Refine search

Actions for selected content:

106116 results in Materials Science

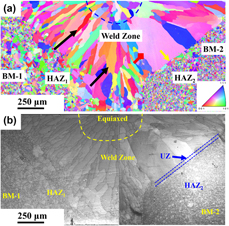

Dissimilar welding of Al0.1CoCrFeNi high-entropy alloy and AISI304 stainless steel

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 04 June 2019, pp. 2683-2694

- Print publication:

- 14 August 2019

-

- Article

- Export citation

Thermal desulfurization of pyrite: An in situ high-T neutron diffraction and DTA–TGA study

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 19 / 14 October 2019

- Published online by Cambridge University Press:

- 04 June 2019, pp. 3243-3253

- Print publication:

- 14 October 2019

-

- Article

- Export citation

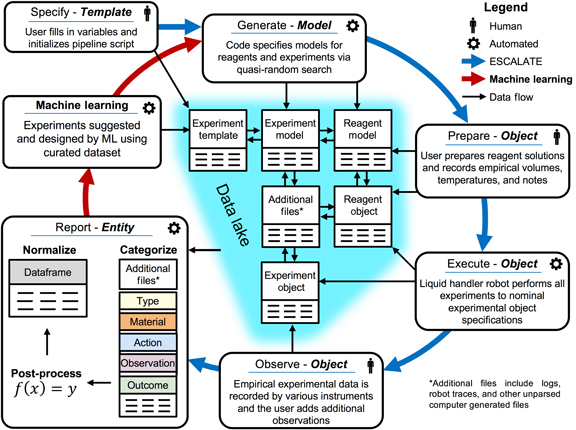

Experiment Specification, Capture and Laboratory Automation Technology (ESCALATE): a software pipeline for automated chemical experimentation and data management

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 04 June 2019, pp. 846-859

- Print publication:

- September 2019

-

- Article

- Export citation

Formation of aligned core/sheath microfiber scaffolds with a poly-L-lactic acid (PLLA) sheath and a conductive poly(3,4-ethylenedioxythiophene) (PEDOT) core

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 11 / 14 June 2019

- Published online by Cambridge University Press:

- 04 June 2019, pp. 1931-1943

- Print publication:

- 14 June 2019

-

- Article

- Export citation

Atmospheric pressure high-power impulse plasma source for deposition of metallic coatings

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 12 / 28 June 2019

- Published online by Cambridge University Press:

- 04 June 2019, pp. 2078-2085

- Print publication:

- 28 June 2019

-

- Article

- Export citation

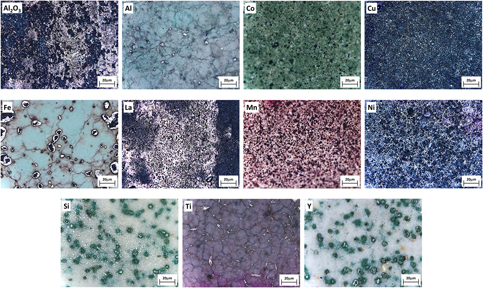

Effect of additions of metal submicron particles on properties of alumina matrix composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 17 / 16 September 2019

- Published online by Cambridge University Press:

- 04 June 2019, pp. 2983-2989

- Print publication:

- 16 September 2019

-

- Article

- Export citation

Fifty Materials That Make the World by Ian Baker

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 510

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

New techniques for imaging and identifying defects in electron microscopy

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 450-458

- Print publication:

- June 2019

-

- Article

- Export citation

ZnO Thin-Film Transistors for Cost-Efficient Flexible Electronics by Fábio Fedrizzi Vidor, Gilson Inácio Wirth, and Ulrich Hilleringmann

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 511

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

From lab to market: Strategies to nanotechnology commercialization in Africa

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 421-422

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

Measurement of local strain

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 459-464

- Print publication:

- June 2019

-

- Article

- Export citation

MRC volume 9 issue 2 Cover and Front matter

-

- Journal:

- MRS Communications / Volume 9 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 01 July 2019, pp. f1-f6

- Print publication:

- June 2019

-

- Article

-

- You have access

- Export citation

Advances in in situ nanomechanical testing

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 438-442

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

Reconstituting and protecting our oceans

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 433

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

Materials Engineering: Bonding, Structure, and Structure-Property Relationships by Susan Trolier-McKinstry and Robert E. Newnham

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 510-511

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

South Africa and China begin student exchange program

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, p. 429

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

Impact of in situ nanomechanics on physical metallurgy

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 465-470

- Print publication:

- June 2019

-

- Article

- Export citation

UK and European materials researchers concerned about Brexit

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 428-429

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRC volume 9 issue 2 Cover and Back matter

-

- Journal:

- MRS Communications / Volume 9 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 01 July 2019, pp. b1-b2

- Print publication:

- June 2019

-

- Article

-

- You have access

- Export citation

Clinical significance of three-dimensional printed biomaterials and biomedical devices

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 6 / June 2019

- Published online by Cambridge University Press:

- 11 June 2019, pp. 494-504

- Print publication:

- June 2019

-

- Article

-

- You have access

- HTML

- Export citation