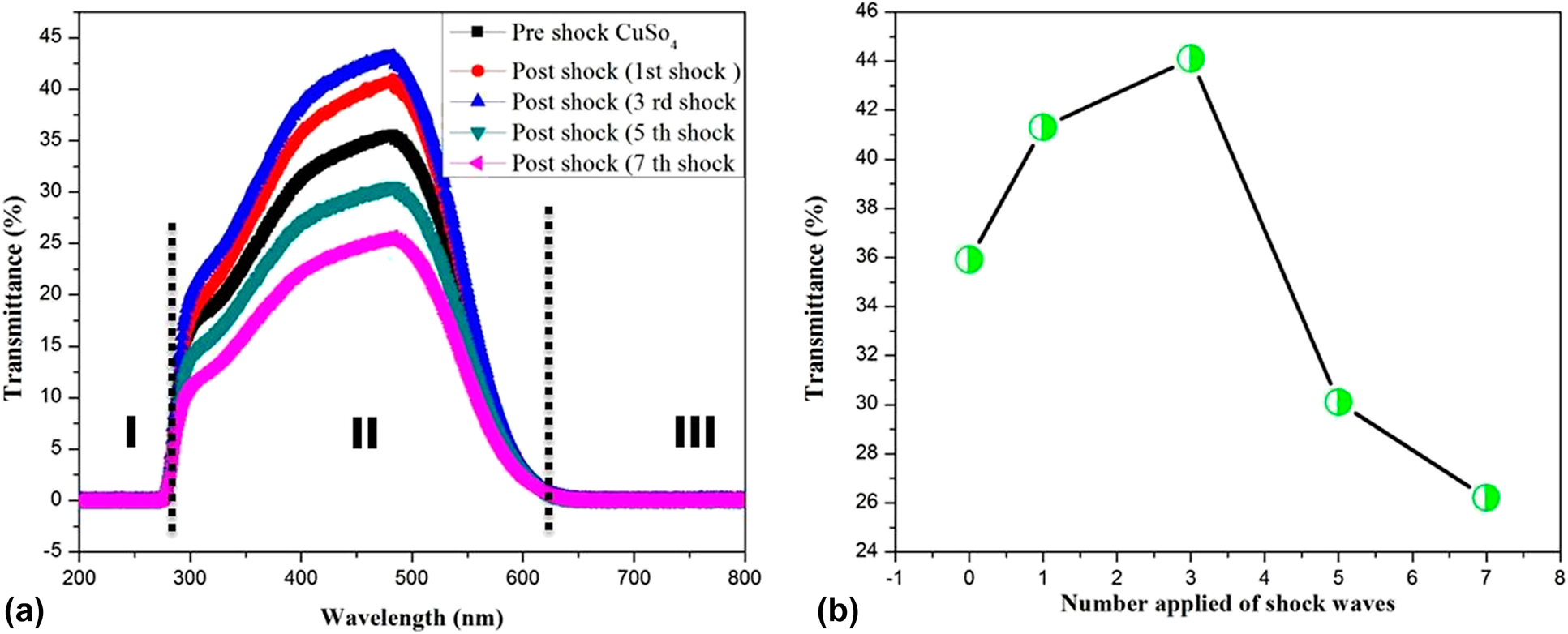

Enhancement of the optical properties of copper sulfate crystal by the influence of shock waves

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 4 / 28 February 2020

- Published online by Cambridge University Press:

- 17 January 2020, pp. 391-400

- Print publication:

- 28 February 2020

-

- Article

- Export citation

Atomistic kinetic Monte Carlo—Embedded atom method simulation on growth and morphology of Cu–Zn–Sn precursor of Cu2ZnSnS4 solar cells

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 3 / 14 February 2020

- Published online by Cambridge University Press:

- 17 January 2020, pp. 252-262

- Print publication:

- 14 February 2020

-

- Article

- Export citation

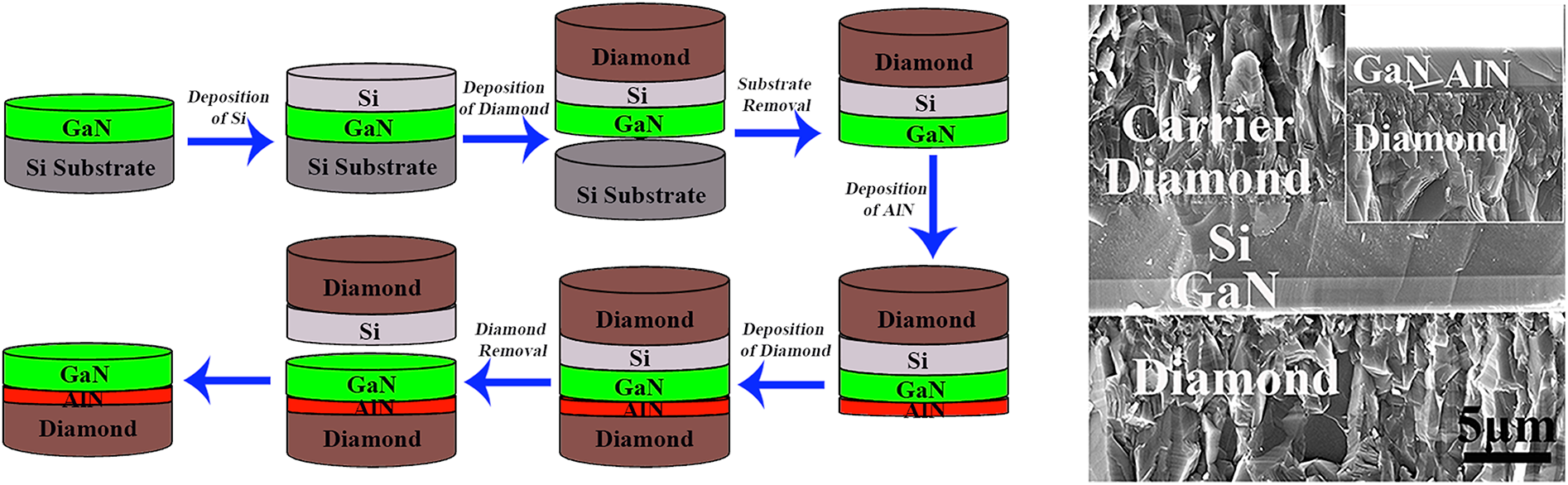

Enhancement of diamond seeding on aluminum nitride dielectric by electrostatic adsorption for GaN-on-diamond preparation

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 5 / 16 March 2020

- Published online by Cambridge University Press:

- 17 January 2020, pp. 508-515

- Print publication:

- 16 March 2020

-

- Article

- Export citation

Crystal structures of two polymorphs of alclometasone dipropionate, C28H37ClO7

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 15 January 2020, pp. 45-52

-

- Article

- Export citation

JMR volume 35 issue 1 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 1 / 14 January 2020

- Published online by Cambridge University Press:

- 14 January 2020, pp. b1-b3

- Print publication:

- 14 January 2020

-

- Article

-

- You have access

- Export citation

Effects of nanoporous Au on ATP synthase

-

- Journal:

- MRS Communications / Volume 10 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 14 January 2020, pp. 173-178

- Print publication:

- March 2020

-

- Article

- Export citation

Announcement

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 1 / 14 January 2020

- Published online by Cambridge University Press:

- 14 January 2020, p. 1

- Print publication:

- 14 January 2020

-

- Article

-

- You have access

- HTML

- Export citation

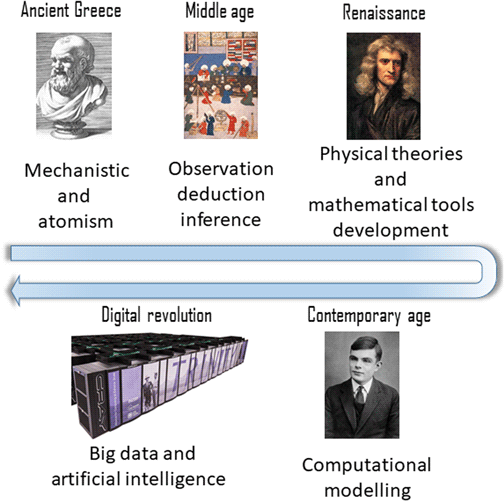

Growing field of materials informatics: databases and artificial intelligence

-

- Journal:

- MRS Communications / Volume 10 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 14 January 2020, pp. 1-10

- Print publication:

- March 2020

-

- Article

- Export citation

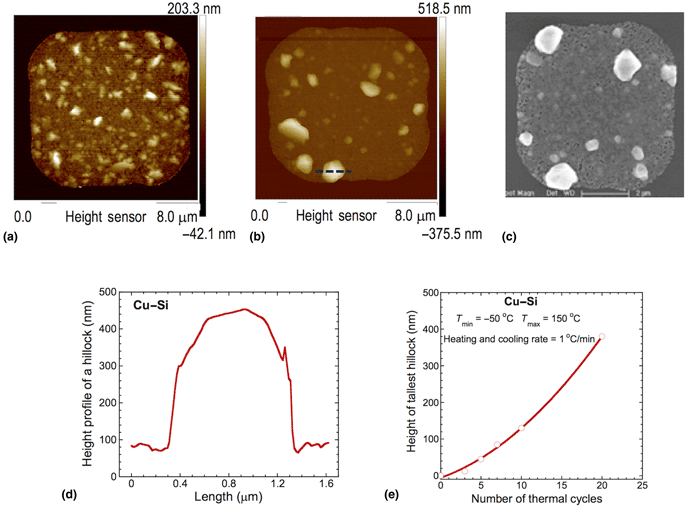

Effects of an interfacial layer on stress relaxation mechanisms active in the Cu–Si thin film system during thermal cycling

-

- Journal:

- MRS Communications / Volume 10 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 14 January 2020, pp. 164-172

- Print publication:

- March 2020

-

- Article

- Export citation

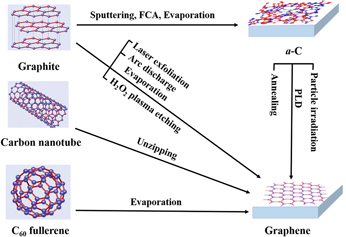

A review of graphene synthesis by indirect and direct deposition methods

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 1 / 14 January 2020

- Published online by Cambridge University Press:

- 14 January 2020, pp. 76-89

- Print publication:

- 14 January 2020

-

- Article

- Export citation

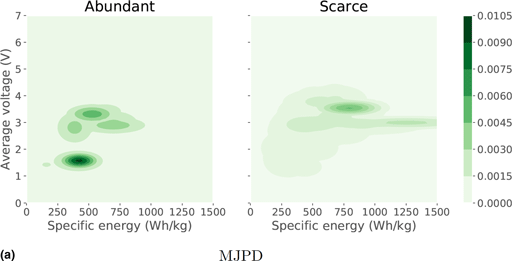

Design space visualization for guiding investments in biodegradable and sustainably sourced materials

-

- Journal:

- MRS Communications / Volume 10 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 14 January 2020, pp. 18-24

- Print publication:

- March 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

JMR volume 35 issue 1 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 1 / 14 January 2020

- Published online by Cambridge University Press:

- 14 January 2020, pp. f1-f5

- Print publication:

- 14 January 2020

-

- Article

-

- You have access

- Export citation

In situ atomic level studies of thermally controlled interlayer stacking shifts in 2D transition metal dichalcogenide bilayers

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 11 / 15 June 2020

- Published online by Cambridge University Press:

- 13 January 2020, pp. 1407-1416

- Print publication:

- 15 June 2020

-

- Article

- Export citation

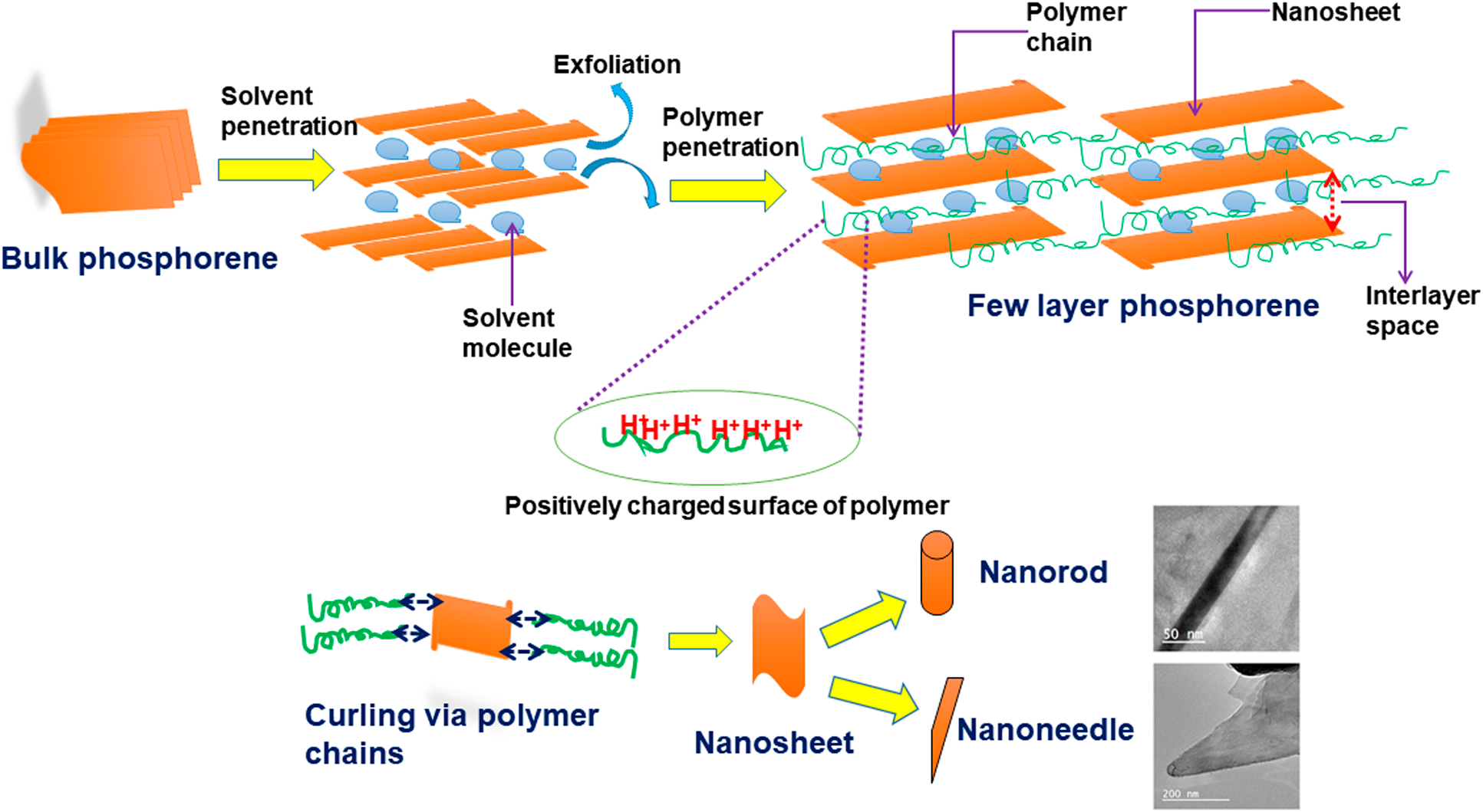

Controlled nanostructures and simultaneous passivation of black phosphorus (phosphorene) with Nafion

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 2 / 28 January 2020

- Published online by Cambridge University Press:

- 13 January 2020, pp. 141-152

- Print publication:

- 28 January 2020

-

- Article

- Export citation

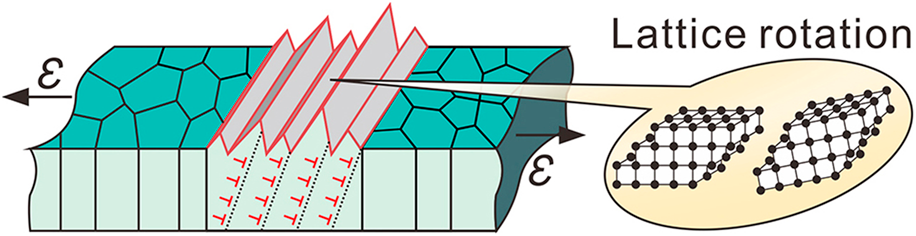

Cumulative shear strain–induced preferential orientation during abnormal grain growth near fatigue crack tips of nanocrystalline Au films

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 4 / 28 February 2020

- Published online by Cambridge University Press:

- 13 January 2020, pp. 372-379

- Print publication:

- 28 February 2020

-

- Article

- Export citation

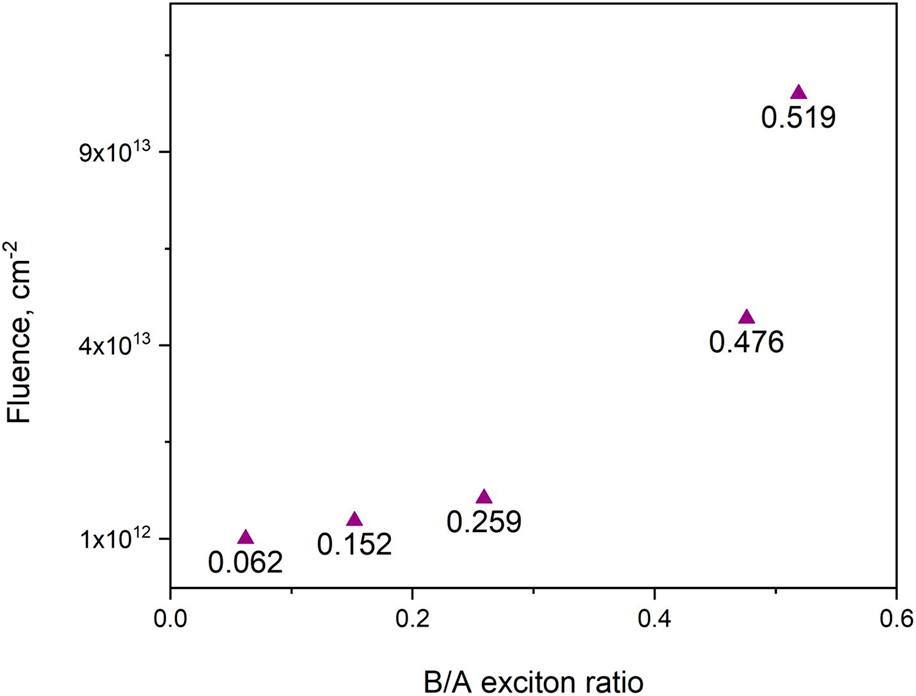

Controlling neutral and charged excitons in MoS2 with defects

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 8 / 28 April 2020

- Published online by Cambridge University Press:

- 13 January 2020, pp. 949-957

- Print publication:

- 28 April 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation