Refine search

Actions for selected content:

106116 results in Materials Science

Nomenclature

-

- Book:

- An Introduction to Composite Materials

- Published online:

- 04 July 2019

- Print publication:

- 11 July 2019, pp xiii-xvi

-

- Chapter

- Export citation

2019 ICDD Spring Meeting 11–15 March – ICDD® Headquarters

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 11 July 2019, pp. 198-202

-

- Article

- Export citation

5 - Elastic Deformation of Laminates

-

- Book:

- An Introduction to Composite Materials

- Published online:

- 04 July 2019

- Print publication:

- 11 July 2019, pp 67-76

-

- Chapter

- Export citation

9 - Fracture Mechanics and the Toughness of Composites

-

- Book:

- An Introduction to Composite Materials

- Published online:

- 04 July 2019

- Print publication:

- 11 July 2019, pp 142-177

-

- Chapter

- Export citation

PDJ volume 34 issue 2 Cover and Front matter

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 11 July 2019, pp. f1-f6

-

- Article

-

- You have access

- Export citation

Calendar of Forthcoming Meetings

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 11 July 2019, pp. 211-212

-

- Article

-

- You have access

- HTML

- Export citation

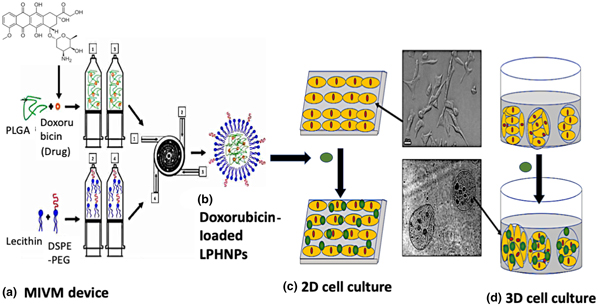

Improving the physiological relevance of drug testing for drug-loaded nanoparticles using 3D tumor cell cultures

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 10 July 2019, pp. 1053-1059

- Print publication:

- September 2019

-

- Article

- Export citation

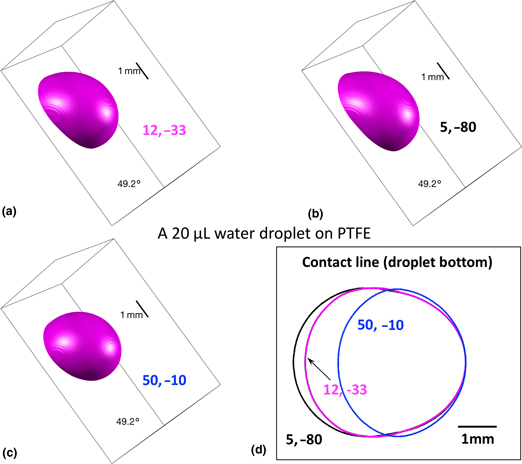

Simulating contact angle hysteresis using pseudo-line tensions

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 10 July 2019, pp. 1060-1066

- Print publication:

- September 2019

-

- Article

- Export citation

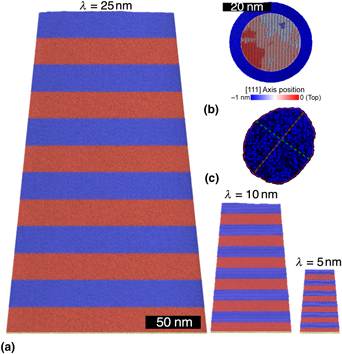

Surface flaws control strain localization in the deformation of Cu|Au nanolaminate pillars

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 10 July 2019, pp. 1067-1071

- Print publication:

- September 2019

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

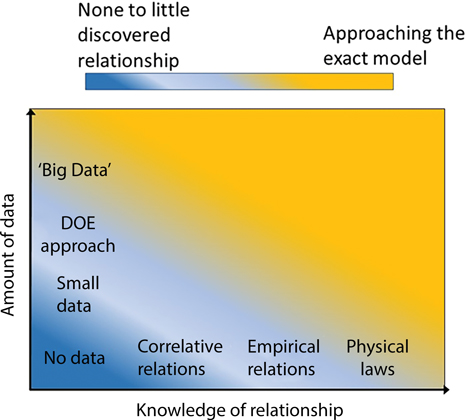

Embedding domain knowledge for machine learning of complex material systems

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 10 July 2019, pp. 806-820

- Print publication:

- September 2019

-

- Article

- Export citation

An Introduction to Composite Materials

-

- Published online:

- 04 July 2019

- Print publication:

- 11 July 2019

-

- Textbook

- Export citation

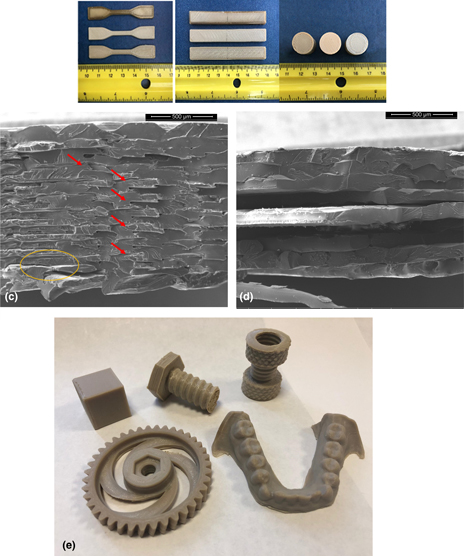

On the thermal processing and mechanical properties of 3D-printed polyether ether ketone

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 03 July 2019, pp. 1046-1052

- Print publication:

- September 2019

-

- Article

- Export citation

A new exponential function to represent the effect of grain size on the strength of pure iron over multiple length scales

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 03 July 2019, pp. 2315-2324

- Print publication:

- 15 July 2019

-

- Article

- Export citation

History of the reciprocal lattice

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 03 July 2019, pp. 260-266

-

- Article

- Export citation

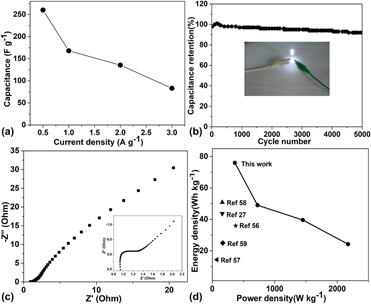

Hierarchical mesoporous Zn–Ni–Co–S microspheres grown on reduced graphene oxide/nickel foam for asymmetric supercapacitors

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 14 / 28 July 2019

- Published online by Cambridge University Press:

- 02 July 2019, pp. 2445-2455

- Print publication:

- 28 July 2019

-

- Article

- Export citation

A new nanoindentation creep technique using constant contact pressure

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 14 / 28 July 2019

- Published online by Cambridge University Press:

- 02 July 2019, pp. 2492-2500

- Print publication:

- 28 July 2019

-

- Article

- Export citation

The machine learning revolution in materials?

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 7 / July 2019

- Published online by Cambridge University Press:

- 12 July 2019, pp. 530-537

- Print publication:

- July 2019

-

- Article

-

- You have access

- HTML

- Export citation

Commercializing colloidal quantum dot photovoltaics

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 7 / July 2019

- Published online by Cambridge University Press:

- 12 July 2019, pp. 524-525

- Print publication:

- July 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS volume 44 issue 7 Cover and Front matter

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 7 / July 2019

- Published online by Cambridge University Press:

- 12 July 2019, pp. f1-f6

- Print publication:

- July 2019

-

- Article

-

- You have access

- Export citation

Engaging and inspiring MRS members

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 7 / July 2019

- Published online by Cambridge University Press:

- 12 July 2019, pp. 517-518

- Print publication:

- July 2019

-

- Article

-

- You have access

- HTML

- Export citation