Refine search

Actions for selected content:

106116 results in Materials Science

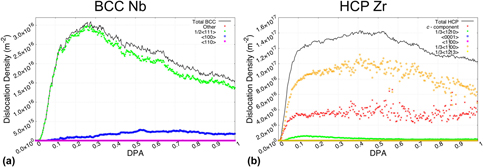

Irradiation resistance of nanostructured interfaces in Zr–Nb metallic multilayers

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 07 March 2019, pp. 2239-2251

- Print publication:

- 15 July 2019

-

- Article

- Export citation

Sixth user workshop on high-power lasers at the linac coherent light source

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 07 March 2019, pp. 79-84

-

- Article

- Export citation

PDJ volume 34 issue 1 Cover and Front matter

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 07 March 2019, pp. f1-f6

-

- Article

-

- You have access

- Export citation

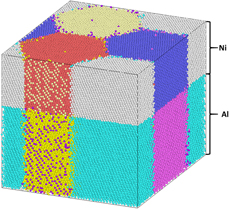

Grain size effects on Ni/Al nanolaminate combustion

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 06 March 2019, pp. 2229-2238

- Print publication:

- 15 July 2019

-

- Article

- Export citation

An energy-based nanoindentation method to assess localized residual stresses and mechanical properties on shot-peened materials

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 7 / 15 April 2019

- Published online by Cambridge University Press:

- 06 March 2019, pp. 1121-1129

- Print publication:

- 15 April 2019

-

- Article

- Export citation

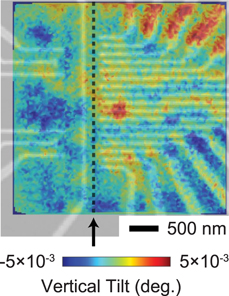

Electrode-induced lattice distortions in GaAs multi-quantum-dot arrays

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 8 / 29 April 2019

- Published online by Cambridge University Press:

- 06 March 2019, pp. 1291-1301

- Print publication:

- 29 April 2019

-

- Article

- Export citation

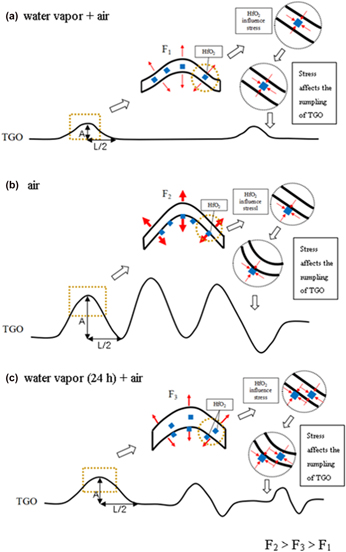

Effect of water vapor on the failure behavior of thermal barrier coating with Hf-doped NiCoCrAlY bond coating

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 06 March 2019, pp. 2653-2663

- Print publication:

- 14 August 2019

-

- Article

- Export citation

Crystal plasticity modeling the deformation in nanodomained heterogenous structures

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 9 / 14 May 2019

- Published online by Cambridge University Press:

- 06 March 2019, pp. 1555-1563

- Print publication:

- 14 May 2019

-

- Article

- Export citation

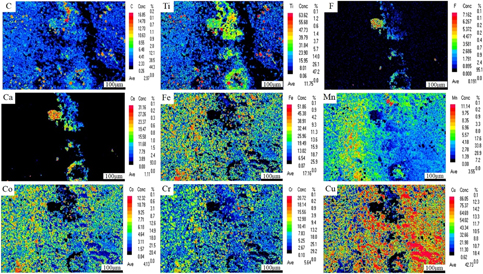

Microstructural evolution and wear performance of the high-entropy FeMnCoCr alloy/TiC/CaF2 self-lubricating composite coatings on copper prepared by laser cladding for continuous casting mold

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 10 / 28 May 2019

- Published online by Cambridge University Press:

- 06 March 2019, pp. 1714-1725

- Print publication:

- 28 May 2019

-

- Article

- Export citation

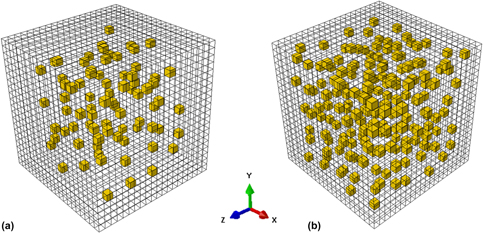

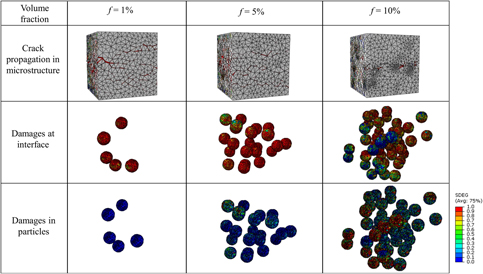

3D multiscale modeling of fracture in metal matrix composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 06 March 2019, pp. 2285-2294

- Print publication:

- 15 July 2019

-

- Article

- Export citation

Effects of titanium addition on microstructure and mechanical properties of CrFeNiTix (x = 0.2–0.6) compositionally complex alloys

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 05 March 2019, pp. 819-828

- Print publication:

- 14 March 2019

-

- Article

- Export citation

Nanostructured surface coatings for titanium alloy implants

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 11 / 14 June 2019

- Published online by Cambridge University Press:

- 04 March 2019, pp. 1892-1899

- Print publication:

- 14 June 2019

-

- Article

- Export citation

An in situ study on Kr ion–irradiated crystalline Cu/amorphous-CuNb nanolaminates

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 04 March 2019, pp. 2218-2228

- Print publication:

- 15 July 2019

-

- Article

- Export citation

A review on cyclic deformation damage and fatigue fracture behavior of metallic nanolayered composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 9 / 14 May 2019

- Published online by Cambridge University Press:

- 04 March 2019, pp. 1479-1488

- Print publication:

- 14 May 2019

-

- Article

- Export citation

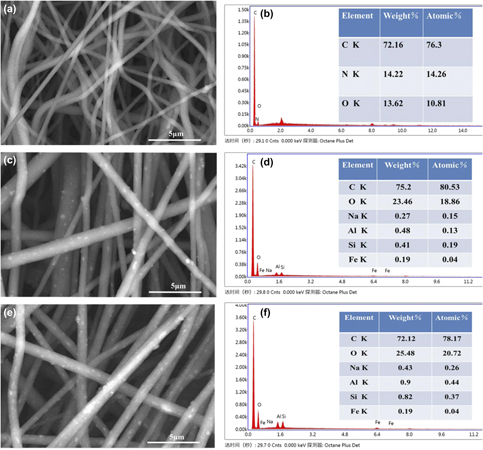

The mineralization of polymer electrospun fibrous membranes modified with tourmaline nanoparticles

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 11 / 14 June 2019

- Published online by Cambridge University Press:

- 04 March 2019, pp. 1900-1910

- Print publication:

- 14 June 2019

-

- Article

- Export citation

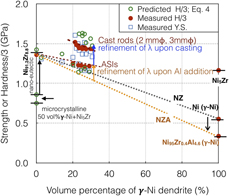

Effect of cooling rate and composition on the microstructure and mechanical properties of (Ni0.92Zr0.08)100−xAlx (0 ≤ x ≤ 4 at.%) ultrafine eutectic composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 10 / 28 May 2019

- Published online by Cambridge University Press:

- 04 March 2019, pp. 1704-1713

- Print publication:

- 28 May 2019

-

- Article

- Export citation

Effect of niobium addition in FeCoNiCuNbx high-entropy alloys

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 04 March 2019, pp. 700-708

- Print publication:

- 14 March 2019

-

- Article

- Export citation

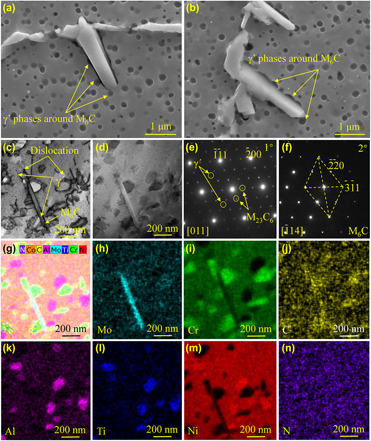

Research on the coarsening mechanism of precipitations and its effect on toughness for nickel-based weld metal during thermal aging

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 15 / 14 August 2019

- Published online by Cambridge University Press:

- 04 March 2019, pp. 2705-2713

- Print publication:

- 14 August 2019

-

- Article

- Export citation

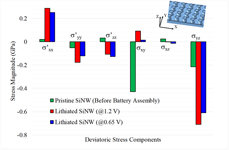

Stress evolution in silicon nanowires during electrochemical lithiation using in situ synchrotron X-ray microdiffraction

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 9 / 14 May 2019

- Published online by Cambridge University Press:

- 04 March 2019, pp. 1622-1631

- Print publication:

- 14 May 2019

-

- Article

- Export citation

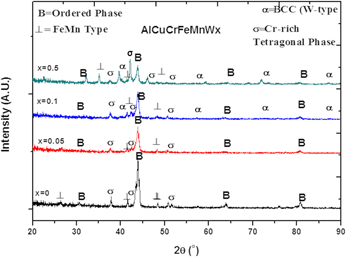

Materials-structure-property correlation study of spark plasma sintered AlCuCrFeMnWx (x = 0, 0.05, 0.1, 0.5) high-entropy alloys

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 04 March 2019, pp. 767-776

- Print publication:

- 14 March 2019

-

- Article

- Export citation