Refine search

Actions for selected content:

106116 results in Materials Science

PDJ volume 35 issue 4 Cover and Back matter

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 4 / December 2020

- Published online by Cambridge University Press:

- 14 December 2020, pp. b1-b4

-

- Article

-

- You have access

- Export citation

Editorial

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 4 / December 2020

- Published online by Cambridge University Press:

- 14 December 2020, p. 225

-

- Article

-

- You have access

- HTML

- Export citation

69th Annual Denver X-ray conference report – a virtual event!

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 4 / December 2020

- Published online by Cambridge University Press:

- 14 December 2020, pp. 304-306

-

- Article

- Export citation

Calendar of Forthcoming Meetings

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 4 / December 2020

- Published online by Cambridge University Press:

- 14 December 2020, pp. 302-303

-

- Article

-

- You have access

- HTML

- Export citation

PDJ volume 35 issue 4 Cover and Front matter

-

- Journal:

- Powder Diffraction / Volume 35 / Issue 4 / December 2020

- Published online by Cambridge University Press:

- 14 December 2020, pp. f1-f6

-

- Article

-

- You have access

- Export citation

JMR volume 35 issue 23-24 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 23-24 / 14 December 2020

- Published online by Cambridge University Press:

- 14 December 2020, pp. f1-f5

- Print publication:

- 14 December 2020

-

- Article

-

- You have access

- Export citation

JMR volume 35 issue 23-24 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 35 / Issue 23-24 / 14 December 2020

- Published online by Cambridge University Press:

- 14 December 2020, pp. b1-b6

- Print publication:

- 14 December 2020

-

- Article

-

- You have access

- Export citation

A review on the recent advances concerning the fatigue performance of titanium alloys for orthopedic applications

-

- Journal:

- Journal of Materials Research , First View

- Published online by Cambridge University Press:

- 07 December 2020, pp. 1-15

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

CAREER CENTRAL

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, pp. 1062-1063

- Print publication:

- December 2020

-

- Article

-

- You have access

- Export citation

Proteins for bioinspired optical and electronic materials

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, pp. 1027-1033

- Print publication:

- December 2020

-

- Article

- Export citation

MRS Journal Highlights

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, p. 983

- Print publication:

- December 2020

-

- Article

-

- You have access

- HTML

- Export citation

Considerations for leveraging flexible loads to decarbonize electricity and transportation

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, pp. 992-993

- Print publication:

- December 2020

-

- Article

-

- You have access

- HTML

- Export citation

Nanostructured Immiscible Polymer Blends by Suprakas Sinha Ray and Reza Salehiyan Elsevier, 2020 240 pages, $126 paperback (eBook $154) ISBN: 9780128167076

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, pp. 1059-1060

- Print publication:

- December 2020

-

- Article

-

- You have access

- HTML

- Export citation

Rheological properties of engineered protein polymer networks

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, pp. 1048-1054

- Print publication:

- December 2020

-

- Article

- Export citation

Towards simulating a realistic data analysis with an optimised angular power spectrum of spectroscopic galaxy surveys

-

- Journal:

- Experimental Results / Volume 1 / 2020

- Published online by Cambridge University Press:

- 01 December 2020, e54

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

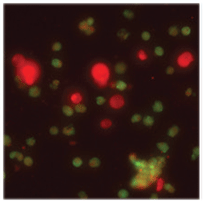

Liquid–liquid phase separation of proteins and peptides derived from biological materials: Discovery, protein engineering, and emerging applications

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, pp. 1039-1047

- Print publication:

- December 2020

-

- Article

- Export citation

MRC volume 10 issue 4 Cover and Back matter

-

- Journal:

- MRS Communications / Volume 10 / Issue 4 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, pp. b1-b2

- Print publication:

- December 2020

-

- Article

-

- You have access

- Export citation

MRS Bulletin names Raman as Postdoctoral Publication Prize recipient

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, p. 1055

- Print publication:

- December 2020

-

- Article

-

- You have access

- HTML

- Export citation

Nanotechnology shows promise for next-generation vaccines in the fight against COVID-19

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, pp. 981-982

- Print publication:

- December 2020

-

- Article

-

- You have access

- HTML

- Export citation

Design for recycling: The circular economy starts here

-

- Journal:

- MRS Bulletin / Volume 45 / Issue 12 / December 2020

- Published online by Cambridge University Press:

- 10 December 2020, p. 989

- Print publication:

- December 2020

-

- Article

-

- You have access

- HTML

- Export citation