Refine search

Actions for selected content:

106116 results in Materials Science

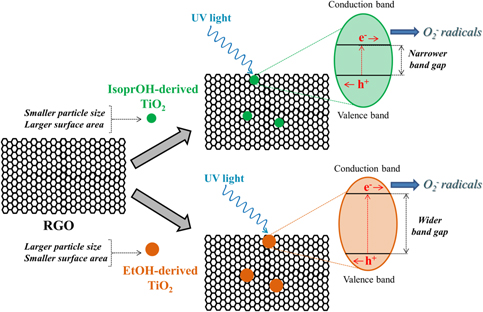

Solvent effect on the structure and photocatalytic behavior of TiO2-RGO nanocomposites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 23 / 16 December 2019

- Published online by Cambridge University Press:

- 22 November 2019, pp. 3918-3930

- Print publication:

- 16 December 2019

-

- Article

- Export citation

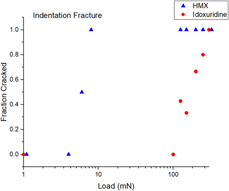

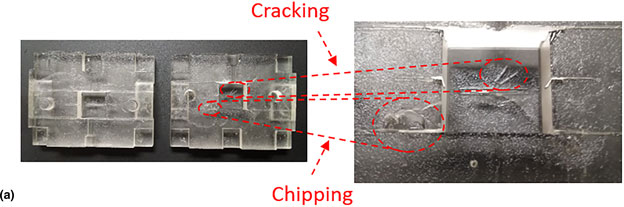

Indentation fracture behavior of energetic and inert molecular crystals

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 23 / 16 December 2019

- Published online by Cambridge University Press:

- 22 November 2019, pp. 3954-3963

- Print publication:

- 16 December 2019

-

- Article

- Export citation

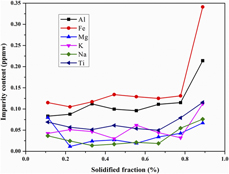

Preparation and microstructural characteristics of solar-grade multicrystalline silicon by directional solidification in an axial magnetic field

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 23 / 16 December 2019

- Published online by Cambridge University Press:

- 22 November 2019, pp. 3931-3945

- Print publication:

- 16 December 2019

-

- Article

- Export citation

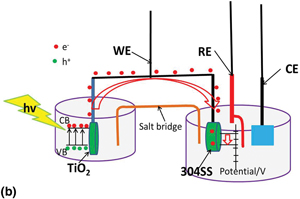

Cadmium sulfide/lead sulfide co-sensitized TiO2 enhances photoelectrochemical performance and corrosion resistance of 304 stainless steel

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 19 November 2019, pp. 1361-1369

- Print publication:

- December 2019

-

- Article

- Export citation

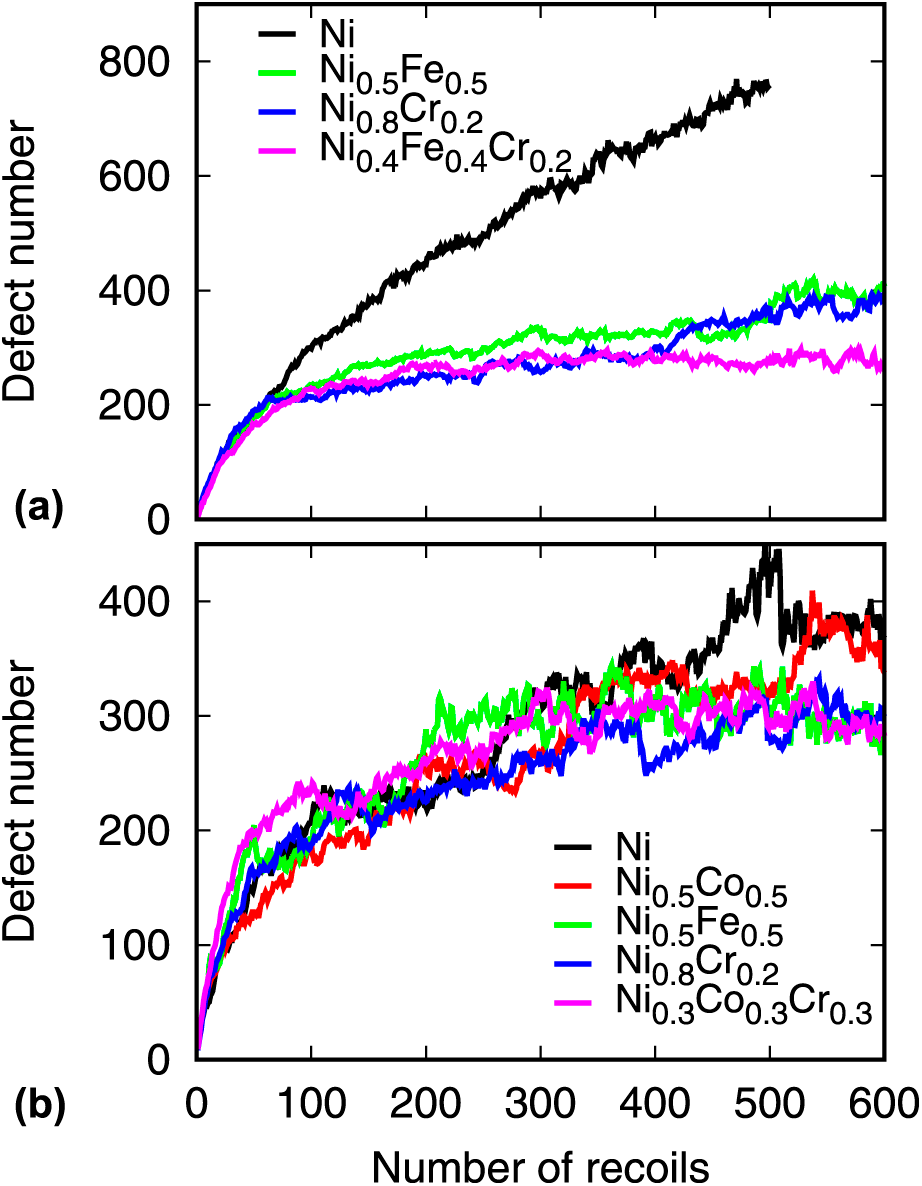

On the role of heterogeneity in concentrated solid-solution alloys in enhancing their irradiation resistance

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 8 / 28 April 2020

- Published online by Cambridge University Press:

- 19 November 2019, pp. 1103-1112

- Print publication:

- 28 April 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

N-doped carbon nanosheets as high-performance anodes for Li- and Na-ion batteries

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 1 / 14 January 2020

- Published online by Cambridge University Press:

- 18 November 2019, pp. 12-19

- Print publication:

- 14 January 2020

-

- Article

- Export citation

Glucomannan asymmetric membranes for wound dressing–Erratum

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 2 / 28 January 2020

- Published online by Cambridge University Press:

- 14 November 2019, p. 216

- Print publication:

- 28 January 2020

-

- Article

- Export citation

Thin film encapsulation for the organic light-emitting diodes display via atomic layer deposition

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 7 / 14 April 2020

- Published online by Cambridge University Press:

- 14 November 2019, pp. 681-700

- Print publication:

- 14 April 2020

-

- Article

-

- You have access

- HTML

- Export citation

Loss in acoustic metasurfaces: a blessing in disguise

-

- Journal:

- MRS Communications / Volume 10 / Issue 1 / March 2020

- Published online by Cambridge University Press:

- 14 November 2019, pp. 32-41

- Print publication:

- March 2020

-

- Article

- Export citation

JMR volume 34 issue 21 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 21 / 14 November 2019

- Published online by Cambridge University Press:

- 15 November 2019, pp. b1-b5

- Print publication:

- 14 November 2019

-

- Article

-

- You have access

- Export citation

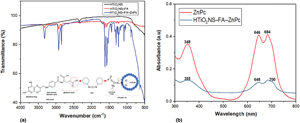

TiO2 hollow nanospheres functionalized with folic acid and ZnPc for targeted photodynamic therapy in glioblastoma cancer

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 14 November 2019, pp. 1242-1248

- Print publication:

- December 2019

-

- Article

- Export citation

JMR volume 34 issue 21 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 21 / 14 November 2019

- Published online by Cambridge University Press:

- 15 November 2019, pp. f1-f5

- Print publication:

- 14 November 2019

-

- Article

-

- You have access

- Export citation

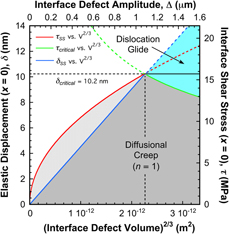

On the mechanisms of stress relaxation and intensification at the lithium/solid-state electrolyte interface

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 21 / 14 November 2019

- Published online by Cambridge University Press:

- 15 November 2019, pp. 3593-3616

- Print publication:

- 14 November 2019

-

- Article

- Export citation

Three-dimensional-printed molds and materials for injection molding and rapid tooling applications

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 14 November 2019, pp. 1267-1283

- Print publication:

- December 2019

-

- Article

- Export citation

Alloying behavior and thermal stability of mechanically alloyed nano AlCoCrFeNiTi high-entropy alloy—CORRIGENDUM

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 2 / 28 January 2020

- Published online by Cambridge University Press:

- 13 November 2019, p. 215

- Print publication:

- 28 January 2020

-

- Article

- Export citation

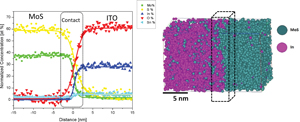

Study of indium tin oxide–MoS2 interface by atom probe tomography

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 13 November 2019, pp. 1261-1266

- Print publication:

- December 2019

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

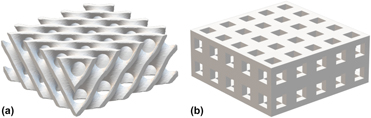

Influence of geometry on cell proliferation of PLA and alumina scaffolds constructed by additive manufacturing

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 22 / 28 November 2019

- Published online by Cambridge University Press:

- 11 November 2019, pp. 3757-3765

- Print publication:

- 28 November 2019

-

- Article

- Export citation

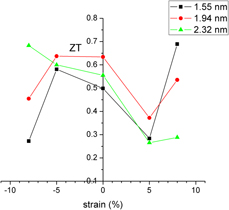

Strain dependence of the thermoelectric performance of porous armchair silicene nanoribbons

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 23 / 16 December 2019

- Published online by Cambridge University Press:

- 11 November 2019, pp. 3946-3953

- Print publication:

- 16 December 2019

-

- Article

- Export citation

Well-ordered spherical LiNi0.8Co0.1Mn0.1O2 cathode material for lithium-ion batteries

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 1 / 14 January 2020

- Published online by Cambridge University Press:

- 11 November 2019, pp. 51-57

- Print publication:

- 14 January 2020

-

- Article

- Export citation

Preparation and characterization of heat-insulating Ag/TiO2 composite membranes based on magnetron sputtering technology

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 5 / 16 March 2020

- Published online by Cambridge University Press:

- 11 November 2019, pp. 473-480

- Print publication:

- 16 March 2020

-

- Article

- Export citation