Refine search

Actions for selected content:

106116 results in Materials Science

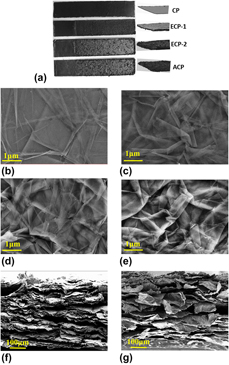

Enhanced capacitive performance of activated carbon paper electrode material

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 14 / 28 July 2019

- Published online by Cambridge University Press:

- 29 July 2019, pp. 2472-2481

- Print publication:

- 28 July 2019

-

- Article

- Export citation

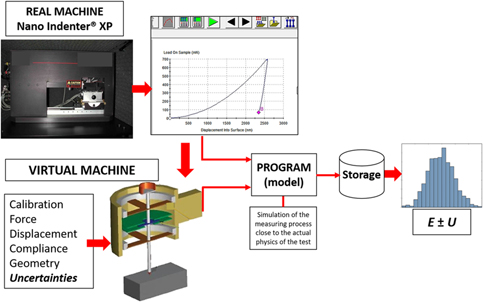

Virtual machine concept applied to uncertainties estimation in instrumented indentation testing

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 14 / 28 July 2019

- Published online by Cambridge University Press:

- 29 July 2019, pp. 2501-2516

- Print publication:

- 28 July 2019

-

- Article

- Export citation

JMR volume 34 issue 14 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 14 / 28 July 2019

- Published online by Cambridge University Press:

- 29 July 2019, pp. f1-f5

- Print publication:

- 28 July 2019

-

- Article

-

- You have access

- Export citation

Antibody-conjugated near-infrared luminescent silicon quantum dots for biosensing

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 26 July 2019, pp. 1079-1086

- Print publication:

- September 2019

-

- Article

- Export citation

X-ray characterization of crosslinked methacrylate copolymers for application as dielectric layers in organic electronics

-

- Journal:

- Powder Diffraction / Volume 34 / Issue S1 / September 2019

- Published online by Cambridge University Press:

- 25 July 2019, pp. S71-S81

-

- Article

- Export citation

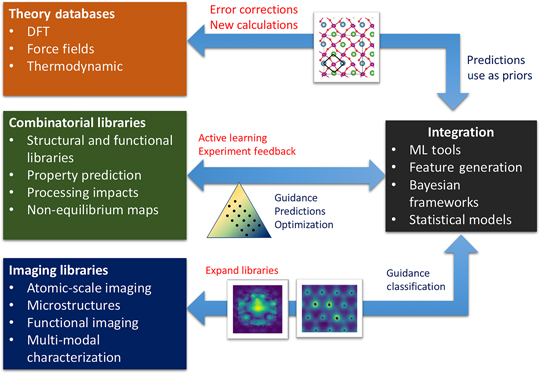

Materials science in the artificial intelligence age: high-throughput library generation, machine learning, and a pathway from correlations to the underpinning physics

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 22 July 2019, pp. 821-838

- Print publication:

- September 2019

-

- Article

- Export citation

DNA nanotechnology for building artificial dynamic systems – ERRATUM

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 22 July 2019, p. 665

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

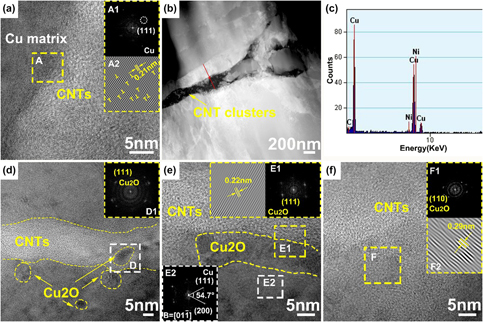

Optimizing the interface bonding in Cu matrix composites by using functionalized carbon nanotubes and cold rolling

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 19 July 2019, pp. 2600-2608

- Print publication:

- 14 August 2019

-

- Article

- Export citation

Effect of substrate properties on isothermal fatigue of aerosol jet printed nano-Ag traces on flex

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 16 / 28 August 2019

- Published online by Cambridge University Press:

- 19 July 2019, pp. 2903-2910

- Print publication:

- 28 August 2019

-

- Article

- Export citation

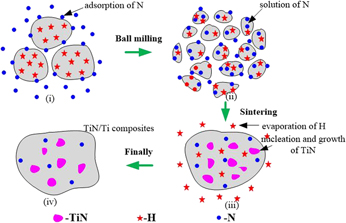

Nano-sized TiN-reinforced composites: Fabrication, microstructure, and mechanical properties

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 19 July 2019, pp. 2582-2589

- Print publication:

- 14 August 2019

-

- Article

- Export citation

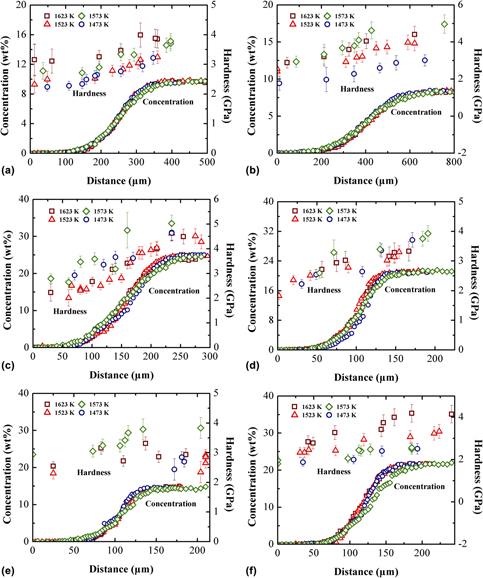

Study of microstructure and mechanical property heterogeneity throughout the wall thickness of high strength aluminum alloy thick-wall pipe

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 19 July 2019, pp. 2736-2745

- Print publication:

- 14 August 2019

-

- Article

- Export citation

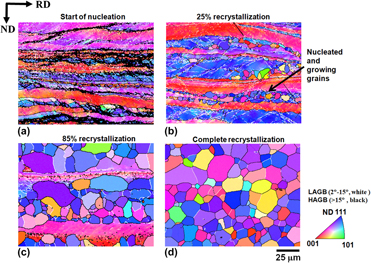

Recrystallization behavior of a cold rolled Ti–15V–3Sn–3Cr–3Al alloy

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 18 July 2019, pp. 3082-3092

- Print publication:

- 30 September 2019

-

- Article

- Export citation

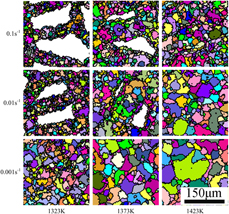

Cellular automaton modeling of dynamic recrystallization of Ni–Cr–Mo-based C276 superalloy during hot compression

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 16 July 2019, pp. 3093-3103

- Print publication:

- 30 September 2019

-

- Article

- Export citation

A green and facile strategy for hierarchically porous poly(L-lactic acid)/poly(ε-caprolactone) monolithic composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 17 / 16 September 2019

- Published online by Cambridge University Press:

- 16 July 2019, pp. 2990-2999

- Print publication:

- 16 September 2019

-

- Article

- Export citation

Composition-dependent hardness and Young’s modulus in fcc Ni–X (X = Rh, Ta, W, Re, Os, and Ir) alloys: Experimental measurements and CALPHAD modeling

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 16 July 2019, pp. 3104-3115

- Print publication:

- 30 September 2019

-

- Article

- Export citation

Density functional theory meta GGA study of water adsorption in MIL-53(Cr)

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 16 July 2019, pp. 227-232

-

- Article

- Export citation

Thermodynamic properties of lanthanum, neodymium, gadolinium hafnates (Ln2Hf2O7): Calorimetric and KEMS studies

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 19 / 14 October 2019

- Published online by Cambridge University Press:

- 16 July 2019, pp. 3326-3336

- Print publication:

- 14 October 2019

-

- Article

- Export citation

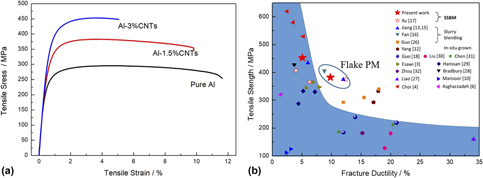

Fabrication and mechanical properties of CNT/Al composites via shift-speed ball milling and hot-rolling

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 16 July 2019, pp. 2609-2619

- Print publication:

- 14 August 2019

-

- Article

- Export citation

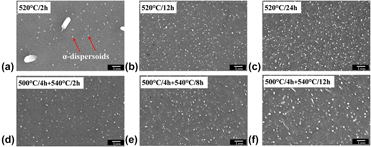

Precipitation behavior of dispersoids and elevated-temperature properties in Al–Si–Mg foundry alloy with Mo addition

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 16 July 2019, pp. 3071-3081

- Print publication:

- 30 September 2019

-

- Article

- Export citation

Thermodynamics of BaNd2O4 and phase diagram of the BaO–Nd2O3 system

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 19 / 14 October 2019

- Published online by Cambridge University Press:

- 16 July 2019, pp. 3337-3342

- Print publication:

- 14 October 2019

-

- Article

- Export citation