Refine search

Actions for selected content:

106116 results in Materials Science

Structural and optical properties of Ba(Co1−xZnx)SiO4 (x = 0.2, 0.4, 0.6, 0.8)

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 20 June 2019, pp. 242-250

-

- Article

- Export citation

Index

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 513-528

-

- Chapter

- Export citation

Chapter 6 - Crystallization Process Analysis by Population Balance Modeling

-

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 172-196

-

- Chapter

- Export citation

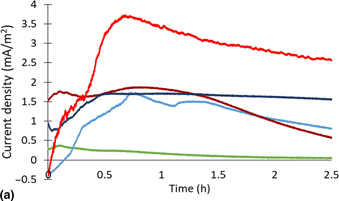

Peptide-mediated binding of gold nanoparticles to E. coli for enhanced microbial fuel cell power generation

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 20 June 2019, pp. 904-909

- Print publication:

- September 2019

-

- Article

- Export citation

Chapter 4 - The Influence of Impurities and Additives on Crystallization

-

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 115-135

-

- Chapter

- Export citation

Contributors

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp viii-viii

-

- Chapter

- Export citation

Chapter 16 - Precipitation and Crystallization of Pigments

-

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 479-512

-

- Chapter

- Export citation

Preface to the Third Edition

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp xiii-xiii

-

- Chapter

- Export citation

Preface to the Second Edition

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp xi-xii

-

- Chapter

- Export citation

Chapter 7 - Selection and Design of Industrial Crystallizers

-

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 197-215

-

- Chapter

- Export citation

Chapter 11 - Monitoring and Advanced Control of Crystallization Processes

-

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 313-345

-

- Chapter

- Export citation

Copyright page

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp iv-iv

-

- Chapter

- Export citation

An improved process for the graphene preparation via redox potential control

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 20 June 2019, pp. 3212-3219

- Print publication:

- 30 September 2019

-

- Article

- Export citation

Hydrogen embrittlement of C40 transition-metal disilicides

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 20 June 2019, pp. 3163-3172

- Print publication:

- 30 September 2019

-

- Article

- Export citation

Chapter 13 - Crystallization in the Pharmaceutical Industry

-

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 380-413

-

- Chapter

- Export citation

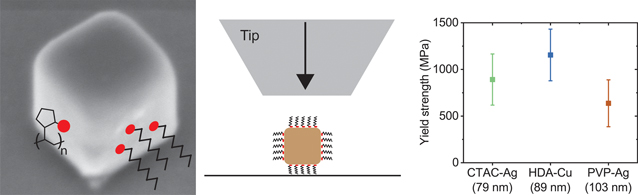

Dislocation surface nucleation in surfactant-passivated metallic nanocubes

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 20 June 2019, pp. 1029-1033

- Print publication:

- September 2019

-

- Article

- Export citation

Chapter 2 - Crystals and Crystal Growth

-

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 32-75

-

- Chapter

- Export citation

Chapter 12 - Batch Crystallization

-

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 346-379

-

- Chapter

- Export citation

Preface to the First Edition

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp ix-x

-

- Chapter

- Export citation

Chapter 8 - Precipitation Processes

-

-

- Book:

- Handbook of Industrial Crystallization

- Published online:

- 14 June 2019

- Print publication:

- 20 June 2019, pp 216-265

-

- Chapter

- Export citation