Refine search

Actions for selected content:

106116 results in Materials Science

Researchers magnetize single copper atoms

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, p. 86

- Print publication:

- February 2019

-

- Article

-

- You have access

- HTML

- Export citation

Opportunities for materials science: From molecules to neural networks

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, pp. 124-129

- Print publication:

- February 2019

-

- Article

- Export citation

MRS volume 44 issue 2 Cover and Back matter

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, pp. b1-b2

- Print publication:

- February 2019

-

- Article

-

- You have access

- Export citation

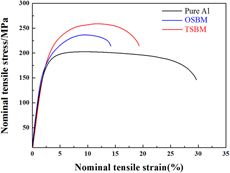

In situ Al4C3 nanorods and carbon nanotubes hybrid-reinforced aluminum matrix composites prepared by a novel two-step ball milling

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 7 / 15 April 2019

- Published online by Cambridge University Press:

- 01 February 2019, pp. 1248-1257

- Print publication:

- 15 April 2019

-

- Article

- Export citation

US 116th Congress sets new record for members with STEM backgrounds

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, pp. 88-90

- Print publication:

- February 2019

-

- Article

-

- You have access

- HTML

- Export citation

Dirac material heterostructures lead to next-generation spintronics

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, pp. 86-87

- Print publication:

- February 2019

-

- Article

-

- You have access

- HTML

- Export citation

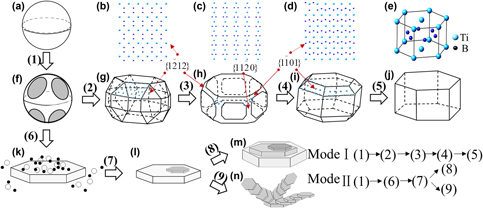

A green steam-modified delignification method to prepare low-lignin delignified wood for thick, large highly transparent wood composites

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 6 / 28 March 2019

- Published online by Cambridge University Press:

- 01 February 2019, pp. 932-940

- Print publication:

- 28 March 2019

-

- Article

- Export citation

Bioinspired nonequilibrium search for novel materials

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, pp. 96-105

- Print publication:

- February 2019

-

- Article

- Export citation

Many aspects of cross-disciplinary worldwide research activity featured at 2018 MRS Fall Meeting

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, pp. 137-139

- Print publication:

- February 2019

-

- Article

-

- You have access

- HTML

- Export citation

Australia’s GenCost 2018 finds renewables are cheapest new-build power

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, p. 90

- Print publication:

- February 2019

-

- Article

-

- You have access

- HTML

- Export citation

LOOK AGAIN

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, p. 144

- Print publication:

- February 2019

-

- Article

-

- You have access

- HTML

- Export citation

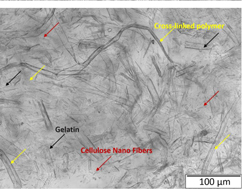

Biologically inspired far-from-equilibrium materials

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, pp. 91-95

- Print publication:

- February 2019

-

- Article

-

- You have access

- HTML

- Export citation

Autonomous materials from biomimicry

-

- Journal:

- MRS Bulletin / Volume 44 / Issue 2 / February 2019

- Published online by Cambridge University Press:

- 12 February 2019, pp. 119-123

- Print publication:

- February 2019

-

- Article

- Export citation

Crystal structure of oxybutynin hydrochloride hemihydrate, C22H32NO3Cl(H2O)0.5

-

- Journal:

- Powder Diffraction / Volume 34 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 30 January 2019, pp. 50-58

-

- Article

- Export citation

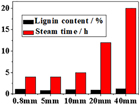

Synthesis of nanoscale spherical TiB2 particles in Al matrix by regulating Sc contents

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 7 / 15 April 2019

- Published online by Cambridge University Press:

- 30 January 2019, pp. 1258-1265

- Print publication:

- 15 April 2019

-

- Article

- Export citation

Cellulose hydrogel as a flexible gel electrolyte layer

-

- Journal:

- MRS Communications / Volume 9 / Issue 1 / March 2019

- Published online by Cambridge University Press:

- 30 January 2019, pp. 122-128

- Print publication:

- March 2019

-

- Article

- Export citation

Thermochemistry of volatile metal hydroxides and oxyhydroxides at elevated temperatures

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 3 / 14 February 2019

- Published online by Cambridge University Press:

- 30 January 2019, pp. 394-407

- Print publication:

- 14 February 2019

-

- Article

- Export citation

Size effects on material yield strength/deformation/fracturing properties

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 13 / 15 July 2019

- Published online by Cambridge University Press:

- 30 January 2019, pp. 2161-2176

- Print publication:

- 15 July 2019

-

- Article

- Export citation

Simultaneous insulation and modification of quartz tuning fork surface by single-step plasma polymerization technique with amine-rich precursors – ERRATUM

-

- Journal:

- MRS Communications / Volume 9 / Issue 3 / September 2019

- Published online by Cambridge University Press:

- 30 January 2019, p. 1124

- Print publication:

- September 2019

-

- Article

-

- You have access

- HTML

- Export citation

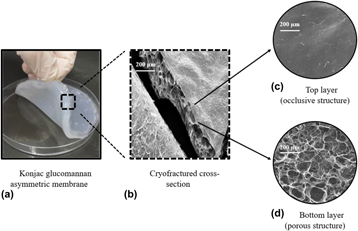

Glucomannan asymmetric membranes for wound dressing

-

- Journal:

- Journal of Materials Research / Volume 34 / Issue 4 / 28 February 2019

- Published online by Cambridge University Press:

- 30 January 2019, pp. 481-489

- Print publication:

- 28 February 2019

-

- Article

- Export citation