Refine search

Actions for selected content:

106116 results in Materials Science

Whither computing

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 6 / June 2020

- Published online by Cambridge University Press:

- 16 June 2020, p. 421

- Print publication:

- June 2020

-

- Article

-

- You have access

- HTML

- Export citation

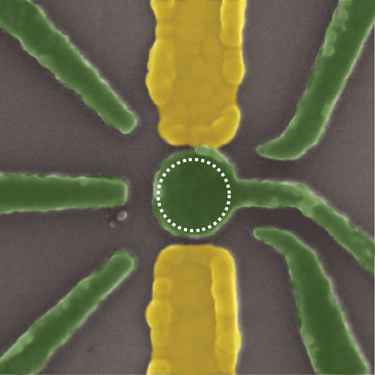

Materials science for quantum information science and technology

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 6 / June 2020

- Published online by Cambridge University Press:

- 16 June 2020, pp. 485-497

- Print publication:

- June 2020

-

- Article

- Export citation

Foundations of Biomaterials Engineering by Maria Cristina Tanzi, Silvia Farè, and Gabriele Candiani Academic Press, 2019 572 pages, $99.95 (e-book $97.99) ISBN 9780081010341 (e-book ISBN 9780128094594)

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 6 / June 2020

- Published online by Cambridge University Press:

- 16 June 2020, p. 501

- Print publication:

- June 2020

-

- Article

-

- You have access

- HTML

- Export citation

Controlled radical polymerization enables sense of texture in haptics

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 6 / June 2020

- Published online by Cambridge University Press:

- 16 June 2020, p. 409

- Print publication:

- June 2020

-

- Article

-

- You have access

- HTML

- Export citation

Biochemistry for Materials Science: Catalysts, Complexes and Proteins by Akio Makishima Elsevier, 2019 329 pages, $150 ISBN 9780128170540 (e-book 9780128168967)

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 6 / June 2020

- Published online by Cambridge University Press:

- 16 June 2020, p. 500

- Print publication:

- June 2020

-

- Article

-

- You have access

- HTML

- Export citation

JMR volume 35 issue 10 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 10 / 28 May 2020

- Published online by Cambridge University Press:

- 29 May 2020, pp. b1-b2

- Print publication:

- 28 May 2020

-

- Article

-

- You have access

- Export citation

JMR volume 35 issue 10 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 10 / 28 May 2020

- Published online by Cambridge University Press:

- 29 May 2020, pp. f1-f5

- Print publication:

- 28 May 2020

-

- Article

-

- You have access

- Export citation

Emerging soluble organic redox materials for next-generation grid energy-storage applications

-

- Journal:

- MRS Communications / Volume 10 / Issue 2 / June 2020

- Published online by Cambridge University Press:

- 28 May 2020, pp. 215-229

- Print publication:

- June 2020

-

- Article

- Export citation

An alternative neutron diffractometer performance for strain/stress measurements

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 3 / September 2020

- Published online by Cambridge University Press:

- 28 May 2020, pp. 185-189

-

- Article

- Export citation

Glucose-sensing properties of citrate-functionalized maghemite nanoparticle–modified indium tin oxide electrodes

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 10 / 28 May 2020

- Published online by Cambridge University Press:

- 29 May 2020, pp. 1279-1289

- Print publication:

- 28 May 2020

-

- Article

- Export citation

Total pattern analyses for non-crystalline materials

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 2 / June 2020

- Published online by Cambridge University Press:

- 27 May 2020, pp. 82-88

-

- Article

- Export citation

Integration of AlN piezoelectric thin films on ultralow fatigue TiNiCu shape memory alloys

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 10 / 28 May 2020

- Published online by Cambridge University Press:

- 27 May 2020, pp. 1298-1306

- Print publication:

- 28 May 2020

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

On the relation between ionospheric parameters and sunspot number

-

- Journal:

- Experimental Results / Volume 1 / 2020

- Published online by Cambridge University Press:

- 27 May 2020, e13

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Surface treatment of titanium by anodization and iron deposition: mechanical and biological properties

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 10 / 28 May 2020

- Published online by Cambridge University Press:

- 26 May 2020, pp. 1290-1297

- Print publication:

- 28 May 2020

-

- Article

- Export citation

Hydrothermal synthesis of carbon nanotube–titania composites for enhanced photocatalytic performance

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 11 / 15 June 2020

- Published online by Cambridge University Press:

- 26 May 2020, pp. 1451-1460

- Print publication:

- 15 June 2020

-

- Article

- Export citation

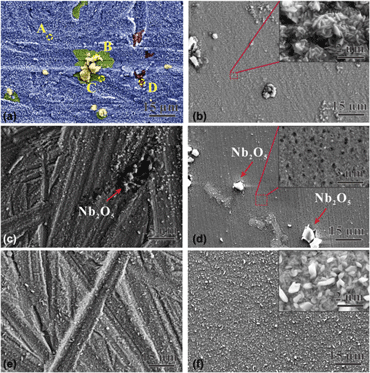

A comparative investigation of long-term oxidation behavior of selective laser melting–fabricated Inconel 718 at 650 °C

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 15 / 14 August 2020

- Published online by Cambridge University Press:

- 26 May 2020, pp. 2036-2045

- Print publication:

- 14 August 2020

-

- Article

- Export citation

Design, synthesis, and characterization of glycyrrhetinic acid-mediated multifunctional liver-targeting polymeric carrier materials

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 10 / 28 May 2020

- Published online by Cambridge University Press:

- 26 May 2020, pp. 1236-1248

- Print publication:

- 28 May 2020

-

- Article

- Export citation

Influence of substrate bias voltage on structure and properties of DC magnetron sputtered Ni–Zr alloy thin films

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 12 / 29 June 2020

- Published online by Cambridge University Press:

- 26 May 2020, pp. 1543-1555

- Print publication:

- 29 June 2020

-

- Article

- Export citation

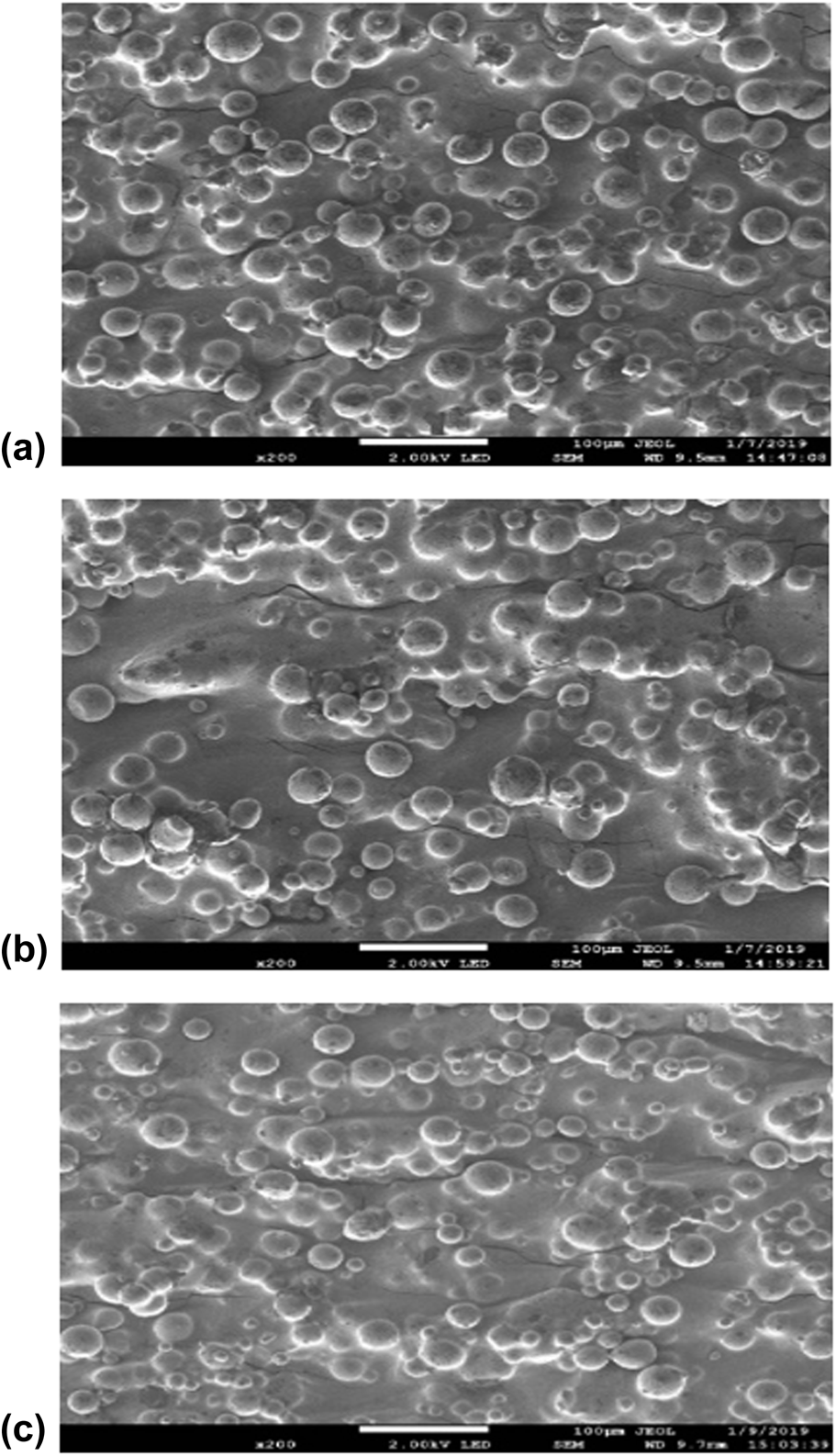

Influence of selective laser melting scanning speed parameter on the surface morphology, surface roughness, and micropores for manufactured Ti6Al4V parts

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 15 / 14 August 2020

- Published online by Cambridge University Press:

- 26 May 2020, pp. 2025-2035

- Print publication:

- 14 August 2020

-

- Article

- Export citation

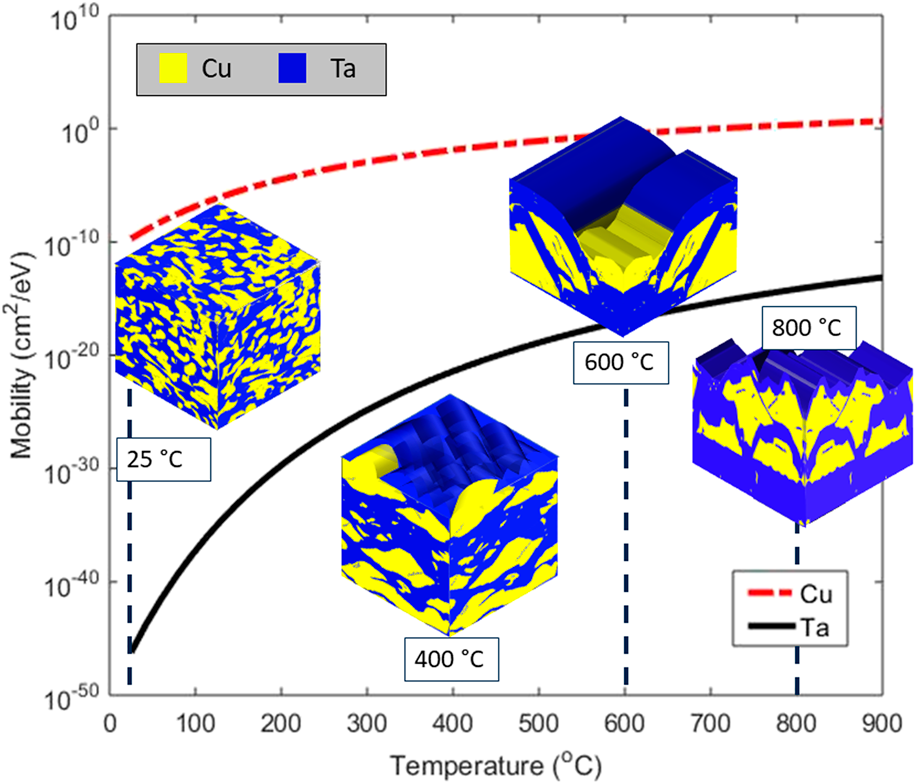

Microstructural characterization of phase-separated co-deposited Cu–Ta immiscible alloy thin films

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 12 / 29 June 2020

- Published online by Cambridge University Press:

- 26 May 2020, pp. 1531-1542

- Print publication:

- 29 June 2020

-

- Article

- Export citation