Refine search

Actions for selected content:

106116 results in Materials Science

Energy materials for transient power sources

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 121-128

- Print publication:

- February 2020

-

- Article

- Export citation

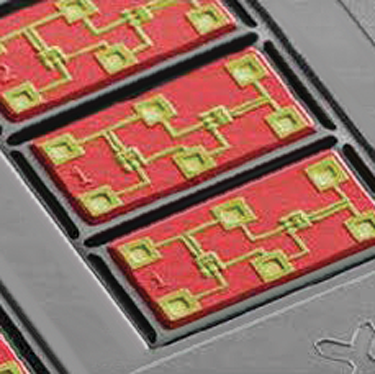

Advanced manufacturing for transient electronics

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 113-120

- Print publication:

- February 2020

-

- Article

- Export citation

MRS Journal Highlights

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, p. 142

- Print publication:

- February 2020

-

- Article

-

- You have access

- HTML

- Export citation

The emergence of transient electronic devices

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 87-95

- Print publication:

- February 2020

-

- Article

-

- You have access

- HTML

- Export citation

MRS volume 45 issue 2 Cover and Back matter

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. b1-b2

- Print publication:

- February 2020

-

- Article

-

- You have access

- Export citation

MRS Bulletin Volume Organizers guide technical theme topics for 2021

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, p. 148

- Print publication:

- February 2020

-

- Article

-

- You have access

- HTML

- Export citation

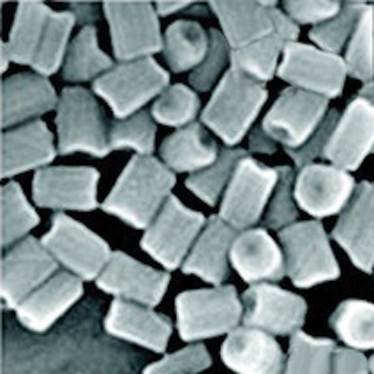

Self-assembly of functional nanoscale materials

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 135-141

- Print publication:

- February 2020

-

- Article

- Export citation

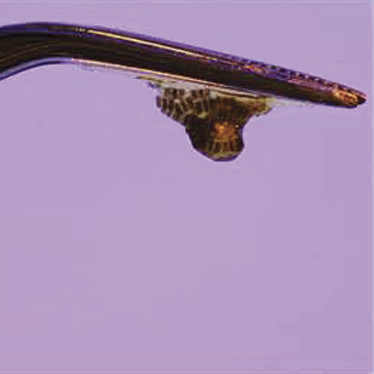

Inorganic materials for transient electronics in biomedical applications

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 103-112

- Print publication:

- February 2020

-

- Article

- Export citation

LOOK AGAIN

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, p. 152

- Print publication:

- February 2020

-

- Article

-

- You have access

- HTML

- Export citation

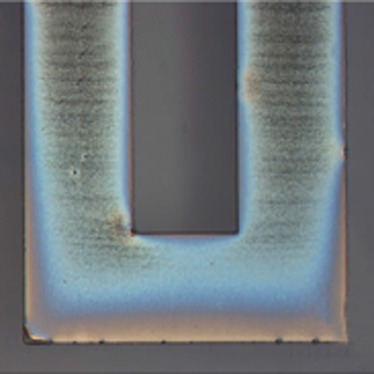

Material strategies for on-demand smart transient electronics

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 129-134

- Print publication:

- February 2020

-

- Article

- Export citation

Exploring user facilities

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 2 / February 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 146-147

- Print publication:

- February 2020

-

- Article

-

- You have access

- HTML

- Export citation

Certification of Standard Reference Material 660c for powder diffraction

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 31 January 2020, pp. 17-22

-

- Article

- Export citation

Tuning surface texture of electrospun polycaprolactone fibers: Effects of solvent systems and relative humidity

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 3 / 14 February 2020

- Published online by Cambridge University Press:

- 31 January 2020, pp. 332-342

- Print publication:

- 14 February 2020

-

- Article

- Export citation

Characterization and Rietveld refinements of new dense ceramics Ba3−xSrxTb3−xCexO9 (x = 1 and 1.5) perovskites

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 31 January 2020, pp. 23-30

-

- Article

- Export citation

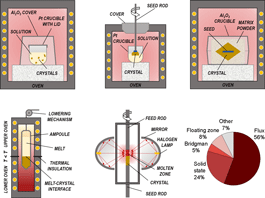

(K,Na)NbO3-based piezoelectric single crystals: Growth methods, properties, and applications

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 8 / 28 April 2020

- Published online by Cambridge University Press:

- 31 January 2020, pp. 990-1016

- Print publication:

- 28 April 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Van der Waals epitaxy and composition control of layered SnSxSe2−x alloy thin films

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 11 / 15 June 2020

- Published online by Cambridge University Press:

- 31 January 2020, pp. 1386-1396

- Print publication:

- 15 June 2020

-

- Article

- Export citation

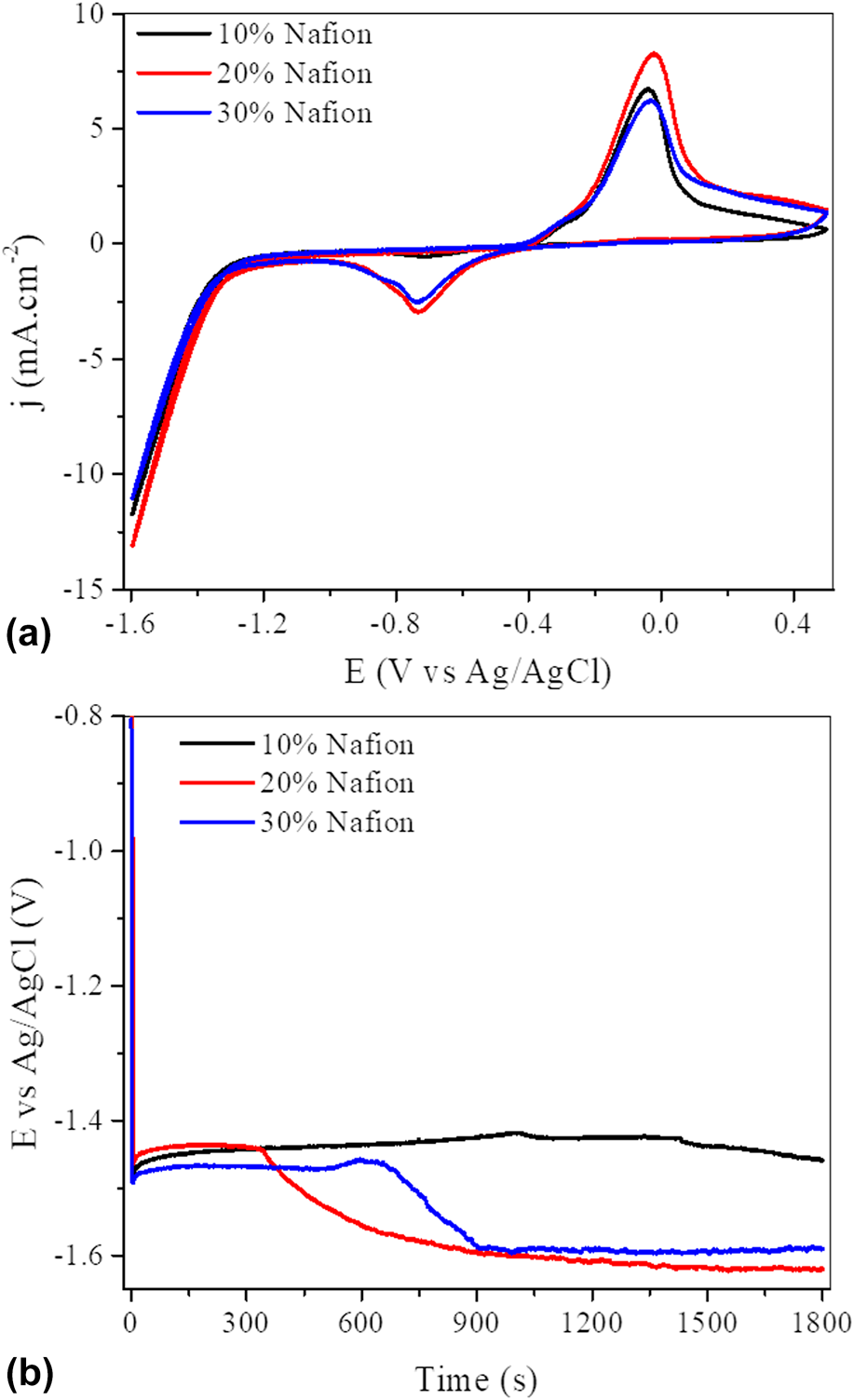

Electrochemical reduction of CO2 to formic acid on Bi2O2CO3/carbon fiber electrodes

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 3 / 14 February 2020

- Published online by Cambridge University Press:

- 31 January 2020, pp. 272-280

- Print publication:

- 14 February 2020

-

- Article

- Export citation

7 - Quantum Hall Effects in Graphene

-

- Book:

- Introduction to Graphene-Based Nanomaterials

- Published online:

- 10 January 2020

- Print publication:

- 30 January 2020, pp 210-236

-

- Chapter

- Export citation

2 - Electronic Properties of Carbon-Based Nanostructures

-

- Book:

- Introduction to Graphene-Based Nanomaterials

- Published online:

- 10 January 2020

- Print publication:

- 30 January 2020, pp 11-69

-

- Chapter

- Export citation

Frontmatter

-

- Book:

- Introduction to Graphene-Based Nanomaterials

- Published online:

- 10 January 2020

- Print publication:

- 30 January 2020, pp i-iv

-

- Chapter

- Export citation