1. Introduction

Understanding the immiscible fluid flows in fractured rock formations is critical for various geotechnical applications, including water resources management (De Dios et al. Reference De Dios, Delgado, Martínez, Ramos, lvarez, Iñaki, Juan and Salvador2017; Ren et al. Reference Ren, Ma, Wang, Fan and Zhu2017), environmental protection (Bikkina et al. Reference Bikkina, Wan, Kim, Kneafsey and Tokunaga2016; Zhang et al. Reference Zhang, Li, Adenutsi and Lai2017) and energy storage (Kim et al. Reference Kim, Kwon, Sanchez and Cho2011; Meng, Liu & Wang Reference Meng, Liu and Wang2017). These processes frequently involve the displacement of a wetting fluid by a non-wetting fluid, also referred to as drainage, within fractured media. Prominent examples include the displacement of brine by supercritical CO2 during carbon capture and storage (Miocic et al. Reference Miocic, Gilfillan, Roberts, Edlmann, McDermott and Haszeldine2016) and the migration of pressurised gases through water-saturated materials in nuclear waste repositories (Muller et al. Reference Muller, Finsterle, Grimsich, Baltzer, Muller, Rector, Payer and Apps2019). To support effective planning and risk assessment, accurate models of these flow processes are necessary, which are capable of predicting flow velocities and spatial fluid distributions. While two-phase flows in porous media have been extensively studied over the past two decades, fewer studies have focused specifically on this dynamics within geological fractures.

Immiscible displacements in open rough-walled fractures can be subject to different types of flow instabilities, driven by density or viscosity contrasts between the two fluids, and capillary forces also play an important role in allowing fluid-fluid interfaces to more easily invade large (respectively, small) aperture areas when the wetting fluid is the displaced (respectively, displacing) fluid (Glass et al. Reference Glass, Nicholl and Yarrington1998, Reference Glass, Rajaram and Detwiler2003; Detwiler, Rajaram & Glass Reference Detwiler, Rajaram and Glass2009). The relative magnitudes of gravity, viscous and capillary forces are typically estimated in terms of the capillary number

![]() $Ca$

(typical ratio of the viscous forces to the capillary forces), the Bond number

$Ca$

(typical ratio of the viscous forces to the capillary forces), the Bond number

![]() $Bo$

(typical ratio of the gravitational force to the capillary forces), and the ratio of the two fluids’ viscosities,

$Bo$

(typical ratio of the gravitational force to the capillary forces), and the ratio of the two fluids’ viscosities,

![]() $M$

. To properly capture the effect of all these forces in a model is challenging. Additionally, molecular-scale phenomena, including thin wetting films and moving contact lines, are challenging to model accurately (Meakin & Tartakovsky Reference Meakin and Tartakovsky2009; Krishna, Méheust & Neuweiler Reference Krishna, Méheust and Neuweiler2024).

$M$

. To properly capture the effect of all these forces in a model is challenging. Additionally, molecular-scale phenomena, including thin wetting films and moving contact lines, are challenging to model accurately (Meakin & Tartakovsky Reference Meakin and Tartakovsky2009; Krishna, Méheust & Neuweiler Reference Krishna, Méheust and Neuweiler2024).

In applications, flow processes need to be considered over large length scales in the range of tens to hundreds of metres. Yet, when flow instabilities are present, large-scale flow patterns may be impacted by small-scale properties or processes, in particular the properties of the fractures’ aperture fields. Fracture surfaces, either artificial, or in natural environments such as the subsurface, exhibit self-affine scaling behaviour, with Hurst exponents typically ranging between 0.5 and 0.8 (Bouchaud, Lapasset & Planès Reference Bouchaud, Lapasset and Planès1990; Schmittbuhl, Schmitt & Scholz Reference Schmittbuhl, Schmitt and Scholz1995; Boffa, Allain & Hulin Reference Boffa, Allain and Hulin1998), and matching of the wall topographies with each other over a characteristic correlation scale (Brown Reference Brown1995). The span of relevant length scales is thus very large.

To model the drainage process using direct numerical simulation (DNS), the Navier–Stokes equations, coupled with an interface capturing or tracking technique, are solved numerically. Although large viscosity and density ratios (Meakin & Tartakovsky Reference Meakin and Tartakovsky2009), as well as a large range of capillary numbers (Chen et al. Reference Chen, Guo, Wu and Hu2018; Krishna et al. Reference Krishna, Méheust and Neuweiler2024), can be captured, the computational cost of DNS of immiscible two-phase flow, in particular if wetting films need to be resolved, can become very large, as discussed in Krishna et al. (Reference Krishna, Méheust and Neuweiler2024) for fracture geometries, or Horgue et al. (Reference Horgue, Augier, Quintard and Prat2012) for porous media. Particle methods such as lattice Boltzmann methods (Dou, Zhou & Sleep Reference Dou, Zhou and Sleep2013; Guiltinan et al. Reference Guiltinan, Santos, Cardenas, Espinoza and Kang2021), and Lagrangian mesh-free methods such as smoothed particle hydrodynamics (Tartakovsky & Meakin Reference Tartakovsky and Meakin2005), which also provide hydrodynamic-scale resolution and respect conservation principles (Lee & Lin Reference Lee and Lin2005), are also potentially capable of handling a wide range of

![]() $Ca$

,

$Ca$

,

![]() $Bo$

and

$Bo$

and

![]() $M$

values. However, these methods encounter challenges in relating the model parameters and the underlying physics of the modelled fluid flow (Porter et al. Reference Porter, Coon, Kang, Moulton and Carey2012).

$M$

values. However, these methods encounter challenges in relating the model parameters and the underlying physics of the modelled fluid flow (Porter et al. Reference Porter, Coon, Kang, Moulton and Carey2012).

The computational demand for models accounting for the entire range of physical phenomena at play can be very large. Simplified models have been derived for flow in fractures, in particular for restricted flow regimes. Invasion percolation schemes, able to describe quasi-static fluid–fluid interface displacement controlled entirely by capillary forces, have been adapted from porous media to fracture geometries to address regimes of very slow displacements (i.e. very small

![]() $Ca$

) (Glass, Nicholl & Yarrington Reference Glass, Nicholl and Yarrington1998; Neuweiler, Sorensen & Kinzelbach Reference Neuweiler, Sorensen and Kinzelbach2004; Yang et al. Reference Yang, Niemi, Fagerlund and Illangasekare2012, Reference Yang, Neuweiler, Méheust, Fagerlund and Niemi2016). A few attempts have also been made to simulate two-phase flow in single fracture using pore network models; they have proven to be computationally efficient (Hughes & Blunt Reference Hughes and Blunt2001; Ferer et al. Reference Ferer, Crandall, Ahmadi and Smith2011), but it is difficult with this approach to properly model the in-plane component of the capillary pressure at fluid-fluid interfaces. More recently, a very efficient model was proposed to describe flow conditions for which viscous forces are the dominant displacement driver (Yang et al. Reference Yang, Méheust, Neuweiler, Hu, Niemi and Chen2019), with a single fluid–fluid interface. Another approach to flows over large scales is to consider volume-averaged upscaled models. This approach is used extensively to simulate large-scale two-phase flow in porous media (e.g. reservoir simulations), however, such models are non-local and provide convincing predictions only for restricted flow regimes (see e.g. Picchi & Battiato Reference Picchi and Battiato2018), with no interface instabilities, and are not well-suited to address media with multiscale properties, such as fracture geometries.

$Ca$

) (Glass, Nicholl & Yarrington Reference Glass, Nicholl and Yarrington1998; Neuweiler, Sorensen & Kinzelbach Reference Neuweiler, Sorensen and Kinzelbach2004; Yang et al. Reference Yang, Niemi, Fagerlund and Illangasekare2012, Reference Yang, Neuweiler, Méheust, Fagerlund and Niemi2016). A few attempts have also been made to simulate two-phase flow in single fracture using pore network models; they have proven to be computationally efficient (Hughes & Blunt Reference Hughes and Blunt2001; Ferer et al. Reference Ferer, Crandall, Ahmadi and Smith2011), but it is difficult with this approach to properly model the in-plane component of the capillary pressure at fluid-fluid interfaces. More recently, a very efficient model was proposed to describe flow conditions for which viscous forces are the dominant displacement driver (Yang et al. Reference Yang, Méheust, Neuweiler, Hu, Niemi and Chen2019), with a single fluid–fluid interface. Another approach to flows over large scales is to consider volume-averaged upscaled models. This approach is used extensively to simulate large-scale two-phase flow in porous media (e.g. reservoir simulations), however, such models are non-local and provide convincing predictions only for restricted flow regimes (see e.g. Picchi & Battiato Reference Picchi and Battiato2018), with no interface instabilities, and are not well-suited to address media with multiscale properties, such as fracture geometries.

Another approach to improve the efficiency of numerical models while considering the whole variety of physical processes at play, is to reduce the dimensionality of the model. In fracture geometries this can be done by depth integration, i.e. integrating the flow equations over the direction perpendicular to the mean fracture plane. Physical effects that may no longer be accounted for explicitly, as the third dimension is not explicitly resolved, are then captured by effective terms or parameters that are derived in the course of the depth integration. For instance, the Reynolds equation has been widely used to simulate stationary single-phase flow in rough fractures (Brown, Stockman & Reeves Reference Brown, Stockman and Reeves1995; Zimmerman & Yeo Reference Zimmerman and Yeo2000; Méheust & Schmittbuhl Reference Méheust and Schmittbuhl2001; He et al. Reference He, Sinan, Kwak and Hoteit2021). It combines the conservation of the fluid mass and the local cubic law, which states that the relation between the local flux (i.e. velocity integrated over the fracture aperture) and the pressure gradient is identical to that relating the global flow rate per transverse unit length to the macroscopic pressure gradient in a parallel plate (i.e. planar) fracture. The local cubic law can be rigorously derived from the stationary Stokes equation under the lubrication approximation, which assumes that the gradient of the fracture’s aperture field is much smaller than 1 everywhere (see, e.g. Zimmerman & Yeo Reference Zimmerman and Yeo2000). More general depth integrations of the Navier–Stokes equations over flow domains with a uniform aperture have been proposed for (i) single-phase flow in Hele-Shaw cell geometries, coupled to heat transport (Letelier, Mujica & Ortega Reference Letelier, Mujica and Ortega2019), miscible fluid mixing (Letelier et al. Reference Letelier, Ulloa, Leyrer and Ortega2023) and solute-actuated natural convection (De Paoli et al. Reference De Paoli, Alipour and Soldati2020; De et al. Reference De, Meunier, Méheust and Nadal2021), (ii) single-phase flow in two-dimensional (2-D) (microfluidic) porous media (Izumoto et al. Reference Izumoto, Huisman, Zimmermann, Heyman, Gomez, Tabuteau, Laniel, Vereecken, Méheust and Le Borgne2022) and (iii) two-phase flow in similar 2-D porous media (Horgue et al. Reference Horgue, Augier, Duru, Prat and Quintard2013; Ferrari et al. Reference Ferrari, Jimenez‐Martinez, Borgne, Méheust and Lunati2015). The latter type of studies is the closest to what interests us here. Horgue et al. (Reference Horgue, Augier, Duru, Prat and Quintard2013) studied the spreading of a liquid jet across in-line arrays of cylinders positioned within a Hele-Shaw cell, experimentally and numerically. They found that the depth-integrated 2-D model could reproduce most of the experimental observations with some differences in time and space scales due to the difficulty in incorporating all 3-D effects in the 2-D model. Ferrari et al. (Reference Ferrari, Jimenez‐Martinez, Borgne, Méheust and Lunati2015) applied the same approach to reproduce primary drainage experiments in a 2-D random porous medium consisting of cylindrical grains within a Hele-Shaw cell. Their investigation also showed excellent agreement between the 2-D integrated model and the experimental results. However, in all these works, the confining length (aperture) in the direction transverse to the plane of interest was (or assumed to be) uniform. A recent example of a 2-D depth-integrated model in a rough fracture geometry is the generalised lubrication theory derived for coupled electrohydrodynamic transport in rough fractures by Dewangan et al. (Reference Dewangan, Ghosh, Le Borgne and Méheust2022), but it addresses single-phase flow. Hence, to our knowledge, the depth integration of the Navier–Stokes equation has so far not been used to model immiscible two-phase flow in geometries with space-varying apertures. In this study, we propose such a 2-D depth-integrated model of immiscible two-phase flow in fractures with varying apertures, and investigate to which extent, and under which conditions, such a model can successfully predict the displacement patterns.

In the model, the third dimension effects that need to be accounted for in the 2-D equations are the following: (i) the drag force exerted by the two rough fracture walls on account of the no-slip wall boundary conditions (same as for the monophasic flow, see Ferrari et al. Reference Ferrari, Jimenez‐Martinez, Borgne, Méheust and Lunati2015; De et al. Reference De, Meunier, Méheust and Nadal2021; Izumoto et al. Reference Izumoto, Huisman, Zimmermann, Heyman, Gomez, Tabuteau, Laniel, Vereecken, Méheust and Le Borgne2022) and (ii) the out-of-plane component of the capillary pressure interface curvature. Furthermore, in the 2-D model, the fracture aperture field is expected to dictate the storage capacity available at a particular location in the fracture plane, and the displacement of fluid-fluid interfaces must depend on this local storage capacity. In the following, to derive the 2-D model equations, we incorporate those specific aspects by rigorously depth integrating the 3-D Navier–Stokes equations over the local fracture aperture, and adding the out-of-plane capillary pressure component to the resulting 2-D momentum equation.

To track the fluid–fluid interface positions within the mean fracture plane, one must use a method pertaining to one of two broad categories: (a) interface tracking methods, where either marker particles or height functions are used to mark or track the interface (Fukai et al. Reference Fukai, Shiiba, Yamamoto, Miyatake, Poulikakos, Megaridis and Zhao1995; Tryggvason et al. Reference Tryggvason, Bunner, Esmaeeli, Juric, Al-Rawahi, Tauber, Han, Nas and Jan2001); and (b) interface-capturing methods, where an indicator function is used to denote the location of the interface, which is then advected by the velocity field to model the interface motion. Interface tracking methods (a) maintain a sharp interface, allowing for more accurate calculations of curvature and surface tension. However, since they involve solving a moving boundary problem, these methods are less suitable for flows with large interface deformations, such as breakup or coalescence (Gopala & van Wachem Reference Gopala and van Wachem2008). In contrast, the Eulerian framework-based interface-capturing methods (b) are more suitable for complex interface motion. Depending on the choice of the indicator function, interface-capturing methods are sub-classified as level-set (Sethian Reference Sethian1996; Osher & Fedkiw Reference Osher and Fedkiw2005), phase-field (Sun & Beckermann Reference Sun and Beckermann2007, Reference Sun and Beckermann2008) and volume of fluid (VOF) (Hirt & Nichols Reference Hirt and Nichols1981; Ubbink & Issa Reference Ubbink and Issa1999; Rusche Reference Rusche2003) methods. We chose the VOF method, which has been successfully demonstrated to model immiscible flow through porous media with sub-pore resolution, and describe characteristic phenomena such as viscous deformation of the meniscus, snap-off and coalescence, jumps and abrupt reconfiguration of the interface (Ferrari & Lunati Reference Ferrari and Lunati2013). It was also the method of choice for the aforementioned study of primary drainage in 2-D two-phase flows by Ferrari et al. (Reference Ferrari, Jimenez‐Martinez, Borgne, Méheust and Lunati2015).

In this study, we thus formulate a 2-D depth-integrated flow model for immiscible two-phase flow in open, rough-walled fractures, accounting for all physical forces that may act on the fluid phases and the interfaces between them. We capture the fluid-fluid interface using the VOF method, and assume the lubrication approximation, that is, the aperture field’s gradient is sufficiently small everywhere, and, consequently, also assume that the local velocity profile along the direction perpendicular to the mean fracture plane is parabolic. The latter assumption is only required to write the depth-integrated nonlinear convective derivative of momentum as a function of the depth-integrated velocity field, as well as to express the term accounting for the friction imposed onto the fluid by the fracture walls (see point (i)) above). The model is implemented numerically using the open-source computational fluid dynamics (CFD) code OpenFOAM (2012), and validated by comparison with full 3-D VOF-based simulations (see Krishna et al. Reference Krishna, Méheust and Neuweiler2024) in the classical configuration of the growth of a single viscous finger in a Hele-Shaw geometry (Saffman & Taylor Reference Saffman and Taylor1958). It is then applied to primary drainage in a realistic rough fracture geometry under various capillary numbers, comprehensively comparing the predictions of our 2-D model with those obtained from the 3-D numerical simulations, based on various hydrodynamic-scale and macroscopic observables. We thus analyse the depth-integrated model’s output to test to which extent, and under which conditions, the flow physics in such unstable immiscible two-phase flow conditions can be well predicted by such a reduced-dimension model. We obtain good agreements with the predictions of corresponding 3-D simulations for almost all flow conditions, in particular thanks to the convincing accounting of capillary forces, which requires an explicit term accounting for the out-of-plane curvature’s contribution. Furthermore, we show that the model can provide convincing predictions in realistic geometries for which the lubrication approximation is only loosely verified. We also discuss the computational efficiency of the depth-integrated model.

The paper is organised as follows. In § 2, we describe the first-principle governing equations within the VOF framework. Section 3 is dedicated to the derivation of both the single- and two-phase 2-D depth-integrated models. The two-phase flow 2-D model validation in the Saffman–Taylor configuration and the study of primary drainage in a rough fracture are presented in § 4. Section 5 presents a summary of the study, its conclusions and discusses future prospects. Appendix A is dedicated to showing how the model reduces to the well-known Reynolds equation for monophasic steady-state Stokes flow. Appendix B and Appendix C present analyses respectively supporting the choice made for the effective wetting angle and testing the model’s sensitivity to contact angle. Appendix D justifies the chosen aperture field discretisation, while single-phase 2-D model results in a rough fracture geometry are presented in Appendix E.

2. Theoretical background

To describe the isothermal flow of two immiscible, incompressible, Newtonian fluids, we employ a whole domain formulation (Scardovelli & Zaleski Reference Scardovelli and Zaleski1999): the two phases are treated as one single fluid with spatially varying physical properties, namely the density

![]() $\rho$

and dynamic viscosity

$\rho$

and dynamic viscosity

![]() $\mu$

. The boundary conditions (velocity continuity and stress balance) arising at the fluid–fluid interfaces are replaced by a force defined mathematically in the entire domain but whose magnitude is significant only in the interface region (Ferrari & Lunati Reference Ferrari and Lunati2013). This approach eliminates the need to solve a challenging and computationally expensive moving boundary problem. In the following subsections, we briefly describe the governing equations and the chosen whole domain formulation, which is the VOF method. For a more detailed presentation on this topic, the readers are encouraged to see Berberović et al. (Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009), Rusche (Reference Rusche2003) and Deshpande et al. (Reference Deshpande, Anumolu and Trujillo2012a

).

$\mu$

. The boundary conditions (velocity continuity and stress balance) arising at the fluid–fluid interfaces are replaced by a force defined mathematically in the entire domain but whose magnitude is significant only in the interface region (Ferrari & Lunati Reference Ferrari and Lunati2013). This approach eliminates the need to solve a challenging and computationally expensive moving boundary problem. In the following subsections, we briefly describe the governing equations and the chosen whole domain formulation, which is the VOF method. For a more detailed presentation on this topic, the readers are encouraged to see Berberović et al. (Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009), Rusche (Reference Rusche2003) and Deshpande et al. (Reference Deshpande, Anumolu and Trujillo2012a

).

2.1. First-principle equations

The whole domain formulation results in a single set of Navier–Stokes equations describing the flow of two immiscible, Newtonian fluids

for the conservation of mass, and

for the conservation of momentum. In the above equations,

![]() $\boldsymbol{u} = (u,v,w)$

is the velocity field,

$\boldsymbol{u} = (u,v,w)$

is the velocity field,

![]() $p$

is the pressure field,

$p$

is the pressure field,

![]() $\boldsymbol{g}$

is the gravitational acceleration and

$\boldsymbol{g}$

is the gravitational acceleration and

![]() $\mathsf{\boldsymbol E}= (\boldsymbol{\nabla }\boldsymbol{u} + \boldsymbol{\nabla }\boldsymbol{u}^T)/2$

is the rate-of-strain tensor. The term representing the viscous forces in the momentum equation (2.2) can thus be expressed as

$\mathsf{\boldsymbol E}= (\boldsymbol{\nabla }\boldsymbol{u} + \boldsymbol{\nabla }\boldsymbol{u}^T)/2$

is the rate-of-strain tensor. The term representing the viscous forces in the momentum equation (2.2) can thus be expressed as

where

![]() $\boldsymbol \nabla \boldsymbol u$

denotes the element-wise product of the vectorial operator

$\boldsymbol \nabla \boldsymbol u$

denotes the element-wise product of the vectorial operator

![]() $\boldsymbol \nabla$

and the velocity vector. The last term in (2.2) accounts for the capillary forces acting on fluid–fluid interfaces,

$\boldsymbol \nabla$

and the velocity vector. The last term in (2.2) accounts for the capillary forces acting on fluid–fluid interfaces,

![]() $\sigma$

being the surface tension coefficient,

$\sigma$

being the surface tension coefficient,

![]() $\kappa$

the interface curvature,

$\kappa$

the interface curvature,

![]() $\boldsymbol{n}$

a unit vector normal to the interface and

$\boldsymbol{n}$

a unit vector normal to the interface and

![]() $\delta _{\Gamma }$

a Dirac function which is non-zero only at the interface.

$\delta _{\Gamma }$

a Dirac function which is non-zero only at the interface.

2.2. The volume of fluid method

In the VOF method pioneered by Hirt & Nichols (Reference Hirt and Nichols1981), the interface is not explicitly defined or tracked; instead, it is reconstructed based on a fluid indicator function

![]() $\gamma$

. A grid cell occupied by fluid 1 is indicated by

$\gamma$

. A grid cell occupied by fluid 1 is indicated by

![]() $\gamma = 1$

, while

$\gamma = 1$

, while

![]() $\gamma = 0$

indicates the presence of the other phase, fluid 2. Intermediate values of

$\gamma = 0$

indicates the presence of the other phase, fluid 2. Intermediate values of

![]() $\gamma$

between zero and one only occur in the fluid–fluid interface region. The physical properties of the single, effective fluid in (2.2) are then defined as

$\gamma$

between zero and one only occur in the fluid–fluid interface region. The physical properties of the single, effective fluid in (2.2) are then defined as

where

![]() $\boldsymbol{x}(x,y,z)$

is the position vector and

$\boldsymbol{x}(x,y,z)$

is the position vector and

![]() $\rho _1$

,

$\rho _1$

,

![]() $\rho _2$

,

$\rho _2$

,

![]() $\mu _1$

and

$\mu _1$

and

![]() $\mu _2$

are the bulk-fluid properties (densities and viscosities) of the individual fluid phases. The effective fluid velocity is analogously defined as a weighted average of the velocities of individual phases

$\mu _2$

are the bulk-fluid properties (densities and viscosities) of the individual fluid phases. The effective fluid velocity is analogously defined as a weighted average of the velocities of individual phases

The capillary force in (2.2) is evaluated using the continuum surface force (CSF) model of Brackbill, Kothe & Zemach (Reference Brackbill, Kothe and Zemach1992), which replaces the surface force at the interface by the corresponding volumetric force

which is non-negligible only within the interface region, defined as the region where

![]() $0\lt \gamma \lt 1$

. The curvature of the fluid–fluid interface,

$0\lt \gamma \lt 1$

. The curvature of the fluid–fluid interface,

![]() $\kappa$

, is the sum of the two principal components: one defined in the mean plane of the fracture,

$\kappa$

, is the sum of the two principal components: one defined in the mean plane of the fracture,

![]() $xy$

, and thus denoted as the in-plane curvature

$xy$

, and thus denoted as the in-plane curvature

![]() $\kappa _{xy}$

, and the other defined in a plane perpendicular to the latter and denoted as out-of-plane curvature

$\kappa _{xy}$

, and the other defined in a plane perpendicular to the latter and denoted as out-of-plane curvature

![]() $\kappa _z$

$\kappa _z$

Note that the partition of the curvature into its two principal components has no purpose for the full 3-D modelling of the two-phase flow (see our recent paper on the topic (Krishna et al. Reference Krishna, Méheust and Neuweiler2024)), but it will come handy for the depth-averaged model presented in § 3.

To model the behaviour of the triple line at which fluid–fluid interfaces meet solid walls, properly accounting for the wetting of these walls by the two fluids, the VOF method uses the classical Young’s law,

![]() $\sigma \cos\theta = \sigma _{{nw}}-\sigma _{{w}}$

, where

$\sigma \cos\theta = \sigma _{{nw}}-\sigma _{{w}}$

, where

![]() $\theta$

is the static equilibrium contact angle and

$\theta$

is the static equilibrium contact angle and

![]() $\sigma _{{nw}}$

(respectively,

$\sigma _{{nw}}$

(respectively,

![]() $\sigma _{{w}}$

) is the surface tension coefficients of the non-wetting (respectively, wetting) fluid–solid interface. For a detailed discussion on contact angles and wettability, see Lunati (Reference Lunati2007) and Ferrari & Lunati (Reference Ferrari and Lunati2013). In the context of the VOF method, Young’s law is enforced within the CSF model, as first suggested by Brackbill et al. (Reference Brackbill, Kothe and Zemach1992), by imposing the following constraint on the unit vector normal to the interface at the wall,

$\sigma _{{w}}$

) is the surface tension coefficients of the non-wetting (respectively, wetting) fluid–solid interface. For a detailed discussion on contact angles and wettability, see Lunati (Reference Lunati2007) and Ferrari & Lunati (Reference Ferrari and Lunati2013). In the context of the VOF method, Young’s law is enforced within the CSF model, as first suggested by Brackbill et al. (Reference Brackbill, Kothe and Zemach1992), by imposing the following constraint on the unit vector normal to the interface at the wall,

![]() $\boldsymbol{n_w}$

:

$\boldsymbol{n_w}$

:

where

![]() $\boldsymbol{n}_s$

is the unit vector normal to the wall pointing into the solid and

$\boldsymbol{n}_s$

is the unit vector normal to the wall pointing into the solid and

![]() $ \boldsymbol{n}_t$

is a unit vector tangent to the solid and pointing into the wetting phase.

$ \boldsymbol{n}_t$

is a unit vector tangent to the solid and pointing into the wetting phase.

The velocity field resulting from the solution of (2.1) and (2.2) then provides the changes in the fluid–fluid interfaces’ position by solving a simple advection equation for the indicator function

![]() $\gamma$

. In the VOF model as implemented in OpenFOAM (2012), this advection equation reads as

$\gamma$

. In the VOF model as implemented in OpenFOAM (2012), this advection equation reads as

where an additional ‘compression term’, active only at the interface (

![]() $0\lt \gamma \lt 1$

), has been added to limit interface smearing due to numerical diffusion (Klostermann, Schaake & Schwarze Reference Klostermann, Schaake and Schwarze2013). In this compression term,

$0\lt \gamma \lt 1$

), has been added to limit interface smearing due to numerical diffusion (Klostermann, Schaake & Schwarze Reference Klostermann, Schaake and Schwarze2013). In this compression term,

![]() $\boldsymbol{u}_{{r}}$

is a suitable ‘compression velocity’, which is evaluated according to (Berberović et al. Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009)

$\boldsymbol{u}_{{r}}$

is a suitable ‘compression velocity’, which is evaluated according to (Berberović et al. Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009)

Note that this formulation ensures that the compression velocity operates exclusively in the direction perpendicular to the interface. To limit the value of

![]() $\boldsymbol{u}_{{r}}$

, the maximum velocity in the flow domain is chosen as the worst case value (Berberović et al. Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009). The compression coefficient

$\boldsymbol{u}_{{r}}$

, the maximum velocity in the flow domain is chosen as the worst case value (Berberović et al. Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009). The compression coefficient

![]() $C_{\gamma }$

regulates the degree of interface compression; we use

$C_{\gamma }$

regulates the degree of interface compression; we use

![]() $C_{\gamma } = 1$

, which corresponds to a balance between interface compression and unwanted parasitic velocities (Deshpande et al. Reference Deshpande, Anumolu and Trujillo2012a

; Hoang et al. Reference Hoang, van Steijn, Portela, Kreutzer and Kleijn2013); for details, please see Rusche (Reference Rusche2003) and Berberović et al. (Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009).

$C_{\gamma } = 1$

, which corresponds to a balance between interface compression and unwanted parasitic velocities (Deshpande et al. Reference Deshpande, Anumolu and Trujillo2012a

; Hoang et al. Reference Hoang, van Steijn, Portela, Kreutzer and Kleijn2013); for details, please see Rusche (Reference Rusche2003) and Berberović et al. (Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009).

2.2.1. Modified pressure formulation

The numerical implementation of the boundary conditions for pressure is simplified if the so-called dynamic pressure formulation,

![]() $p_{{d}}$

, is used (Berberović et al. Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009; Rusche Reference Rusche2003)

$p_{{d}}$

, is used (Berberović et al. Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009; Rusche Reference Rusche2003)

The resulting body force density is the negative gradient of the dynamic pressure

consisting of the body force density due to pressure, the opposite of the gravitational body force, and an additional contribution arising from the density gradient. With this change of working variable, and including the strain-rate tensor simplification (2.3) together with the expression of the capillary force (2.6), the final form of the momentum equation is

3. Depth-integrated 2-D model

In this section we present the derivation of the 2-D, depth-integrated model for flow in open rough-walled fractures. As a preliminary, we first derive depth-integrated equations for single-phase flow, and then extend the model to two-phase flow using the VOF approach. The flow domain lies in the

![]() $x,y,z$

Cartesian coordinates,

$x,y,z$

Cartesian coordinates,

![]() $xy$

being the horizontal vectorial plane and

$xy$

being the horizontal vectorial plane and

![]() $z$

being the vertical coordinate. The aperture field of the fracture is defined as

$z$

being the vertical coordinate. The aperture field of the fracture is defined as

![]() $a = z_2 - z_1$

, where

$a = z_2 - z_1$

, where

![]() $z_2(x,y)$

(respectively,

$z_2(x,y)$

(respectively,

![]() $z_1(x,y))$

is a function of

$z_1(x,y))$

is a function of

![]() $x$

and

$x$

and

![]() $y$

that represents the vertical position of the top (respectively, bottom) wall of the fracture at horizontal position

$y$

that represents the vertical position of the top (respectively, bottom) wall of the fracture at horizontal position

![]() $(x,y)$

.

$(x,y)$

.

3.1. Assumptions and definitions

We make the following two assumptions:

![]() $\mathcal{A}$

: the gradients of the aperture field are small:

$\mathcal{A}$

: the gradients of the aperture field are small:

![]() $\|\nabla a(x,y)\| \ll 1$

. This is the classical lubrication approximation, from which it follows that (i) the vertical momentum exchange is negligible, and the vertical component of the velocity field is a lot smaller than the horizontal components (

$\|\nabla a(x,y)\| \ll 1$

. This is the classical lubrication approximation, from which it follows that (i) the vertical momentum exchange is negligible, and the vertical component of the velocity field is a lot smaller than the horizontal components (

![]() $w \ll u,v$

) (see Méheust & Schmittbuhl Reference Méheust and Schmittbuhl2001), and (ii) the dynamic pressure

$w \ll u,v$

) (see Méheust & Schmittbuhl Reference Méheust and Schmittbuhl2001), and (ii) the dynamic pressure

![]() $p_{{d}}$

can be considered to not vary in the

$p_{{d}}$

can be considered to not vary in the

![]() $z$

direction.

$z$

direction.

![]() $\mathcal{B}$

: in the case of two-phase flow, the presence of a wetting film which adheres to the fracture’s walls is neglected, i.e. the phase fraction

$\mathcal{B}$

: in the case of two-phase flow, the presence of a wetting film which adheres to the fracture’s walls is neglected, i.e. the phase fraction

![]() $\gamma$

is assumed to be independent of the

$\gamma$

is assumed to be independent of the

![]() $z$

coordinate. Hence, the gradients of phase fraction, density and viscosity are all contained in the

$z$

coordinate. Hence, the gradients of phase fraction, density and viscosity are all contained in the

![]() $xy$

plane (and non-negligible only in the interface region). This assumption, which is depicted in figure 1, is reasonable if the thickness of the film is very small compared with the aperture, which is the case at sufficiently small capillary numbers, with a range of suitable

$xy$

plane (and non-negligible only in the interface region). This assumption, which is depicted in figure 1, is reasonable if the thickness of the film is very small compared with the aperture, which is the case at sufficiently small capillary numbers, with a range of suitable

![]() $Ca$

values extending at least up to

$Ca$

values extending at least up to

![]() $10^{-3}$

(Krishna et al. Reference Krishna, Méheust and Neuweiler2024). Note that the validity of these assumptions will be tested and discussed in § 4.

$10^{-3}$

(Krishna et al. Reference Krishna, Méheust and Neuweiler2024). Note that the validity of these assumptions will be tested and discussed in § 4.

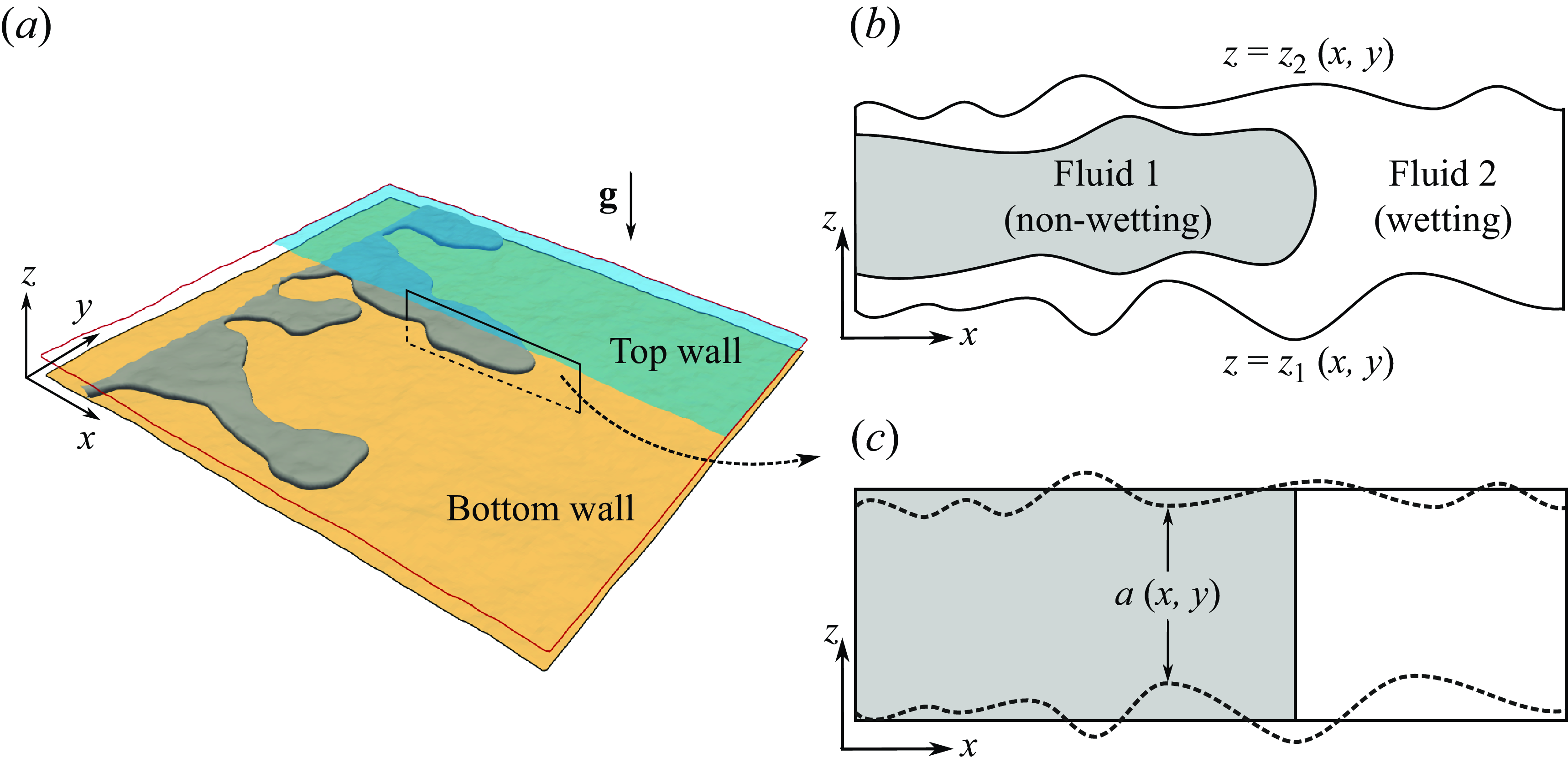

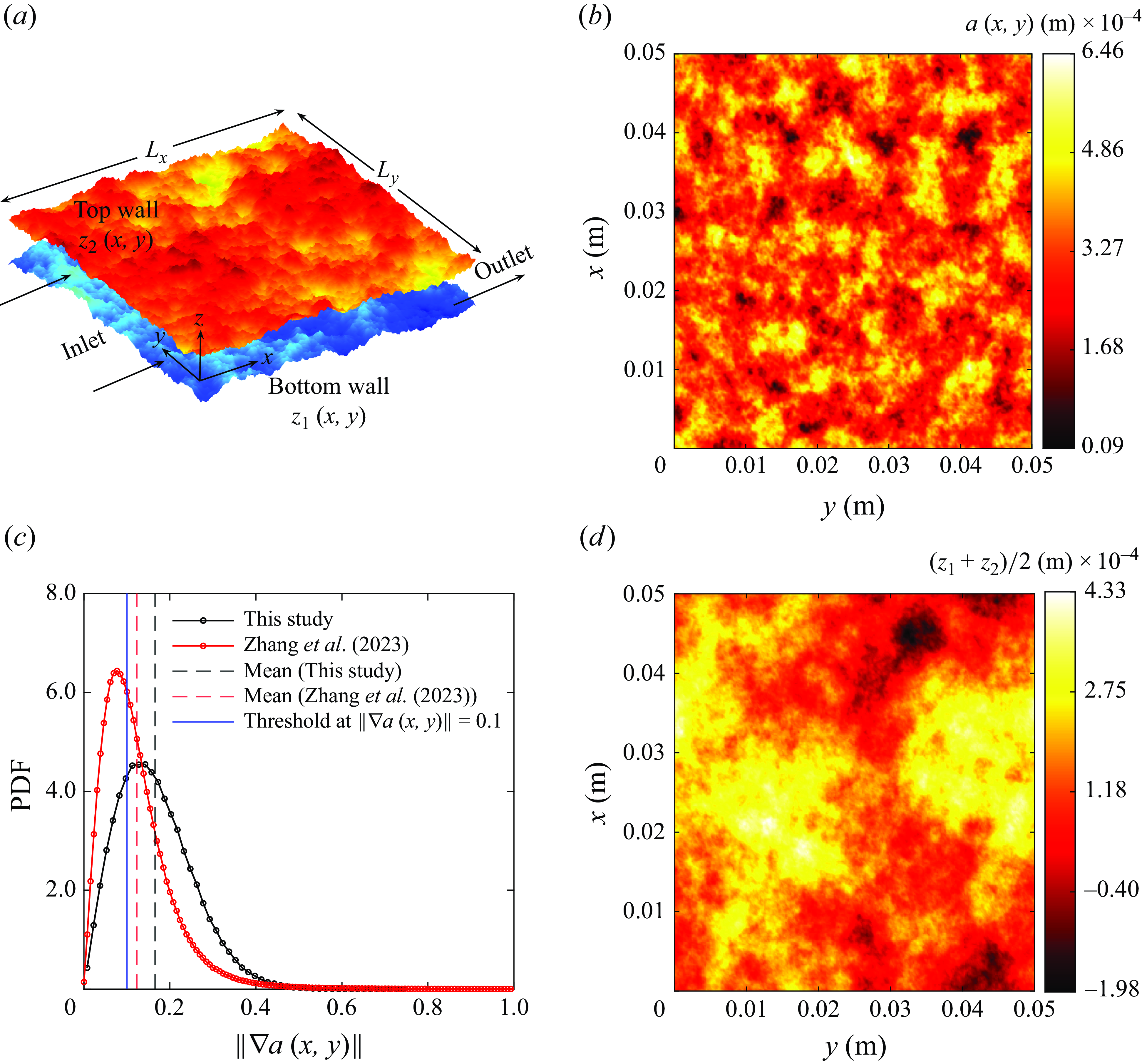

Figure 1.

![]() $(a)$

Three-dimensional (3-D) illustration of immiscible two-phase flow in a rough fracture of mean horizontal plane (

$(a)$

Three-dimensional (3-D) illustration of immiscible two-phase flow in a rough fracture of mean horizontal plane (

![]() $xy$

). (b) Vertical (

$xy$

). (b) Vertical (

![]() $xz$

) cross-sectional view of the 3-D displacement: the non-wetting fluid 1 (darker region) displaces the wetting fluid 2, leading to the formation of a wetting film adhering to the top and bottom walls.

$xz$

) cross-sectional view of the 3-D displacement: the non-wetting fluid 1 (darker region) displaces the wetting fluid 2, leading to the formation of a wetting film adhering to the top and bottom walls.

![]() $(c)$

The 2-D depth-integrated formulation reduces the description to two dimensions in the

$(c)$

The 2-D depth-integrated formulation reduces the description to two dimensions in the

![]() $xy$

plane, and can thus not account for the presence of such a wetting film; this is equivalent to assuming a fluid–fluid interface that does not depend on the vertical coordinate

$xy$

plane, and can thus not account for the presence of such a wetting film; this is equivalent to assuming a fluid–fluid interface that does not depend on the vertical coordinate

![]() $z$

in three dimensions. The thickness in the vertical direction is only shown for illustration, as it has no physical meaning in the 2-D formulation.

$z$

in three dimensions. The thickness in the vertical direction is only shown for illustration, as it has no physical meaning in the 2-D formulation.

We define the 2-D depth-averaged velocity field

![]() $\boldsymbol{U} = (U,V)$

as

$\boldsymbol{U} = (U,V)$

as

In the framework of the VOF formulation of two-phase flow, the definition of the bulk phase velocity also applies to the 2-D velocity field, i.e.

3.2. Depth-integrated formalism for single-phase flow

For single-phase, incompressible flow, where a single fluid occupies the entire flow domain, the governing flow equations are the continuity and momentum conservation, which read respectively as

Below, we integrate these governing 3-D equations over the

![]() $z$

coordinate, and the resulting integrals are then simplified using the Leibniz theorem and the fundamental theorem of calculus, along with the no-slip boundary condition for the velocity at the walls, to obtain the 2-D equations for the equivalent depth-integrated model.

$z$

coordinate, and the resulting integrals are then simplified using the Leibniz theorem and the fundamental theorem of calculus, along with the no-slip boundary condition for the velocity at the walls, to obtain the 2-D equations for the equivalent depth-integrated model.

3.2.1. Depth-integrated continuity equation

Integrating the continuity equation, (3.3), over

![]() $z$

, yields

$z$

, yields

where we have used the definitions of the 2-D velocity field from (3.1). The above equation indicates that, unlike in the 3-D model where the velocity field

![]() $\boldsymbol{u}$

is divergence free, in the 2-D depth-integrated model the divergence-free constraint applies to the quantity

$\boldsymbol{u}$

is divergence free, in the 2-D depth-integrated model the divergence-free constraint applies to the quantity

which has been previously termed local flux in the literature (Méheust & Schmittbuhl Reference Méheust and Schmittbuhl2001).

3.2.2. Depth-integrated momentum equation

Next, we perform the depth-integration of the momentum equation (3.4), and develop the terms one by one as follows.

Temporal derivative of the momentum density

3.2.2.1. Convective derivative of the momentum density:

Depth integration of the inertial term, when written in component form, e.g. for the

![]() $x$

direction, and considering the no-slip conditions on the top and bottom walls, reads as

$x$

direction, and considering the no-slip conditions on the top and bottom walls, reads as

The integration of the

![]() $y$

component can be treated in the same way. We notice in the above equation the appearance of the nonlinear terms,

$y$

component can be treated in the same way. We notice in the above equation the appearance of the nonlinear terms,

![]() $\int _{z_1}^{z_2}\rho u_iu_j\: \text{d}z$

, where

$\int _{z_1}^{z_2}\rho u_iu_j\: \text{d}z$

, where

![]() $i,j\in 1,2$

are the indices denoting the

$i,j\in 1,2$

are the indices denoting the

![]() $u, v$

velocity components. There is no general integrated form for these integrals, as they depend on the vertical velocity profile. They can be expressed by using a momentum correction factor

$u, v$

velocity components. There is no general integrated form for these integrals, as they depend on the vertical velocity profile. They can be expressed by using a momentum correction factor

![]() $\beta$

which accounts for the

$\beta$

which accounts for the

![]() $z$

-dependence of the velocity field (Chanson Reference Chanson2004)

$z$

-dependence of the velocity field (Chanson Reference Chanson2004)

The depth-integrated inertial term in vectorial form can thus be written as

The approximation made above is reasonable on account of our lubrication assumption

![]() $\mathcal{A}$

(i), which implies a parabolic vertical velocity profile. Consequently, we use

$\mathcal{A}$

(i), which implies a parabolic vertical velocity profile. Consequently, we use

![]() $\beta =1.2$

in this study, corresponding to a parabolic vertical velocity profile throughout the fracture plane (similar to that observed in plane Poiseuille flow (Gerhart, Hochstein & Gerhart Reference Gerhart, Hochstein and Gerhart2020)).

$\beta =1.2$

in this study, corresponding to a parabolic vertical velocity profile throughout the fracture plane (similar to that observed in plane Poiseuille flow (Gerhart, Hochstein & Gerhart Reference Gerhart, Hochstein and Gerhart2020)).

3.2.2.2. Dynamic pressure force:

Using assumption

![]() $\mathcal{A}$

(ii) of constant pressure in the

$\mathcal{A}$

(ii) of constant pressure in the

![]() $z$

direction, depth integrating the pressure term results in the following:

$z$

direction, depth integrating the pressure term results in the following:

3.2.2.3. Viscous force:

Depth integrating the last term of the momentum equation (3.4), which accounts for the viscous dissipation, we obtain, for the component form in

![]() $x$

$x$

Applying the Leibniz rule twice to

![]() $\partial ^2 ( \int _{z_1}^{z_2} u \text{d}z) / \partial x^2$

, considering the no-flow boundary conditions at the walls and using the depth-averaged field definition (3.1), leads to

$\partial ^2 ( \int _{z_1}^{z_2} u \text{d}z) / \partial x^2$

, considering the no-flow boundary conditions at the walls and using the depth-averaged field definition (3.1), leads to

In the case of a flat surface (e.g. Hele-Shaw cell), the last two terms on the right-hand side of the above equation vanish. For surfaces with spatially varying apertures, they are not expected to entirely vanish, but, based on the lubrication approximation

![]() $\mathcal{A}$

(i), they can be neglected. A similar simplification can be made for the second integral of (3.12), leaving the last term, which results in

$\mathcal{A}$

(i), they can be neglected. A similar simplification can be made for the second integral of (3.12), leaving the last term, which results in

This is the

![]() $x$

component

$x$

component

![]() $\tau _{w,x}$

of the wall shear stress resulting from the no-slip boundary conditions at the fracture walls. Hence, (3.12) can be written as

$\tau _{w,x}$

of the wall shear stress resulting from the no-slip boundary conditions at the fracture walls. Hence, (3.12) can be written as

The procedure outlined above can then be repeated for the

![]() $y$

component of the viscous term, where the component of the wall shear stress becomes

$y$

component of the viscous term, where the component of the wall shear stress becomes

![]() $\tau _{w,y}$

. In vectorial notation, the depth-integrated viscous term can finally be written as

$\tau _{w,y}$

. In vectorial notation, the depth-integrated viscous term can finally be written as

where,

![]() $\boldsymbol{\tau _{w}}$

is the wall shear stress vector accounting for the drag by the fracture walls. There is no general theoretical expression for this drag term as it depends on the

$\boldsymbol{\tau _{w}}$

is the wall shear stress vector accounting for the drag by the fracture walls. There is no general theoretical expression for this drag term as it depends on the

![]() $z$

-dependence of the velocity. However, as mentioned above, with the assumption of a parabolic vertical velocity profile, the drag term can then be calculated to be the following Darcian term:

$z$

-dependence of the velocity. However, as mentioned above, with the assumption of a parabolic vertical velocity profile, the drag term can then be calculated to be the following Darcian term:

where

![]() $k=a^2/12$

is the local parallel plate permeability of the fracture.

$k=a^2/12$

is the local parallel plate permeability of the fracture.

3.2.3. Complete depth-integrated model for monophasic flow

Putting together the integrals of the individual terms discussed above, the 2-D depth-integrated single-phase flow equations can now be expressed as a function of the local flux

![]() $\boldsymbol Q$

(defined in (3.6)) as follows:

$\boldsymbol Q$

(defined in (3.6)) as follows:

Note that the conserved quantity in this 2-D model is the local flux

![]() $\boldsymbol Q$

. The 2-D depth-averaged velocity

$\boldsymbol Q$

. The 2-D depth-averaged velocity

![]() $\boldsymbol{U} = \boldsymbol{Q}/a$

is obtained as a post-processed quantity. The particular case of steady-state Stokes flow yields the well-known Reynolds equation (Brown Reference Brown1987), as discussed in Appendix A.

$\boldsymbol{U} = \boldsymbol{Q}/a$

is obtained as a post-processed quantity. The particular case of steady-state Stokes flow yields the well-known Reynolds equation (Brown Reference Brown1987), as discussed in Appendix A.

3.3. Depth-integrated formalism for two-phase flow

We now combine the VOF formulation for two-phase flow, as outlined in § 2, and the depth-integrated approach presented in § 3.2, based on the same assumptions.

3.3.1. Depth-integrated continuity equation

As for the monophasic case, depth-integrating the two-phase continuity equation (2.1) leads to

3.3.2. Depth-integrated phase-fraction advection equation

Using the assumption

![]() $\mathcal{B}$

made in § 3.1, i.e. neglecting the presence of displaced fluid films on the fracture walls, amounts to assuming that the indicator function

$\mathcal{B}$

made in § 3.1, i.e. neglecting the presence of displaced fluid films on the fracture walls, amounts to assuming that the indicator function

![]() $\gamma$

does not depend on

$\gamma$

does not depend on

![]() $z$

. Hence, depth integrating the phase-fraction advection equation (2.9), first without taking into account the ‘compression term’, yields

$z$

. Hence, depth integrating the phase-fraction advection equation (2.9), first without taking into account the ‘compression term’, yields

To reduce numerical diffusion, we then introduce an additional compression term

![]() $\boldsymbol{\nabla }\cdot [\boldsymbol{Q}_{{r}}\gamma (1-\gamma)]$

, analogous to the compression term introduced in (2.9). In this 2-D formulation of the compression term, the compression local flux

$\boldsymbol{\nabla }\cdot [\boldsymbol{Q}_{{r}}\gamma (1-\gamma)]$

, analogous to the compression term introduced in (2.9). In this 2-D formulation of the compression term, the compression local flux

![]() $\boldsymbol{Q}_{{r}}$

is analogous to the compression velocity

$\boldsymbol{Q}_{{r}}$

is analogous to the compression velocity

![]() $\boldsymbol u_{{r}}$

in (2.10), and is similarly defined, as

$\boldsymbol u_{{r}}$

in (2.10), and is similarly defined, as

The complete depth-integrated phase-fraction equation is thus given by

Note that, in the above equation, the aperture field

![]() $a(x,y)$

modifies the temporal derivative of the phase-fraction

$a(x,y)$

modifies the temporal derivative of the phase-fraction

![]() $\gamma$

, and thus accounts for the storage capacity available at any location.

$\gamma$

, and thus accounts for the storage capacity available at any location.

3.3.3. Depth-integrated momentum equation

We now perform the depth-integration of the two-phase momentum equation in its final form (2.13). The integrals for the temporal and the convective derivatives of the momentum density, as well as the dynamic pressure force, read identically to the corresponding monophasic integrals (see § 3.2.2, (3.7), (3.10) and (3.11) respectively). The remaining integrals are presented as follows.

3.3.3.1. Viscous force

Compared with the single-phase case, the viscous dissipation term(s) in the two-phase momentum equation (2.13) has an additional contribution arising from the viscosity gradient, which is non-negligible in the interface region. The depth integration of these two terms reads as

Using assumption

![]() $\mathcal{B}$

(§ 3.1), the derivative of the viscosity with respect to

$\mathcal{B}$

(§ 3.1), the derivative of the viscosity with respect to

![]() $z$

can be neglected. Hence, integrating the first term leads to the same formulation as for the single-phase viscous term integral (3.16). When written in component form, the integral of the

$z$

can be neglected. Hence, integrating the first term leads to the same formulation as for the single-phase viscous term integral (3.16). When written in component form, the integral of the

![]() $x$

component of the second term can be written as

$x$

component of the second term can be written as

where the last term can be neglected (

![]() $\partial \mu / \partial z \simeq 0$

). Again, as a consequence of the lubrication approximation, we can assume that the in-plane gradient of viscosity is independent of

$\partial \mu / \partial z \simeq 0$

). Again, as a consequence of the lubrication approximation, we can assume that the in-plane gradient of viscosity is independent of

![]() $z$

; using the 2-D averaged velocity definition (3.1), the integrals can then be simplified to

$z$

; using the 2-D averaged velocity definition (3.1), the integrals can then be simplified to

A similar argument can be used to simplify the

![]() $y$

component of the integral of

$y$

component of the integral of

![]() $\boldsymbol{\nabla }\boldsymbol{u} \cdot \nabla \mu$

, and finally, we obtain the following expression for the depth-integrated viscous force:

$\boldsymbol{\nabla }\boldsymbol{u} \cdot \nabla \mu$

, and finally, we obtain the following expression for the depth-integrated viscous force:

3.3.3.2. Density gradient term

The depth integration of the term containing gravity and the density gradient (which is significant only at the interface) results in

where

![]() $\boldsymbol{g}_\| = (g_x,g_y)$

is the projection of the gravity acceleration onto the mean fracture plane, and

$\boldsymbol{g}_\| = (g_x,g_y)$

is the projection of the gravity acceleration onto the mean fracture plane, and

![]() $g_z$

is its component in the direction normal to that plane (

$g_z$

is its component in the direction normal to that plane (

![]() $z$

direction). The above integral shows that for the 2-D integrated model, to fully describe the gravitational effects, an additional geometric field, namely the mean vertical positions of the fracture, is needed. It must be noted that in the right-hand side of the above equation, the position vector

$z$

direction). The above integral shows that for the 2-D integrated model, to fully describe the gravitational effects, an additional geometric field, namely the mean vertical positions of the fracture, is needed. It must be noted that in the right-hand side of the above equation, the position vector

![]() $\boldsymbol{x}$

is restricted to two dimensions

$\boldsymbol{x}$

is restricted to two dimensions

![]() $x$

and

$x$

and

![]() $y$

.

$y$

.

3.3.3.3. Surface tension force

The curvature

![]() $\kappa$

, which is defined by (2.7), is the sum of the in-plane curvature

$\kappa$

, which is defined by (2.7), is the sum of the in-plane curvature

![]() $\kappa _{xy}$

and the out-of-plane curvature

$\kappa _{xy}$

and the out-of-plane curvature

![]() $\kappa _{z}$

. For the 2-D depth-integrated model, where no out-of-plane curvature can be described by the model, the corresponding capillary force contribution must be taken into account explicitly by adding to

$\kappa _{z}$

. For the 2-D depth-integrated model, where no out-of-plane curvature can be described by the model, the corresponding capillary force contribution must be taken into account explicitly by adding to

![]() $\kappa$

a term that accounts for the out-of-plane curvature

$\kappa$

a term that accounts for the out-of-plane curvature

where

![]() $\theta _{{e}}$

is an effective contact angle at fluid–fluid–solid contact lines. This angle is not necessarily the real equilibrium contact angle; its value is discussed at the beginning of § 4.

$\theta _{{e}}$

is an effective contact angle at fluid–fluid–solid contact lines. This angle is not necessarily the real equilibrium contact angle; its value is discussed at the beginning of § 4.

Here, we have used our assumption

![]() $\mathcal{A}$

of small gradients for the aperture field and assumed for the out-of-plane term that the vertical velocity profiles are parabolic everywhere in the fracture plane (which is also classically assumed to derive the local cubic law for stationary monophasic flow) (Park & Homsy Reference Park and Homsy1984). The above approximation of the out-of-plane curvature term may be oversimplifying in cases where deviations from a symmetric interface are to be expected, such as surfaces with different wetting properties on opposite sides, such as may occur in configurations of heterogeneous wetting properties of the fracture walls. With this assumption, the depth-integrated surface tension is then evaluated as

$\mathcal{A}$

of small gradients for the aperture field and assumed for the out-of-plane term that the vertical velocity profiles are parabolic everywhere in the fracture plane (which is also classically assumed to derive the local cubic law for stationary monophasic flow) (Park & Homsy Reference Park and Homsy1984). The above approximation of the out-of-plane curvature term may be oversimplifying in cases where deviations from a symmetric interface are to be expected, such as surfaces with different wetting properties on opposite sides, such as may occur in configurations of heterogeneous wetting properties of the fracture walls. With this assumption, the depth-integrated surface tension is then evaluated as

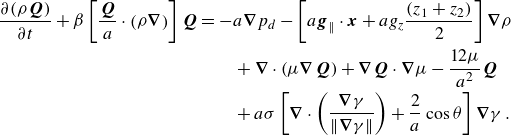

3.3.4. Complete theoretical description for two-phase flow

Finally, we can now write the two-phase 2-D depth-integrated governing equations as

\begin{equation} \begin{aligned} \frac {\partial (\rho \boldsymbol{Q})}{\partial t} + \beta \left [ \frac {\boldsymbol{Q}}{a} \cdot \left ( \rho \boldsymbol{\nabla } \right) \right] \boldsymbol{Q} &= -a\boldsymbol{\nabla } p_{{d}} - \left [ a\boldsymbol{g}_{\|} \cdot \boldsymbol{x} + a g_z \frac {(z_1 + z_2)}{2} \right] \boldsymbol{\nabla } \rho \\ &\qquad +\boldsymbol{\nabla } \cdot \left ( \mu \boldsymbol{\nabla } \boldsymbol{Q} \right) + \boldsymbol{\nabla } \boldsymbol{Q} \cdot \boldsymbol{\nabla } \mu - \frac {12 \mu }{a^2} \boldsymbol{Q} \\ &\qquad + a\sigma \left [ \boldsymbol{\nabla } \cdot \left ( \frac {\boldsymbol{\nabla } \gamma }{\| \boldsymbol{\nabla } \gamma \|} \right) + \frac {2}{a} \cos \theta \right] \boldsymbol{\nabla } \gamma \:. \end{aligned} \end{equation}

\begin{equation} \begin{aligned} \frac {\partial (\rho \boldsymbol{Q})}{\partial t} + \beta \left [ \frac {\boldsymbol{Q}}{a} \cdot \left ( \rho \boldsymbol{\nabla } \right) \right] \boldsymbol{Q} &= -a\boldsymbol{\nabla } p_{{d}} - \left [ a\boldsymbol{g}_{\|} \cdot \boldsymbol{x} + a g_z \frac {(z_1 + z_2)}{2} \right] \boldsymbol{\nabla } \rho \\ &\qquad +\boldsymbol{\nabla } \cdot \left ( \mu \boldsymbol{\nabla } \boldsymbol{Q} \right) + \boldsymbol{\nabla } \boldsymbol{Q} \cdot \boldsymbol{\nabla } \mu - \frac {12 \mu }{a^2} \boldsymbol{Q} \\ &\qquad + a\sigma \left [ \boldsymbol{\nabla } \cdot \left ( \frac {\boldsymbol{\nabla } \gamma }{\| \boldsymbol{\nabla } \gamma \|} \right) + \frac {2}{a} \cos \theta \right] \boldsymbol{\nabla } \gamma \:. \end{aligned} \end{equation}

3.4. Solution procedure with OpenFOAM

All numerical simulations have been implemented using the open-source CFD code OpenFOAM (2012), which employs a cell-centre-based finite volume approach for spatial discretisation with second-order accuracy. For time integration, the implicit Euler scheme is used, which results in first-order accuracy in time. The computational mesh for both the 3-D and 2-D models was generated using the blockMesh utility of OpenFOAM, which results in structured hexahedral elements. Although all our simulations use structured hexahedral mesh elements, the 2-D depth-integrated model implementation is not restricted to such mesh elements, and can easily be applied to other mesh alternatives, e.g. unstructured tetrahedral cells.

The monophasic 3-D governing equations ((3.3) and (3.4)) are solved using pisoFoam, which is a transient, single-phase, Navier–Stokes solver provided in OpenFOAM. We employ the interFoam solver of OpenFOAM to solve the two-phase governing equations for the 3-D VOF model ((2.1), (2.9) and (2.13)). The numerical implementation of the 2-D depth-integrated models, both single phase ((3.18) and (3.19)) and two phase ((3.31), (3.32) and (3.33)), is performed by modifying the two aforementioned solvers in OpenFOAM. While the overall solution algorithm remains largely the same, our changes to the solvers account for the change of variable from the 3-D velocity field

![]() $\boldsymbol u$

to the 2-D local flux

$\boldsymbol u$

to the 2-D local flux

![]() $\boldsymbol Q$

, and for the additional terms appearing in the governing equations, e.g. the Darcian drag term in the momentum equation. For details on the finite volume discretisation methods and the solution procedures of the two Navier–Stokes solvers namely, pisoFoam and interFoam, the reader is encouraged to see Jasak (Reference Jasak1996), Weller et al. (Reference Weller, Tabor, Jasak and Fureby1998), Rusche (Reference Rusche2003), Berberović et al. (Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009) and Deshpande et al. (Reference Deshpande, Anumolu and Trujillo2012a

). In all simulations, we initialise the time step with a very low value (

$\boldsymbol Q$

, and for the additional terms appearing in the governing equations, e.g. the Darcian drag term in the momentum equation. For details on the finite volume discretisation methods and the solution procedures of the two Navier–Stokes solvers namely, pisoFoam and interFoam, the reader is encouraged to see Jasak (Reference Jasak1996), Weller et al. (Reference Weller, Tabor, Jasak and Fureby1998), Rusche (Reference Rusche2003), Berberović et al. (Reference Berberović, van Hinsberg, Jakirlić, Roisman and Tropea2009) and Deshpande et al. (Reference Deshpande, Anumolu and Trujillo2012a

). In all simulations, we initialise the time step with a very low value (

![]() ${\sim}10^{-8}$

s) and employ a run-time adjustable time-step scheme, which ensures numerical stability by automatically adjusting the time steps according to the Courant–Friedrichs–Lewy (CFL) criterion (Rusche Reference Rusche2003). The maximum allowed CFL number for all cases is set to

${\sim}10^{-8}$

s) and employ a run-time adjustable time-step scheme, which ensures numerical stability by automatically adjusting the time steps according to the Courant–Friedrichs–Lewy (CFL) criterion (Rusche Reference Rusche2003). The maximum allowed CFL number for all cases is set to

![]() $0.5$

.

$0.5$

.

4. Results and discussions

In this section, we begin by validating the two-phase, 2-D depth-integrated model through comparison with results from corresponding 3-D direct numerical simulations for the classic Hele-Shaw viscous fingering case, following the study by Saffman & Taylor (Reference Saffman and Taylor1958). It must be noted, that the validation of the 3-D model has been discussed in detail in our previous work (Krishna et al. Reference Krishna, Méheust and Neuweiler2024), thus interested readers may refer to it. Subsequently, we apply the 2-D model to a synthetic rough fracture geometry, comparing its performance against the 3-D model results. As an initial step in validating the 2-D model, we have also compared the single-phase 2-D results with those from the full 3-D model for the fracture geometry. These comparisons are detailed in Appendix E.

4.1. Choice of the effective contact angle in the depth-integrated model

The theoretical description of the out-of-plane curvature contribution presented above in § 3.2.2, (3.29) assumes the absence of a wetting film. However, as a wetting film is expected and was also found in all 3-D film-resolved simulations, using the static equilibrium contact angle as effective contact angle in (3.29) of the 2-D depth-integrated model is not consistent with the physics at play. This effect is also illustrated in figure 20 in Appendix B for the idealised case of the flow between two smooth parallel plates (Hele-Shaw cell configuration). The presence of a thin wetting film of the defending fluid on the top and bottom walls increases the curvature of the interface at the finger tip, as compared with a scenario where no wetting film would be present. Assuming the tip to be circular (which is reasonable since local apertures are small and much smaller than the in-plane radius of curvature of the interface), and depending on the film thickness, the effective meniscus, estimated as the circle tangent to the finger at its tip, may either not meet the cell walls (in most cases, in which case the best estimate for the effective contact angle is

![]() $\theta _{{e}}=180^\circ$

) or meet them at an angle different from that of the equilibrium contact angle

$\theta _{{e}}=180^\circ$

) or meet them at an angle different from that of the equilibrium contact angle

![]() $\theta$

. By considering the angle at which the circle meets the walls as an effective contact angle, the out-of-plane curvature estimate (3.29) could be improved by accounting for the film thickness (Park & Homsy Reference Park and Homsy1984) and its dependence on the capillary number (see Appendix C). As this approach would imply using a local capillary number (Anjos et al. Reference Anjos, Zhao, Lowengrub, Bao and Li2021) and as the derivations are based on flat surfaces, so the validity for rough surfaces is a priori unclear. This effect is not accounted for in the model.

$\theta$

. By considering the angle at which the circle meets the walls as an effective contact angle, the out-of-plane curvature estimate (3.29) could be improved by accounting for the film thickness (Park & Homsy Reference Park and Homsy1984) and its dependence on the capillary number (see Appendix C). As this approach would imply using a local capillary number (Anjos et al. Reference Anjos, Zhao, Lowengrub, Bao and Li2021) and as the derivations are based on flat surfaces, so the validity for rough surfaces is a priori unclear. This effect is not accounted for in the model.

In this work, to ensure consistency between the 2-D and 3-D models, we adopt an effective contact angle value of

![]() $\theta _{{e}}=180^\circ$

for approximating the out-of-plane curvature and the resulting capillary pressure component. Supporting analysis of the finger tip curvature and the effective contact angle in the resolved-film Hele-Shaw configuration is presented in Appendix B. Furthermore, the sensitivity of our 2-D model to variations in contact angle is discussed in Appendix C.

$\theta _{{e}}=180^\circ$

for approximating the out-of-plane curvature and the resulting capillary pressure component. Supporting analysis of the finger tip curvature and the effective contact angle in the resolved-film Hele-Shaw configuration is presented in Appendix B. Furthermore, the sensitivity of our 2-D model to variations in contact angle is discussed in Appendix C.

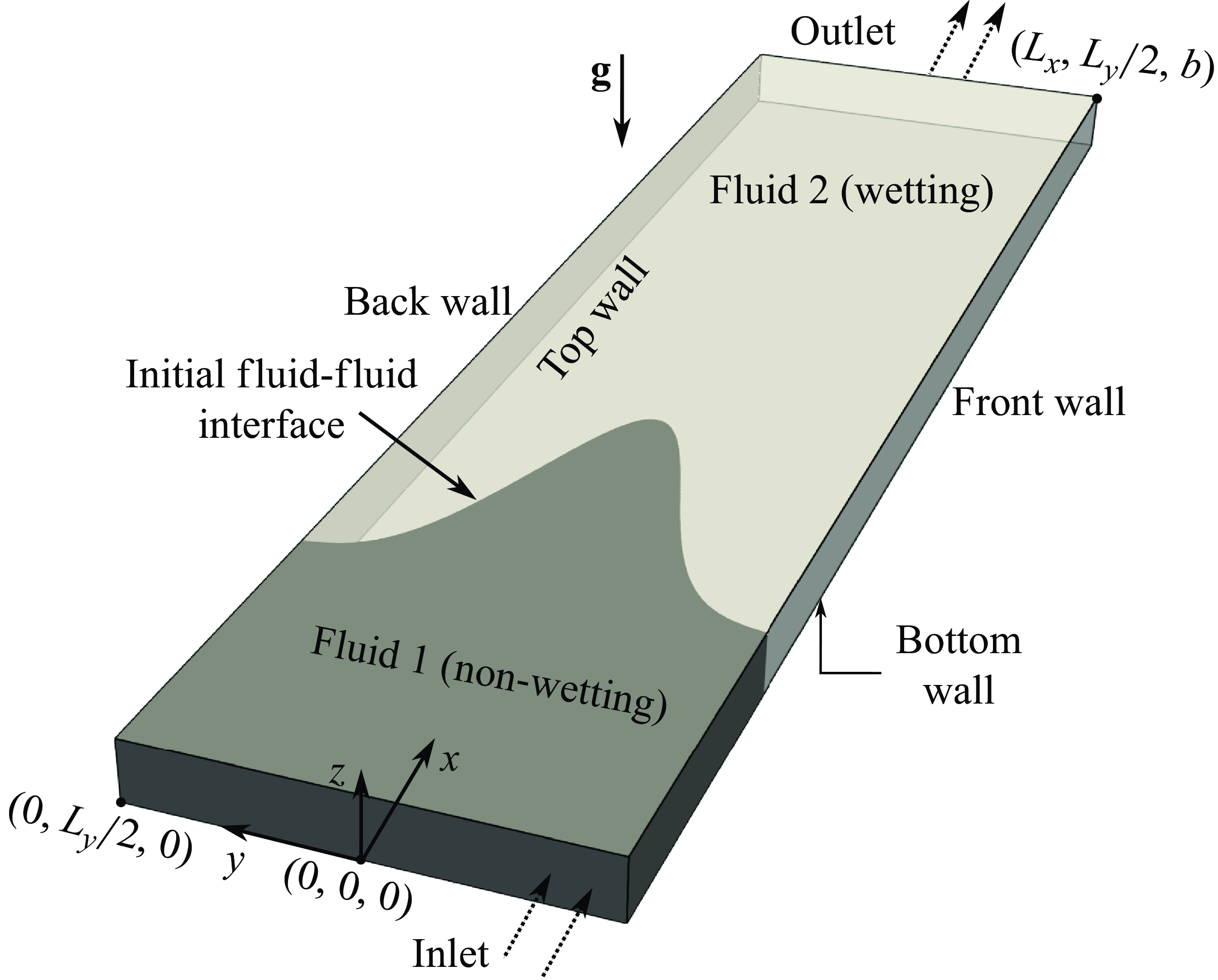

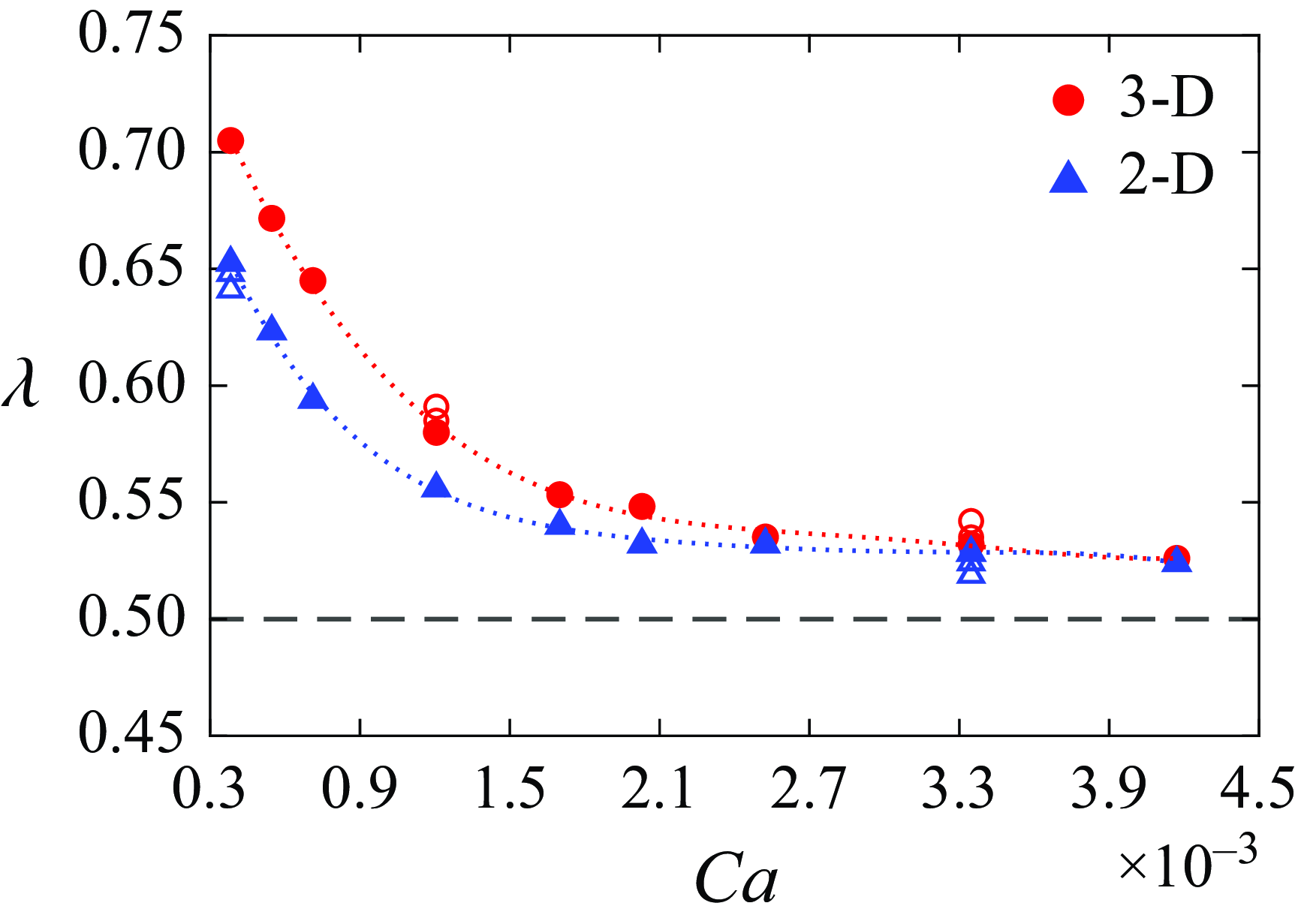

4.2. Validation of the two-phase 2-D depth-integrated model

We validate our two-phase 2-D depth-integrated model by examining viscous fingering in a conventional Hele-Shaw cell, which consists of two parallel planar walls separated by a fixed aperture

![]() $a(x,y) = b$

that is much smaller than the wall’s extension along their plane (figure 2). This set-up replicates the classic experiment by Saffman & Taylor (Reference Saffman and Taylor1958), where a less viscous fluid displaces a more viscous one, leading to the formation of a stable finger with a width-to-channel width ratio (

$a(x,y) = b$

that is much smaller than the wall’s extension along their plane (figure 2). This set-up replicates the classic experiment by Saffman & Taylor (Reference Saffman and Taylor1958), where a less viscous fluid displaces a more viscous one, leading to the formation of a stable finger with a width-to-channel width ratio (

![]() $\lambda$

) of 0.5, except at very slow driving velocities, for which

$\lambda$

) of 0.5, except at very slow driving velocities, for which

![]() $\lambda$

approaches 1.0.

$\lambda$

approaches 1.0.

Figure 2. Schematic of the Hele-Shaw cell used for validating the 2-D depth-integrated two-phase flow model against the 3-D model. The cell dimensions are: length

![]() $L_x=100$

mm (

$L_x=100$

mm (

![]() $x\in [0,L_x]$

), width

$x\in [0,L_x]$

), width

![]() $L_y=12.5$

mm (

$L_y=12.5$

mm (

![]() $y\in [-L_y/2,L_y/2]$

) and constant vertical aperture

$y\in [-L_y/2,L_y/2]$

) and constant vertical aperture

![]() $b=0.4$

mm (

$b=0.4$

mm (

![]() $z\in [0,b]$

). The width-to-thickness ratio is

$z\in [0,b]$

). The width-to-thickness ratio is

![]() $L_y/b = 31.25$

. The initial fluid–fluid interface (at

$L_y/b = 31.25$

. The initial fluid–fluid interface (at

![]() $t=0$

) has Gaussian profile in the horizontal (

$t=0$

) has Gaussian profile in the horizontal (

![]() $xy$

) plane. The darker region represents the invading fluid and the lighter region the defending fluid.

$xy$

) plane. The darker region represents the invading fluid and the lighter region the defending fluid.

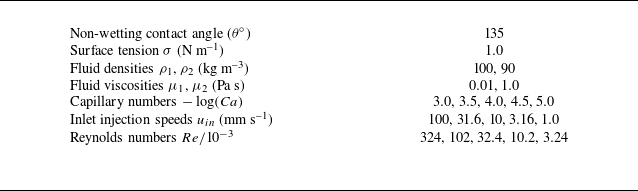

4.2.1. Numerical set-up and flow conditions

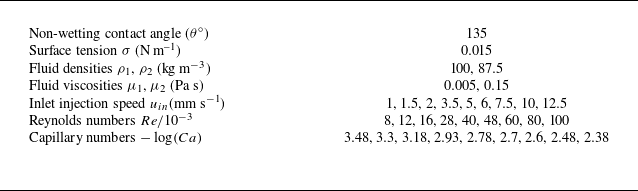

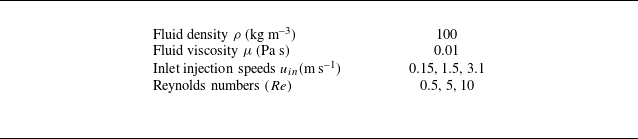

The numerical set-up for validation (shown in figure 2) is adapted from the original configuration by Saffman & Taylor (Reference Saffman and Taylor1958), with slight modifications to enhance computational efficiency. To promote a single dominant finger growth without extending the channel length excessively, we apply an initial perturbation to the fluid interface (figure 2). Fluid 1 represents the invading, less viscous, non-wetting phase, while fluid 2 is the defending, more viscous, wetting phase, with material properties listed in table 1. The viscosity ratio

![]() $\mu _2/\mu _1=30$

matches that of the original experiments. Flow conditions were defined by injection velocities

$\mu _2/\mu _1=30$

matches that of the original experiments. Flow conditions were defined by injection velocities

![]() $\boldsymbol{u}(x=0,y,z) = (u_{{in}},0,0)$

, where

$\boldsymbol{u}(x=0,y,z) = (u_{{in}},0,0)$

, where

![]() $u_{{in}}$

is the injection speed in the longitudinal

$u_{{in}}$

is the injection speed in the longitudinal

![]() $x$

direction. The resulting Reynolds (

$x$

direction. The resulting Reynolds (

![]() $Re = \rho _1 u_{{in}} b / \mu _1$

) and capillary (

$Re = \rho _1 u_{{in}} b / \mu _1$

) and capillary (

![]() $Ca = \mu _1 u_{{in}}/\sigma$

) numbers are provided in table 1. In the 2-D integrated model, where the primary variable is the local flux

$Ca = \mu _1 u_{{in}}/\sigma$

) numbers are provided in table 1. In the 2-D integrated model, where the primary variable is the local flux

![]() $\boldsymbol{Q} = (Q_x, Q_y)$

, the inlet flux is set to

$\boldsymbol{Q} = (Q_x, Q_y)$

, the inlet flux is set to

![]() $Q_{{in}}=u_{{in}}\:b$

.

$Q_{{in}}=u_{{in}}\:b$

.

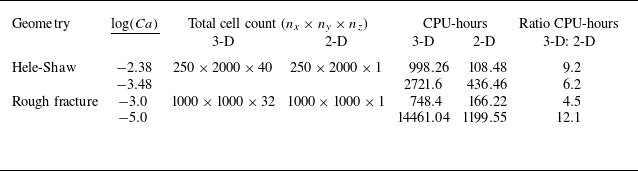

Table 1. Fluid properties and flow parameters used for the Hele-Shaw channel simulations.

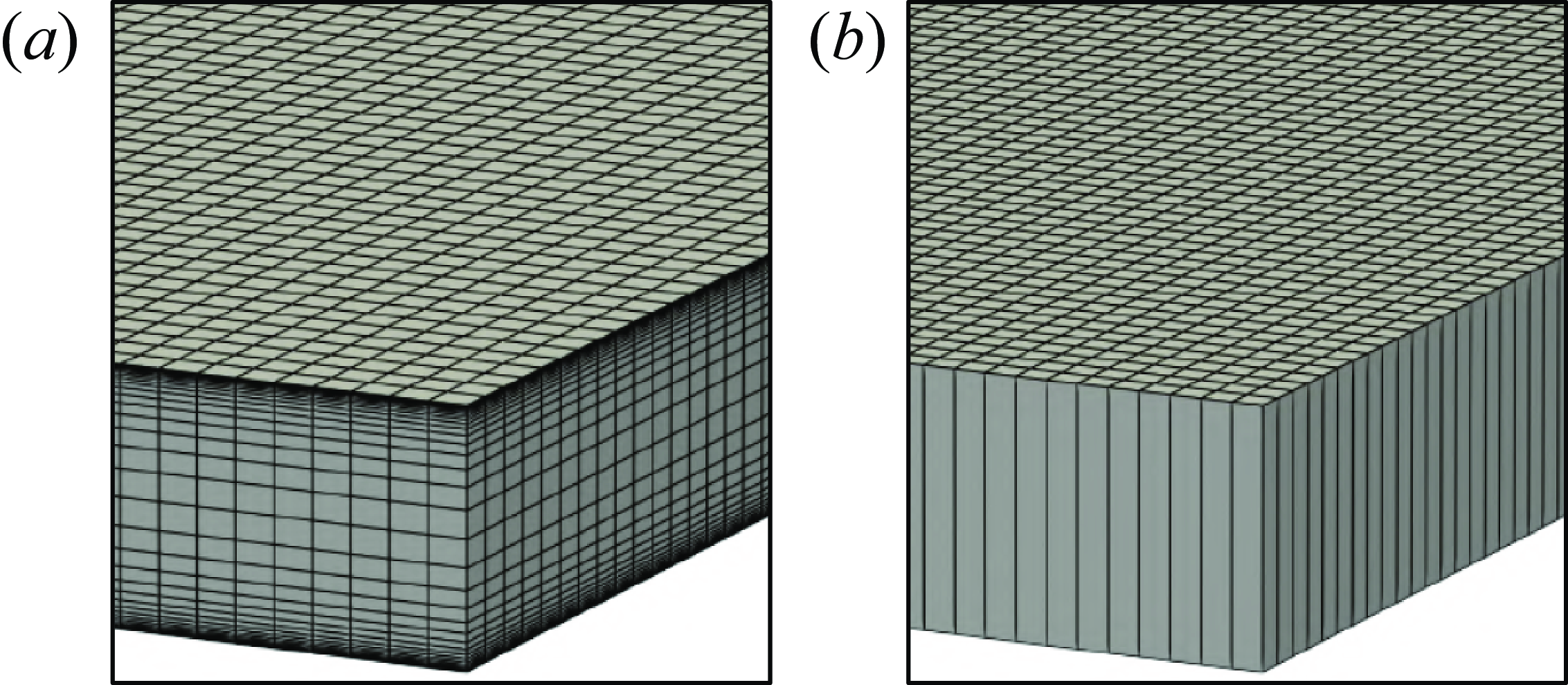

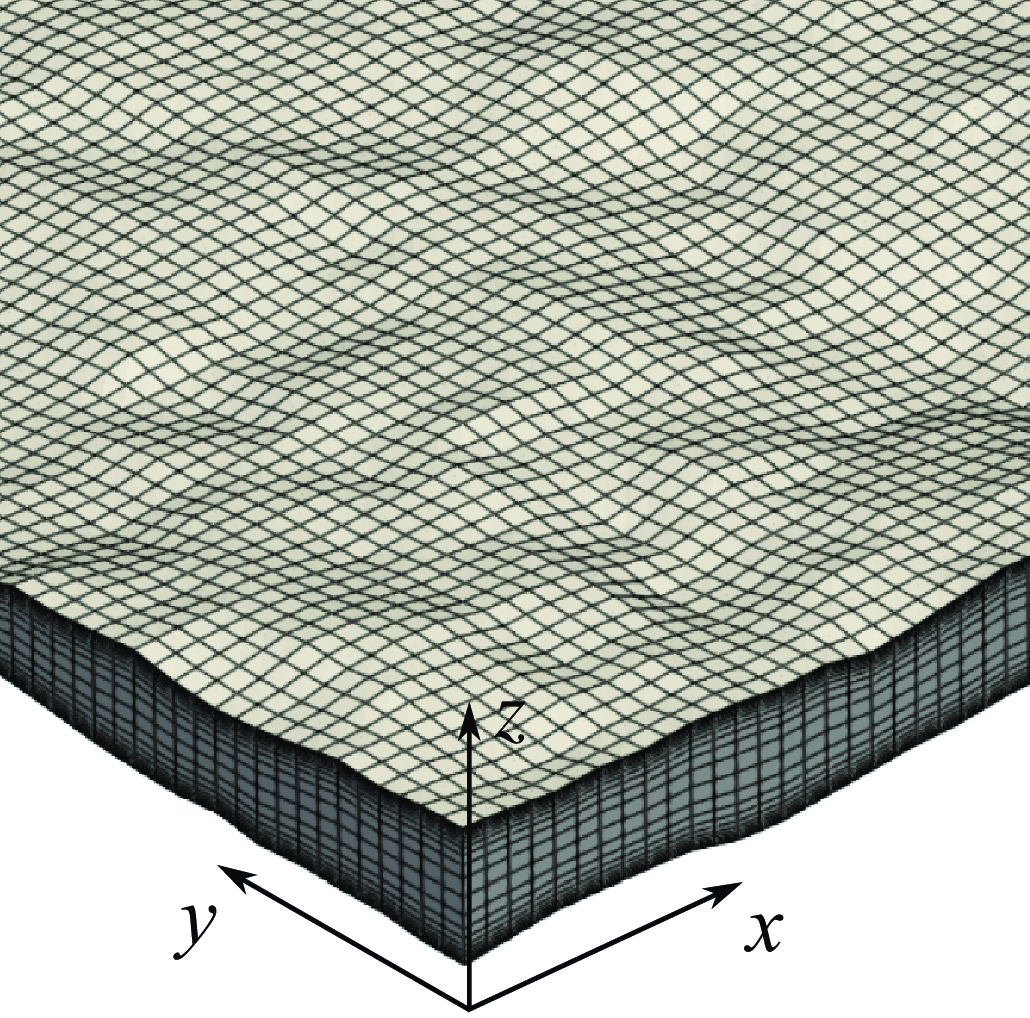

The 3-D computational mesh (figure 3

a) uses 40 cells in the

![]() $z$

direction, with finer grading near the walls to resolve the thin film. The 2-D mesh (figure 3

b) has a single cell in the

$z$

direction, with finer grading near the walls to resolve the thin film. The 2-D mesh (figure 3

b) has a single cell in the

![]() $z$

direction, without boundary conditions on the top and bottom faces. The boundary conditions imposed on different domain boundaries for both the 2-D and the 3-D models are listed in table 2.

$z$

direction, without boundary conditions on the top and bottom faces. The boundary conditions imposed on different domain boundaries for both the 2-D and the 3-D models are listed in table 2.

Figure 3. Computational mesh for the Hele-Shaw domain, featuring a horizontal discretisation of

![]() $\Delta x = b/8$

, where

$\Delta x = b/8$

, where

![]() $\Delta x = \Delta y$

is the characteristic uniform horizontal grid resolution in the

$\Delta x = \Delta y$

is the characteristic uniform horizontal grid resolution in the

![]() $xy$

plane. For the 3-D simulation (a), the cells near the top and bottom walls (

$xy$

plane. For the 3-D simulation (a), the cells near the top and bottom walls (

![]() $z=0$

,

$z=0$

,

![]() $z=b$

) have a vertical resolution of

$z=b$

) have a vertical resolution of

![]() $0.3$

µm, while cells near the mid-plane (

$0.3$

µm, while cells near the mid-plane (

![]() $z=b/2$

) have a resolution of

$z=b/2$

) have a resolution of

![]() $30$

µm. The cell-to-cell expansion ratio is 1.2, resulting in a total of

$30$

µm. The cell-to-cell expansion ratio is 1.2, resulting in a total of

![]() $2.0\times 10^7$

cells (

$2.0\times 10^7$

cells (

![]() $250 \times 2000 \times 40$

). For the 2-D simulation (b), the vertical grid consists of one constant-size cell, with the total number of grid cells being

$250 \times 2000 \times 40$

). For the 2-D simulation (b), the vertical grid consists of one constant-size cell, with the total number of grid cells being

![]() $5.0\times 10^5$

(

$5.0\times 10^5$

(

![]() $250 \times 2000 \times 1$

).

$250 \times 2000 \times 1$

).

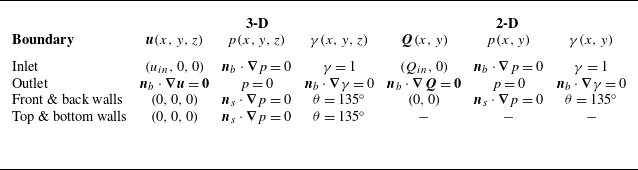

Table 2. Boundary conditions for the two-phase 3-D and 2-D depth-integrated numerical simulations.

![]() $\boldsymbol{n}_{{b}}$

denotes the normal to the boundaries other than the solid walls, namely the inlet and outlet.

$\boldsymbol{n}_{{b}}$

denotes the normal to the boundaries other than the solid walls, namely the inlet and outlet.

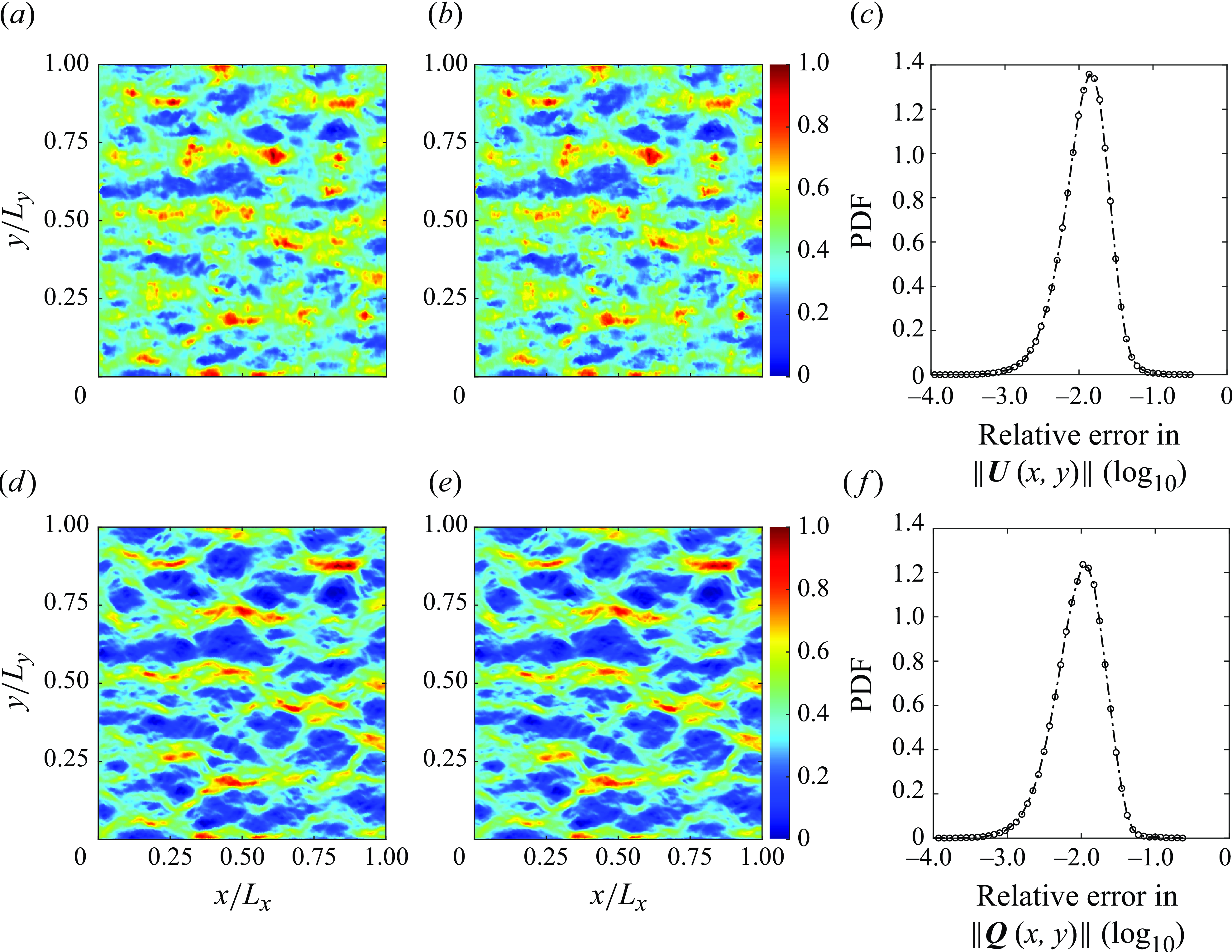

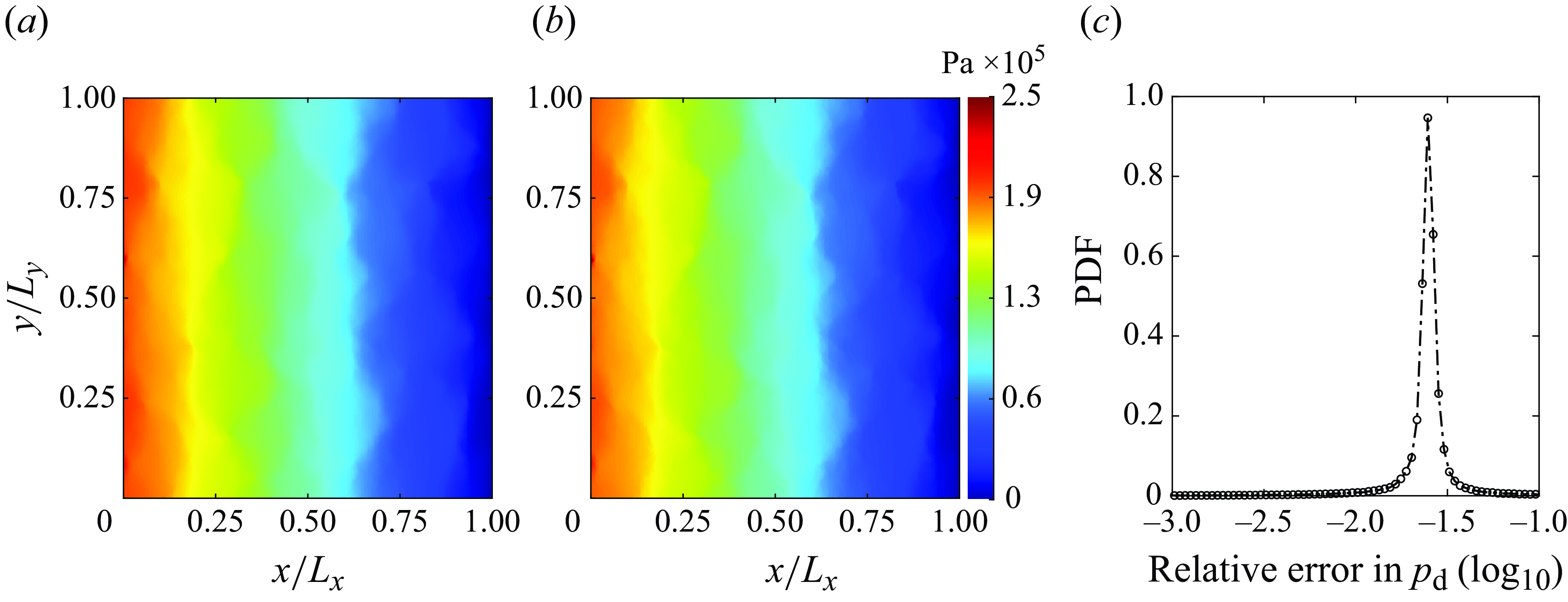

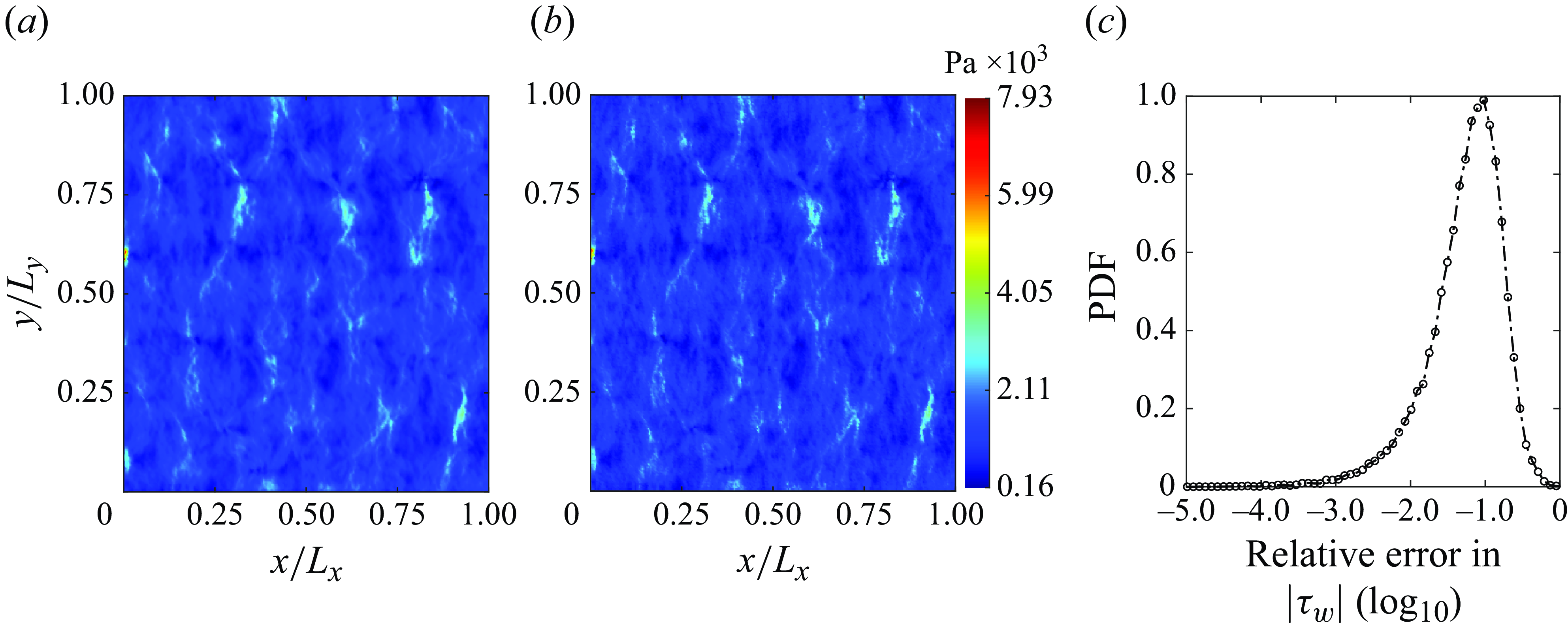

4.2.2. Validation and comparison with 3-D model results

We now compare the results obtained with the 2-D simulations based on the depth-averaged model with those obtained with the 3-D simulations.

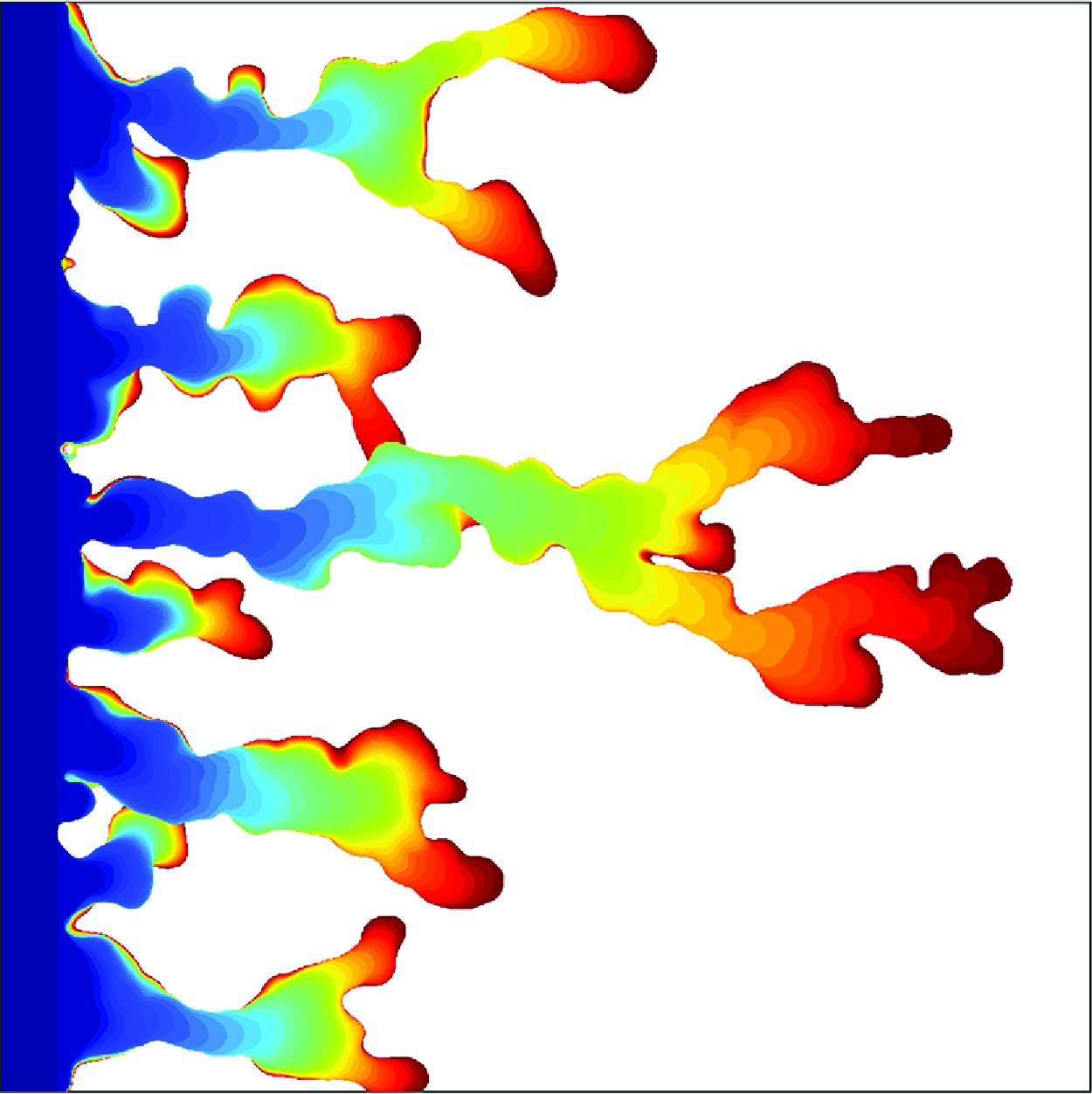

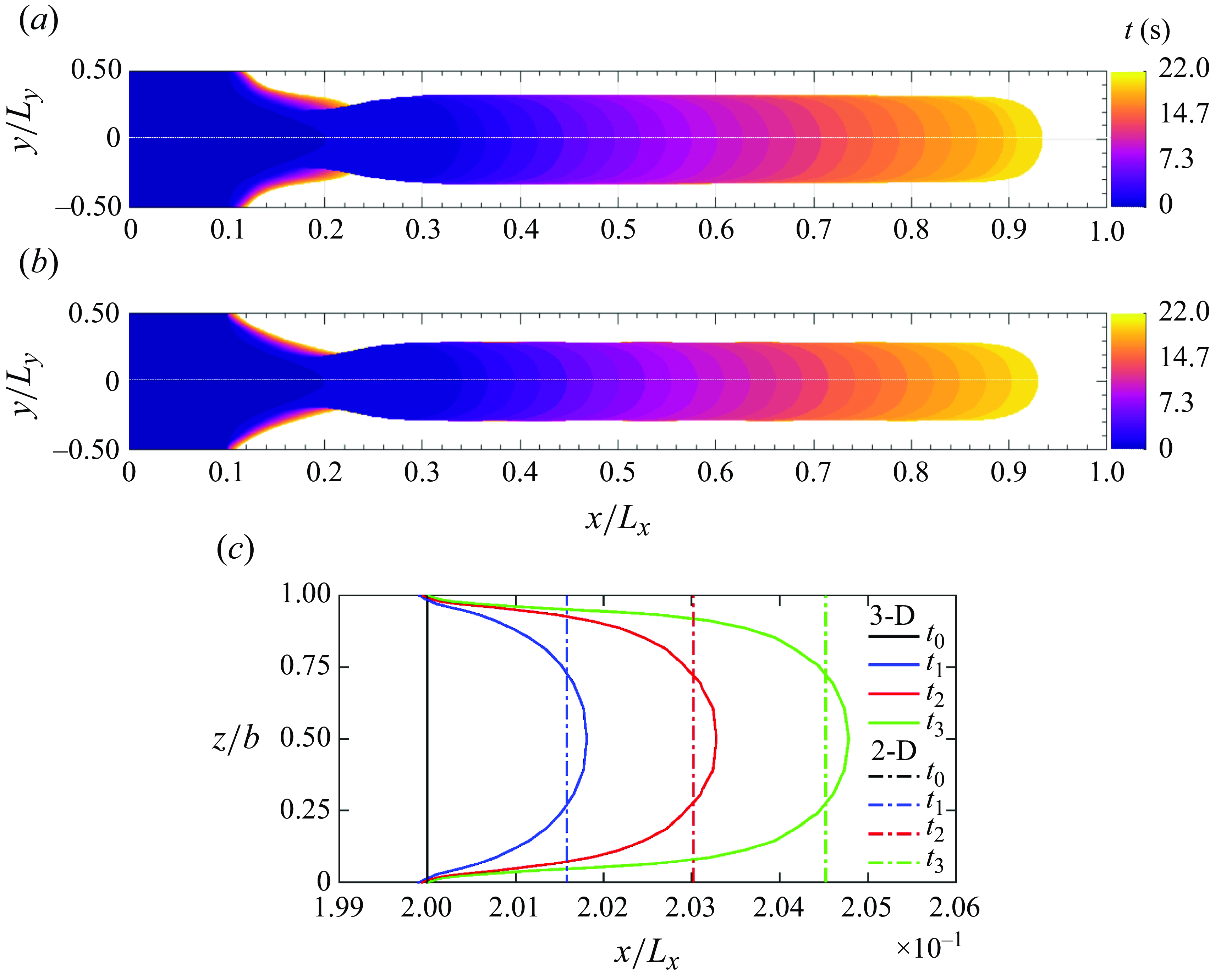

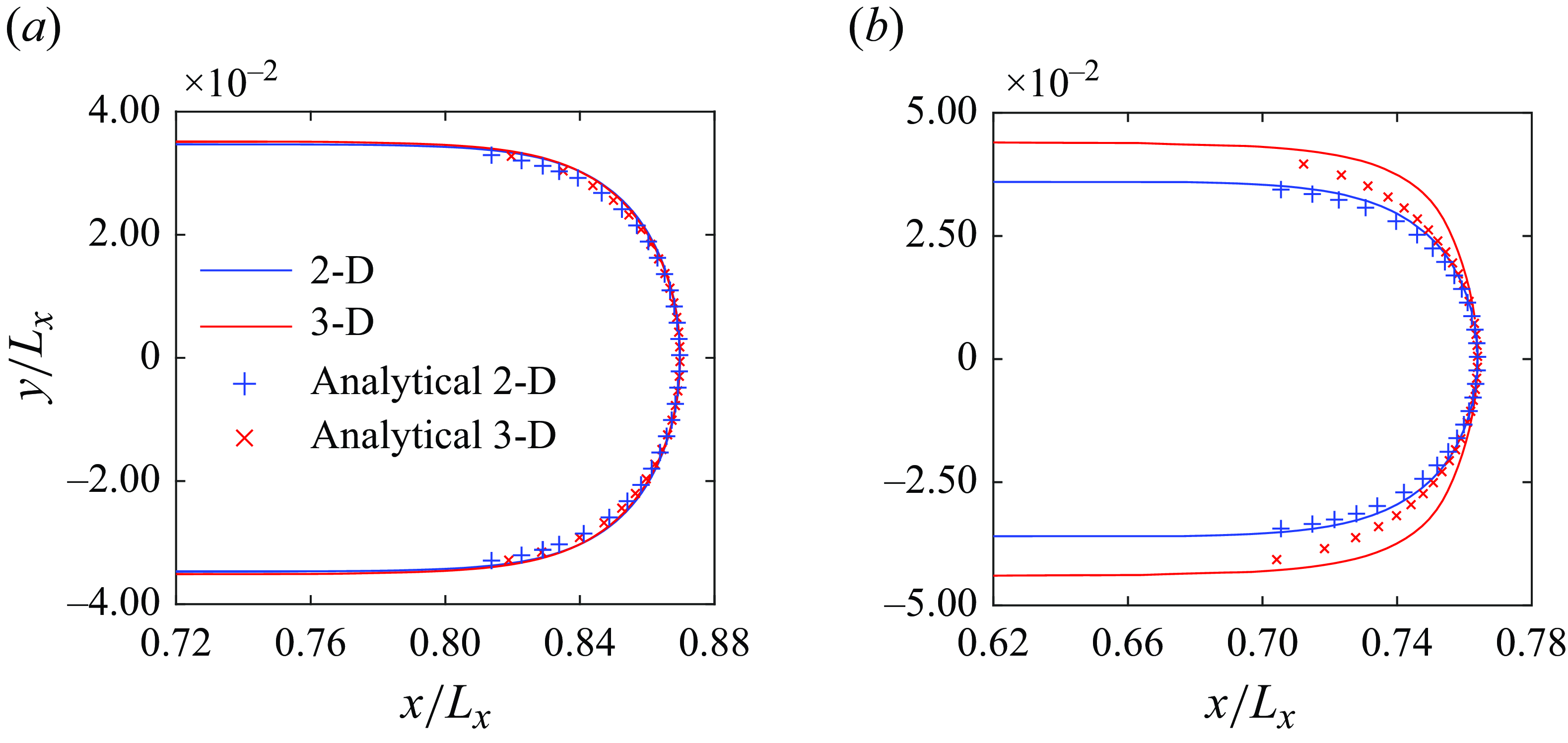

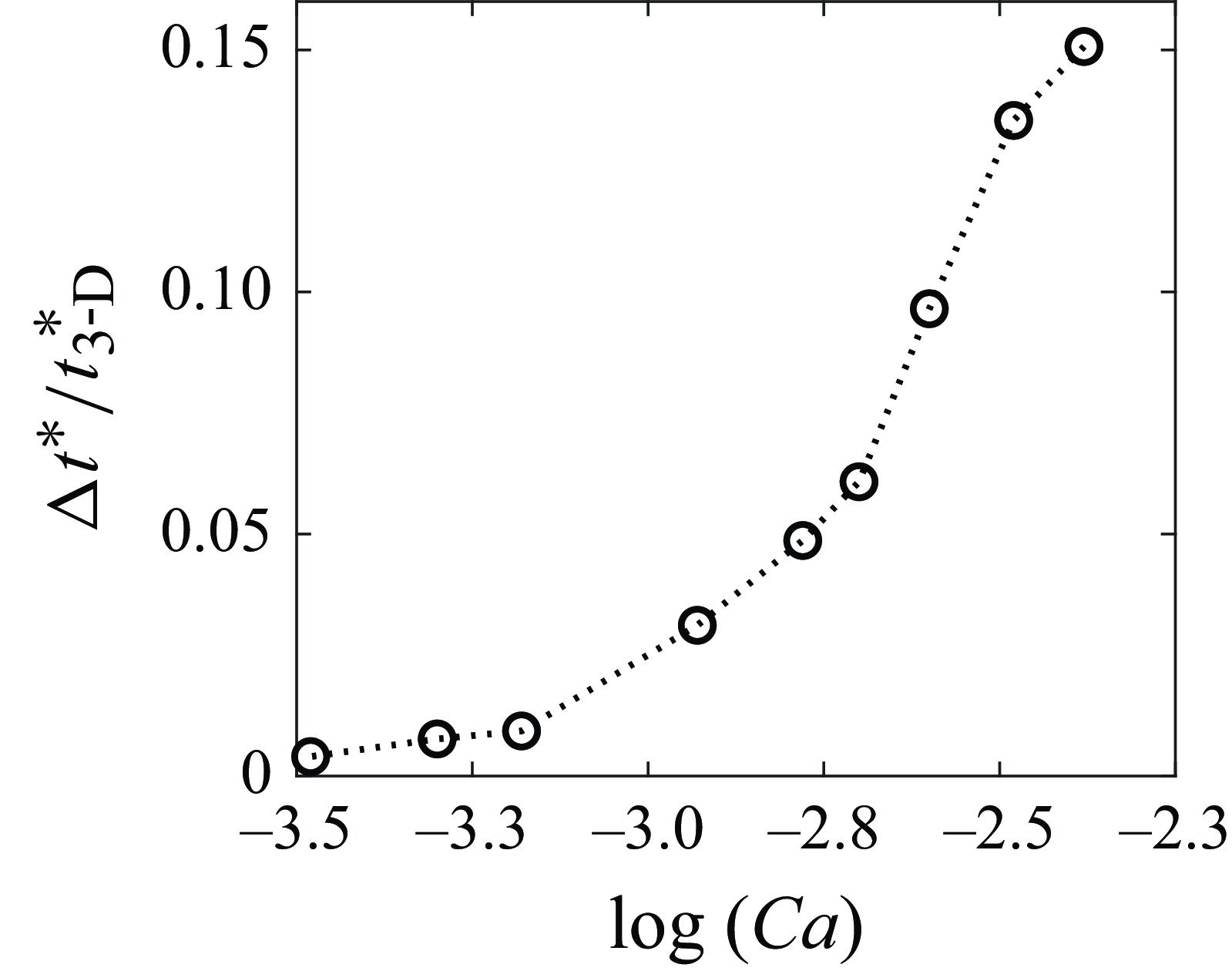

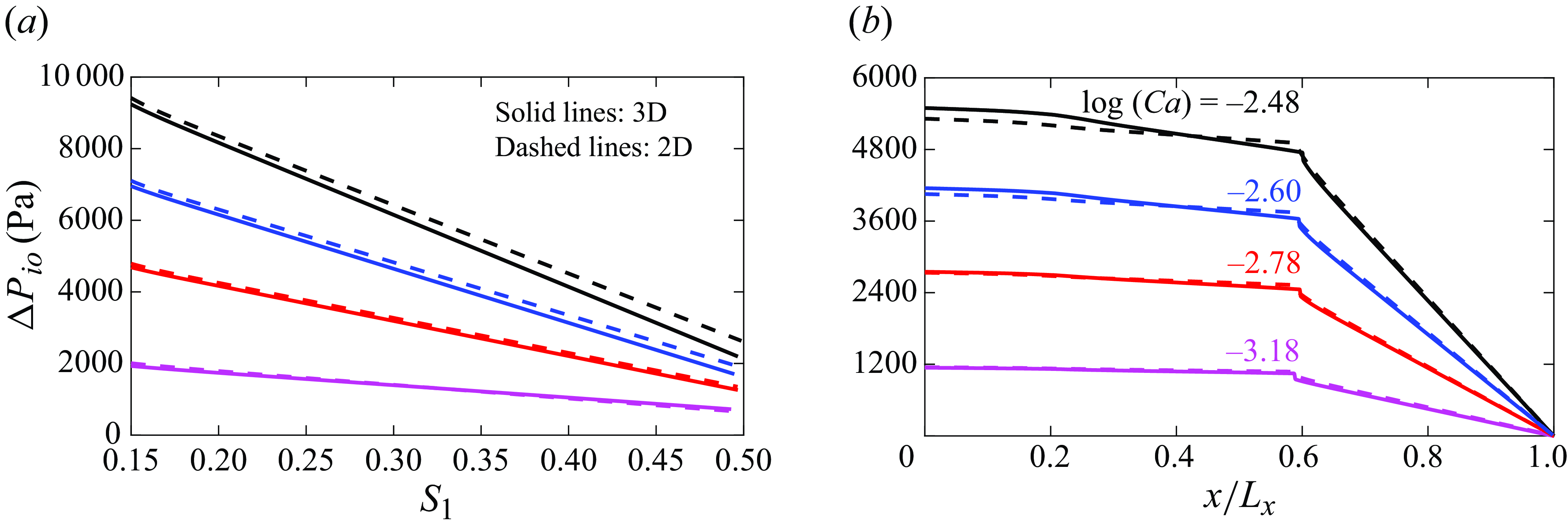

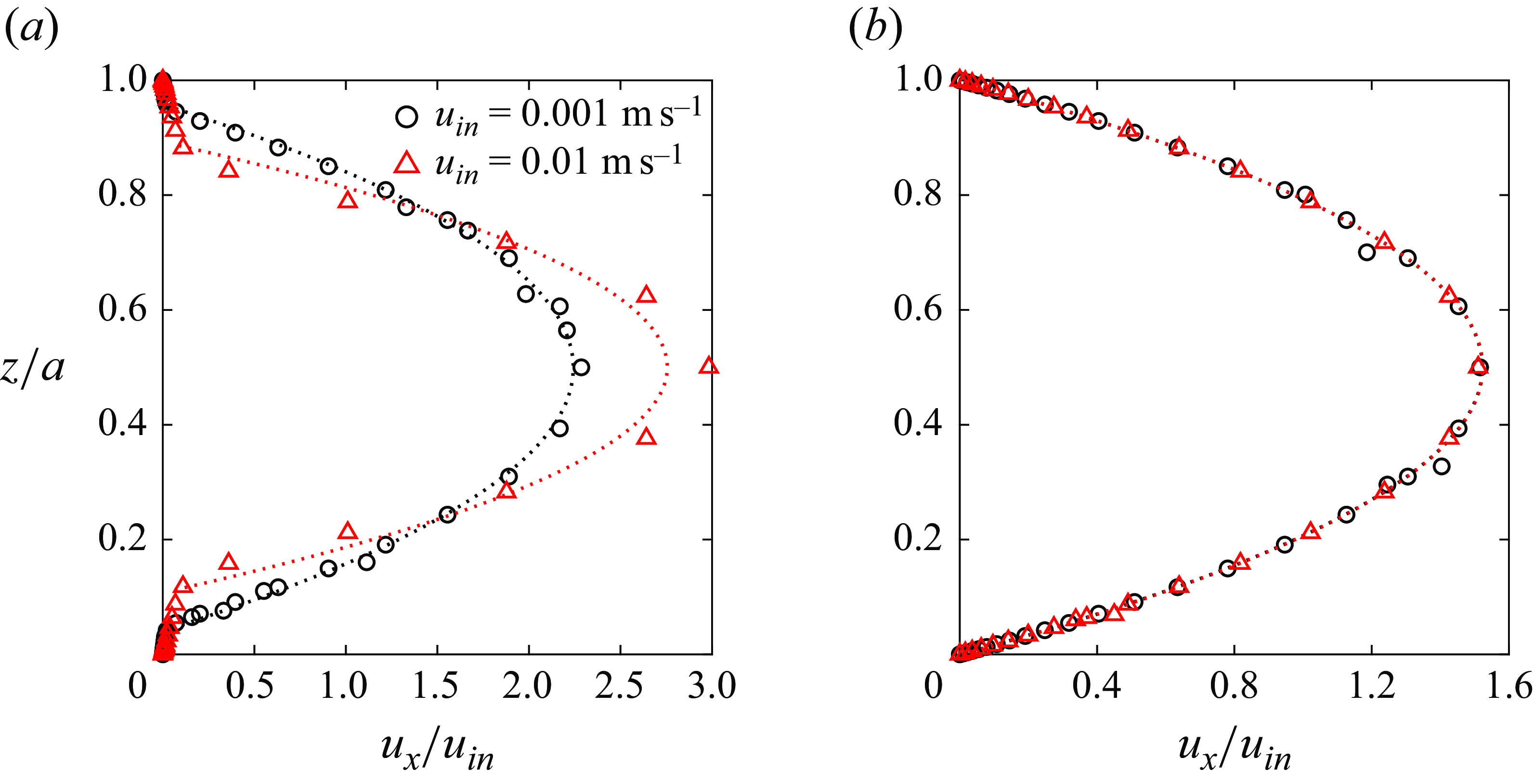

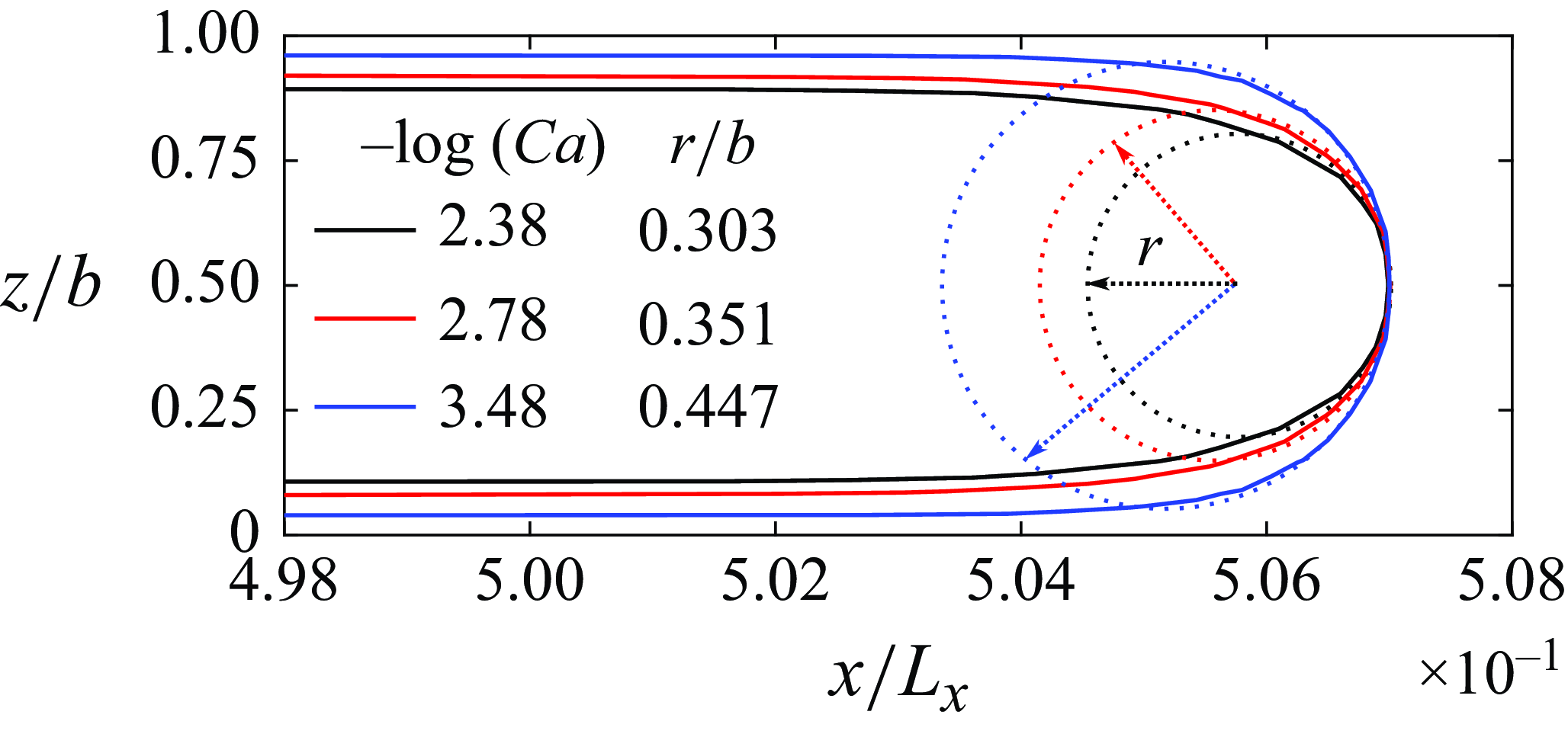

Width and tip shape of the viscous finger: the evolution of the fluid–fluid interface for a representative case (

![]() $Re=0.016$

,

$Re=0.016$

,

![]() $\log (Ca)=-3.18$

) is depicted in figure 4. Both the 3-D (figure 4

a) and 2-D (figure 4

b) simulations successfully reproduce the development of a single finger of the invading fluid, in line with the findings of Saffman & Taylor (Reference Saffman and Taylor1958). At

$\log (Ca)=-3.18$

) is depicted in figure 4. Both the 3-D (figure 4

a) and 2-D (figure 4

b) simulations successfully reproduce the development of a single finger of the invading fluid, in line with the findings of Saffman & Taylor (Reference Saffman and Taylor1958). At

![]() $x \approx 0.02$

m, in the neck region of the finger, its width in the 3-D case is notably larger than that observed in the 2-D simulation. This trend holds true across different injection velocities. Figure 4(c) shows the fluid–fluid interface in the longitudinal vertical mid-plane for the 3-D simulation at three different times. For the 2-D simulation, the interface is shown as the vertical line corresponding to the longitudinal mid-line at the same times. Note that, in agreement with previous studies (Bretherton Reference Bretherton1961; Horgue et al. Reference Horgue, Augier, Quintard and Prat2012), our 3-D simulations confirm that the thickness of the defending fluid film decreases as

$x \approx 0.02$

m, in the neck region of the finger, its width in the 3-D case is notably larger than that observed in the 2-D simulation. This trend holds true across different injection velocities. Figure 4(c) shows the fluid–fluid interface in the longitudinal vertical mid-plane for the 3-D simulation at three different times. For the 2-D simulation, the interface is shown as the vertical line corresponding to the longitudinal mid-line at the same times. Note that, in agreement with previous studies (Bretherton Reference Bretherton1961; Horgue et al. Reference Horgue, Augier, Quintard and Prat2012), our 3-D simulations confirm that the thickness of the defending fluid film decreases as

![]() $Ca$

decreases (see Krishna et al. (Reference Krishna, Méheust and Neuweiler2024) for further details).

$Ca$

decreases (see Krishna et al. (Reference Krishna, Méheust and Neuweiler2024) for further details).

Figure 4. Evolution of the invading fluid finger for

![]() $(a)$

3-D and

$(a)$

3-D and

![]() $(b)$

2-D simulations, with

$(b)$

2-D simulations, with

![]() $u_{{in}} = 2.0\times 10^{-3}$

m s−1,

$u_{{in}} = 2.0\times 10^{-3}$

m s−1,

![]() $Re=0.016$

and

$Re=0.016$

and

![]() $\log (Ca)=-3.18$

. Each location within the flow domain that is reached by the finger at some time is coloured according to that time, as indicated by the colour scale.

$\log (Ca)=-3.18$

. Each location within the flow domain that is reached by the finger at some time is coloured according to that time, as indicated by the colour scale.

![]() $(c)$

Vertical profiles of the fluid–fluid interface in the longitudinal vertical mid-plane of the flow cell, comparing early stages of 3-D (solid curves) and 2-D (dashed lines) simulations. The initial interface position (

$(c)$

Vertical profiles of the fluid–fluid interface in the longitudinal vertical mid-plane of the flow cell, comparing early stages of 3-D (solid curves) and 2-D (dashed lines) simulations. The initial interface position (

![]() $t_0 = 0 \text{ s}$

) is shown by the vertical black line. Coloured lines represent interface positions at

$t_0 = 0 \text{ s}$

) is shown by the vertical black line. Coloured lines represent interface positions at

![]() $t_1 = 0.04 \text{ s}$

,

$t_1 = 0.04 \text{ s}$

,

![]() $t_2 = 0.08 \text{ s}$

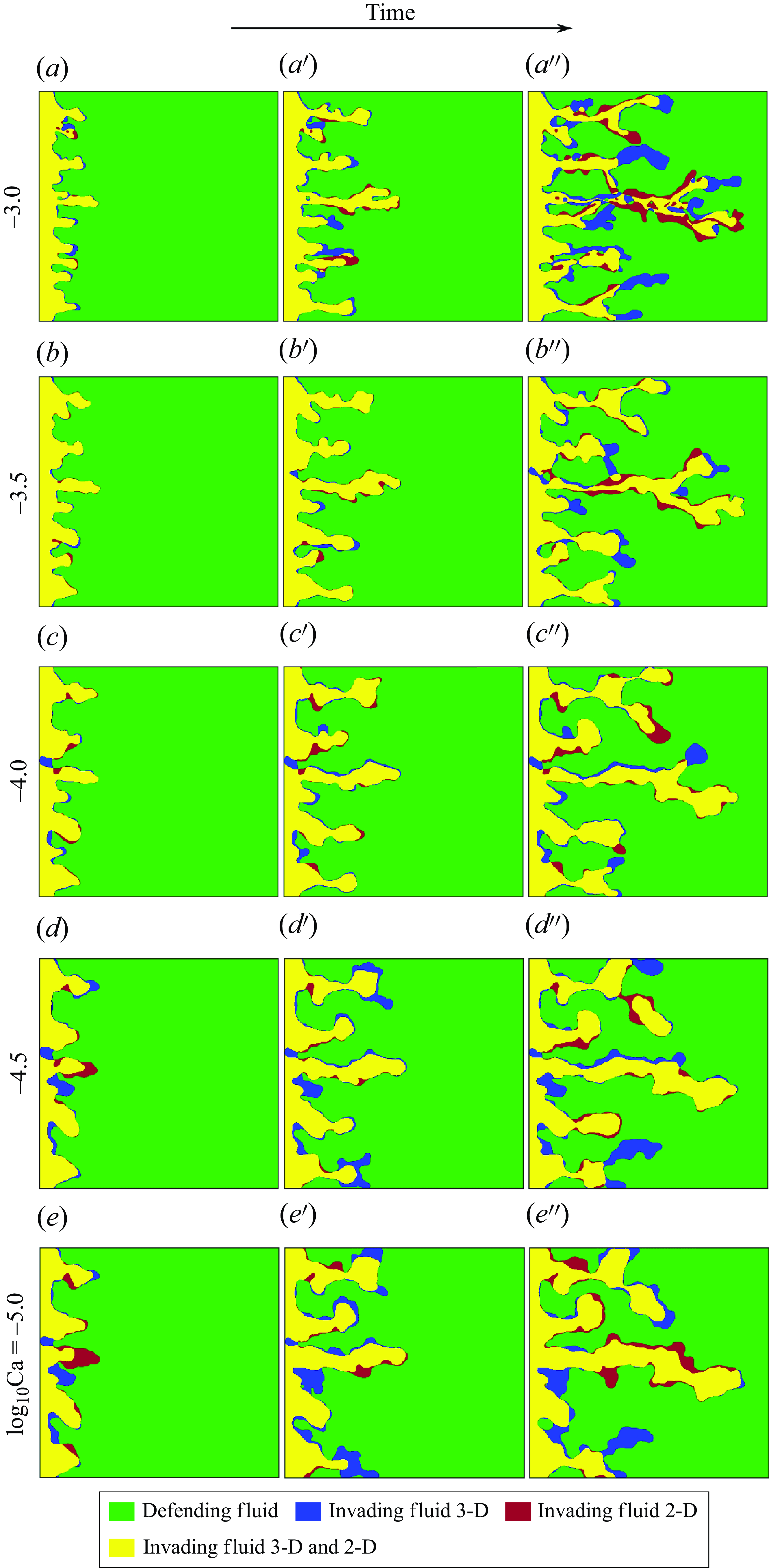

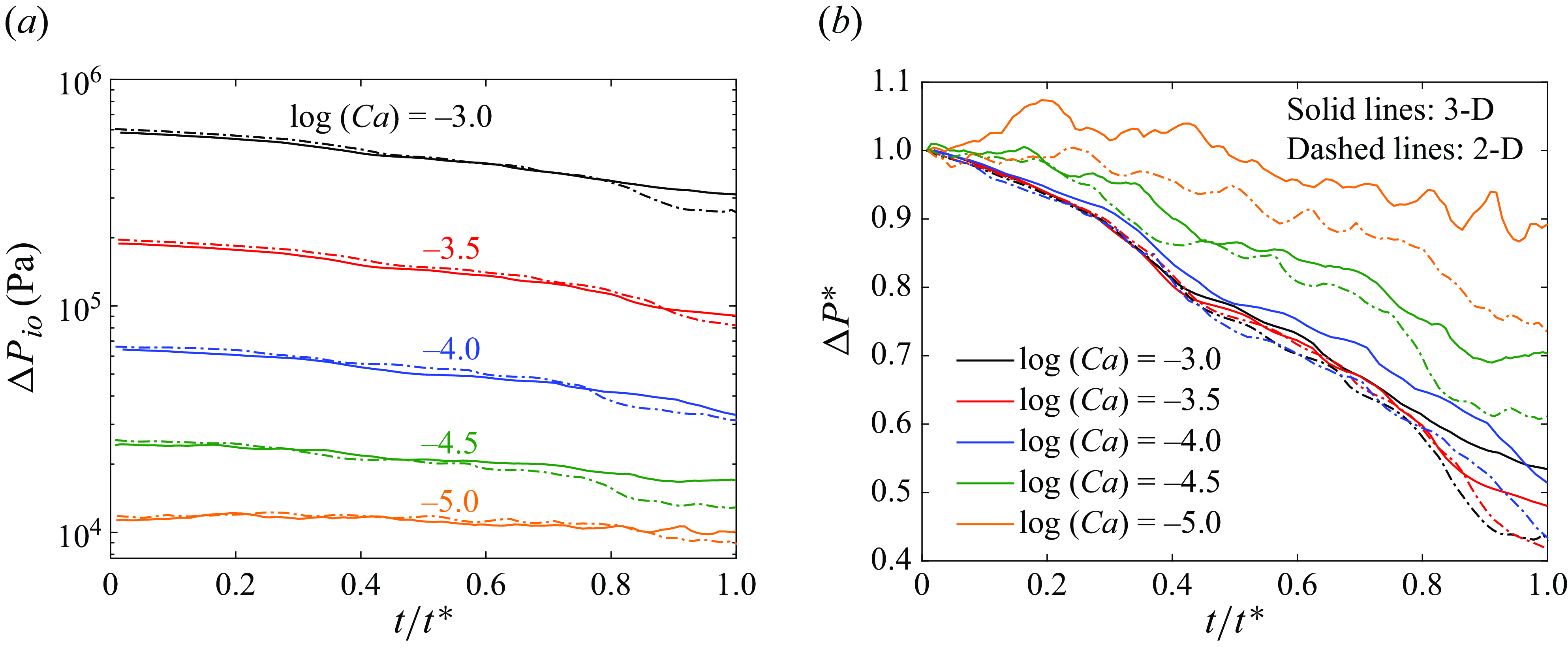

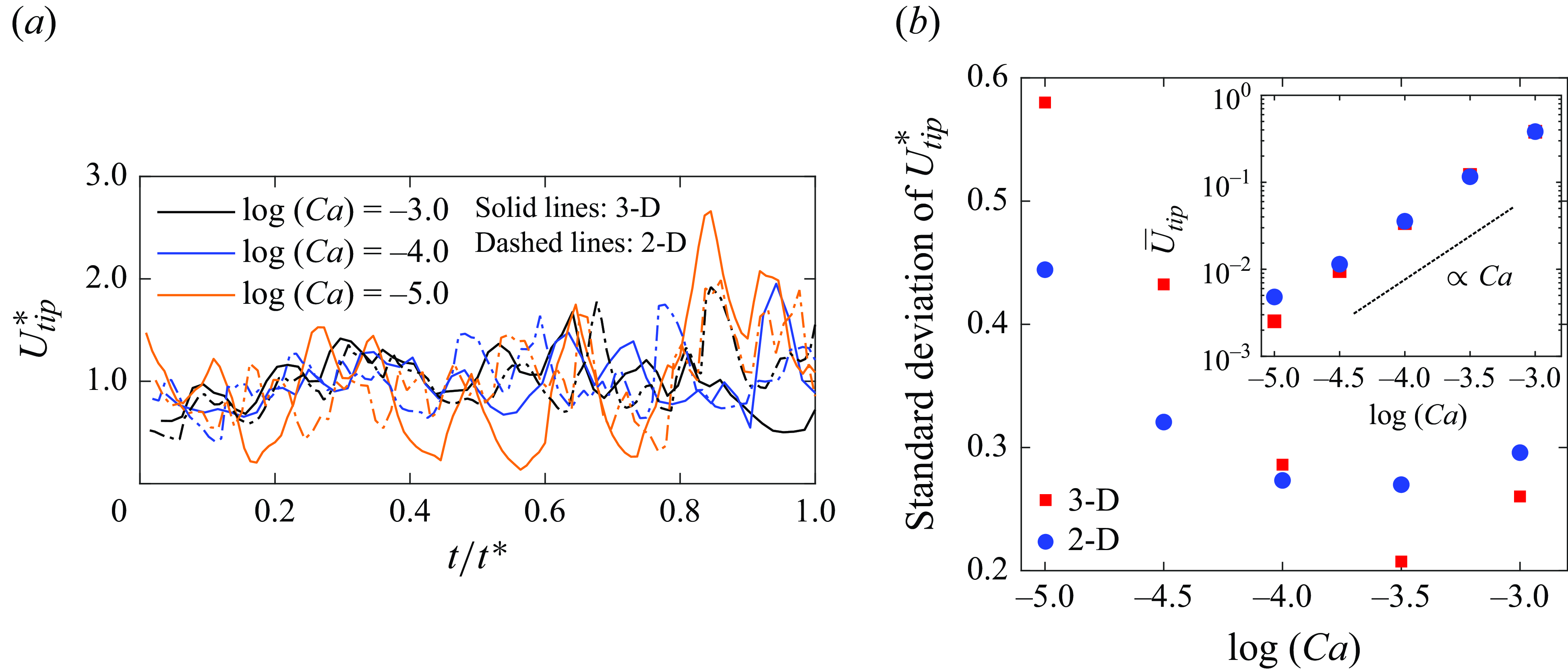

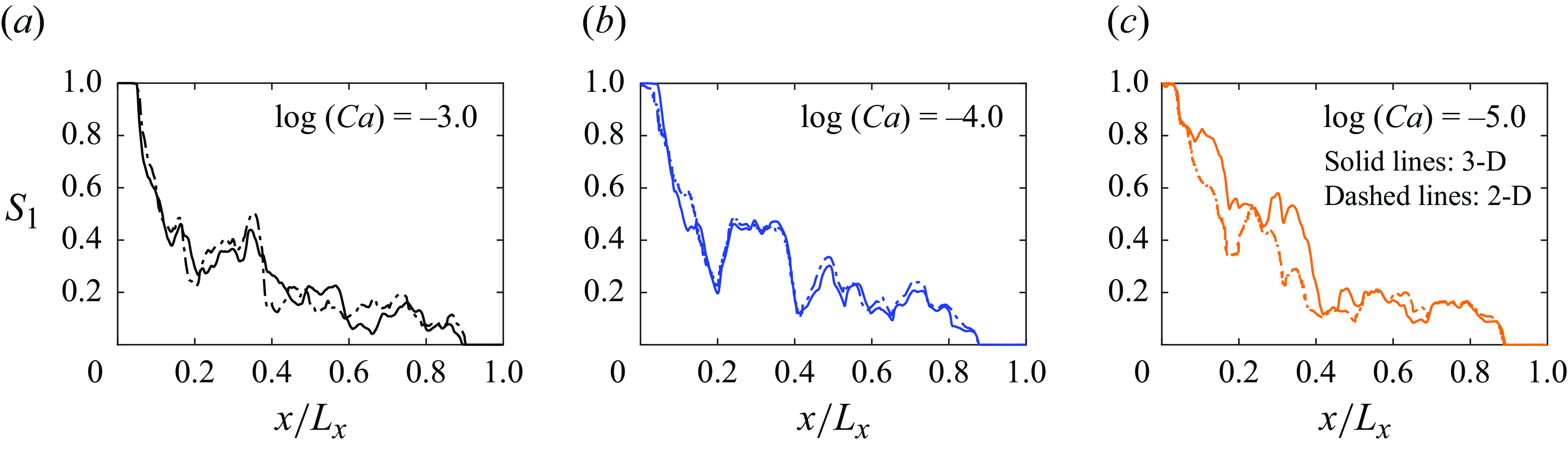

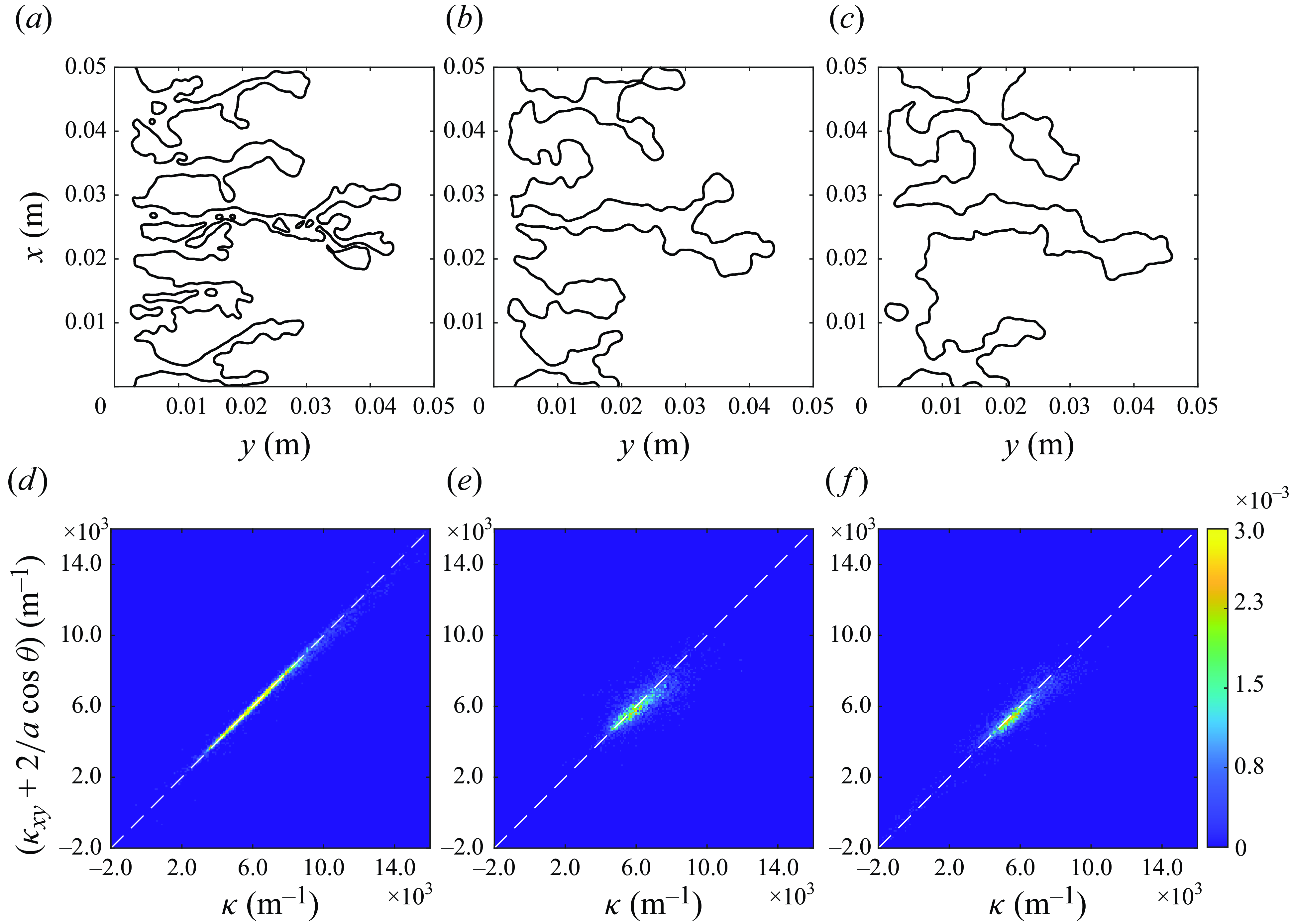

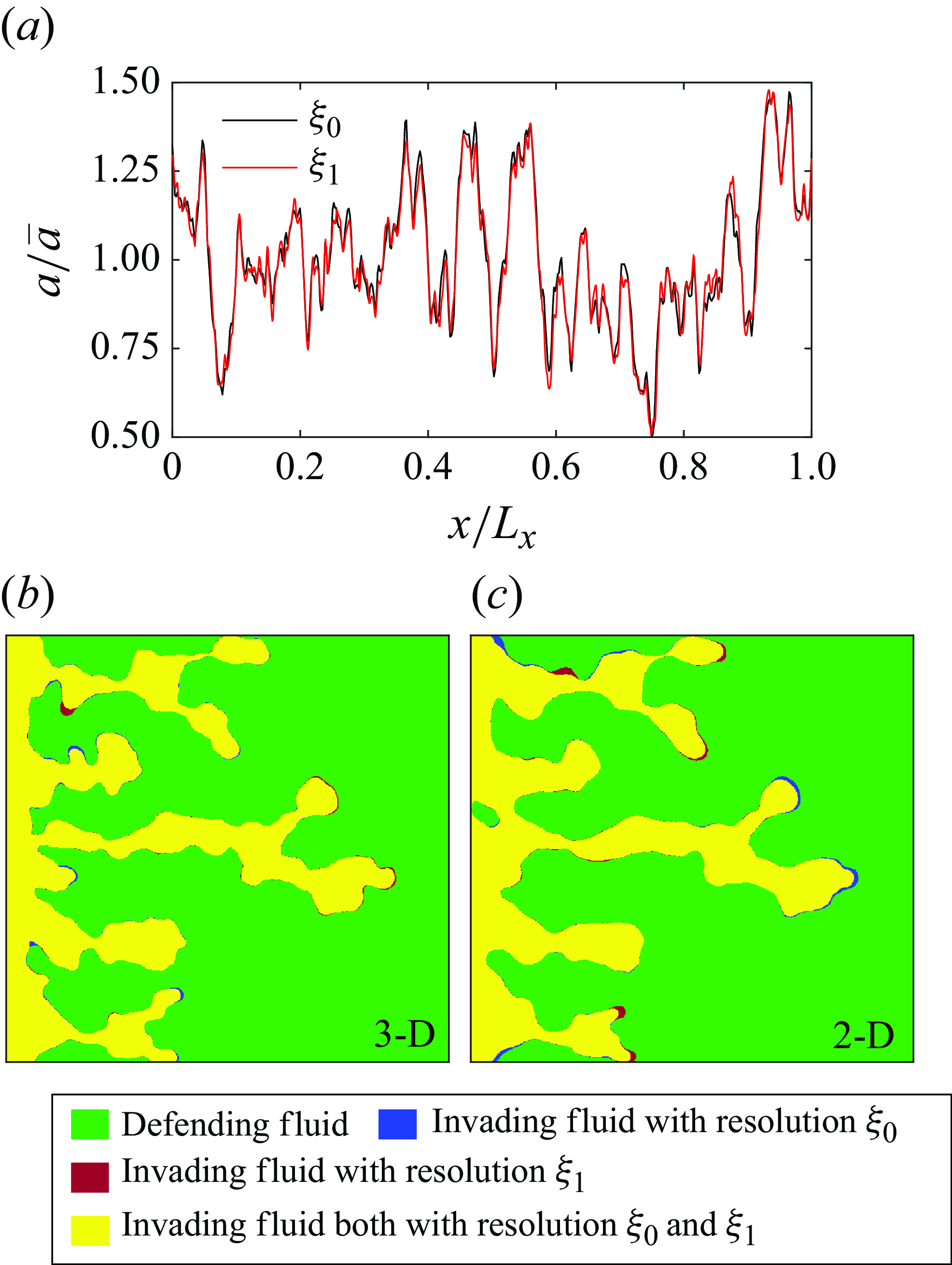

and