Refine search

Actions for selected content:

106116 results in Materials Science

Annealing of LiCoO2 films on flexible stainless steel for thin film lithium batteries

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 1 / 14 January 2020

- Published online by Cambridge University Press:

- 22 October 2019, pp. 31-41

- Print publication:

- 14 January 2020

-

- Article

- Export citation

Understanding plasticity in irradiated alloys through TEM in situ compression pillar tests

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 8 / 28 April 2020

- Published online by Cambridge University Press:

- 22 October 2019, pp. 1037-1050

- Print publication:

- 28 April 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Improved mechanical performance and wear resistance of Ti-coated cBN–WC–Ni composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 22 / 28 November 2019

- Published online by Cambridge University Press:

- 22 October 2019, pp. 3844-3852

- Print publication:

- 28 November 2019

-

- Article

- Export citation

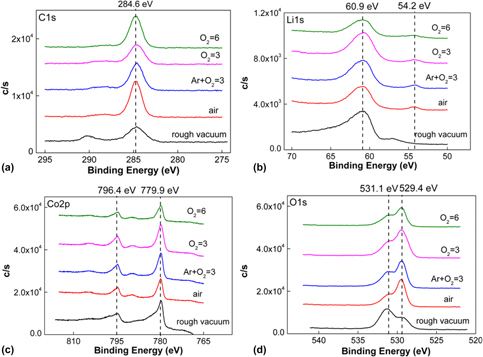

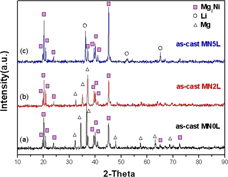

Effects of volatilization of lithium on hydrogen storage characteristics of Mg–Ni–Li alloy

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 20 / 28 October 2019

- Published online by Cambridge University Press:

- 18 October 2019, pp. 3583-3588

- Print publication:

- 28 October 2019

-

- Article

- Export citation

Flexible low-voltage paper transistors harnessing ion gel/cellulose fiber composites

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 8 / 28 April 2020

- Published online by Cambridge University Press:

- 18 October 2019, pp. 940-948

- Print publication:

- 28 April 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Optimized mixed phases to achieve improved performance of organic solar cells

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 17 October 2019, pp. 1235-1241

- Print publication:

- December 2019

-

- Article

- Export citation

Non-invasive oral cancer detection from saliva using zinc oxide–reduced graphene oxide nanocomposite based bioelectrode

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 17 October 2019, pp. 1227-1234

- Print publication:

- December 2019

-

- Article

- Export citation

Thermodynamics of Complex Solids

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 19 / 14 October 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. 3241-3242

- Print publication:

- 14 October 2019

-

- Article

- Export citation

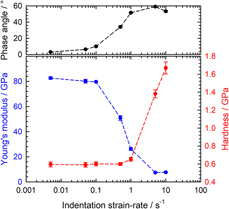

Critical issues in conducting constant strain rate nanoindentation tests at higher strain rates

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 20 / 28 October 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. 3495-3503

- Print publication:

- 28 October 2019

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Cyclic indentation of polymers: Instantaneous elastic modulus from reloading, energy analysis, and cyclic creep

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 21 / 14 November 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. 3688-3698

- Print publication:

- 14 November 2019

-

- Article

- Export citation

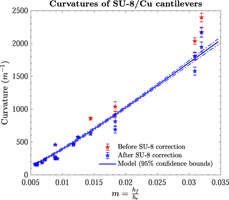

Residual stress–driven test technique for freestanding ultrathin films: Elastic behavior and residual strain

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 20 / 28 October 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. 3474-3482

- Print publication:

- 28 October 2019

-

- Article

- Export citation

An auto-combustion synthesis and luminescence properties of polyhedral YVO4: Ln3+ (Ln = Eu, Sm, Yb/Er, Yb/Tm) microcrystals

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 21 / 14 November 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. 3636-3644

- Print publication:

- 14 November 2019

-

- Article

- Export citation

JMR volume 34 issue 19 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 19 / 14 October 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. f1-f5

- Print publication:

- 14 October 2019

-

- Article

-

- You have access

- Export citation

Dual light-emitting Yb3+,Er3+-doped La(IO3)3 iodate nanocrystals: up-conversion and second harmonic generation

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. 1221-1226

- Print publication:

- December 2019

-

- Article

- Export citation

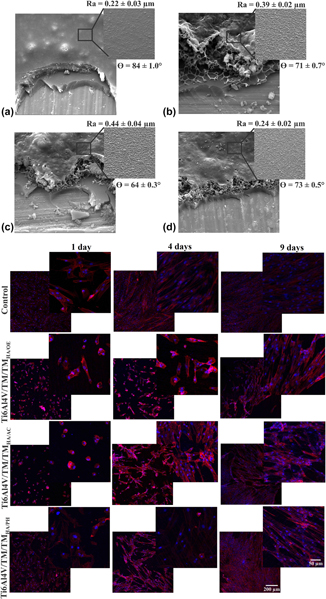

Osteogenic differentiation of mesenchymal stem cells on hybrid coatings sterilized by different processes

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 20 / 28 October 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. 3400-3411

- Print publication:

- 28 October 2019

-

- Article

- Export citation

JMR volume 34 issue 19 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 19 / 14 October 2019

- Published online by Cambridge University Press:

- 14 October 2019, pp. b1-b2

- Print publication:

- 14 October 2019

-

- Article

-

- You have access

- Export citation

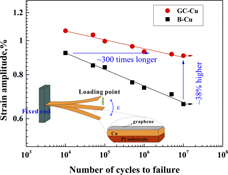

Bilayer graphene-covered Cu flexible electrode with excellent mechanical reliability and electrical performance

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 21 / 14 November 2019

- Published online by Cambridge University Press:

- 11 October 2019, pp. 3645-3653

- Print publication:

- 14 November 2019

-

- Article

- Export citation

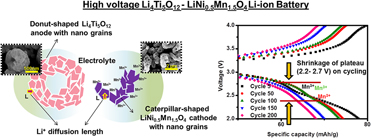

Synergic effect of nanostructuring and excess Mn3+ content in the electrochemical performance of Li4Ti5O12–LiNi0.5Mn1.5O4 Li-ion full-cells

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 1 / 14 January 2020

- Published online by Cambridge University Press:

- 11 October 2019, pp. 42-50

- Print publication:

- 14 January 2020

-

- Article

- Export citation

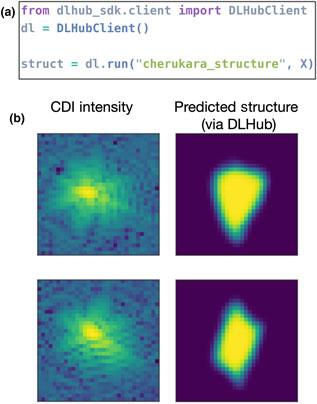

A data ecosystem to support machine learning in materials science

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 1125-1133

- Print publication:

- December 2019

-

- Article

- Export citation

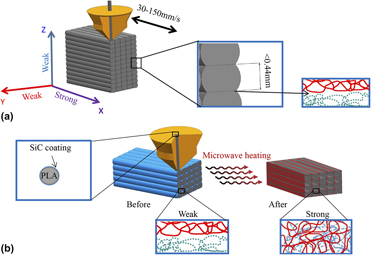

Improved mechanical properties of 3D-printed SiC/PLA composite parts by microwave heating

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 20 / 28 October 2019

- Published online by Cambridge University Press:

- 09 October 2019, pp. 3412-3419

- Print publication:

- 28 October 2019

-

- Article

- Export citation