Refine search

Actions for selected content:

106116 results in Materials Science

Minerals with a mission: Carol Jantzen establishes Fredericks Mineral Gallery for STEM education

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 430-432

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS volume 44 issue 6 Cover and Back matter

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. b1-b2

- Print publication:

- June 2019

-

- Article

-

- You have access

- Export citation

US and Israel issue call for proposals for energy center

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 429

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

Insights into fundamental deformation processes from advanced in situ transmission electron microscopy

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 443-449

- Print publication:

- June 2019

-

- Article

- Export citation

Advanced microelectromechanical systems-based nanomechanical testing: Beyond stress and strain measurements

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 487-493

- Print publication:

- June 2019

-

- Article

- Export citation

In situ small-scale mechanical testing under extreme environments

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 471-477

- Print publication:

- June 2019

-

- Article

- Export citation

Research in Earth’s frozen wastelands

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 434-435

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

2019 MRS Spring Meeting offers something for everyone

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 505-508

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

LOOK AGAIN

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 512

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

Research Highlights: Perovskites

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 423-424

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

Designing heterogeneous hierarchical material systems: a holistic approach to structural and materials design

-

- Journal:

- MRS Communications / Volume 9 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 07 June 2019, pp. 628-636

- Print publication:

- June 2019

-

- Article

- Export citation

Insights into tribology from in situ nanoscale experiments

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 478-486

- Print publication:

- June 2019

-

- Article

- Export citation

Energy Focus: Ceramic nanoneedle arrays increase sunlight absorptance in concentrated solar power plants

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 425

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS volume 44 issue 6 Cover and Front matter

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. f1-f6

- Print publication:

- June 2019

-

- Article

-

- You have access

- Export citation

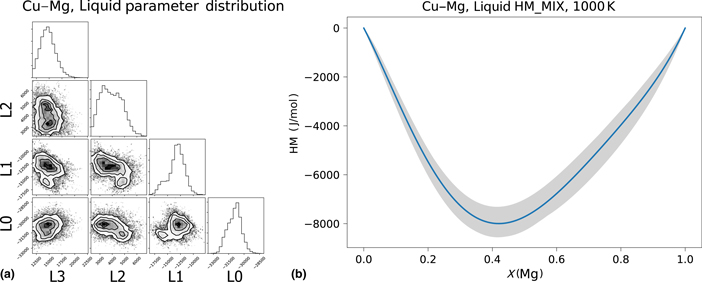

ESPEI for efficient thermodynamic database development, modification, and uncertainty quantification: application to Cu–Mg

-

- Journal:

- MRS Communications / Volume 9 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 04 June 2019, pp. 618-627

- Print publication:

- June 2019

-

- Article

- Export citation

Waste-plastic processing provides global challenges and opportunities

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 436-437

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

Illuminated graphene oxide membranes pump ions against concentration gradient

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 426

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS Journal Highlights

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 427

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

ISMES VIII to be held July 21–27 at Caltech

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 458

- Print publication:

- June 2019

-

- Article

-

- You have access

- Export citation

George Crabtree: Physicist and proponent of sustainable energy

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 509

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation