Refine search

Actions for selected content:

106116 results in Materials Science

JMR volume 34 issue 5 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 14 March 2019, pp. b1-b3

- Print publication:

- 14 March 2019

-

- Article

-

- You have access

- Export citation

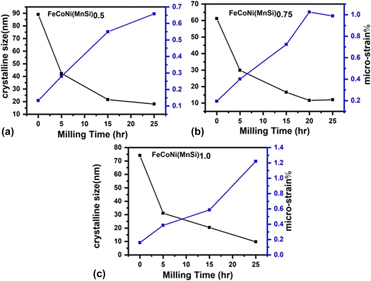

Microstructure and magnetic behavior of FeCoNi(Mn–Si)x (x = 0.5, 0.75, 1.0) high-entropy alloys

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 14 March 2019, pp. 829-840

- Print publication:

- 14 March 2019

-

- Article

- Export citation

High-entropy alloys by mechanical alloying: A review

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 14 March 2019, pp. 664-686

- Print publication:

- 14 March 2019

-

- Article

- Export citation

Crystalline behaviors of HMX-Al composites in solvents: A molecular dynamics and experimental study

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 14 March 2019, pp. 867-875

- Print publication:

- 14 March 2019

-

- Article

- Export citation

Electrochemical single-step obtention and characterization of a biomimetic TiO2-HA NTs covered by chitosan

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 11 / 14 June 2019

- Published online by Cambridge University Press:

- 13 March 2019, pp. 1868-1878

- Print publication:

- 14 June 2019

-

- Article

- Export citation

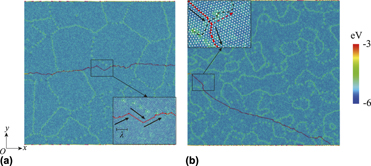

Grain size effects on dynamic fracture instability in polycrystalline graphene under tear loading

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 13 March 2019, pp. 2209-2217

- Print publication:

- 15 July 2019

-

- Article

- Export citation

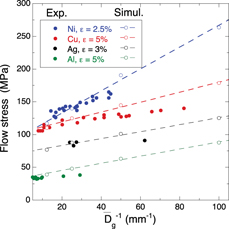

Grain boundary strengthening of FCC polycrystals

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 13 March 2019, pp. 2263-2274

- Print publication:

- 15 July 2019

-

- Article

- Export citation

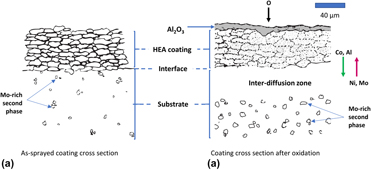

First report on cold-sprayed AlCoCrFeNi high-entropy alloy and its isothermal oxidation

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 13 March 2019, pp. 796-806

- Print publication:

- 14 March 2019

-

- Article

- Export citation

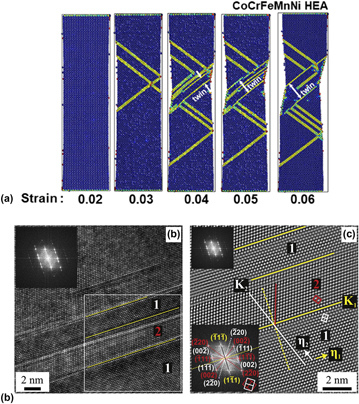

Atomistic modeling of nanoscale plasticity in high-entropy alloys

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 9 / 14 May 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 1509-1532

- Print publication:

- 14 May 2019

-

- Article

- Export citation

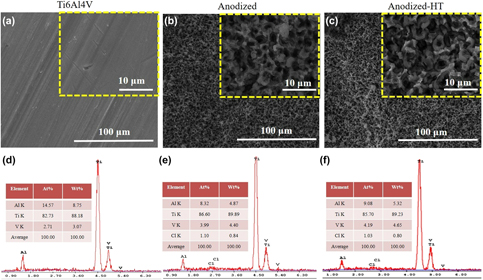

Fabrication of micropit structures on Ti6Al4V alloy using fluoride-free anodization for orthopedic applications

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 7 / 15 April 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 1084-1092

- Print publication:

- 15 April 2019

-

- Article

- Export citation

Impact of linker positions for thieno[3,2-b]thiophene in wide band gap benzo[1,2-b:4,5-b′]dithiophene-based photovoltaic polymers

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 12 / 28 June 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 2057-2066

- Print publication:

- 28 June 2019

-

- Article

- Export citation

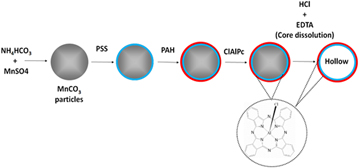

Fabrication of polyelectrolyte microspheres using porous manganese carbonate as sacrificial template for drug delivery application

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 8 / 29 April 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 1353-1362

- Print publication:

- 29 April 2019

-

- Article

- Export citation

Rheological behavior of semisolid hypereutectic Al–Si alloys

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 12 / 28 June 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 2105-2113

- Print publication:

- 28 June 2019

-

- Article

- Export citation

Fabrication of novel resinous diamond composites with acrylonitrile butadiene styrene/polyvinyl chloride/dioctyl phthalate/diamond by hot pressing molding

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 10 / 28 May 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 1734-1743

- Print publication:

- 28 May 2019

-

- Article

- Export citation

Facile synthesis of nearly monodisperse AgCu alloy nanoparticles with synergistic effect against oxidation and electromigration

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 12 / 28 June 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 2095-2104

- Print publication:

- 28 June 2019

-

- Article

- Export citation

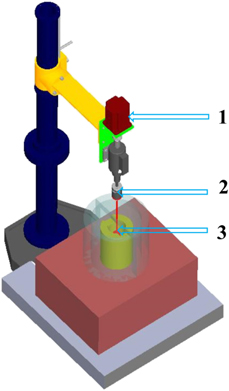

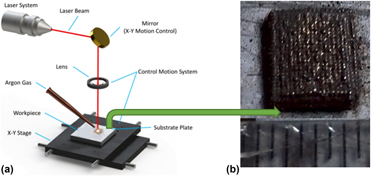

Bulk titanium–graphene nanocomposites fabricated by selective laser melting

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 10 / 28 May 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 1744-1753

- Print publication:

- 28 May 2019

-

- Article

- Export citation

Sandwich-structure styrene-butadiene-styrene block copolymer (SBS)/polypropylene (PP) blends: The role of PP molecular weight

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 6 / 28 March 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 982-990

- Print publication:

- 28 March 2019

-

- Article

- Export citation

Peak shape analysis of deep level transient spectra: An alternative to the Arrhenius plot

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 10 / 28 May 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 1654-1668

- Print publication:

- 28 May 2019

-

- Article

- Export citation

Size-independent strength of amorphous–HCP crystalline metallic nanolayers

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 2275-2284

- Print publication:

- 15 July 2019

-

- Article

- Export citation

Bimetallic metal–organic frameworks-derived mesoporous CdxZn1−xS polyhedrons for enhanced photocatalytic hydrogen evolution

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 10 / 28 May 2019

- Published online by Cambridge University Press:

- 12 March 2019, pp. 1773-1784

- Print publication:

- 28 May 2019

-

- Article

- Export citation