Refine search

Actions for selected content:

106116 results in Materials Science

Investigation of the flexural and thermomechanical properties of nanoclay/graphene reinforced carbon fiber epoxy composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 21 / 14 November 2019

- Published online by Cambridge University Press:

- 09 October 2019, pp. 3678-3687

- Print publication:

- 14 November 2019

-

- Article

- Export citation

Role of oligomer structures in the surface chemistry of amidinate metal complexes used for atomic layer deposition of thin films

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 7 / 14 April 2020

- Published online by Cambridge University Press:

- 07 October 2019, pp. 720-731

- Print publication:

- 14 April 2020

-

- Article

-

- You have access

- HTML

- Export citation

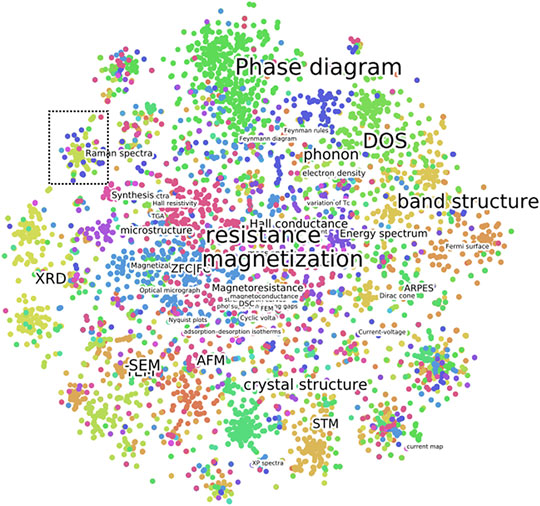

A picture is worth a thousand words: applying natural language processing tools for creating a quantum materials database map

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 07 October 2019, pp. 1134-1141

- Print publication:

- December 2019

-

- Article

- Export citation

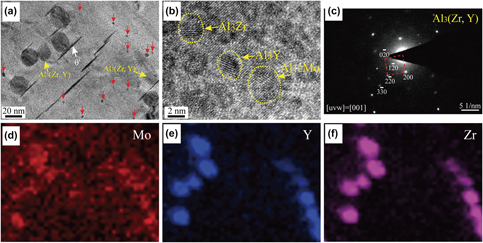

Effect of Mo, Zr, and Y on the high-temperature properties of Al–Cu–Mn alloy

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 22 / 28 November 2019

- Published online by Cambridge University Press:

- 07 October 2019, pp. 3853-3861

- Print publication:

- 28 November 2019

-

- Article

- Export citation

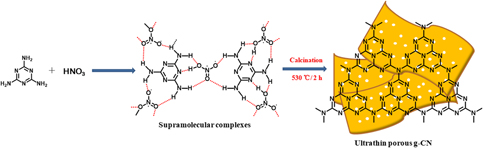

Ultrathin porous g-CN nanosheets fabricated by direct calcination of pre-treated melamine for enhanced photocatalytic performance

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 20 / 28 October 2019

- Published online by Cambridge University Press:

- 07 October 2019, pp. 3462-3473

- Print publication:

- 28 October 2019

-

- Article

- Export citation

Improvement of mechanical properties of extruded AZX912 magnesium alloy using high-temperature solution treatment

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 21 / 14 November 2019

- Published online by Cambridge University Press:

- 02 October 2019, pp. 3725-3734

- Print publication:

- 14 November 2019

-

- Article

- Export citation

Effect of void defect on c-axis deformation of single-crystal Ti under uniaxial stress conditions: Evolution of tension twinning and dislocations

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 21 / 14 November 2019

- Published online by Cambridge University Press:

- 02 October 2019, pp. 3699-3706

- Print publication:

- 14 November 2019

-

- Article

- Export citation

Recommended reading

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, p. 820

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

LOOK AGAIN

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, p. 824

- Print publication:

- October 2019

-

- Article

- Export citation

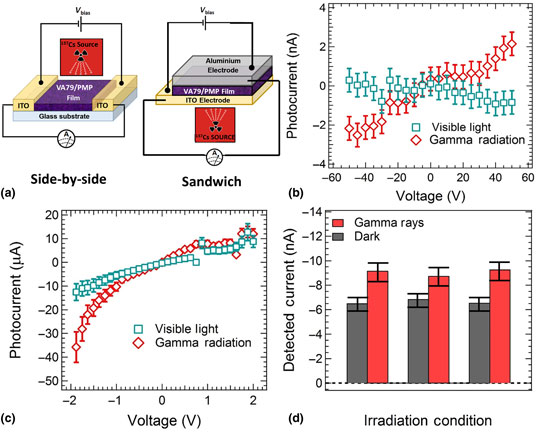

Printable ionizing radiation sensors fabricated from nanoparticulate blends of organic scintillators and polymer semiconductors

-

- Journal:

- MRS Communications / Volume 9 / Issue 4 / December 2019

- Published online by Cambridge University Press:

- 01 October 2019, pp. 1206-1213

- Print publication:

- December 2019

-

- Article

- Export citation

Intermetallic samarium cobalt deforms without dislocation activity

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, p. 744

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

Imperfect architected materials: Mechanics and topology optimization

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 766-772

- Print publication:

- October 2019

-

- Article

- Export citation

New Zealand seeks comments to hydrogen plan

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, p. 749

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

US begins construction of unique neutron imaging instrument to accelerate materials discovery

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 748-749

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS Communications Abstracts

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 796-797

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

CAREER CENTRAL

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 821-823

- Print publication:

- October 2019

-

- Article

-

- You have access

- Export citation

Research highlights: Perovskites

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 742-743

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

Dissipation of radiation energy in concentrated solid-solution alloys: Unique defect properties and microstructural evolution

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 798-811

- Print publication:

- October 2019

-

- Article

- Export citation

Report highlights Australia’s opportunity in critical minerals

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, p. 749

- Print publication:

- October 2019

-

- Article

-

- You have access

- HTML

- Export citation

Additive manufacturing and processing of architected materials

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 10 / October 2019

- Published online by Cambridge University Press:

- 10 October 2019, pp. 782-788

- Print publication:

- October 2019

-

- Article

- Export citation