Refine search

Actions for selected content:

106116 results in Materials Science

MnFeTiOx/attapulgite catalysts with excellent potassium resistance for SCR of NOx with NH3 at low temperatures

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 7 / 15 April 2019

- Published online by Cambridge University Press:

- 26 February 2019, pp. 1188-1199

- Print publication:

- 15 April 2019

-

- Article

- Export citation

Elastomer-based MEMS optical interferometric transducers for highly sensitive surface stress sensing for biomolecular detection

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 26 February 2019, pp. 381-389

- Print publication:

- March 2019

-

- Article

- Export citation

Effect of sterilization processes on nanostructured Ti6Al4V surfaces obtained by electropolishing

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 8 / 29 April 2019

- Published online by Cambridge University Press:

- 26 February 2019, pp. 1439-1446

- Print publication:

- 29 April 2019

-

- Article

- Export citation

Hot deformation behavior of the high-entropy alloy CoCuFeMnNi

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 21 February 2019, pp. 744-755

- Print publication:

- 14 March 2019

-

- Article

- Export citation

In vitro evaluation of a novel multiwalled carbon nanotube/nanohydroxyapatite/polycaprolactone composite for bone tissue engineering

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 4 / 28 February 2019

- Published online by Cambridge University Press:

- 21 February 2019, pp. 532-544

- Print publication:

- 28 February 2019

-

- Article

- Export citation

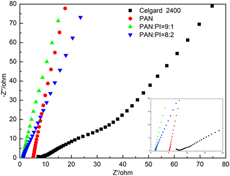

Study on preparation of polyacrylonitrile/polyimide composite lithium-ion battery separator by electrospinning

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 4 / 28 February 2019

- Published online by Cambridge University Press:

- 20 February 2019, pp. 642-651

- Print publication:

- 28 February 2019

-

- Article

- Export citation

G-protein-coupled receptors function as logic gates for nanoparticle binding using systems and synthetic biology approach

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 11 / 14 June 2019

- Published online by Cambridge University Press:

- 20 February 2019, pp. 1854-1867

- Print publication:

- 14 June 2019

-

- Article

- Export citation

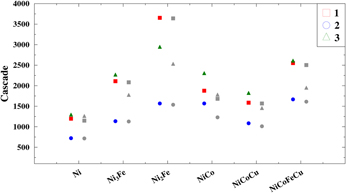

Radiation stability of nanocrystalline single-phase multicomponent alloys

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 20 February 2019, pp. 854-866

- Print publication:

- 14 March 2019

-

- Article

- Export citation

Electrodeposition of Co–Ni–P/graphene oxide composite coating with enhanced wear and corrosion resistance

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 10 / 28 May 2019

- Published online by Cambridge University Press:

- 20 February 2019, pp. 1726-1733

- Print publication:

- 28 May 2019

-

- Article

- Export citation

Conversion of waste plastic into ordered mesoporous carbon for electrochemical applications

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 6 / 28 March 2019

- Published online by Cambridge University Press:

- 18 February 2019, pp. 941-949

- Print publication:

- 28 March 2019

-

- Article

- Export citation

Influence of boron nitride on reinforcement to improve high temperature oxidation resistance of titanium

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 7 / 15 April 2019

- Published online by Cambridge University Press:

- 18 February 2019, pp. 1279-1289

- Print publication:

- 15 April 2019

-

- Article

- Export citation

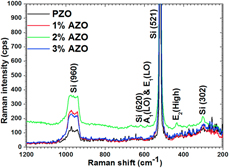

A structural, morphological, linear, and nonlinear optical spectroscopic studies of nanostructured Al-doped ZnO thin films: An effect of Al concentrations

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 8 / 29 April 2019

- Published online by Cambridge University Press:

- 18 February 2019, pp. 1309-1317

- Print publication:

- 29 April 2019

-

- Article

- Export citation

Alloying behavior and thermal stability of mechanically alloyed nano AlCoCrFeNiTi high-entropy alloy

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 15 February 2019, pp. 787-795

- Print publication:

- 14 March 2019

-

- Article

- Export citation

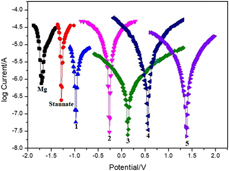

Microstructure and corrosion resistance of Ni–P gradient coating/stannate conversion film on magnesium alloy

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 6 / 28 March 2019

- Published online by Cambridge University Press:

- 15 February 2019, pp. 1064-1072

- Print publication:

- 28 March 2019

-

- Article

- Export citation

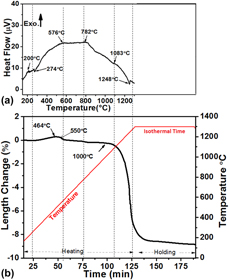

Nearly full-density pressureless sintering of AlCoCrFeNi-based high-entropy alloy powders

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 5 / 14 March 2019

- Published online by Cambridge University Press:

- 14 February 2019, pp. 777-786

- Print publication:

- 14 March 2019

-

- Article

- Export citation

Review of surface water interactions with metal oxide nanoparticles

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 3 / 14 February 2019

- Published online by Cambridge University Press:

- 15 February 2019, pp. 416-427

- Print publication:

- 14 February 2019

-

- Article

- Export citation

Systematic dependence of kinetic and thermodynamic barriers to homogeneous silica nucleation on NaCl and amino acids

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 3 / 14 February 2019

- Published online by Cambridge University Press:

- 15 February 2019, pp. 442-455

- Print publication:

- 14 February 2019

-

- Article

- Export citation

Introduction

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 3 / 14 February 2019

- Published online by Cambridge University Press:

- 15 February 2019, pp. 357-358

- Print publication:

- 14 February 2019

-

- Article

- Export citation

JMR volume 34 issue 3 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 3 / 14 February 2019

- Published online by Cambridge University Press:

- 15 February 2019, pp. f1-f5

- Print publication:

- 14 February 2019

-

- Article

-

- You have access

- Export citation

JMR volume 34 issue 3 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 3 / 14 February 2019

- Published online by Cambridge University Press:

- 15 February 2019, pp. b1-b2

- Print publication:

- 14 February 2019

-

- Article

-

- You have access

- Export citation