Refine search

Actions for selected content:

106116 results in Materials Science

Mechanochemical synthesis of two-dimensional metal-organic frameworks

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 11 April 2019, pp. 119-123

-

- Article

- Export citation

Structure analysis of a phenylpyrazole carboxylic acid derivative crystallizing with three molecules in the asymmetric unit (Z′ = 3) using X-ray powder diffraction

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 11 April 2019, pp. 151-158

-

- Article

- Export citation

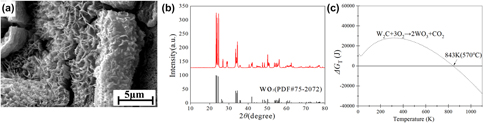

Effect of oxidation on thermal fatigue behavior of cast tungsten carbide particle/steel substrate surface composite

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 10 / 28 May 2019

- Published online by Cambridge University Press:

- 11 April 2019, pp. 1754-1761

- Print publication:

- 28 May 2019

-

- Article

- Export citation

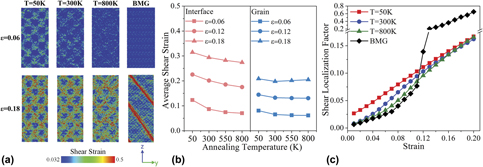

Interfacial plasticity governs strain delocalization in metallic nanoglasses

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 11 April 2019, pp. 2325-2336

- Print publication:

- 15 July 2019

-

- Article

- Export citation

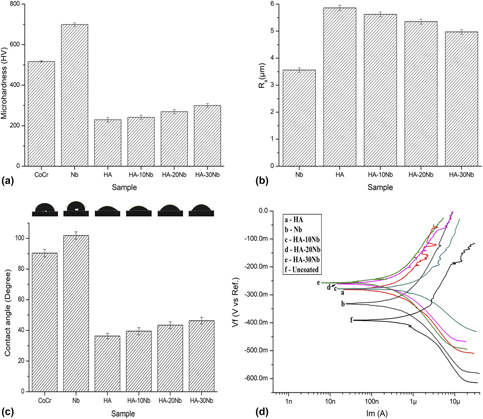

Investigation of the in vitro corrosion behavior and biocompatibility of niobium (Nb)-reinforced hydroxyapatite (HA) coating on CoCr alloy for medical implants

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 10 / 28 May 2019

- Published online by Cambridge University Press:

- 11 April 2019, pp. 1678-1691

- Print publication:

- 28 May 2019

-

- Article

- Export citation

Mineral analysis of river sand around Mt. Tsukuba for provenance estimation of Atamadai type pottery (2500–1500 BC) from Hinoki site (Tochigi, Japan)

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 08 April 2019, pp. 159-163

-

- Article

- Export citation

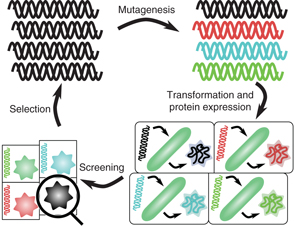

Towards the directed evolution of protein materials

-

- Journal:

- MRS Communications / Volume 9 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 08 April 2019, pp. 441-455

- Print publication:

- June 2019

-

- Article

- Export citation

Quantum Theory of Materials

-

- Published online:

- 05 April 2019

- Print publication:

- 18 April 2019

-

- Textbook

- Export citation

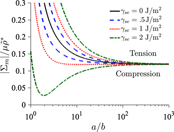

Anomalous size effects in nanoporous materials induced by high surface energies

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 05 April 2019, pp. 2337-2346

- Print publication:

- 15 July 2019

-

- Article

- Export citation

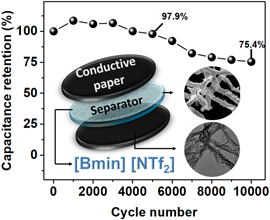

Renewable supercapacitors based on cellulose/carbon nanotubes/[Bmim][NTf2] ionic liquid

-

- Journal:

- MRS Communications / Volume 9 / Issue 2 / June 2019

- Published online by Cambridge University Press:

- 03 April 2019, pp. 726-729

- Print publication:

- June 2019

-

- Article

- Export citation

Bian and Jackson to receive MRS Postdoctoral Awards

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, p. 305

- Print publication:

- April 2019

-

- Article

-

- You have access

- HTML

- Export citation

Crystal microstructures inspire architected 3D printed metamaterials

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, p. 233

- Print publication:

- April 2019

-

- Article

-

- You have access

- HTML

- Export citation

Application of computational tools in alloy design

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, pp. 247-251

- Print publication:

- April 2019

-

- Article

- Export citation

Robotics: Science preceding science fiction

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, pp. 295-301

- Print publication:

- April 2019

-

- Article

-

- You have access

- HTML

- Export citation

MRS volume 44 issue 4 Cover and Back matter

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, pp. b1-b2

- Print publication:

- April 2019

-

- Article

-

- You have access

- Export citation

Xu named MRS Outstanding Young Investigator

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, p. 304

- Print publication:

- April 2019

-

- Article

-

- You have access

- HTML

- Export citation

Meyyappan to receive MRS Impact Award

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, pp. 303-304

- Print publication:

- April 2019

-

- Article

-

- You have access

- HTML

- Export citation

Government shutdowns hamper progress in materials research

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, pp. 234-235

- Print publication:

- April 2019

-

- Article

-

- You have access

- HTML

- Export citation

CAREER CENTRAL

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, p. 319

- Print publication:

- April 2019

-

- Article

-

- You have access

- Export citation

Fan to be presented with the Mid-Career Researcher Award

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 4 / April 2019

- Published online by Cambridge University Press:

- 09 April 2019, p. 303

- Print publication:

- April 2019

-

- Article

-

- You have access

- HTML

- Export citation