Refine search

Actions for selected content:

106116 results in Materials Science

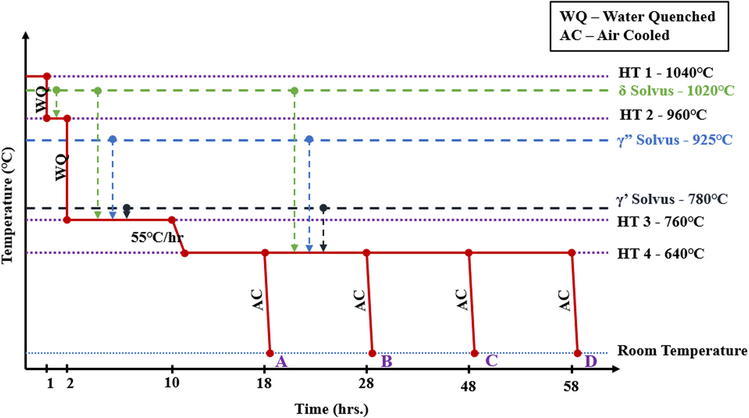

Effect of heat treatment on the modification of microstructure of selective laser melted (SLM) IN718 and its consequences on mechanical behavior

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 15 / 14 August 2020

- Published online by Cambridge University Press:

- 24 June 2020, pp. 1949-1962

- Print publication:

- 14 August 2020

-

- Article

- Export citation

Study on fracture toughness of 617 Ni-based alloy welded joint under different elevated temperatures

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 14 / 28 July 2020

- Published online by Cambridge University Press:

- 24 June 2020, pp. 1790-1802

- Print publication:

- 28 July 2020

-

- Article

- Export citation

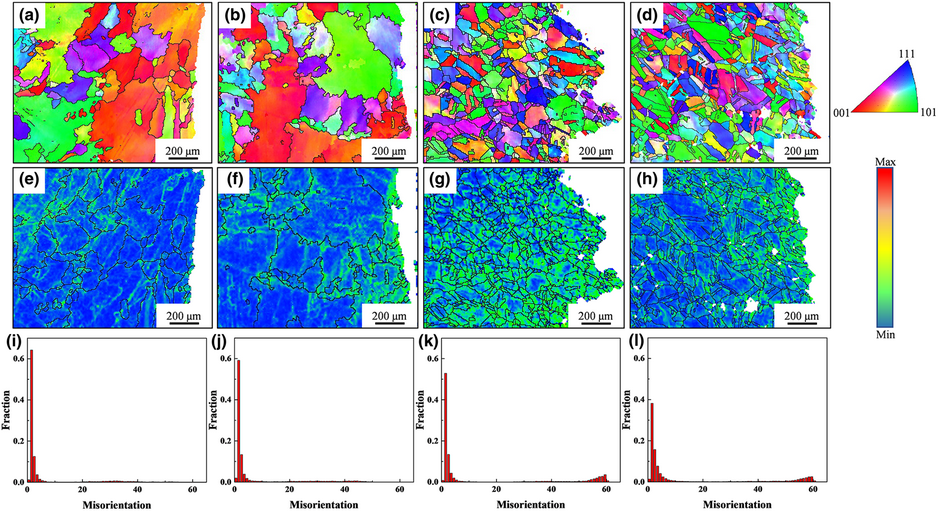

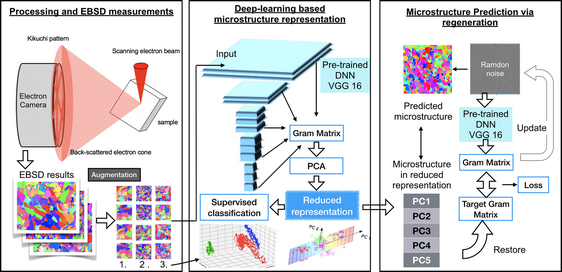

Quantitative microstructure analysis for solid-state metal additive manufacturing via deep learning

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 15 / 14 August 2020

- Published online by Cambridge University Press:

- 24 June 2020, pp. 1936-1948

- Print publication:

- 14 August 2020

-

- Article

- Export citation

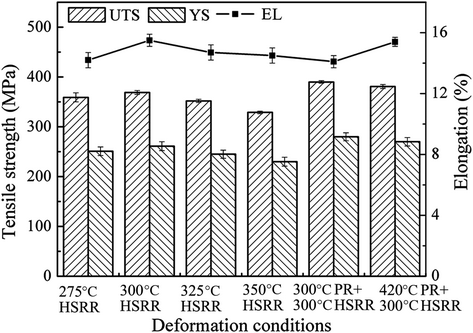

Microstructure evolution and mechanical properties of the ZM61 alloy sheets under different pre-rolling and high strain rate rolling temperatures

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 14 / 28 July 2020

- Published online by Cambridge University Press:

- 24 June 2020, pp. 1817-1824

- Print publication:

- 28 July 2020

-

- Article

- Export citation

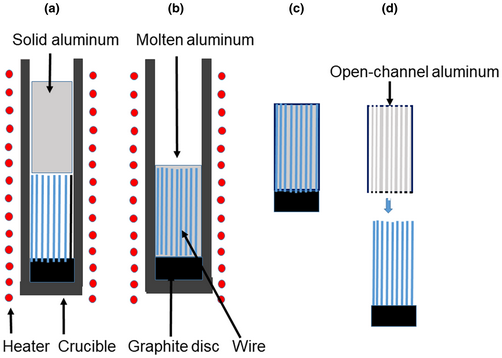

Open-channel metals fabricated by the removal of template wires

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 19 / 14 October 2020

- Published online by Cambridge University Press:

- 24 June 2020, pp. 2535-2546

- Print publication:

- 14 October 2020

-

- Article

- Export citation

Crystal chemistry, X-ray diffraction reference patterns, and bandgap studies for (BaxSr1–x)2CoWO6 (x = 0.1, 0.2, 0.3, 0.5, 0.7, and 0.9)

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 3 / September 2020

- Published online by Cambridge University Press:

- 23 June 2020, pp. 197-205

-

- Article

- Export citation

Testing the flow-through capillary for the study of re-solvation processes in pharmaceutical compounds

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 3 / September 2020

- Published online by Cambridge University Press:

- 23 June 2020, pp. 160-165

-

- Article

- Export citation

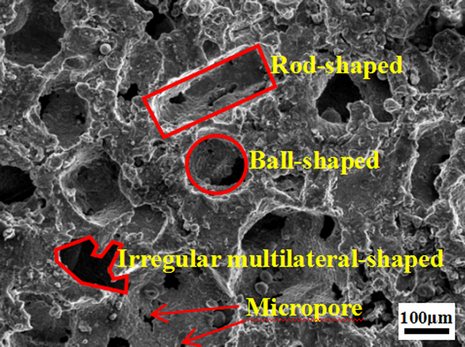

Mechanical properties and damping properties of carbon nanotube-reinforced foam aluminum with small aperture

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 19 / 14 October 2020

- Published online by Cambridge University Press:

- 23 June 2020, pp. 2567-2574

- Print publication:

- 14 October 2020

-

- Article

- Export citation

Assessing atomically thin delta-doping of silicon using mid-infrared ellipsometry

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 16 / 28 August 2020

- Published online by Cambridge University Press:

- 23 June 2020, pp. 2098-2105

- Print publication:

- 28 August 2020

-

- Article

- Export citation

Binary collision of CMAS droplets—Part I: Equal-sized droplets

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 17 / 14 September 2020

- Published online by Cambridge University Press:

- 23 June 2020, pp. 2260-2274

- Print publication:

- 14 September 2020

-

- Article

- Export citation

Copper- and nickel-based flexible polyester electrodes for energy storage devices

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 16 / 28 August 2020

- Published online by Cambridge University Press:

- 23 June 2020, pp. 2115-2125

- Print publication:

- 28 August 2020

-

- Article

- Export citation

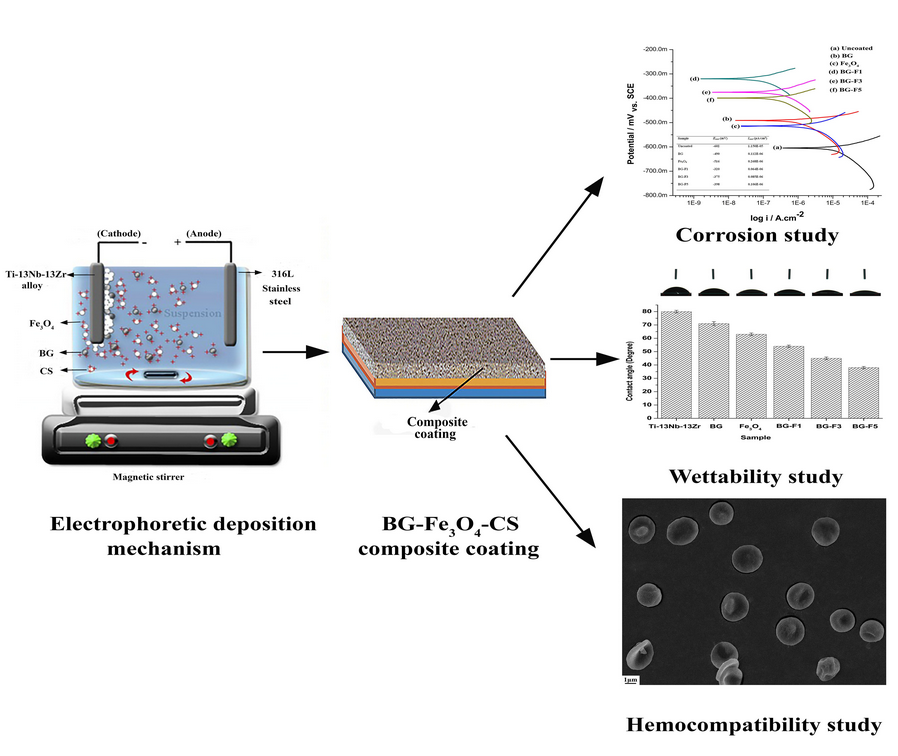

Analysis of in vitro corrosion behavior and hemocompatibility of electrophoretically deposited bioglass–chitosan–iron oxide coating for biomedical applications

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 13 / 14 July 2020

- Published online by Cambridge University Press:

- 22 June 2020, pp. 1749-1761

- Print publication:

- 14 July 2020

-

- Article

- Export citation

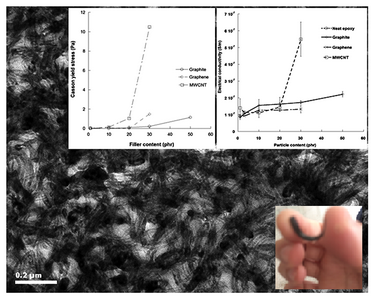

Morphology, rheological, and electrical properties of flexible epoxy/carbon composites cured by UV technique

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 14 / 28 July 2020

- Published online by Cambridge University Press:

- 22 June 2020, pp. 1874-1887

- Print publication:

- 28 July 2020

-

- Article

- Export citation

Salinity decreases transpiration of sorghum plants

-

- Journal:

- Experimental Results / Volume 1 / 2020

- Published online by Cambridge University Press:

- 19 June 2020, e14

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

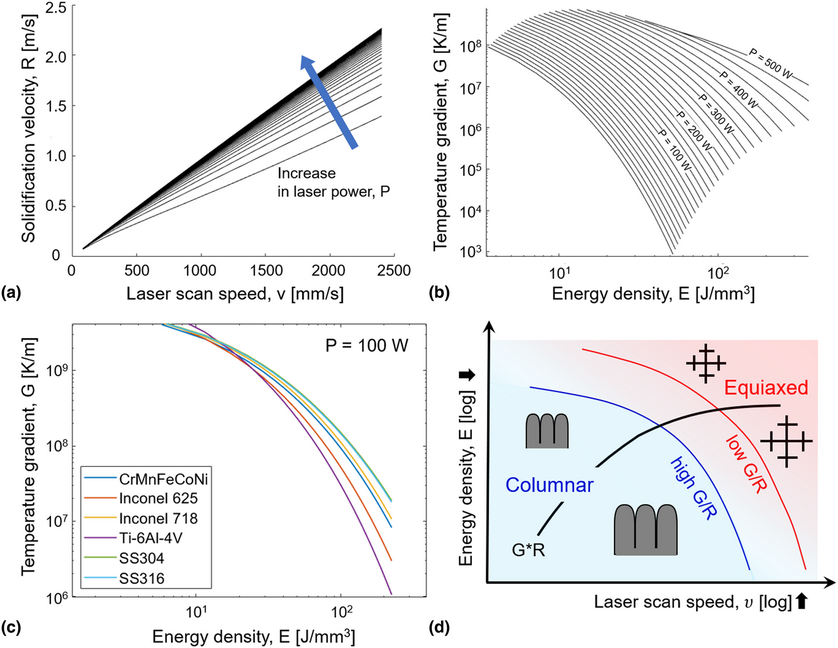

Materials and manufacturing renaissance: Additive manufacturing of high-entropy alloys

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 15 / 14 August 2020

- Published online by Cambridge University Press:

- 19 June 2020, pp. 1963-1983

- Print publication:

- 14 August 2020

-

- Article

- Export citation

Effect of aluminum addition on microstructure and properties of a novel nickel–silicon-containing brass

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 12 / 29 June 2020

- Published online by Cambridge University Press:

- 19 June 2020, pp. 1598-1611

- Print publication:

- 29 June 2020

-

- Article

- Export citation

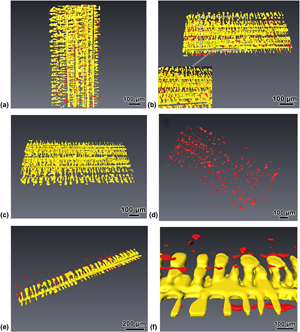

Three-dimensional analysis of dendrites via automated serial sectioning using a Robo-Met.3D

-

- Journal:

- MRS Communications / Volume 10 / Issue 3 / September 2020

- Published online by Cambridge University Press:

- 18 June 2020, pp. 461-466

- Print publication:

- September 2020

-

- Article

- Export citation

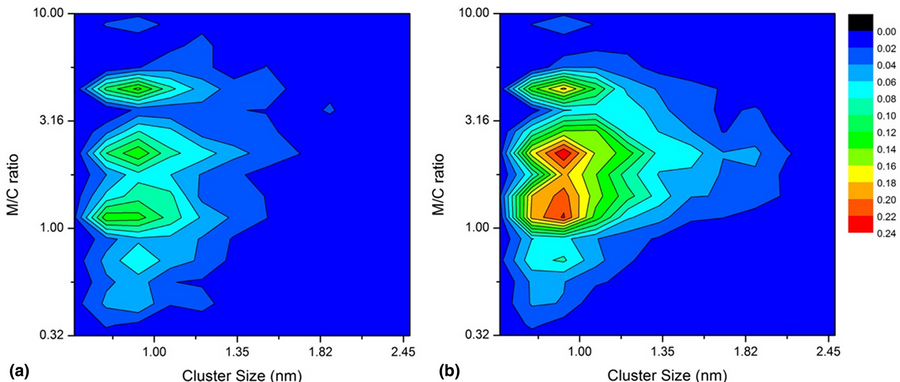

Nanoscale clusters in secondary hardening ultra-high strength steels with 1 and 3 wt% Mo: An atom probe investigation

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 14 / 28 July 2020

- Published online by Cambridge University Press:

- 18 June 2020, pp. 1763-1776

- Print publication:

- 28 July 2020

-

- Article

- Export citation

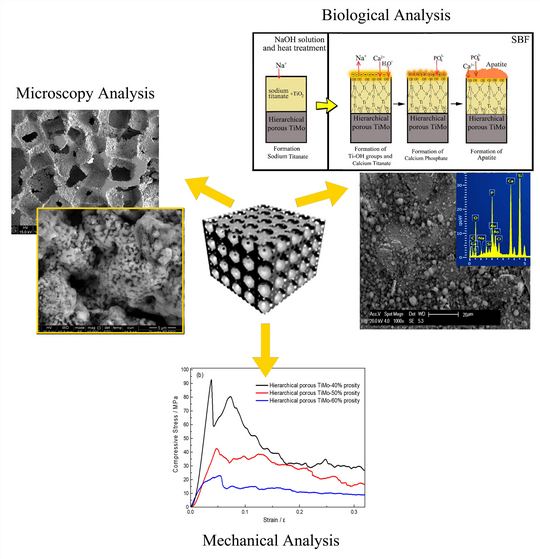

Fabrication, mechanical property and in vitro bioactivity of hierarchical macro-/micro-/nano-porous titanium and titanium molybdenum alloys

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 19 / 14 October 2020

- Published online by Cambridge University Press:

- 18 June 2020, pp. 2597-2609

- Print publication:

- 14 October 2020

-

- Article

- Export citation

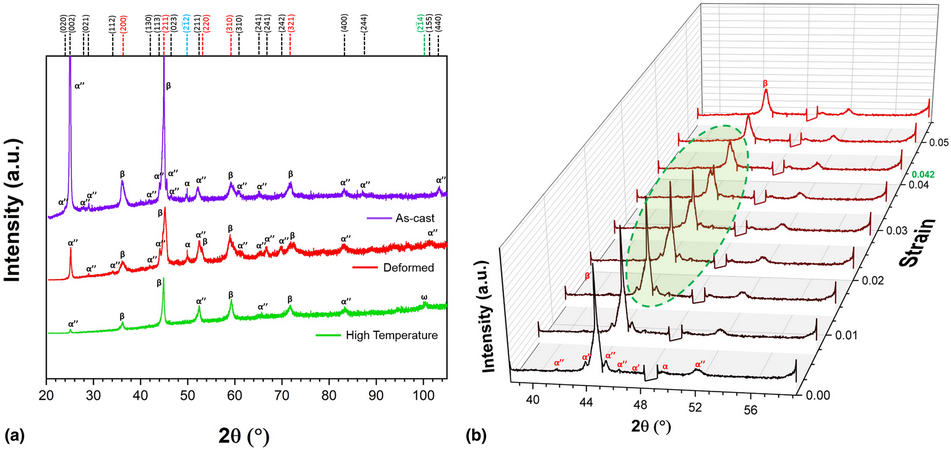

Influence of the deformation rate on phase stability and mechanical properties of a Ti–29Nb–13Ta–4.6Zr–xO alloy analyzed by in situ high-energy X-ray diffraction during compression tests

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 14 / 28 July 2020

- Published online by Cambridge University Press:

- 18 June 2020, pp. 1777-1789

- Print publication:

- 28 July 2020

-

- Article

- Export citation