Refine search

Actions for selected content:

106116 results in Materials Science

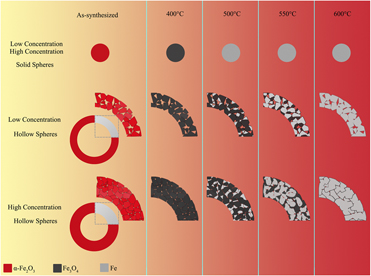

Synthesis of ultra-fine iron powder by combining the flame aerosol synthesis and postreduction

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 23 / 16 December 2019

- Published online by Cambridge University Press:

- 08 November 2019, pp. 3964-3974

- Print publication:

- 16 December 2019

-

- Article

- Export citation

Recent advances in the understanding of high-k dielectric materials deposited by atomic layer deposition for dynamic random-access memory capacitor applications

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 7 / 14 April 2020

- Published online by Cambridge University Press:

- 08 November 2019, pp. 775-794

- Print publication:

- 14 April 2020

-

- Article

-

- You have access

- HTML

- Export citation

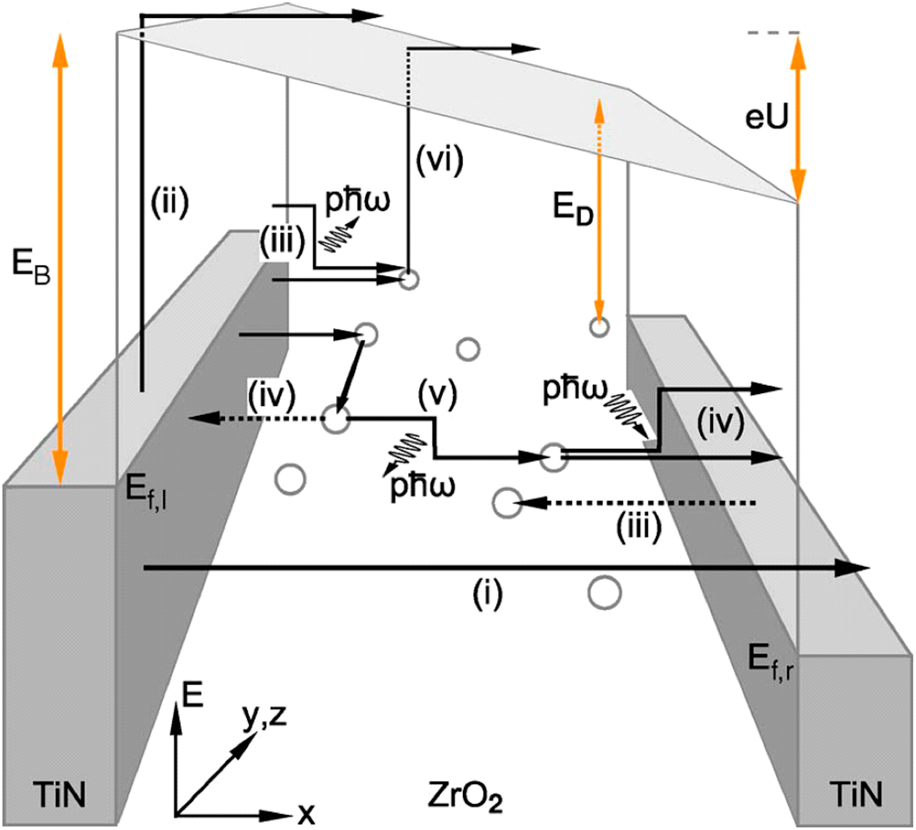

Atomic layer deposition of zirconium oxide thin films

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 7 / 14 April 2020

- Published online by Cambridge University Press:

- 08 November 2019, pp. 804-812

- Print publication:

- 14 April 2020

-

- Article

-

- You have access

- HTML

- Export citation

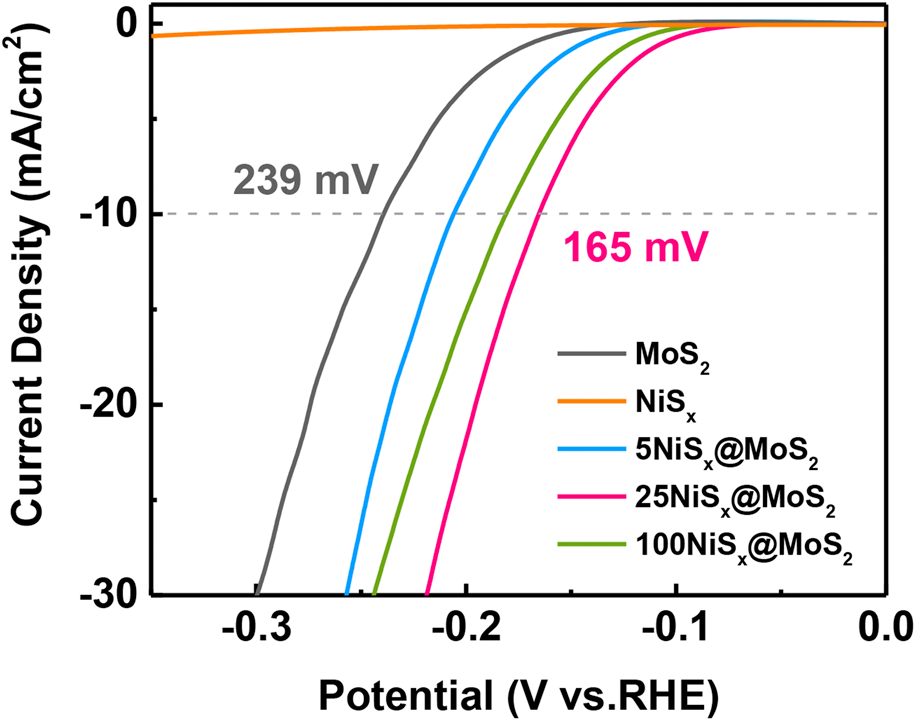

NiSx@MoS2 heterostructure prepared by atomic layer deposition as high-performance hydrogen evolution reaction electrocatalysts in alkaline media

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 7 / 14 April 2020

- Published online by Cambridge University Press:

- 08 November 2019, pp. 822-830

- Print publication:

- 14 April 2020

-

- Article

-

- You have access

- HTML

- Export citation

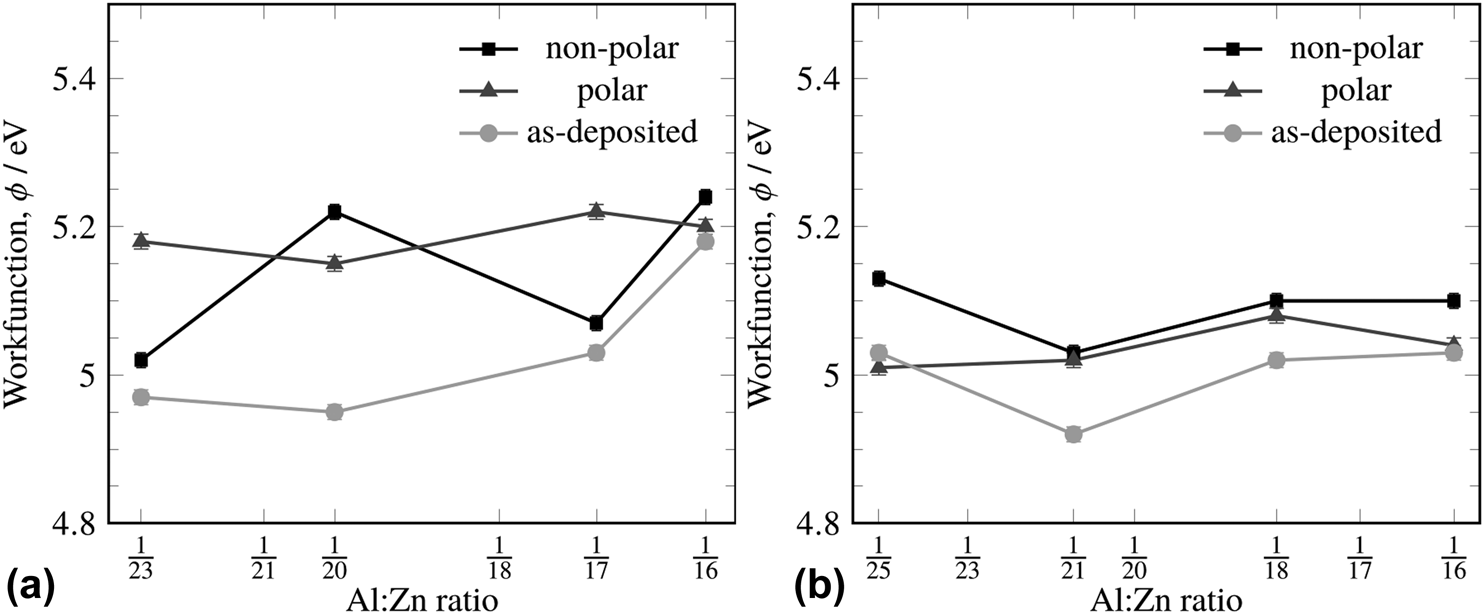

Work function of doped zinc oxide films deposited by ALD

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 7 / 14 April 2020

- Published online by Cambridge University Press:

- 08 November 2019, pp. 756-761

- Print publication:

- 14 April 2020

-

- Article

-

- You have access

- HTML

- Export citation

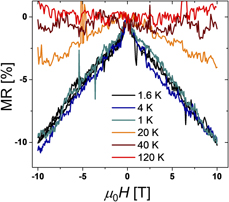

Selective-area growth and transport properties of MnAs/InAs heterojunction nanowires

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 23 / 16 December 2019

- Published online by Cambridge University Press:

- 08 November 2019, pp. 3863-3876

- Print publication:

- 16 December 2019

-

- Article

- Export citation

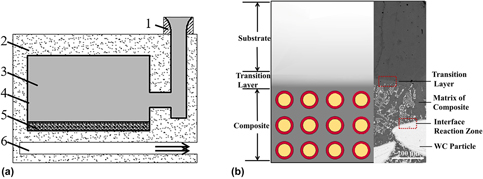

Interfacial thermal fatigue behavior of cast tungsten carbide particle/steel matrix surface composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 22 / 28 November 2019

- Published online by Cambridge University Press:

- 08 November 2019, pp. 3837-3843

- Print publication:

- 28 November 2019

-

- Article

- Export citation

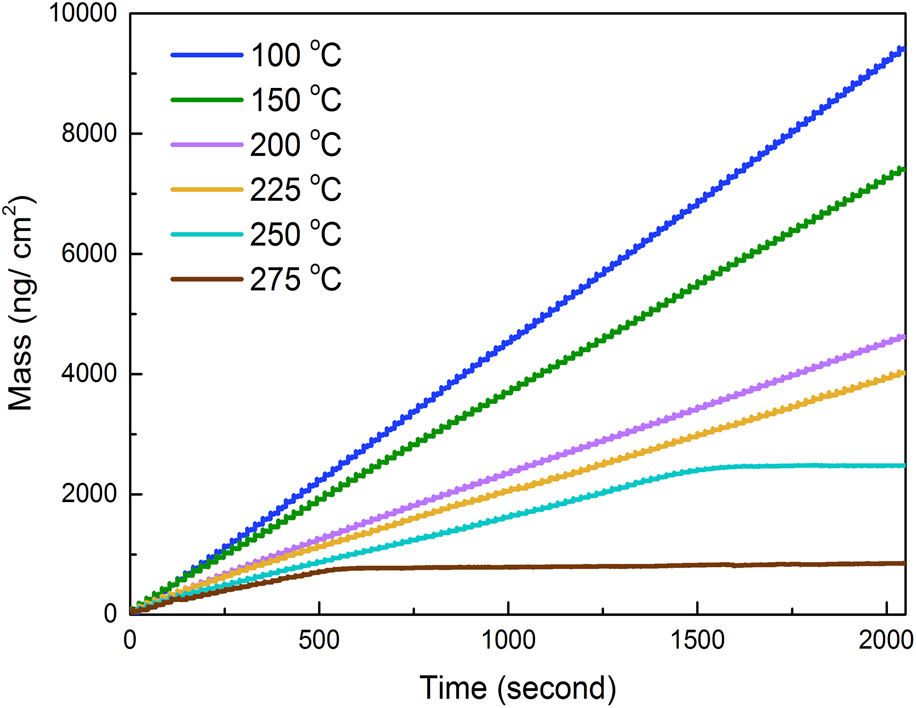

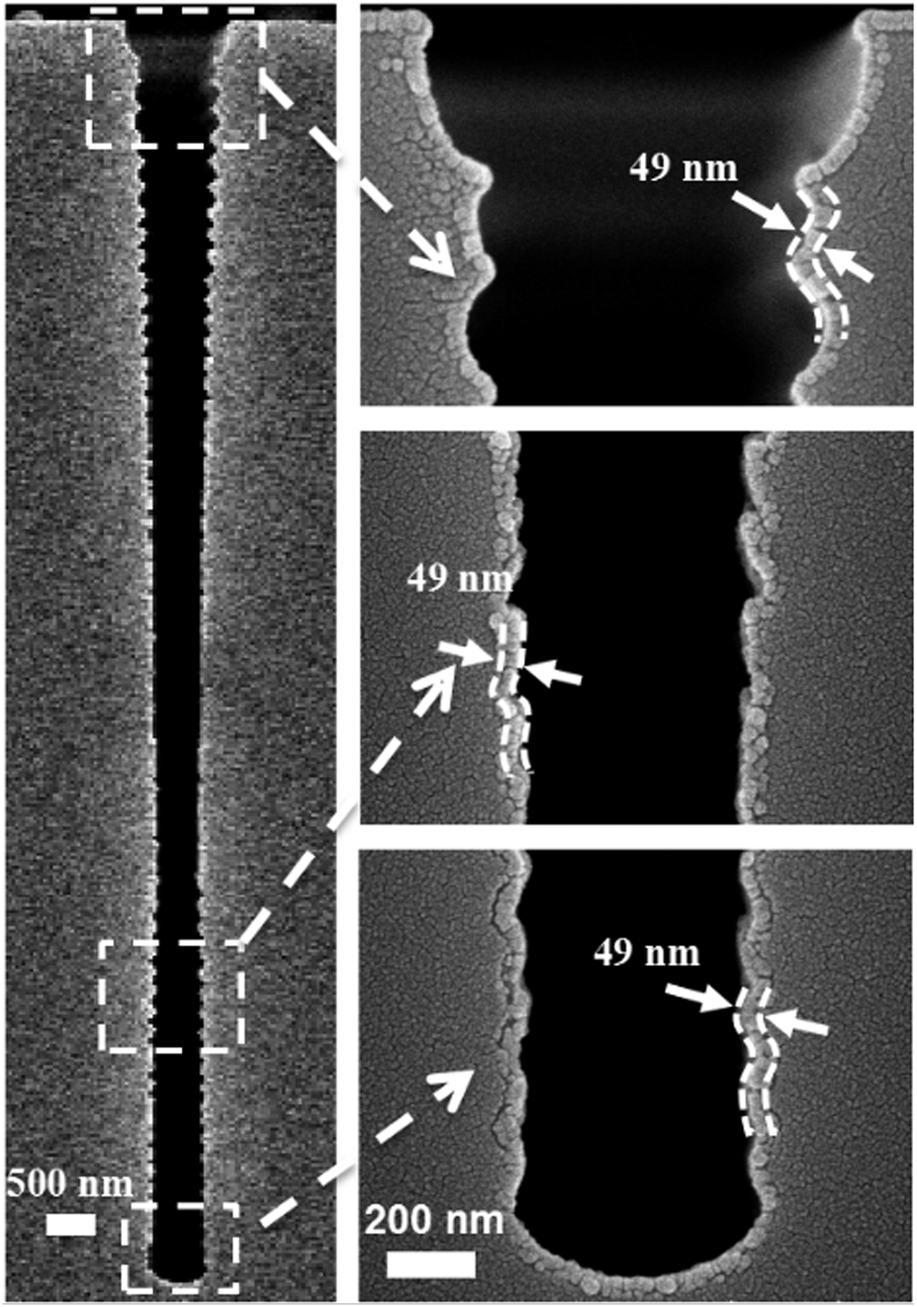

Fabrication of iron carbide by plasma-enhanced atomic layer deposition

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 7 / 14 April 2020

- Published online by Cambridge University Press:

- 08 November 2019, pp. 813-821

- Print publication:

- 14 April 2020

-

- Article

-

- You have access

- HTML

- Export citation

Atomic layer–deposited nanostructures and their applications in energy storage and sensing

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 7 / 14 April 2020

- Published online by Cambridge University Press:

- 08 November 2019, pp. 701-719

- Print publication:

- 14 April 2020

-

- Article

-

- You have access

- HTML

- Export citation

Fracture properties of ultrafine grain chromium correlated to single dislocation processes at room temperature—ADDENDUM

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 24 / 30 December 2019

- Published online by Cambridge University Press:

- 07 November 2019, p. 4085

- Print publication:

- 30 December 2019

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Biocompatibility and anticancer activity of L-phenyl alanine-coated iron oxide magnetic nanoparticles as potential chrysin delivery system—CORRIGENDUM

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 23 / 16 December 2019

- Published online by Cambridge University Press:

- 07 November 2019, p. 3976

- Print publication:

- 16 December 2019

-

- Article

- Export citation

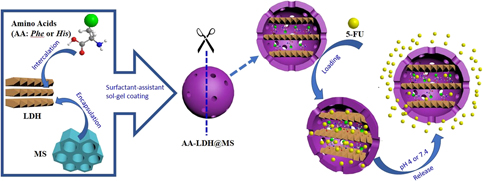

Amino acid–intercalated layered double hydroxide core @ ordered porous silica shell as drug carriers: Design and applications

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 22 / 28 November 2019

- Published online by Cambridge University Press:

- 07 November 2019, pp. 3747-3756

- Print publication:

- 28 November 2019

-

- Article

- Export citation

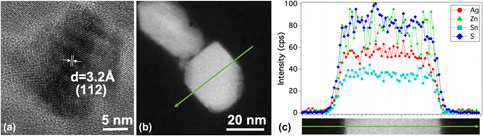

Reaction pathways and optoelectronic characterization of single-phase Ag2ZnSnS4 nanoparticles

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 22 / 28 November 2019

- Published online by Cambridge University Press:

- 07 November 2019, pp. 3810-3818

- Print publication:

- 28 November 2019

-

- Article

- Export citation

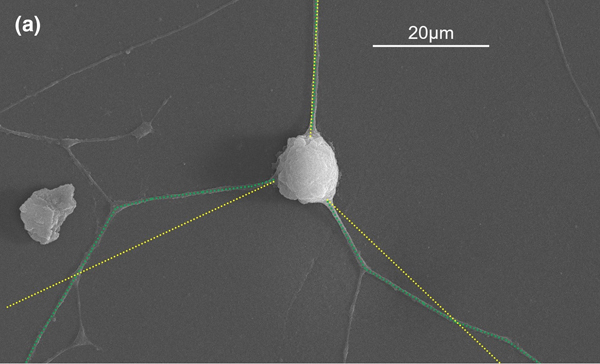

Tunable neuronal scaffold biomaterials through plasmonic photo-patterning of aerogels

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 07 November 2019, pp. 1249-1255

- Print publication:

- December 2019

-

- Article

- Export citation

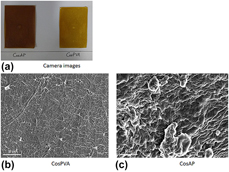

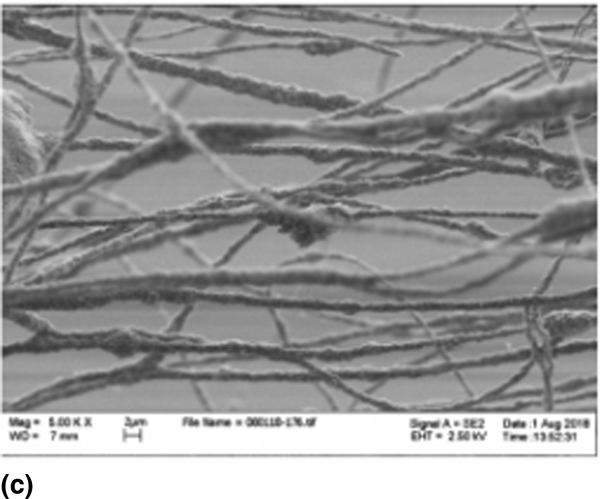

Fabrication of eggshell membrane–based novel buccal mucosa–mimetic surface and mucoadhesion testing of chitosan oligosaccharide films

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 22 / 28 November 2019

- Published online by Cambridge University Press:

- 07 November 2019, pp. 3777-3786

- Print publication:

- 28 November 2019

-

- Article

- Export citation

Synthesis and X-ray diffraction data of (4R)-methyl-3-(1-(4-chlorophenyl)-1H-1,2,3-triazole-4-carbonyl)thiazolidin-4-carboxylate, C14H13ClN4O3S

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 06 November 2019, pp. 41-44

-

- Article

- Export citation

Brush-structured sulfur–polyaniline–graphene composite as cathodes for lithium–sulfur batteries

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 06 November 2019, pp. 1355-1360

- Print publication:

- December 2019

-

- Article

- Export citation

Electrospinning deposition of poly(acrylic acid): platinum/carbon catalyst ink to enhance polymer electrolyte membrane fuel cell performance

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 06 November 2019, pp. 1343-1348

- Print publication:

- December 2019

-

- Article

- Export citation

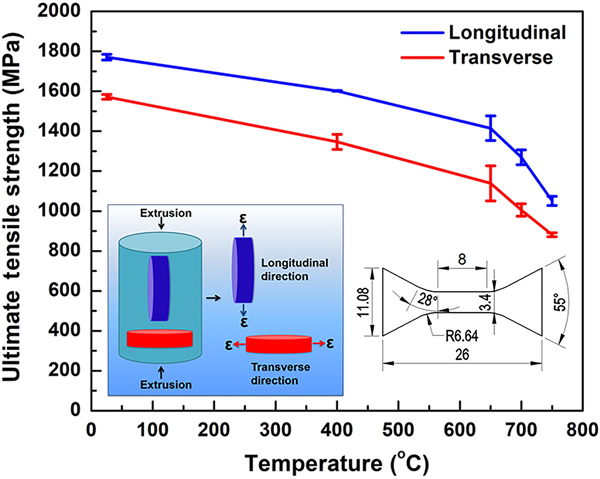

Anisotropic behavior of tensile properties in a hot-extruded polycrystalline nickel-base superalloy

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 06 November 2019, pp. 1349-1354

- Print publication:

- December 2019

-

- Article

- Export citation

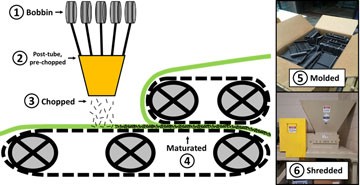

Degradation of E-glass fiber mechanical properties during composite sheet molding compound production for automotive applications

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 06 November 2019, pp. 1256-1260

- Print publication:

- December 2019

-

- Article

- Export citation