Refine search

Actions for selected content:

106116 results in Materials Science

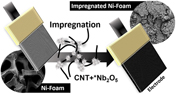

Microwave-assisted hydrothermal synthesis and electrochemical characterization of niobium pentoxide/carbon nanotubes composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 4 / 28 February 2019

- Published online by Cambridge University Press:

- 30 January 2019, pp. 592-599

- Print publication:

- 28 February 2019

-

- Article

- Export citation

Biocompatible methionine-capped CdS/ZnS quantum dots for live cell nucleus imaging

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 344-351

- Print publication:

- March 2019

-

- Article

- Export citation

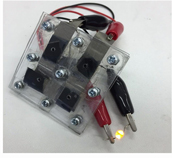

Direct urea fuel cells based on CuNi-plated polymer cloth as a anode catalyst

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 88-91

- Print publication:

- March 2019

-

- Article

- Export citation

Corrosion-resistant nickel thin films by electroless deposition in foam of electrolyte

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 352-359

- Print publication:

- March 2019

-

- Article

- Export citation

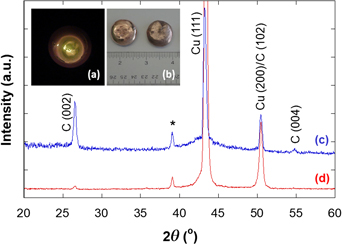

Preparation and electrical conductivity of graphitic carbon-infused copper alloys

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 137-143

- Print publication:

- March 2019

-

- Article

- Export citation

Numerical investigation of spherical indentation on elastic-power-law strain-hardening solids with non-equibiaxial residual stresses

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 360-369

- Print publication:

- March 2019

-

- Article

- Export citation

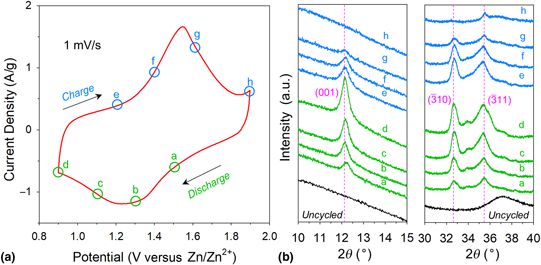

Deciphering charge-storage mechanisms in 3D MnOx@carbon electrode nanoarchitectures for rechargeable zinc-ion cells

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 99-106

- Print publication:

- March 2019

-

- Article

- Export citation

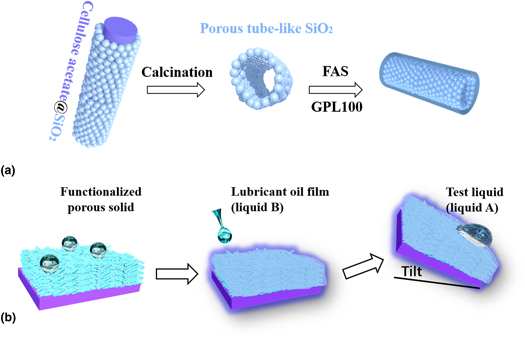

Self-healing liquid-infused surfaces with high transparency for optical devices

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 92-98

- Print publication:

- March 2019

-

- Article

- Export citation

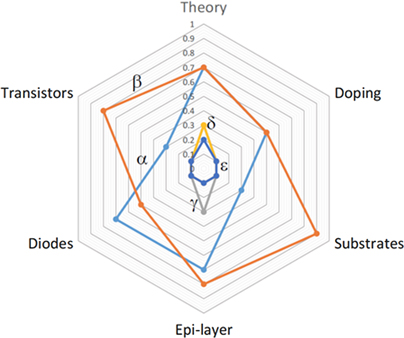

Device processing and junction formation needs for ultra-high power Ga2O3 electronics

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 77-87

- Print publication:

- March 2019

-

- Article

- Export citation

Preparation of nanosized porous oxide layers on titanium by asymmetric AC electrolysis in sulfuric acid

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 194-202

- Print publication:

- March 2019

-

- Article

- Export citation

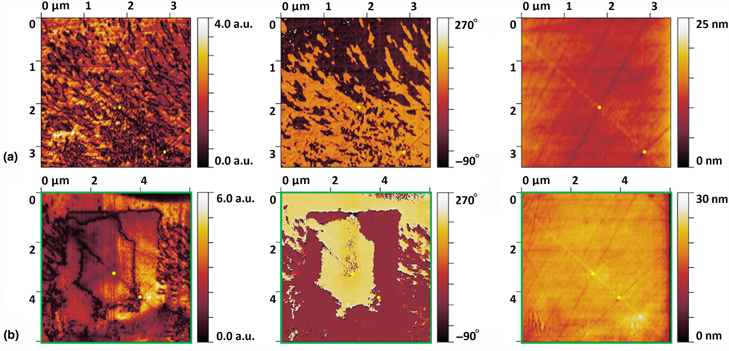

Ferroelectric domain engineering of lithium niobate single crystal confined in glass

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 334-339

- Print publication:

- March 2019

-

- Article

- Export citation

Highly loaded MXene/carbon nanotube yarn electrodes for improved asymmetric supercapacitor performance

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 114-121

- Print publication:

- March 2019

-

- Article

- Export citation

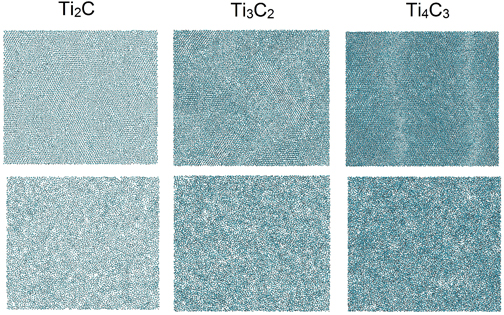

Thermal stability of two-dimensional titanium carbides Tin+1Cn (MXenes) from classical molecular dynamics simulations

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 203-208

- Print publication:

- March 2019

-

- Article

- Export citation

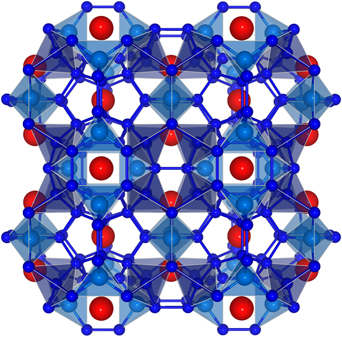

Thermoelectric figure of merit and thermal conductivity of type-I clathrate alloy nanowires

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 370-374

- Print publication:

- March 2019

-

- Article

- Export citation

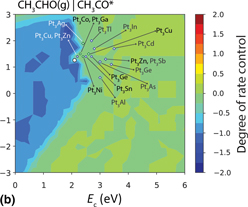

In-silico screening of Pt-based bimetallic alloy catalysts using ab initio microkinetic modeling for non-oxidative dehydrogenation of ethanol to produce acetaldehyde

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 107-113

- Print publication:

- March 2019

-

- Article

- Export citation

Cell viability study of green synthesized CdTe/CdSe quantum dots against osteosarcoma cell line for improved therapeutic action

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. 340-343

- Print publication:

- March 2019

-

- Article

- Export citation

Synergistic effect of carbon nanotube and graphene nanoplatelet addition on microstructure and mechanical properties of AZ31 prepared using hot-pressing sintering – ERRATUM

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 23 / 16 December 2019

- Published online by Cambridge University Press:

- 28 January 2019, p. 3975

- Print publication:

- 16 December 2019

-

- Article

- Export citation

JMR volume 34 issue 2 Cover and Back matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 2 / 28 January 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. b1-b5

- Print publication:

- 28 January 2019

-

- Article

-

- You have access

- Export citation

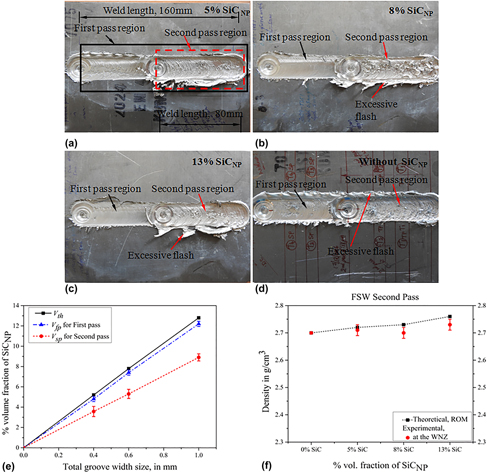

Experimental investigation on effects of varying volume fractions of SiC nanoparticle reinforcement on microstructure and mechanical properties in friction-stir-welded dissimilar joints of AA2024-T351 and AA7075-T651

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 7 / 15 April 2019

- Published online by Cambridge University Press:

- 28 January 2019, pp. 1229-1247

- Print publication:

- 15 April 2019

-

- Article

- Export citation

JMR volume 34 issue 2 Cover and Front matter

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 2 / 28 January 2019

- Published online by Cambridge University Press:

- 29 January 2019, pp. f1-f5

- Print publication:

- 28 January 2019

-

- Article

-

- You have access

- Export citation