Refine search

Actions for selected content:

106116 results in Materials Science

MRS volume 44 issue 10 Cover and Back matter

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. b1-b2

- Print publication:

- October 2019

-

- Article

-

- You have access

- Export citation

Singapore hosts 10th International Conference on Materials for Advanced Technologies

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, p. 817

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

Ultrathin 2D materials synthesized using a sacrificial metallo-hydrogel template

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, p. 745

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

Three-dimensional architected materials and structures: Design, fabrication, and mechanical behavior

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 750-757

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

Multiscale modeling and optimization of the mechanics of hierarchical metamaterials

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 773-781

- Print publication:

- October 2019

-

- Article

- Export citation

Preview: 2019 Materials Research Society Fall Meeting & Exhibit

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 812-816

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS volume 44 issue 10 Cover and Front matter

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. f1-f7

- Print publication:

- October 2019

-

- Article

-

- You have access

- Export citation

MRS Journal Highlights

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, p. 747

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

The extreme mechanics of micro- and nanoarchitected materials

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 758-765

- Print publication:

- October 2019

-

- Article

- Export citation

Advanced instrumentation enables continuous high-resolution x-ray ptychography

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 743-744

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

Flatté, Rowe, Sartori, Shastri, and Wang to chair 2020 MRS Fall Meeting

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 818-819

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

Hydratable polymer networks accelerate solar desalination

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, p. 746

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

Architected materials for advanced electrochemical systems

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 789-795

- Print publication:

- October 2019

-

- Article

- Export citation

Topology of voids and channels in selected porphyrinic compounds

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 30 September 2019, pp. 302-310

-

- Article

- Export citation

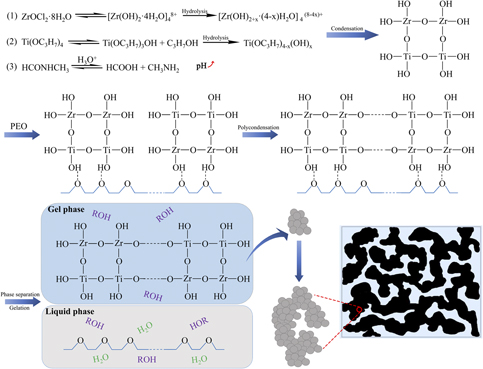

Facile preparation of macro-mesoporous zirconium titanate monoliths via a sol–gel reaction accompanied by phase separation

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 24 / 30 December 2019

- Published online by Cambridge University Press:

- 30 September 2019, pp. 4066-4075

- Print publication:

- 30 December 2019

-

- Article

- Export citation

JMR volume 34 issue 18 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 27 September 2019, pp. f1-f5

- Print publication:

- 30 September 2019

-

- Article

-

- You have access

- Export citation

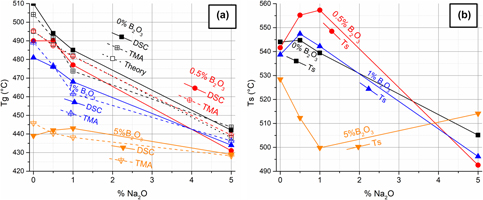

PbO–SiO2-based glass doped with B2O3 and Na2O for coating of thermoelectric materials

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 20 / 28 October 2019

- Published online by Cambridge University Press:

- 27 September 2019, pp. 3563-3572

- Print publication:

- 28 October 2019

-

- Article

- Export citation

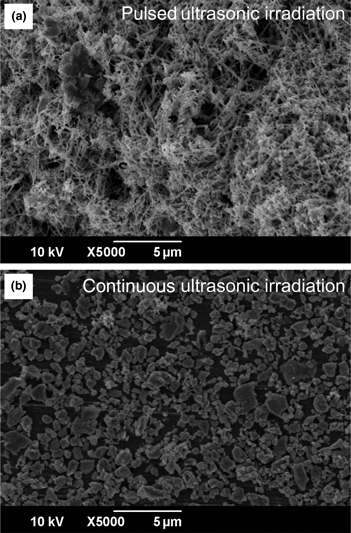

Ultrasonic-induced morphological change of micro/nanodeposits and current change in electrochemical migration

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 27 September 2019, pp. 1331-1334

- Print publication:

- December 2019

-

- Article

- Export citation

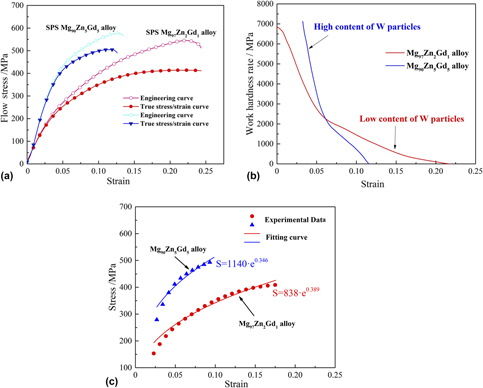

Microstructure and compressive properties of Mg–Zn–Gd alloys containing W-phase nanoparticles developed by the spark plasma sintering of rapid solidification ribbons

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 18 / 30 September 2019

- Published online by Cambridge University Press:

- 27 September 2019, pp. 3130-3140

- Print publication:

- 30 September 2019

-

- Article

- Export citation

Piezoelectric bioMEMS cantilever for measurement of muscle contraction and for actuation of mechanosensitive cells

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 27 September 2019, pp. 1186-1192

- Print publication:

- December 2019

-

- Article

- Export citation