Refine search

Actions for selected content:

106116 results in Materials Science

Processing metallic materials far from equilibrium

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, pp. 906-909

- Print publication:

- November 2020

-

- Article

-

- You have access

- HTML

- Export citation

In situ mapping of chemical segregation using synchrotron x-ray imaging

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, pp. 934-942

- Print publication:

- November 2020

-

- Article

- Export citation

MRS volume 45 issue 11 Cover and Front matter

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, pp. f1-f6

- Print publication:

- November 2020

-

- Article

-

- You have access

- Export citation

Solute trapping in rapid solidification

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, pp. 910-915

- Print publication:

- November 2020

-

- Article

- Export citation

Glassy lithium forms superior metal anode for rechargeable Li batteries

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, pp. 882-883

- Print publication:

- November 2020

-

- Article

-

- You have access

- HTML

- Export citation

2020 Virtual MRS Spring/Fall Meeting & Exhibit first of its kind for Society

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, pp. 965-967

- Print publication:

- November 2020

-

- Article

-

- You have access

- HTML

- Export citation

Pioneering a new publishing model

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, pp. 877-878

- Print publication:

- November 2020

-

- Article

-

- You have access

- HTML

- Export citation

MRS Journal Highlights

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, pp. 880-881

- Print publication:

- November 2020

-

- Article

-

- You have access

- HTML

- Export citation

CAREER CENTRAL

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, p. 975

- Print publication:

- November 2020

-

- Article

-

- You have access

- Export citation

Variation and variability

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, p. 976

- Print publication:

- November 2020

-

- Article

-

- You have access

- HTML

- Export citation

EU announces European Green Deal €1 billion investment

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 11 / November 2020

- Published online by Cambridge University Press:

- 10 November 2020, p. 888

- Print publication:

- November 2020

-

- Article

-

- You have access

- HTML

- Export citation

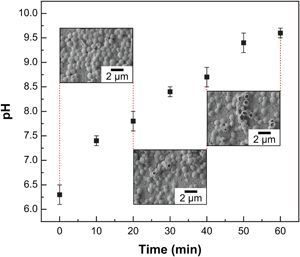

Bacterial inactivation characteristics of magnesium–calcium–zinc alloys for bone implants

-

- Journal:

- MRS Communications / Volume 10 / Issue 4 / December 2020

- Published online by Cambridge University Press:

- 30 October 2020, pp. 609-612

- Print publication:

- December 2020

-

- Article

- Export citation

Nanostructure and compositional segregation of soft magnetic FeNi-based nanocomposites with multiple nanocrystalline phases

-

- Journal:

- Journal of Materials Research , First View

- Published online by Cambridge University Press:

- 29 October 2020, pp. 1-9

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

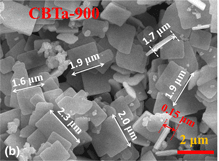

Study of the synthetic process of CaBi2Ta2O9 powder by the molten-salt method

-

- Journal:

- Journal of Materials Research , First View

- Published online by Cambridge University Press:

- 29 October 2020, pp. 1-9

-

- Article

- Export citation

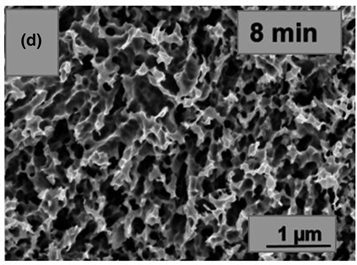

Formation of micro-mechanical interlocking sites by nanoscale sculpturing for composites or hybrid materials with stainless steel

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 23-24 / 14 December 2020

- Published online by Cambridge University Press:

- 29 October 2020, pp. 3145-3156

- Print publication:

- 14 December 2020

-

- Article

- Export citation

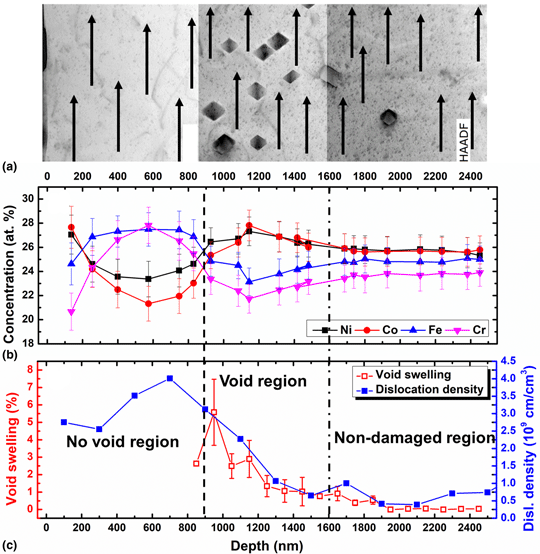

Diffusion-mediated chemical concentration variation and void evolution in ion-irradiated NiCoFeCr high-entropy alloy

-

- Journal:

- Journal of Materials Research , First View

- Published online by Cambridge University Press:

- 29 October 2020, pp. 1-13

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Double transition-metal MXenes: Atomistic design of two-dimensional carbides and nitrides - ADDENDUM

-

- Journal:

- MRS Bulletin , First View

- Published online by Cambridge University Press:

- 29 October 2020, p. 1

-

- Article

-

- You have access

- Export citation

JMR volume 35 issue 20 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 20 / 28 October 2020

- Published online by Cambridge University Press:

- 28 October 2020, pp. b1-b2

- Print publication:

- 28 October 2020

-

- Article

-

- You have access

- Export citation

JMR volume 35 issue 20 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 20 / 28 October 2020

- Published online by Cambridge University Press:

- 28 October 2020, pp. f1-f5

- Print publication:

- 28 October 2020

-

- Article

-

- You have access

- Export citation

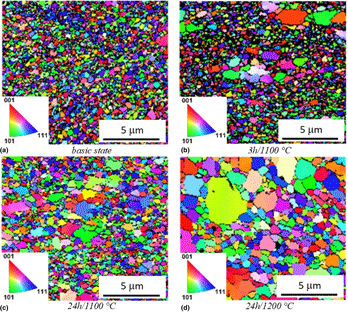

Development of advanced Fe–Al–O ODS alloy microstructure and properties due to heat treatment

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 20 / 28 October 2020

- Published online by Cambridge University Press:

- 28 October 2020, pp. 2789-2797

- Print publication:

- 28 October 2020

-

- Article

- Export citation