Refine search

Actions for selected content:

106116 results in Materials Science

JMR volume 34 issue 15 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 15 August 2019, pp. f1-f5

- Print publication:

- 14 August 2019

-

- Article

-

- You have access

- Export citation

JMR volume 34 issue 15 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 15 August 2019, pp. b1-b5

- Print publication:

- 14 August 2019

-

- Article

-

- You have access

- Export citation

The effect of plastic on performance of activated carbon and study on adsorption of methylene blue

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 17 / 16 September 2019

- Published online by Cambridge University Press:

- 06 August 2019, pp. 3040-3049

- Print publication:

- 16 September 2019

-

- Article

- Export citation

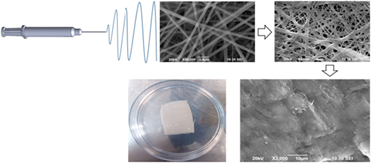

Collagen and elastin scaffold by electrospinning for skin tissue engineering applications

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 16 / 28 August 2019

- Published online by Cambridge University Press:

- 06 August 2019, pp. 2819-2827

- Print publication:

- 28 August 2019

-

- Article

- Export citation

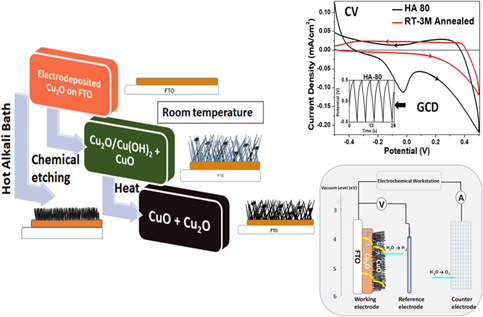

Low temperature–controlled synthesis of hierarchical Cu2O/Cu(OH)2/CuO nanostructures for energy applications

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 06 August 2019, pp. 3173-3185

- Print publication:

- 30 September 2019

-

- Article

- Export citation

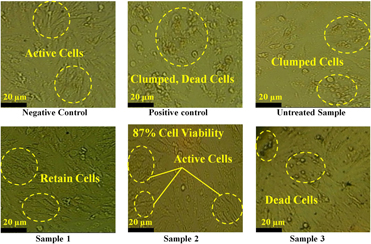

Potential of electrical discharge treatment to enhance the in vitro cytocompatibility and tribological performance of Co–Cr implant

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 16 / 28 August 2019

- Published online by Cambridge University Press:

- 06 August 2019, pp. 2837-2847

- Print publication:

- 28 August 2019

-

- Article

- Export citation

Indium tin oxide nanowires as voltage self-stabilizing supercapacitor electrodes

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 06 August 2019, pp. 3195-3203

- Print publication:

- 30 September 2019

-

- Article

- Export citation

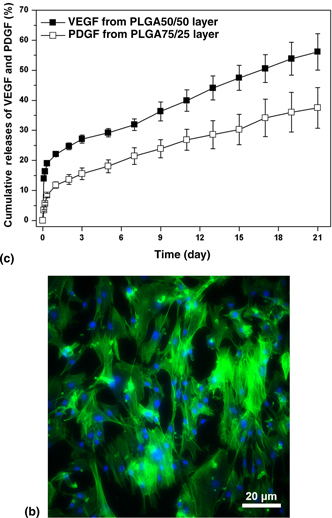

Dual release of VEGF and PDGF from emulsion electrospun bilayer scaffolds consisting of orthogonally aligned nanofibers for gastrointestinal tract regeneration

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 1098-1104

- Print publication:

- September 2019

-

- Article

- Export citation

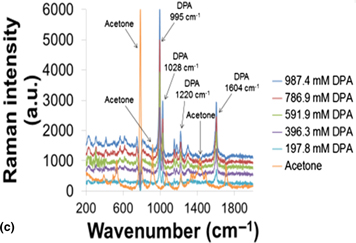

Signal detection limit of a portable Raman spectrometer for the SERS detection of gunshot residue

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 948-955

- Print publication:

- September 2019

-

- Article

- Export citation

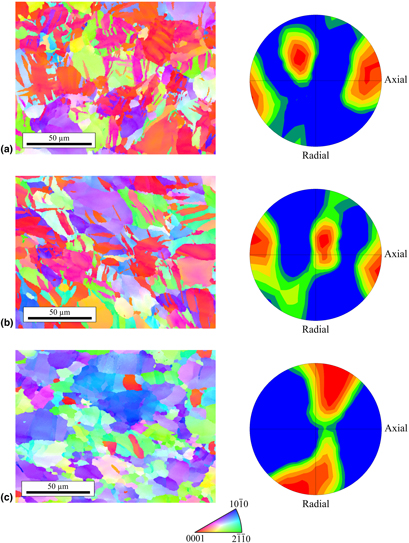

Effect of temperature on the suppression of twinning in textured magnesium

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 1093-1097

- Print publication:

- September 2019

-

- Article

- Export citation

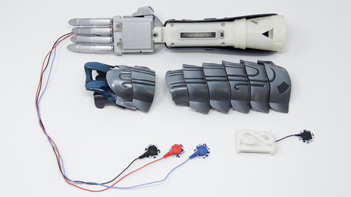

Utilizing additive manufacturing and gamified virtual simulation in the design of neuroprosthetics to improve pediatric outcomes

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 941-947

- Print publication:

- September 2019

-

- Article

- Export citation

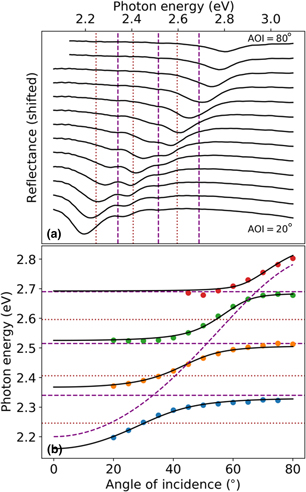

Strong exciton–photon coupling in anthradithiophene microcavities: from isolated molecules to aggregates

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 956-963

- Print publication:

- September 2019

-

- Article

- Export citation

PreDICT: a graphical user interface to the DICVOL14 indexing software program for powder diffraction data

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 233-241

-

- Article

- Export citation

Morphological effects on the third-order nonlinear optical response of polydiacetylene nanofibers

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 1087-1092

- Print publication:

- September 2019

-

- Article

- Export citation

Ultrasonic welding of AZ31B magnesium alloy

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 630-636

- Print publication:

- August 2019

-

- Article

- Export citation

Materials Research Science and Engineering Centers (MRSECs) provide collaboration and diversity in research and outreach

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 658-660

- Print publication:

- August 2019

-

- Article

-

- You have access

- HTML

- Export citation

Influence of adherend properties on the strength of adhesively bonded joints

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 625-629

- Print publication:

- August 2019

-

- Article

- Export citation

Nondestructive evaluation of resistance spot-welded Al-steel joints

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 619-624

- Print publication:

- August 2019

-

- Article

- Export citation

Vaporizing foil actuator welding

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, pp. 637-642

- Print publication:

- August 2019

-

- Article

- Export citation

LOOK AGAIN

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 8 / August 2019

- Published online by Cambridge University Press:

- 05 August 2019, p. 664

- Print publication:

- August 2019

-

- Article

- Export citation