Refine search

Actions for selected content:

106116 results in Materials Science

Agglomerated nickel–cobalt layered double hydroxide nanosheets on reduced graphene oxide clusters as efficient asymmetric supercapacitor electrodes

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 9 / 14 May 2020

- Published online by Cambridge University Press:

- 21 February 2020, pp. 1205-1213

- Print publication:

- 14 May 2020

-

- Article

- Export citation

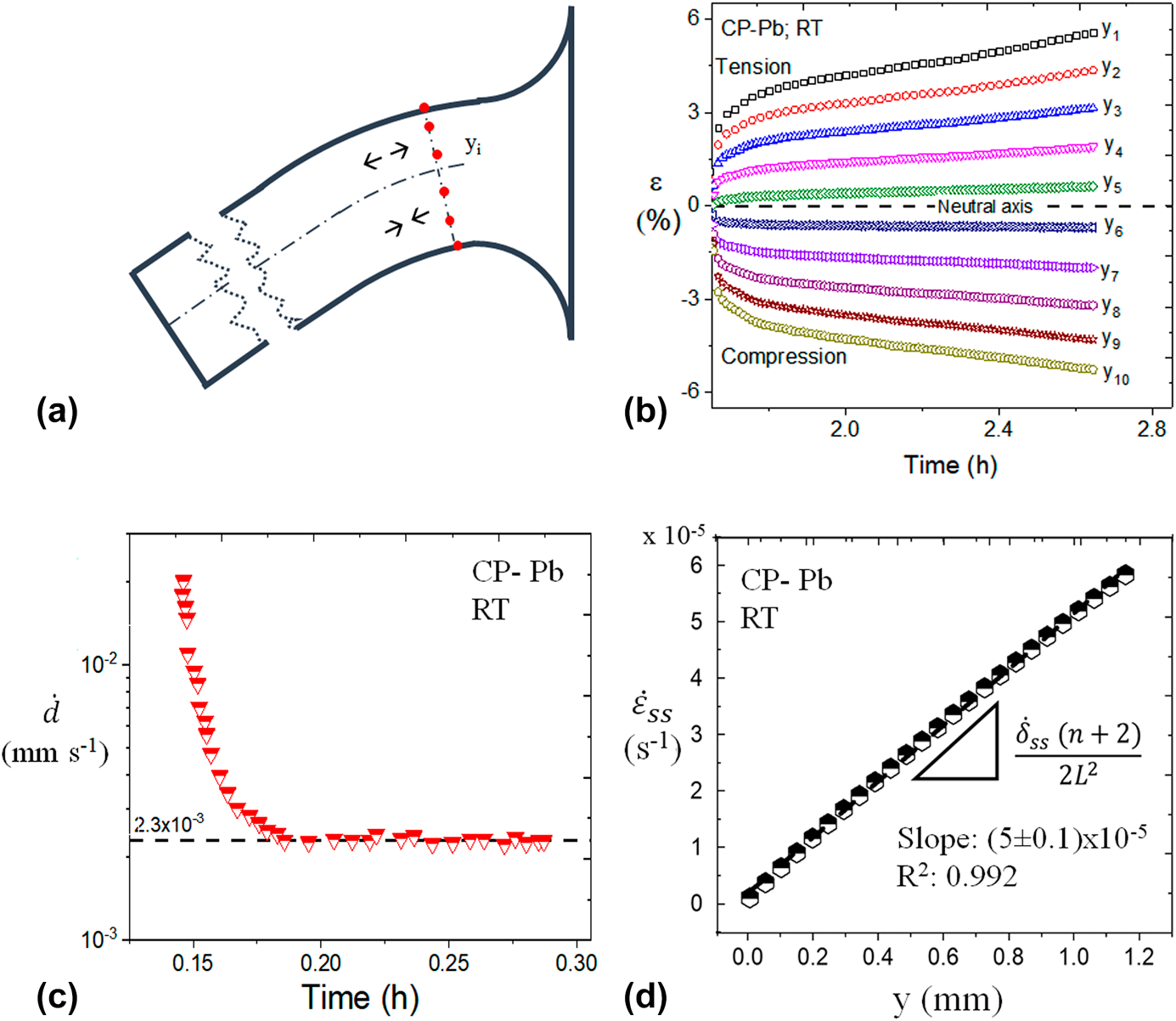

High Throughput Determination of Creep Parameters Using Cantilever Bending: Part I - Steady-State

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 4 / 28 February 2020

- Published online by Cambridge University Press:

- 19 February 2020, pp. 353-361

- Print publication:

- 28 February 2020

-

- Article

- Export citation

High Throughput Determination of Creep Parameters Using Cantilever Bending: Part II - Primary and Steady-State through Uniaxial Equivalency

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 4 / 28 February 2020

- Published online by Cambridge University Press:

- 18 February 2020, pp. 362-371

- Print publication:

- 28 February 2020

-

- Article

- Export citation

Nanoindentation-induced deformation, microfracture, and phase transformation in crystalline materials investigated in situ by acoustic emission

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 4 / 28 February 2020

- Published online by Cambridge University Press:

- 17 February 2020, pp. 380-390

- Print publication:

- 28 February 2020

-

- Article

- Export citation

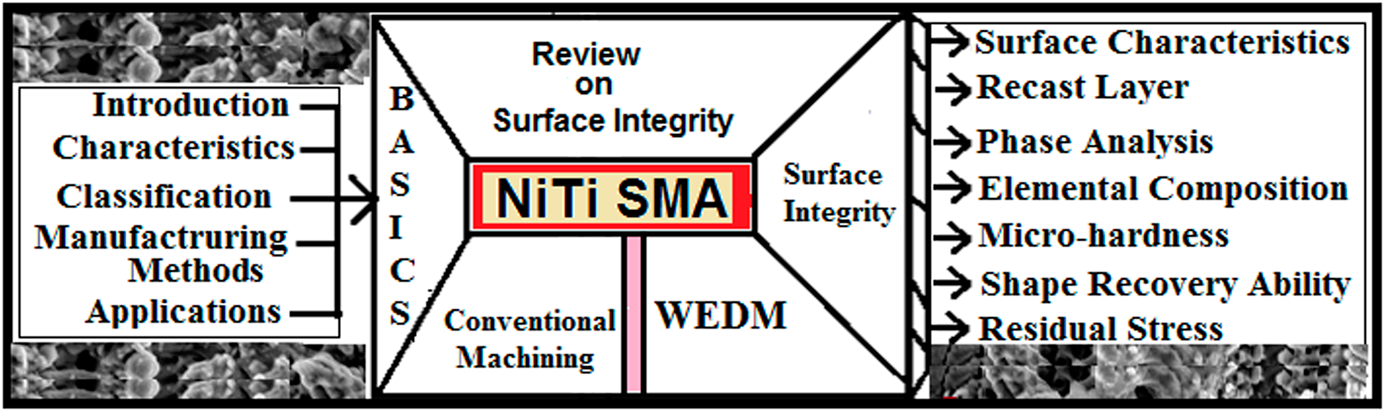

Surface integrity aspects for NiTi shape memory alloys during wire electric discharge machining: A review

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 6 / 30 March 2020

- Published online by Cambridge University Press:

- 17 February 2020, pp. 537-558

- Print publication:

- 30 March 2020

-

- Article

- Export citation

JMR volume 35 issue 3 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 3 / 14 February 2020

- Published online by Cambridge University Press:

- 14 February 2020, pp. f1-f4

- Print publication:

- 14 February 2020

-

- Article

-

- You have access

- Export citation

Microstructure study of U–35 wt.% Zr alloy after quick annealing at 650 °C

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 8 / 28 April 2020

- Published online by Cambridge University Press:

- 14 February 2020, pp. 1095-1102

- Print publication:

- 28 April 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

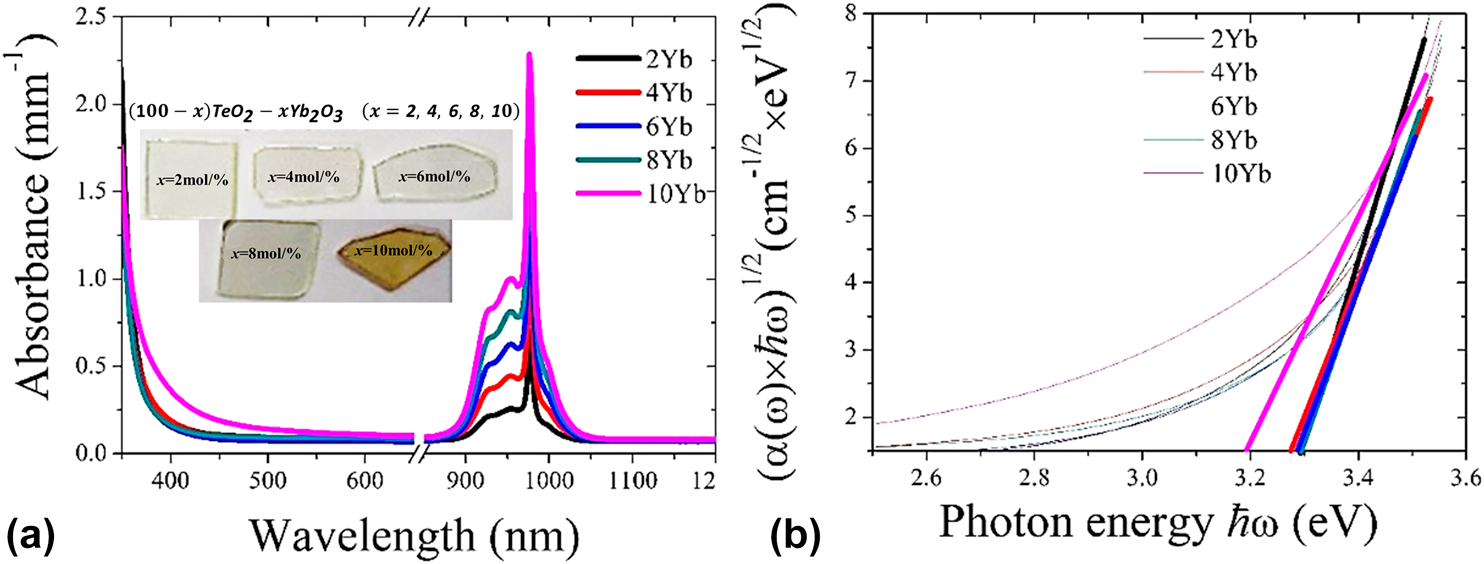

Studies on the influence of structure units on the state of ytterbium ions in TeO2-based glasses

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 4 / 28 February 2020

- Published online by Cambridge University Press:

- 14 February 2020, pp. 422-429

- Print publication:

- 28 February 2020

-

- Article

- Export citation

JMR volume 35 issue 3 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 3 / 14 February 2020

- Published online by Cambridge University Press:

- 14 February 2020, pp. b1-b2

- Print publication:

- 14 February 2020

-

- Article

-

- You have access

- Export citation

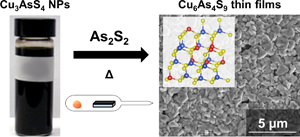

Synthesis and characterization of semiconducting sinnerite (Cu6As4S9) thin films

-

- Journal:

- MRS Communications / Volume 10 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 12 February 2020, pp. 188-193

- Print publication:

- March 2020

-

- Article

- Export citation

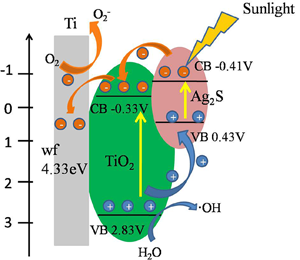

Optimization of photoelectrochemical performance of Ag2S/TiO2 interface by successive ionic layer adsorption and reaction

-

- Journal:

- MRS Communications / Volume 10 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 11 February 2020, pp. 194-199

- Print publication:

- March 2020

-

- Article

- Export citation

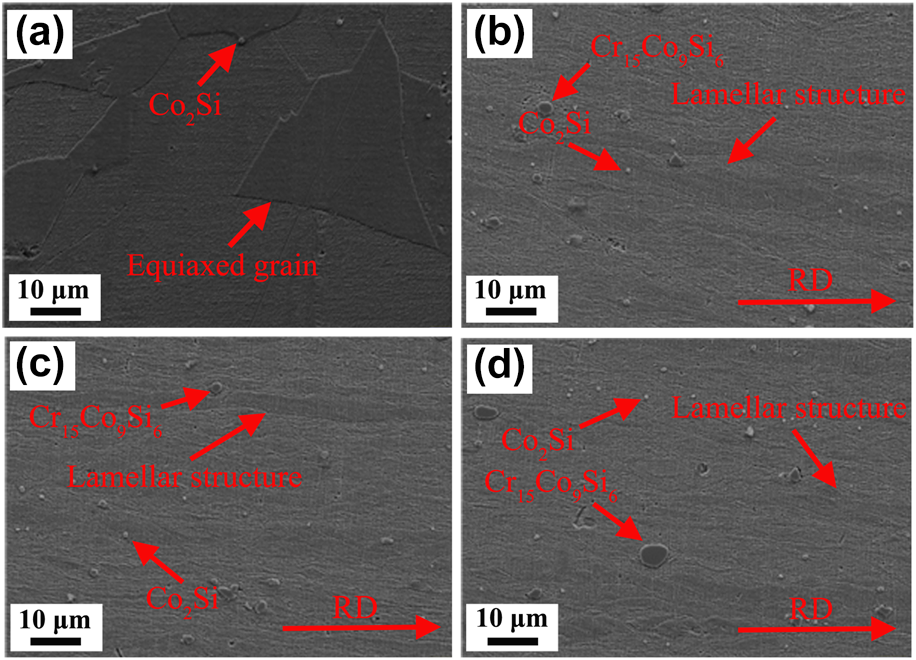

Precipitate phase transformation behavior, microstructure, and properties of Cu–Cr–Co–Si alloy

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 6 / 30 March 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 623-632

- Print publication:

- 30 March 2020

-

- Article

- Export citation

A systematic investigation on physical properties of spray pyrolysis–fabricated CdS thin films for opto-nonlinear applications: An effect of Na doping

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 4 / 28 February 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 410-421

- Print publication:

- 28 February 2020

-

- Article

- Export citation

Crystal structure of 1-propanethiol–Co2(dobdc) from laboratory X-ray powder diffraction data

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 3-6

-

- Article

- Export citation

Relaxor behavior and electrothermal properties of Sn- and Nb-modified (Ba,Ca)TiO3 Pb-free ferroelectric

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 8 / 28 April 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 1017-1027

- Print publication:

- 28 April 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

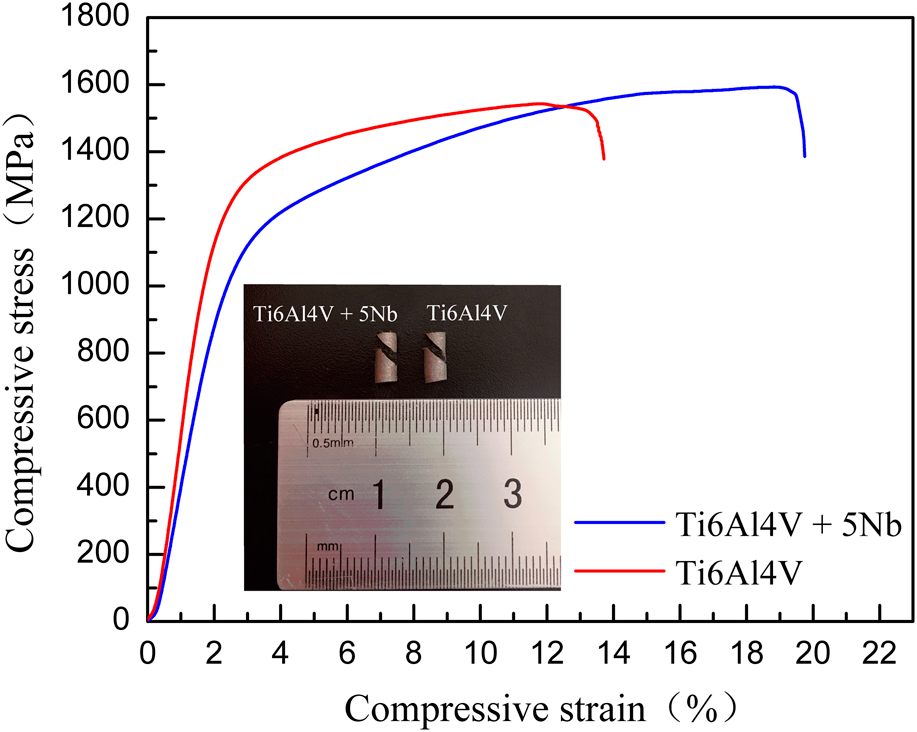

Effect of Nb addition on mechanical properties and corrosion behavior of Ti6Al4V alloy produced by selective laser melting

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 6 / 30 March 2020

- Published online by Cambridge University Press:

- 10 February 2020, pp. 571-579

- Print publication:

- 30 March 2020

-

- Article

- Export citation

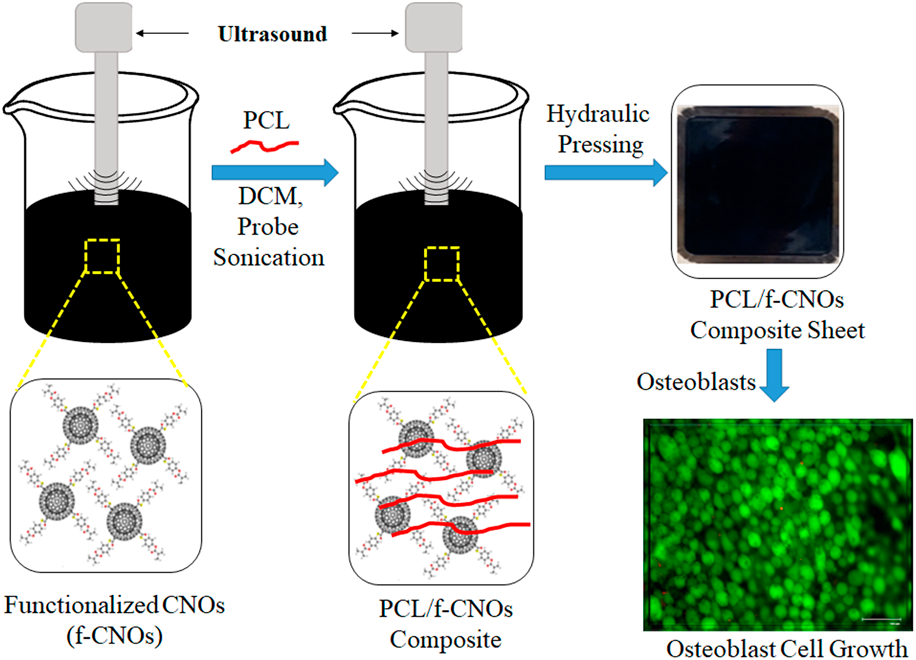

Engineering of functionalized carbon nano-onions reinforced nanocomposites: Fabrication, biocompatibility, and mechanical properties

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 8 / 28 April 2020

- Published online by Cambridge University Press:

- 07 February 2020, pp. 922-930

- Print publication:

- 28 April 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Bulk polycrystalline ceria–doped Al2O3 and YAG ceramics for high-power density laser-driven solid-state white lighting: Effects of crystallinity and extreme temperatures

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 8 / 28 April 2020

- Published online by Cambridge University Press:

- 07 February 2020, pp. 958-971

- Print publication:

- 28 April 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

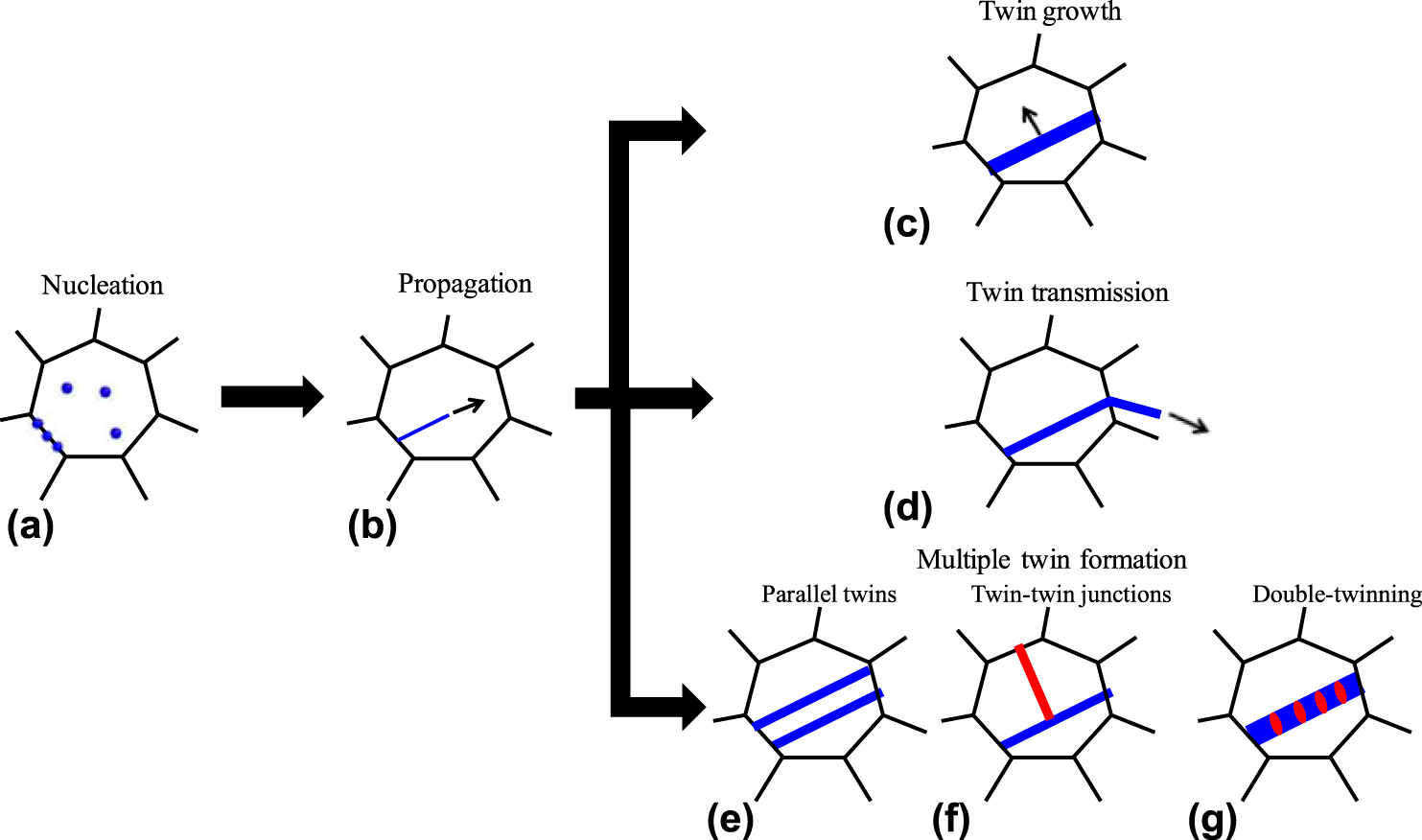

Local microstructure and micromechanical stress evolution during deformation twinning in hexagonal polycrystals

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 3 / 14 February 2020

- Published online by Cambridge University Press:

- 07 February 2020, pp. 217-241

- Print publication:

- 14 February 2020

-

- Article

- Export citation

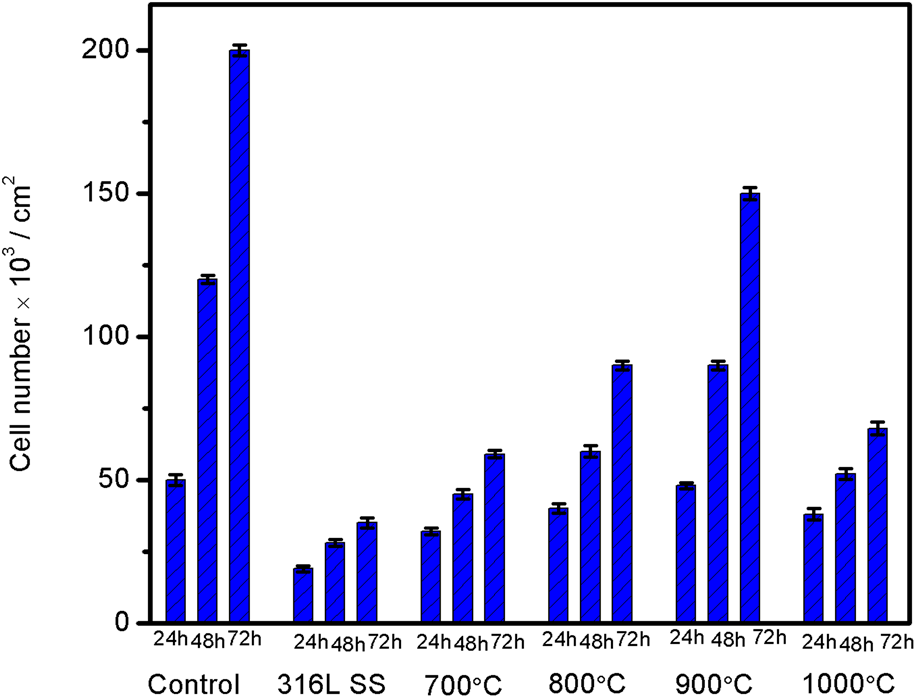

Sintering temperature effects on nano triphasic bioceramic composite coated 316L SS for corrosion resistance, adhesion strength, and cell proliferation on implants

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 6 / 30 March 2020

- Published online by Cambridge University Press:

- 07 February 2020, pp. 580-590

- Print publication:

- 30 March 2020

-

- Article

- Export citation