Refine search

Actions for selected content:

106116 results in Materials Science

Marine biology requires new line of inquiry in materials research

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 597-599

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

Advances in dissimilar metals joining through temperature control of friction stir welding

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 613-618

- Print publication:

- August 2019

-

- Article

- Export citation

Water droplet encased by polymer membrane

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, p. 600

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

Polymers embedded with mechanophores emit white photoluminescence

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, p. 601

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

Carbon Materials: Science and Applications by Deborah D.L. Chung

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 661-662

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

EU Graphene Flagship signals industrial 2D materials

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 604-605

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

Photovoltaic Science and Technology by J.N. Roy and D.N. Bose

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, p. 661

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

South Africa builds on hydrogen fuel-cell program

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, p. 605

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS Journal Highlights

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 606-607

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

Plasma-enhanced CVD dopes carbon into WS2

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 602-603

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

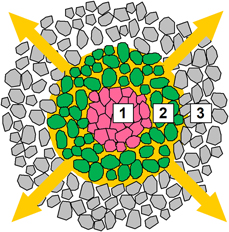

Enabling sustainable transportation through joining of dissimilar lightweight materials

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 608-612

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS authors recently elected to the US National Academy of Engineering

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, p. 657

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS volume 44 issue 8 Cover and Back matter

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. b1-b2

- Print publication:

- August 2019

-

- Article

-

- You have access

- Export citation

Nanomaterials-based flexible and stretchable bioelectronics

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 643-656

- Print publication:

- August 2019

-

- Article

- Export citation

MRS volume 44 issue 8 Cover and Front matter

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. f1-f6

- Print publication:

- August 2019

-

- Article

-

- You have access

- Export citation

CAREER CENTRAL

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, p. 663

- Print publication:

- August 2019

-

- Article

-

- You have access

- Export citation

Crystal structures of cefdinir, C14H13N5O5S2, and cefdinir sesquihydrate C14H13N5O5S2(H2O)1.5

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 31 July 2019, pp. 267-278

-

- Article

- Export citation

Enthalpies of formation of the solid solutions of ZrxY0.5−x/2Ta0.5−x/2O2 (0 ≤ x ≤ 0.2 and 0.65 ≤ x ≤ 1)

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 19 / 14 October 2019

- Published online by Cambridge University Press:

- 29 July 2019, pp. 3343-3350

- Print publication:

- 14 October 2019

-

- Article

- Export citation

Ultra-rapid microwave sintering employing thermal instability and resonant absorption

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 29 July 2019, pp. 2620-2634

- Print publication:

- 14 August 2019

-

- Article

- Export citation

JMR volume 34 issue 14 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 14 / 28 July 2019

- Published online by Cambridge University Press:

- 29 July 2019, pp. b1-b5

- Print publication:

- 28 July 2019

-

- Article

-

- You have access

- Export citation