1. Introduction

Many studies have considered how oscillations of a heated solid surface in an oncoming fluid flow can increase heat transfer from the solid to the fluid. Motions of the boundary alter the flow patterns from the scale of the viscous boundary layer to the larger scale of the outer flow. Previous experimental and computational studies have quantified the resulting heat transfer enhancement for the case of a circular cylinder undergoing translational or rotational oscillations in a two-dimensional cross-flow (Saxena & Laird Reference Saxena and Laird1978; Fu & Tong Reference Fu and Tong2002; Mittal & Al-Mdallal Reference Mittal and Al-Mdallal2018). Typically, significant local heat transfer improvement is observed at the rear part of the cylinder due to the vortex wake.

After the circular cylinder, perhaps the next most common geometry is the flat plate. When a flat plate is held normal to a flow, the flow transitions from steady flow to von Kármán vortex shedding at a lower Reynolds number (Re) than a circular cylinder (Thompson et al. Reference Thompson, Radi, Rao, Sheridan and Hourigan2014), and undergoes a more complex series of wake transitions as Re increases. The flat plate also sheds stronger and larger vortices into the wake. Unlike the circular cylinder, the flat plate lacks rotational symmetry and the vortex-shedding patterns change with the plate’s orientation in the flow. At a moderate Reynolds number of

![]() $\mathcal{O}(100)$

, different plate orientations may lead to a steady, periodic or non-periodic flow (Taira & Colonius Reference Taira and Colonius2009). Oscillating the plate adds new features to the flow. How these different flow patterns influence heat transfer is the focus of the present study.

$\mathcal{O}(100)$

, different plate orientations may lead to a steady, periodic or non-periodic flow (Taira & Colonius Reference Taira and Colonius2009). Oscillating the plate adds new features to the flow. How these different flow patterns influence heat transfer is the focus of the present study.

Heat transfer by oscillating thin plates has important applications in the biological world. Elephants’ ears are thin surfaces that hold large networks of blood vessels, and ear flapping was speculated to make a large contribution to thermoregulation (Sikes Reference Sikes1971). Koffi et al. (Reference Koffi, Andreopoulos and Jiji2014, Reference Koffi, Andreopoulos and Jiji2017) studied the enhancement of heat transfer due to oscillations in computational and experimental models of elephant ears, characterised vortical flow structures and noted an additional heat transfer enhancement in a flexible model relative to a rigid one. Bats vary the blood flow to their wings for thermoregulation, and the constraints of this process affect bats’ survival in cold climates (Reeder & Cowles Reference Reeder and Cowles1951; Rubalcaba et al. Reference Rubalcaba2022). Heat transfer may have also played a role in the evolution of insect wings (Douglas Reference Douglas1981; Kingsolver & Koehl Reference Kingsolver and Koehl1985). Heat stress is a major factor in plant survival and reproductive success (Jagadish, Way & Sharkey Reference Jagadish, Way and Sharkey2021). Many studies have considered the effect of wind-induced oscillations on the cooling of plant leaves, both with and without water evaporation at the leaf surface (Schuepp Reference Schuepp1972; Murphy & Knoerr Reference Murphy and Knoerr1977; Roden & Pearcy Reference Roden and Pearcy1993; Vogel Reference Vogel2009). In this work we focus on heat transfer under prescribed oscillations, but there is also a large body of work on heat transfer when the body motion results from fluid–structure interaction; Mittal & Bhardwaj (Reference Mittal and Bhardwaj2022) reviewed the application of immersed boundary methods in this area.

A model problem that resembles these biological situations was recently studied by Rahman & Tafti (Reference Rahman and Tafti2020a

). They computed the heat transfer enhancement due to sinusoidal oscillations of a heated flat plate with a fixed temperature in an oncoming flow using a two-dimensional (2-D) formulation. The plate was aligned with the oncoming flow direction and oscillated transversely, with a fixed Reynolds number of 100 based on the oncoming flow speed. They varied the plate oscillation amplitude and frequency and computed the Nusselt number averaged over a time interval [

![]() $T$

,

$T$

,

![]() $2T$

], where

$2T$

], where

![]() $T$

ranged from 8 to 16 oscillation periods. They identified the ‘plunge velocity’, i.e. the product of dimensionless amplitude and frequency of the oscillation, as a key parameter for controlling the average Nusselt number. The average Nusselt number increased monotonically with the plunge velocity as it varied from 0.25, close to the limit of no oscillation (a static plate), to 4, a rapid oscillation. When the oscillation amplitude and frequency were varied simultaneously while keeping their product (the plunge velocity) fixed, there was a smaller variation in the average Nusselt number.

$T$

ranged from 8 to 16 oscillation periods. They identified the ‘plunge velocity’, i.e. the product of dimensionless amplitude and frequency of the oscillation, as a key parameter for controlling the average Nusselt number. The average Nusselt number increased monotonically with the plunge velocity as it varied from 0.25, close to the limit of no oscillation (a static plate), to 4, a rapid oscillation. When the oscillation amplitude and frequency were varied simultaneously while keeping their product (the plunge velocity) fixed, there was a smaller variation in the average Nusselt number.

In this paper we study the same system and Reynolds number (

![]() $Re_U$

) as Rahman & Tafti (Reference Rahman and Tafti2020a

) in two dimensions but we now consider the full range of plate orientations and oscillation directions relative to the oncoming flow velocity (see figure 1), instead of just a streamwise orientation and transverse oscillation direction. Also, we consider a fixed-heat-flux boundary condition in addition to the fixed-plate-temperature condition considered by Rahman & Tafti (Reference Rahman and Tafti2020a

). They focused on the effect of plunge velocity and did not discuss the details of the flow and temperature fields. By contrast, our work aims to relate the heat transfer enhancement to the flow patterns. We still consider the plunge velocity, now generalised as the ‘oscillation velocity’ (

$Re_U$

) as Rahman & Tafti (Reference Rahman and Tafti2020a

) in two dimensions but we now consider the full range of plate orientations and oscillation directions relative to the oncoming flow velocity (see figure 1), instead of just a streamwise orientation and transverse oscillation direction. Also, we consider a fixed-heat-flux boundary condition in addition to the fixed-plate-temperature condition considered by Rahman & Tafti (Reference Rahman and Tafti2020a

). They focused on the effect of plunge velocity and did not discuss the details of the flow and temperature fields. By contrast, our work aims to relate the heat transfer enhancement to the flow patterns. We still consider the plunge velocity, now generalised as the ‘oscillation velocity’ (

![]() $A/|\boldsymbol{U}_{\infty }|$

, defined in equation (2.3) below) which differs from the plunge velocity by a factor of

$A/|\boldsymbol{U}_{\infty }|$

, defined in equation (2.3) below) which differs from the plunge velocity by a factor of

![]() $\pi$

. Since the flow is typically chaotic and difficult to characterise at high oscillation velocities (Rahman & Tafti Reference Rahman and Tafti2020a

), we study cases with relatively low

$\pi$

. Since the flow is typically chaotic and difficult to characterise at high oscillation velocities (Rahman & Tafti Reference Rahman and Tafti2020a

), we study cases with relatively low

![]() $A/|\boldsymbol{U}_{\infty }|$

$A/|\boldsymbol{U}_{\infty }|$

![]() $(= 0.2$

and

$(= 0.2$

and

![]() $0.3$

) where the flow computation is more tractable while the heat transfer enhancement is significant. Additionally, we detail how the parameters, particularly the newly added oncoming flow direction

$0.3$

) where the flow computation is more tractable while the heat transfer enhancement is significant. Additionally, we detail how the parameters, particularly the newly added oncoming flow direction

![]() $\gamma$

and the plate oscillation direction

$\gamma$

and the plate oscillation direction

![]() $\alpha$

, influence the global and local heat transfer. An important result is that the global and local heat transfer typically improve as we move from in-plane to transverse oscillations, i.e. as

$\alpha$

, influence the global and local heat transfer. An important result is that the global and local heat transfer typically improve as we move from in-plane to transverse oscillations, i.e. as

![]() $\alpha$

increases from

$\alpha$

increases from

![]() $0^\circ$

to

$0^\circ$

to

![]() $90^\circ$

. The oncoming flow direction

$90^\circ$

. The oncoming flow direction

![]() $\gamma$

and the oscillatory frequency (assuming fixed oscillation velocity) have noticeable but generally weaker effects on the global heat transfer. They strongly alter the flows and spatial distributions of heat transfer quantities, but when taking an average over the plate, these variations are reduced to a surprising extent.

$\gamma$

and the oscillatory frequency (assuming fixed oscillation velocity) have noticeable but generally weaker effects on the global heat transfer. They strongly alter the flows and spatial distributions of heat transfer quantities, but when taking an average over the plate, these variations are reduced to a surprising extent.

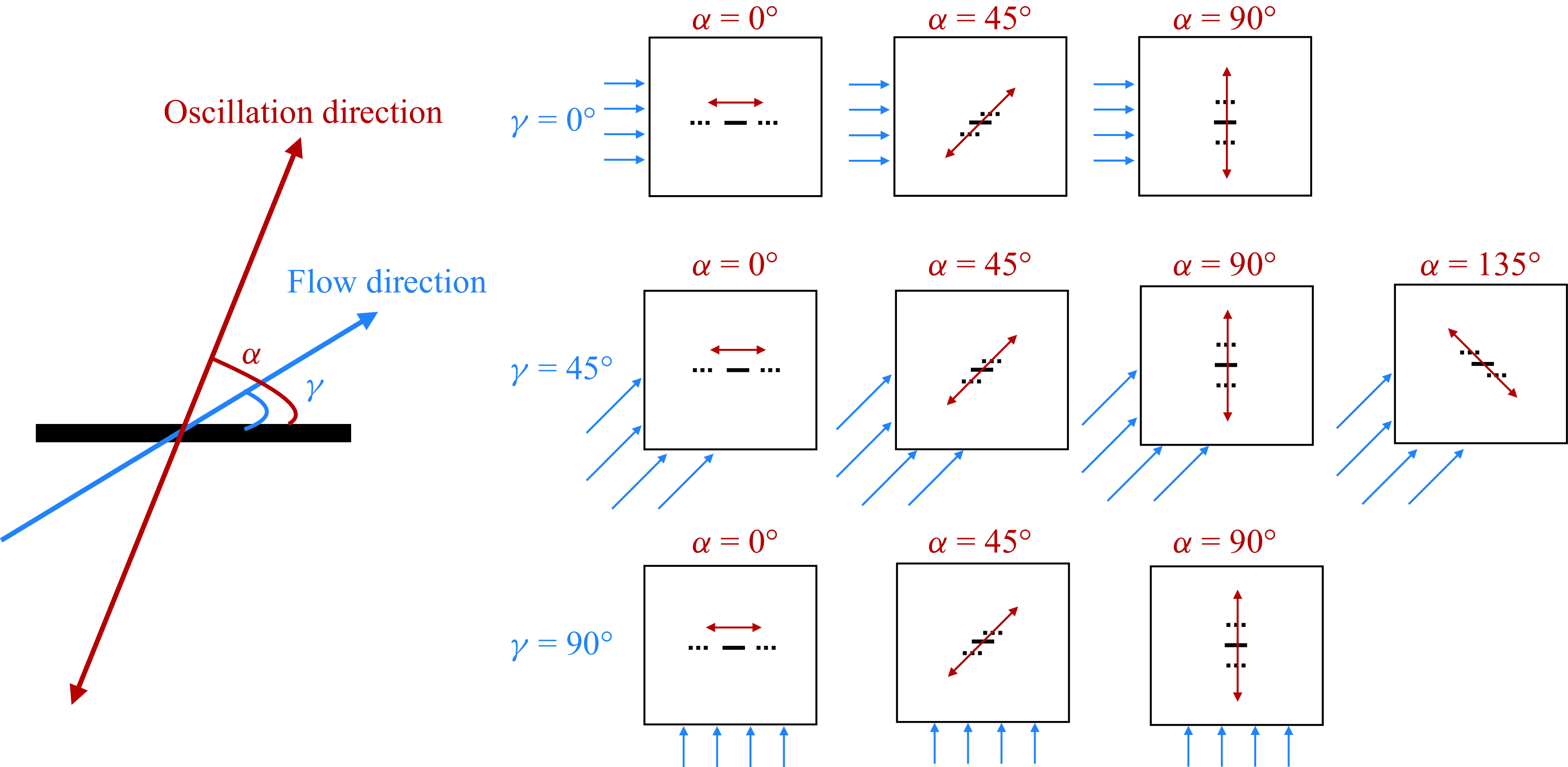

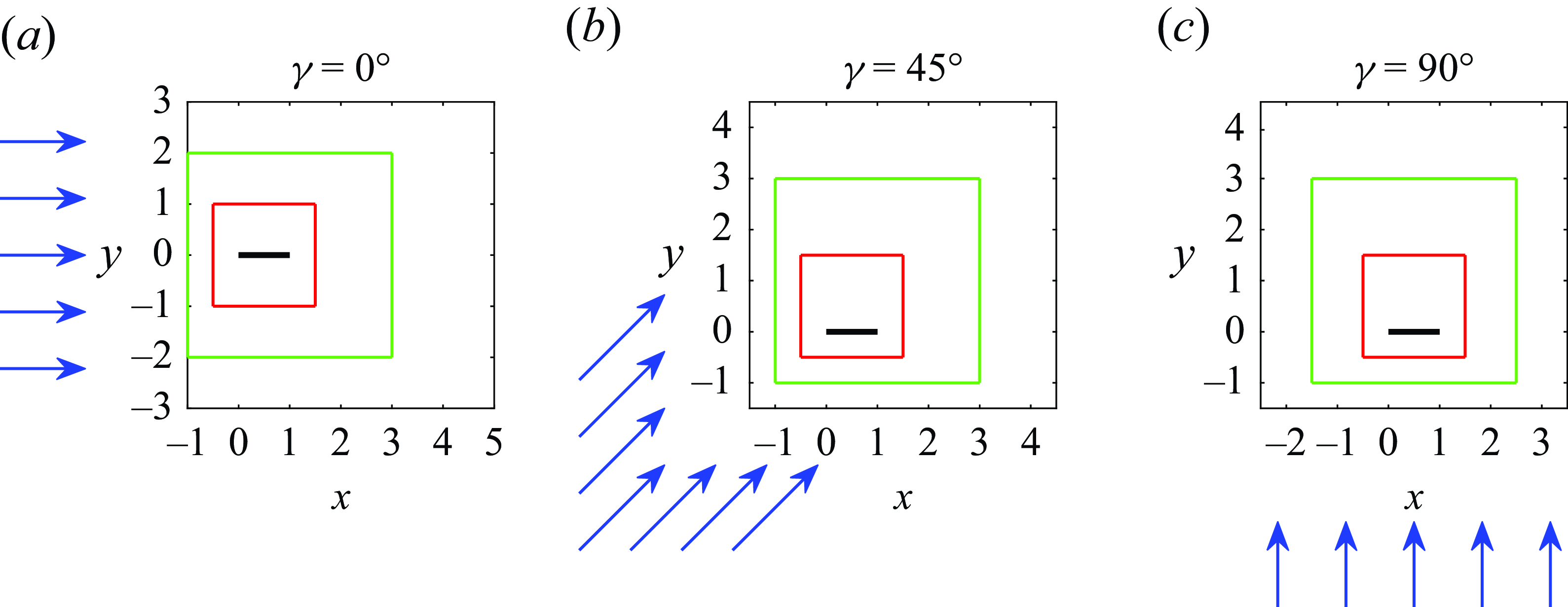

Figure 1. Schematic of the plate orientation and oscillation direction (angle

![]() $\alpha$

) and the background flow direction (angle

$\alpha$

) and the background flow direction (angle

![]() $\gamma$

).

$\gamma$

).

We also note that, in the present study, the Reynolds number based on the oncoming flow speed is 100, but the instantaneous Reynolds number based on the relative velocity between the oscillating plate and the flow can exceed 200 in some cases. Previous studies showed that the flow behind a plate is intrinsically three-dimensional (3-D) beyond a certain critical Reynolds number (

![]() ${\approx}200$

behind a normal plate (Najjar & Vanka Reference Najjar and Vanka1995), and

${\approx}200$

behind a normal plate (Najjar & Vanka Reference Najjar and Vanka1995), and

![]() ${\approx}300$

behind an inclined plate (Yang et al. Reference Yang, Narasimhamurthy, Pettersen and Andersson2012)). Therefore, 3-D effects may begin at parameters near our values. However, Khaledi et al. (Reference Khaledi, Andersson, Barri and Pettersen2012) showed that, for a plate normal to the flow undergoing inline oscillations, the flow remains two-dimensional at

${\approx}300$

behind an inclined plate (Yang et al. Reference Yang, Narasimhamurthy, Pettersen and Andersson2012)). Therefore, 3-D effects may begin at parameters near our values. However, Khaledi et al. (Reference Khaledi, Andersson, Barri and Pettersen2012) showed that, for a plate normal to the flow undergoing inline oscillations, the flow remains two-dimensional at

![]() $Re_U=100$

if the oscillation frequency is sufficiently larger than the natural shedding frequency of the plate. (Two-dimensional flow was reported at plate-oscillation-to-natural-shedding-frequency ratios 1.74 and 2.1 for

$Re_U=100$

if the oscillation frequency is sufficiently larger than the natural shedding frequency of the plate. (Two-dimensional flow was reported at plate-oscillation-to-natural-shedding-frequency ratios 1.74 and 2.1 for

![]() $Re_U=100$

.) In the present study, the lowest oscillation frequency studied is at least twice the natural shedding frequency. Furthermore, the body oscillations seem to suppress the transition from two to three dimensions, at least for circular cylinders (Leontini, Thompson & Hourigan Reference Leontini, Thompson and Hourigan2007; Lo Jacono et al. Reference Jacono, David, Justin, Thompson and Sheridan2010). Therefore, we believe our 2-D formulation at

$Re_U=100$

.) In the present study, the lowest oscillation frequency studied is at least twice the natural shedding frequency. Furthermore, the body oscillations seem to suppress the transition from two to three dimensions, at least for circular cylinders (Leontini, Thompson & Hourigan Reference Leontini, Thompson and Hourigan2007; Lo Jacono et al. Reference Jacono, David, Justin, Thompson and Sheridan2010). Therefore, we believe our 2-D formulation at

![]() $Re_U=100$

is a reasonable model.

$Re_U=100$

is a reasonable model.

The structure of the paper is as follows. In § 2 we present the governing equations and numerical method. Section 3 presents the flow fields and the local heat transfer distributions in the benchmark cases of non-oscillating plates. Section 4 shows the effect of vorticity patterns on global and local heat transfer for oscillating plates with different orientations and oscillation directions. In § 5 we discuss the input power for this system, including the power to oscillate the plates and to drive the oncoming flow. Section 6 presents the conclusions.

2. Governing equations and numerical method

We consider a heated zero-thickness flat plate oscillating sinusoidally in a uniform oncoming flow at angle

![]() $\gamma$

relative to the plane of the plate (see figure 1). The plate oscillates in a direction with angle

$\gamma$

relative to the plane of the plate (see figure 1). The plate oscillates in a direction with angle

![]() $\alpha$

relative to the plane of the plate, different from

$\alpha$

relative to the plane of the plate, different from

![]() $\gamma$

in general. The problem is formulated in two dimensions. We non-dimensionalise all variables using the plate length

$\gamma$

in general. The problem is formulated in two dimensions. We non-dimensionalise all variables using the plate length

![]() $\ell ^\star$

as the characteristic length scale and the plate oscillation period

$\ell ^\star$

as the characteristic length scale and the plate oscillation period

![]() $1/f^\star$

as the characteristic time scale, with

$1/f^\star$

as the characteristic time scale, with

![]() $f^\star$

the plate oscillation frequency. The oscillation period is a convenient reference time scale for our computations, so that a fixed small time step is sufficient to resolve the dynamics over a period of oscillation. Then

$f^\star$

the plate oscillation frequency. The oscillation period is a convenient reference time scale for our computations, so that a fixed small time step is sufficient to resolve the dynamics over a period of oscillation. Then

![]() $f^\star \ell ^\star$

is the characteristic velocity scale. We use the fluid density

$f^\star \ell ^\star$

is the characteristic velocity scale. We use the fluid density

![]() $\rho _f^\star$

as the characteristic mass density.

$\rho _f^\star$

as the characteristic mass density.

We prescribe the plate’s oscillation velocity,

![]() $\boldsymbol{U}_b(t) = (U_b(t), V_b(t))$

as follows:

$\boldsymbol{U}_b(t) = (U_b(t), V_b(t))$

as follows:

where the starred variables and parameters are dimensional and the unstarred variables and parameters are dimensionless. The latter include

![]() $A$

, the plate’s oscillation amplitude (relative to its length). The exponential term makes the simulated flow start smoothly from rest. We use

$A$

, the plate’s oscillation amplitude (relative to its length). The exponential term makes the simulated flow start smoothly from rest. We use

![]() $t_0=0.2$

for all the simulations because it is small enough to make the exponential term decay quickly but large enough to ensure a smooth start.

$t_0=0.2$

for all the simulations because it is small enough to make the exponential term decay quickly but large enough to ensure a smooth start.

The governing equations for an incompressible viscous flow in the (non-inertial) frame of reference attached to the moving plate are (Li, Sherwin & Bearman Reference Li, Sherwin and Bearman2002; Alben Reference Alben2021a )

with

![]() $\boldsymbol{u}(x, y, t)=(u(x, y, t), v(x, y, t))$

and

$\boldsymbol{u}(x, y, t)=(u(x, y, t), v(x, y, t))$

and

![]() $p(x, y, t)$

the flow velocity and pressure, respectively. Here,

$p(x, y, t)$

the flow velocity and pressure, respectively. Here,

![]() $Re_f$

is the frequency-based Reynolds number, included in the list of important dimensionless parameters for this problem

$Re_f$

is the frequency-based Reynolds number, included in the list of important dimensionless parameters for this problem

Here,

![]() $\boldsymbol{U}_{\infty } = (U_{\infty }, V_{\infty }) = (|\boldsymbol{U}_{\infty }|\cos (\gamma ), |\boldsymbol{U}_{\infty }|\sin (\gamma ))$

is the steady far-field oncoming flow velocity and

$\boldsymbol{U}_{\infty } = (U_{\infty }, V_{\infty }) = (|\boldsymbol{U}_{\infty }|\cos (\gamma ), |\boldsymbol{U}_{\infty }|\sin (\gamma ))$

is the steady far-field oncoming flow velocity and

![]() $\nu^{\star}$

is the kinematic viscosity of the fluid. Besides the frequency-based Reynolds number

$\nu^{\star}$

is the kinematic viscosity of the fluid. Besides the frequency-based Reynolds number

![]() $Re_f$

, we can also define a Reynolds number based on

$Re_f$

, we can also define a Reynolds number based on

![]() $\boldsymbol{U}_{\infty }$

, which is

$\boldsymbol{U}_{\infty }$

, which is

![]() $Re_U$

in equation (2.3), also given by the product of

$Re_U$

in equation (2.3), also given by the product of

![]() $Re_f$

and

$Re_f$

and

![]() $|\boldsymbol{U}_{\infty }|$

. In this study, we vary both

$|\boldsymbol{U}_{\infty }|$

. In this study, we vary both

![]() $Re_f$

and

$Re_f$

and

![]() $\boldsymbol{U}_{\infty }$

but fix

$\boldsymbol{U}_{\infty }$

but fix

![]() $Re_U=100$

. The physical interpretation is that the plate length, fluid viscosity and background flow speed are considered fixed, but the plate oscillation frequency varies (as do the oscillation amplitude and direction, and the plate orientation). Another important parameter is

$Re_U=100$

. The physical interpretation is that the plate length, fluid viscosity and background flow speed are considered fixed, but the plate oscillation frequency varies (as do the oscillation amplitude and direction, and the plate orientation). Another important parameter is

![]() $A/|\boldsymbol{U}_{\infty }|$

, which we term the ‘oscillation velocity.’ It is proportional to the ratio between the plate’s oscillation velocity amplitude,

$A/|\boldsymbol{U}_{\infty }|$

, which we term the ‘oscillation velocity.’ It is proportional to the ratio between the plate’s oscillation velocity amplitude,

![]() $2\pi f^\star A^\star$

, and the oncoming flow velocity magnitude,

$2\pi f^\star A^\star$

, and the oncoming flow velocity magnitude,

![]() $|\boldsymbol{U}^\star _{\infty }|$

. For transverse oscillation (

$|\boldsymbol{U}^\star _{\infty }|$

. For transverse oscillation (

![]() $\alpha = 90^\circ$

) in an in-plane flow (

$\alpha = 90^\circ$

) in an in-plane flow (

![]() $\gamma = 0^\circ$

), the `plunge velocity’ (Rahman & Tafti Reference Rahman and Tafti2020a

) (defined as

$\gamma = 0^\circ$

), the `plunge velocity’ (Rahman & Tafti Reference Rahman and Tafti2020a

) (defined as

![]() $\pi f^\star A^\star /|\boldsymbol{U}_{\infty }^\star | = \pi A/|\boldsymbol{U}_{\infty }|$

), or `Strouhal number’ (twice the oscillation velocity) (Triantafyllou et al. Reference Triantafyllou, Triantafyllou and Gopalkrishnan1991, Reference Triantafyllou, Triantafyllou and Grosenbaugh1993) are often used, particularly in studies of locomotion and fluid–structure interaction. Because we consider a wide range of oscillation and flow directions, we use ‘oscillation velocity’ for this class of motions. Rahman & Tafti (Reference Rahman and Tafti2020a

) found that the rate of heat transfer is increased at higher

$\pi f^\star A^\star /|\boldsymbol{U}_{\infty }^\star | = \pi A/|\boldsymbol{U}_{\infty }|$

), or `Strouhal number’ (twice the oscillation velocity) (Triantafyllou et al. Reference Triantafyllou, Triantafyllou and Gopalkrishnan1991, Reference Triantafyllou, Triantafyllou and Grosenbaugh1993) are often used, particularly in studies of locomotion and fluid–structure interaction. Because we consider a wide range of oscillation and flow directions, we use ‘oscillation velocity’ for this class of motions. Rahman & Tafti (Reference Rahman and Tafti2020a

) found that the rate of heat transfer is increased at higher

![]() $A/|\boldsymbol{U}_{\infty }|$

. However, the flow also becomes very chaotic at high

$A/|\boldsymbol{U}_{\infty }|$

. However, the flow also becomes very chaotic at high

![]() $A/|\boldsymbol{U}_{\infty }|$

. In this study, we mainly study flows with

$A/|\boldsymbol{U}_{\infty }|$

. In this study, we mainly study flows with

![]() $A/|\boldsymbol{U}_{\infty }|=0.2$

and

$A/|\boldsymbol{U}_{\infty }|=0.2$

and

![]() $0.3$

. At these relatively low

$0.3$

. At these relatively low

![]() $A/|\boldsymbol{U}_{\infty }|$

values (compared with the range studied by Rahman & Tafti (Reference Rahman and Tafti2020a

)), the flow is typically tractable and heat transfer enhancement is significant so that we can obtain insight into how oscillatory motions alter global and local heat transfer.

$A/|\boldsymbol{U}_{\infty }|$

values (compared with the range studied by Rahman & Tafti (Reference Rahman and Tafti2020a

)), the flow is typically tractable and heat transfer enhancement is significant so that we can obtain insight into how oscillatory motions alter global and local heat transfer.

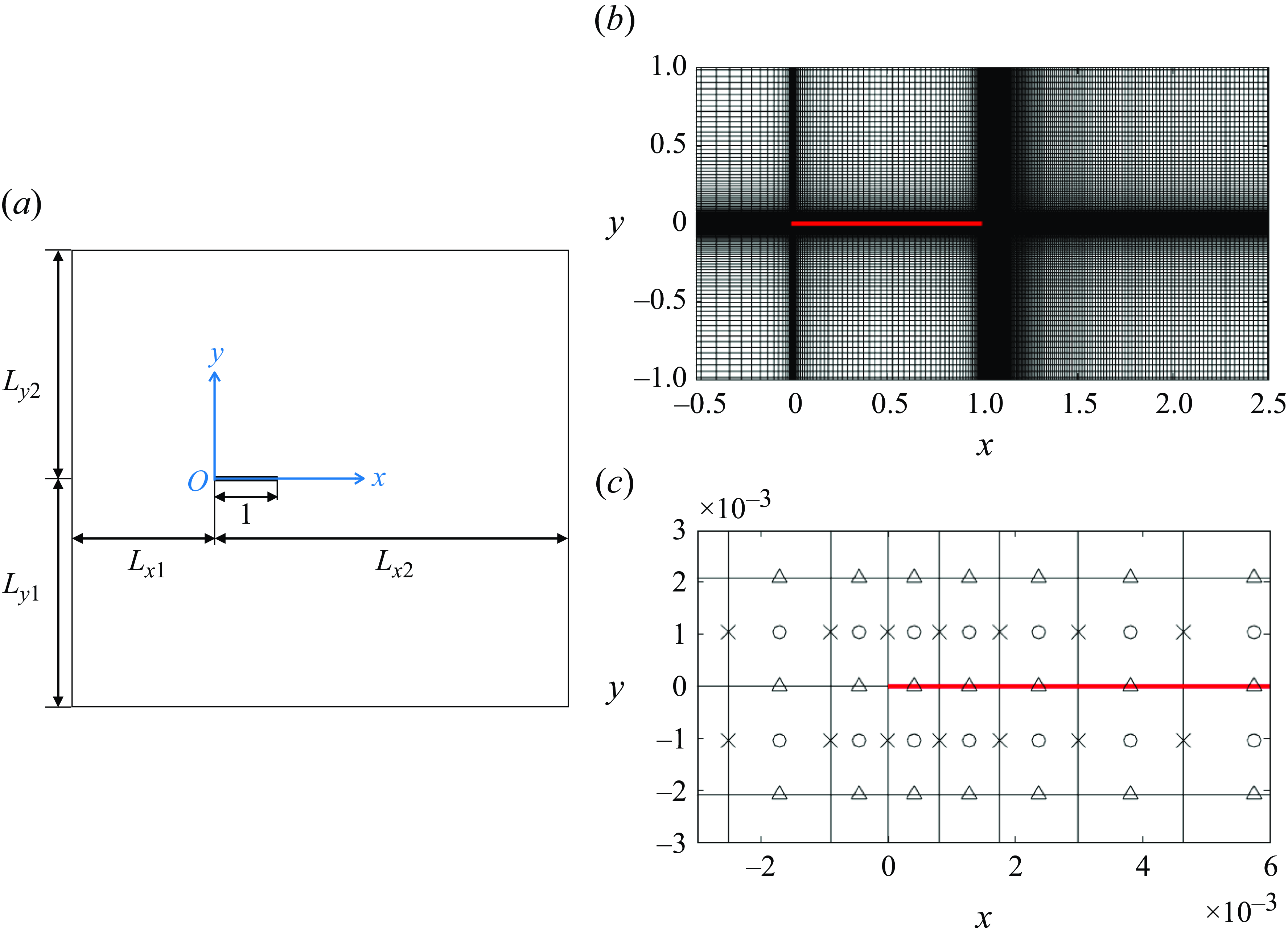

Figure 2. (a) Schematic of the computational domain. All the parameters shown are dimensionless. (b) Example of the non-uniform grid near the plate (red). (c) The marker-and-cell grid near the left edge of the plate. The flow velocity components

![]() $u$

and

$u$

and

![]() $v$

are solved at the crosses and triangles, respectively, while the pressure

$v$

are solved at the crosses and triangles, respectively, while the pressure

![]() $p$

and temperature

$p$

and temperature

![]() $T$

are solved at the circles.

$T$

are solved at the circles.

The temperature field

![]() $T(x,y,t)$

is governed by the unsteady advection-diffusion equation

$T(x,y,t)$

is governed by the unsteady advection-diffusion equation

where

![]() $Pr = \nu ^\star /\kappa ^\star$

is the Prandtl number, with

$Pr = \nu ^\star /\kappa ^\star$

is the Prandtl number, with

![]() $\kappa ^\star$

the thermal diffusivity. In this study, we take air as the fluid, with

$\kappa ^\star$

the thermal diffusivity. In this study, we take air as the fluid, with

![]() $Pr=0.7$

. As shown in figure 2(a), the heated plate is positioned at

$Pr=0.7$

. As shown in figure 2(a), the heated plate is positioned at

![]() $0\leqslant x \leqslant 1, y=0$

. For the temperature boundary conditions on the plate, we consider two cases

$0\leqslant x \leqslant 1, y=0$

. For the temperature boundary conditions on the plate, we consider two cases

In (2.5) the plate temperature is fixed, while in (2.6) the heat flux per unit plate length is fixed. In the latter case we have also equated the temperatures of the top and bottom surfaces of the plate, as we assume the plate is a thin conducting material. If instead of (2.6) we used

![]() $-\partial _y T(y=0^+) = \partial _y T(y=0^-) = 1$

, the top and bottom surfaces of the plate would have different temperatures in general.

$-\partial _y T(y=0^+) = \partial _y T(y=0^-) = 1$

, the top and bottom surfaces of the plate would have different temperatures in general.

We solve equation (2.2) as a fully coupled system for

![]() $\boldsymbol{u}$

and

$\boldsymbol{u}$

and

![]() $p$

, using essentially the same method as in Alben (Reference Alben2021a

), a second-order finite-difference method on the MAC (marker-and-cell) grid (Harlow & Welch Reference Harlow and Welch1965). A portion of the MAC grid is shown in figure 2(c). We solve

$p$

, using essentially the same method as in Alben (Reference Alben2021a

), a second-order finite-difference method on the MAC (marker-and-cell) grid (Harlow & Welch Reference Harlow and Welch1965). A portion of the MAC grid is shown in figure 2(c). We solve

![]() $u$

at the crosses,

$u$

at the crosses,

![]() $v$

at the triangles and

$v$

at the triangles and

![]() $p$

at the circles. The grid spacing is larger toward the boundary of the computational domain and smaller near the plate, where the vorticity is large. An example of the grid is shown in figure 2(b). The details for generating the non-uniform mesh are given in Appendix A. The distances from the plate to the outer boundary (given by

$p$

at the circles. The grid spacing is larger toward the boundary of the computational domain and smaller near the plate, where the vorticity is large. An example of the grid is shown in figure 2(b). The details for generating the non-uniform mesh are given in Appendix A. The distances from the plate to the outer boundary (given by

![]() $L_{x1}$

,

$L_{x1}$

,

![]() $L_{x2}$

,

$L_{x2}$

,

![]() $L_{y1}$

,

$L_{y1}$

,

![]() $L_{y2}$

in figure 2(a) and the outer boundary conditions are chosen differently for each value of

$L_{y2}$

in figure 2(a) and the outer boundary conditions are chosen differently for each value of

![]() $\gamma$

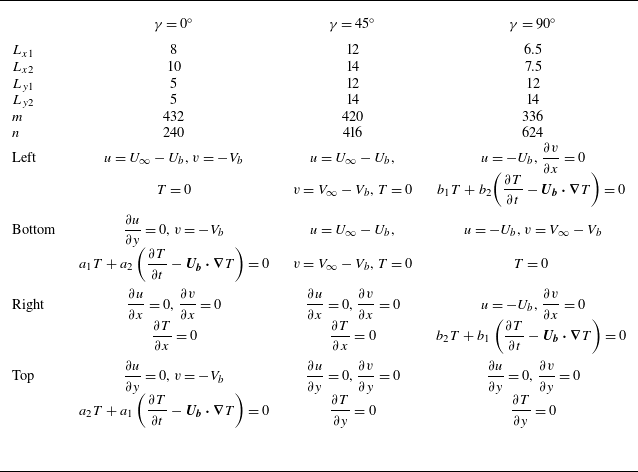

to limit the influence of the outer boundary. We use Dirichlet boundary conditions at the inflow sides and Neumann boundary conditions at the outflow sides. For sides parallel to the mean oncoming flow, we set the normal velocity to the far-field value, and impose zero shear, to avoid vorticity generation (Tamaddon-Jahromi, Townsend & Webster Reference Tamaddon-Jahromi, Townsend and Webster1994; Sen, Mittal & Biswas Reference Sen, Mittal and Biswas2009). These boundary conditions are listed in table 1. On the plate surface, we apply no-slip boundary conditions. At

$\gamma$

to limit the influence of the outer boundary. We use Dirichlet boundary conditions at the inflow sides and Neumann boundary conditions at the outflow sides. For sides parallel to the mean oncoming flow, we set the normal velocity to the far-field value, and impose zero shear, to avoid vorticity generation (Tamaddon-Jahromi, Townsend & Webster Reference Tamaddon-Jahromi, Townsend and Webster1994; Sen, Mittal & Biswas Reference Sen, Mittal and Biswas2009). These boundary conditions are listed in table 1. On the plate surface, we apply no-slip boundary conditions. At

![]() $t=0$

, we assume steady uniform flow with

$t=0$

, we assume steady uniform flow with

![]() $\boldsymbol{u}(x,y,0) = \boldsymbol{U}_{\infty }$

(at points off of the plate), except in one case,

$\boldsymbol{u}(x,y,0) = \boldsymbol{U}_{\infty }$

(at points off of the plate), except in one case,

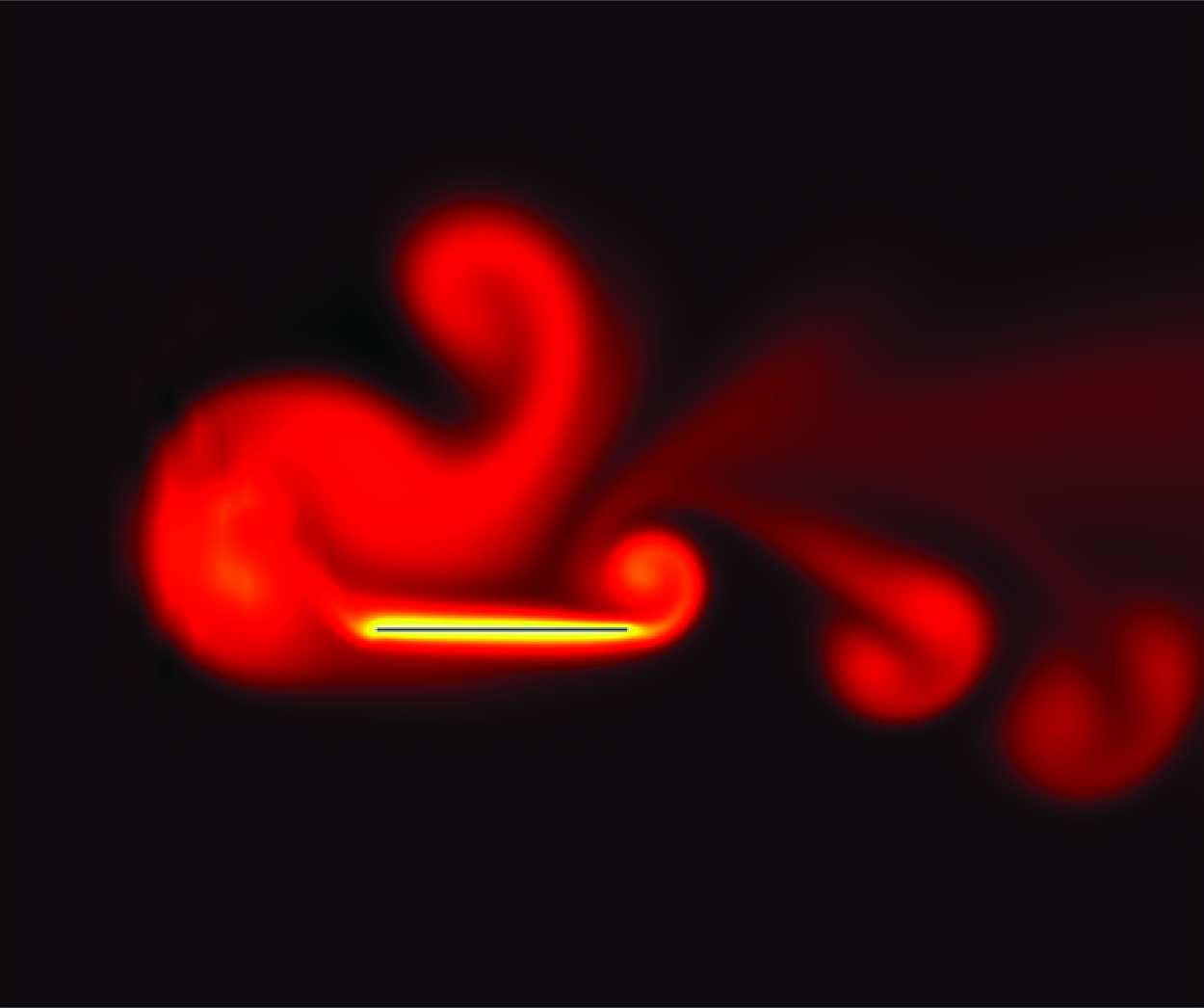

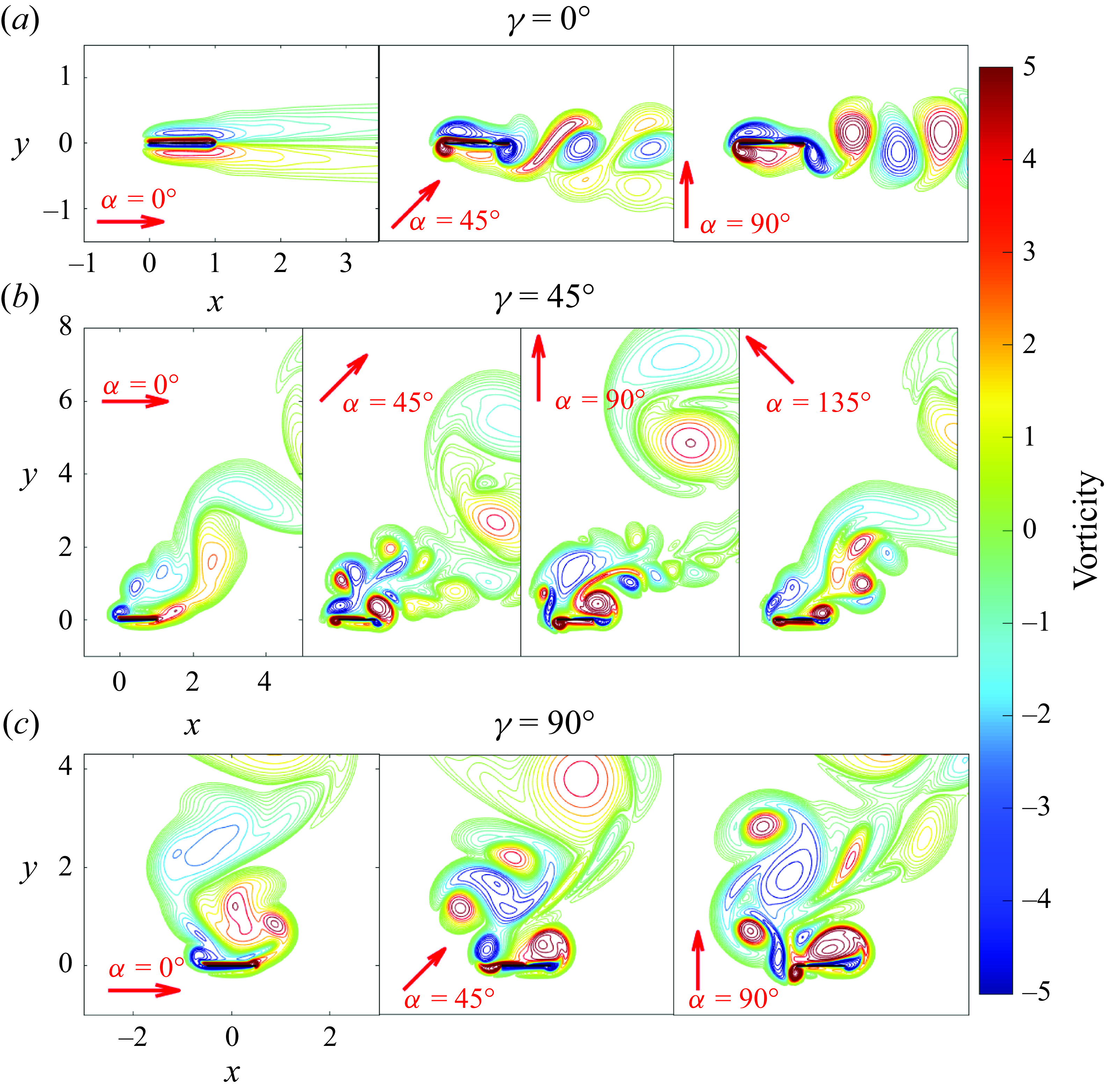

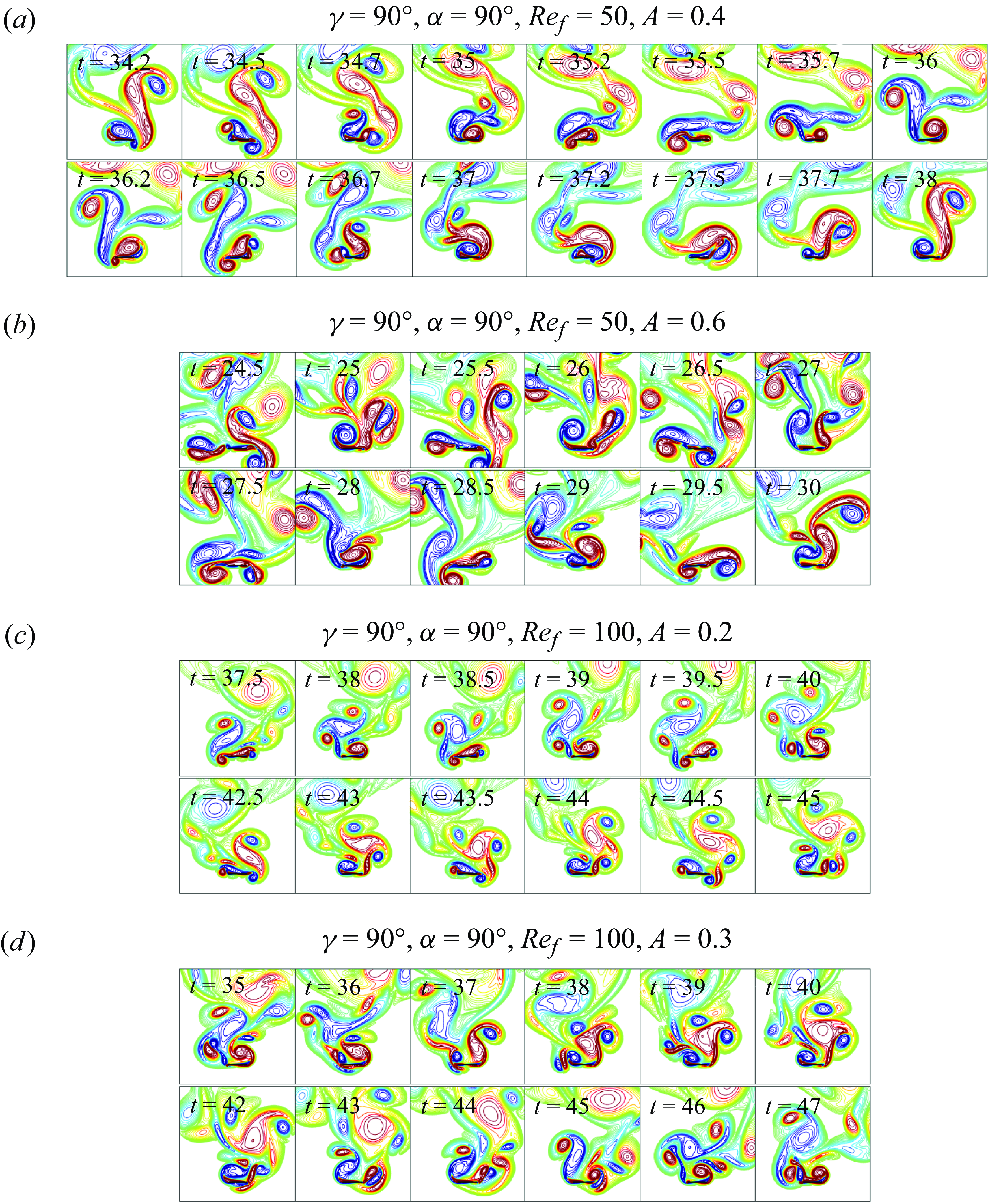

![]() $\alpha = \gamma = 90^\circ$

, where we use an asymmetric initial flow described in § 4.2.3. In figure 3 we provide examples of typical vorticity fields, with

$\alpha = \gamma = 90^\circ$

, where we use an asymmetric initial flow described in § 4.2.3. In figure 3 we provide examples of typical vorticity fields, with

![]() $\gamma$

increasing from the top row to the bottom row, and

$\gamma$

increasing from the top row to the bottom row, and

![]() $\alpha$

increasing from left to right within each row. The overall orientation of the wake relative to the body is set by

$\alpha$

increasing from left to right within each row. The overall orientation of the wake relative to the body is set by

![]() $\gamma$

; both

$\gamma$

; both

![]() $\gamma$

and

$\gamma$

and

![]() $\alpha$

affect the vorticity patterns around the body and particularly within the wake. A main focus of the current study is the effect of these vorticity patterns on heat transfer.

$\alpha$

affect the vorticity patterns around the body and particularly within the wake. A main focus of the current study is the effect of these vorticity patterns on heat transfer.

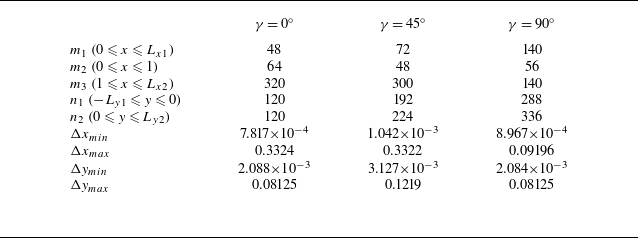

Table 1. The dimensions of the computational domain, the number of grid cells along

![]() $x$

and

$x$

and

![]() $y$

(denoted

$y$

(denoted

![]() $m$

and

$m$

and

![]() $n$

, respectively) and the boundary conditions, with

$n$

, respectively) and the boundary conditions, with

![]() $a_1 = (1+\textrm{sign}(-V_b))/2$

,

$a_1 = (1+\textrm{sign}(-V_b))/2$

,

![]() $a_2 = (1-\textrm{sign}(-V_b))/2$

,

$a_2 = (1-\textrm{sign}(-V_b))/2$

,

![]() $b_1 = (1+\textrm{sign}(-U_b))/2$

and

$b_1 = (1+\textrm{sign}(-U_b))/2$

and

![]() $b_2 = (1-\textrm{sign}(-U_b))/2$

.

$b_2 = (1-\textrm{sign}(-U_b))/2$

.

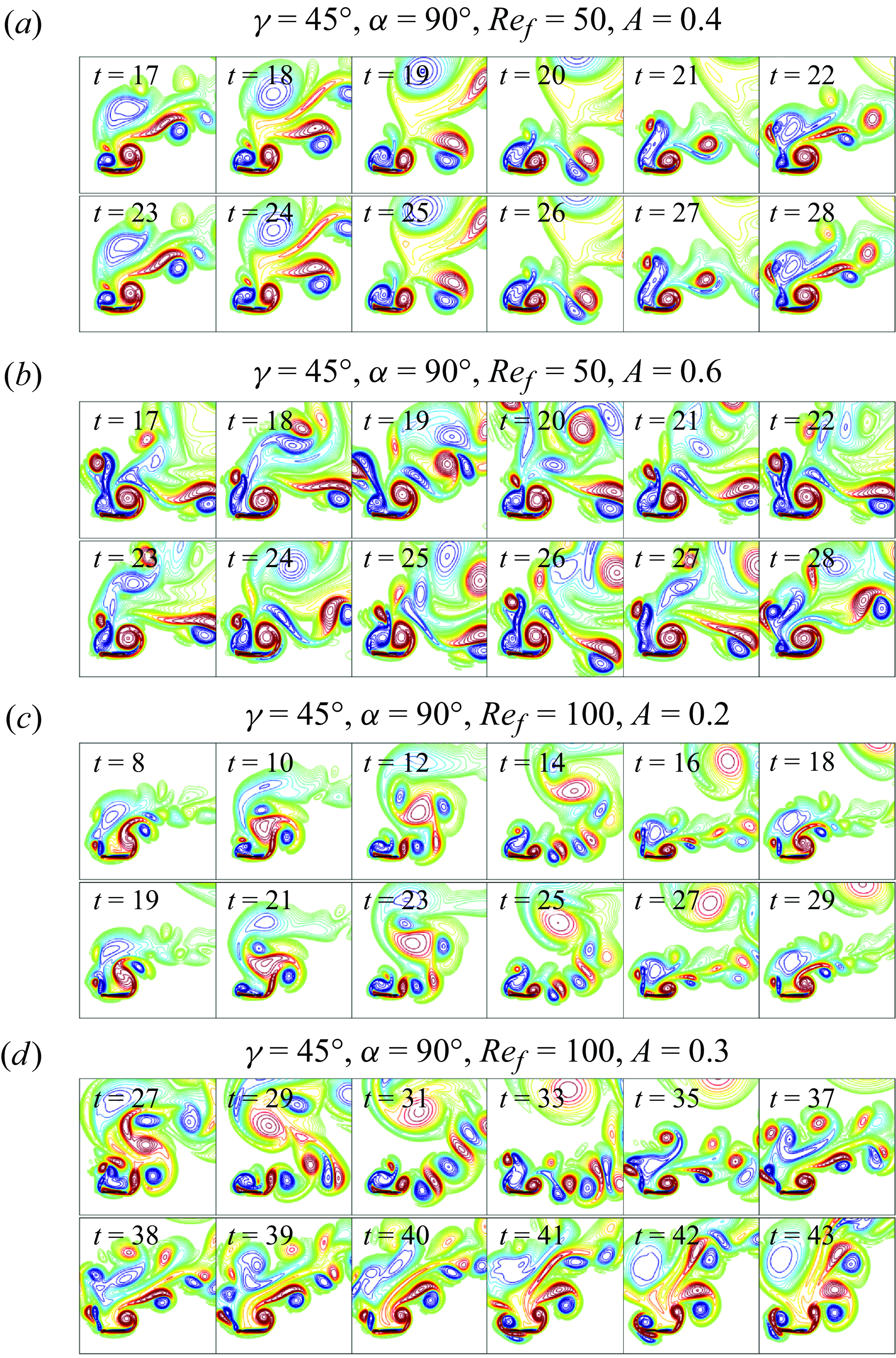

Figure 3. Examples of the vorticity fields for different plate orientations and oscillation directions. The rows from top to bottom have (a)

![]() $\gamma = 0^\circ$

, (b)

$\gamma = 0^\circ$

, (b)

![]() $45^\circ$

and (c)

$45^\circ$

and (c)

![]() $90^\circ$

. The red arrow indicates instantaneous plate oscillation direction given by

$90^\circ$

. The red arrow indicates instantaneous plate oscillation direction given by

![]() $\alpha$

. Within each row,

$\alpha$

. Within each row,

![]() $\alpha$

increases in increments of

$\alpha$

increases in increments of

![]() $45^\circ$

moving rightward, starting at

$45^\circ$

moving rightward, starting at

![]() $0^\circ$

in the leftmost panel. All of the examples have

$0^\circ$

in the leftmost panel. All of the examples have

![]() $Re_f=100$

,

$Re_f=100$

,

![]() $Re_U=100$

,

$Re_U=100$

,

![]() $A=0.2$

and

$A=0.2$

and

![]() $A/|\boldsymbol{U}_{\infty }|=0.2$

.

$A/|\boldsymbol{U}_{\infty }|=0.2$

.

After computing the flow velocity

![]() $\boldsymbol{u}$

, we solve for the temperature using a second-order discretisation of (2.4) at the same grid points as

$\boldsymbol{u}$

, we solve for the temperature using a second-order discretisation of (2.4) at the same grid points as

![]() $p$

(the centres of the MAC grid cells). Either (2.5) or (2.6) is applied in one-sided finite-difference formulas for the

$p$

(the centres of the MAC grid cells). Either (2.5) or (2.6) is applied in one-sided finite-difference formulas for the

![]() $y$

-derivatives in (2.4) on either side of the plate, depending on whether we fix the plate temperature or the heat flux. As with

$y$

-derivatives in (2.4) on either side of the plate, depending on whether we fix the plate temperature or the heat flux. As with

![]() $\boldsymbol{u}$

, we apply different outer boundary conditions for

$\boldsymbol{u}$

, we apply different outer boundary conditions for

![]() $T$

depending on

$T$

depending on

![]() $\gamma$

, i.e. which sides of the computational domain are the inflow and outflow boundaries. These are listed in table 1. We apply

$\gamma$

, i.e. which sides of the computational domain are the inflow and outflow boundaries. These are listed in table 1. We apply

![]() $T=0$

at inflow boundaries and

$T=0$

at inflow boundaries and

![]() $\partial T/\partial n = 0$

at outflow boundaries, with

$\partial T/\partial n = 0$

at outflow boundaries, with

![]() $\partial /\partial n$

the normal derivative. For sides parallel to the mean oncoming flow, we switch between Dirichlet and outflow boundary conditions for

$\partial /\partial n$

the normal derivative. For sides parallel to the mean oncoming flow, we switch between Dirichlet and outflow boundary conditions for

![]() $T$

depending on whether the flow is inward or outward at a given time, as shown in table 1. At

$T$

depending on whether the flow is inward or outward at a given time, as shown in table 1. At

![]() $t = 0$

the temperature is set to zero at all points in the fluid, i.e.

$t = 0$

the temperature is set to zero at all points in the fluid, i.e.

![]() $T(x,y,0)=0$

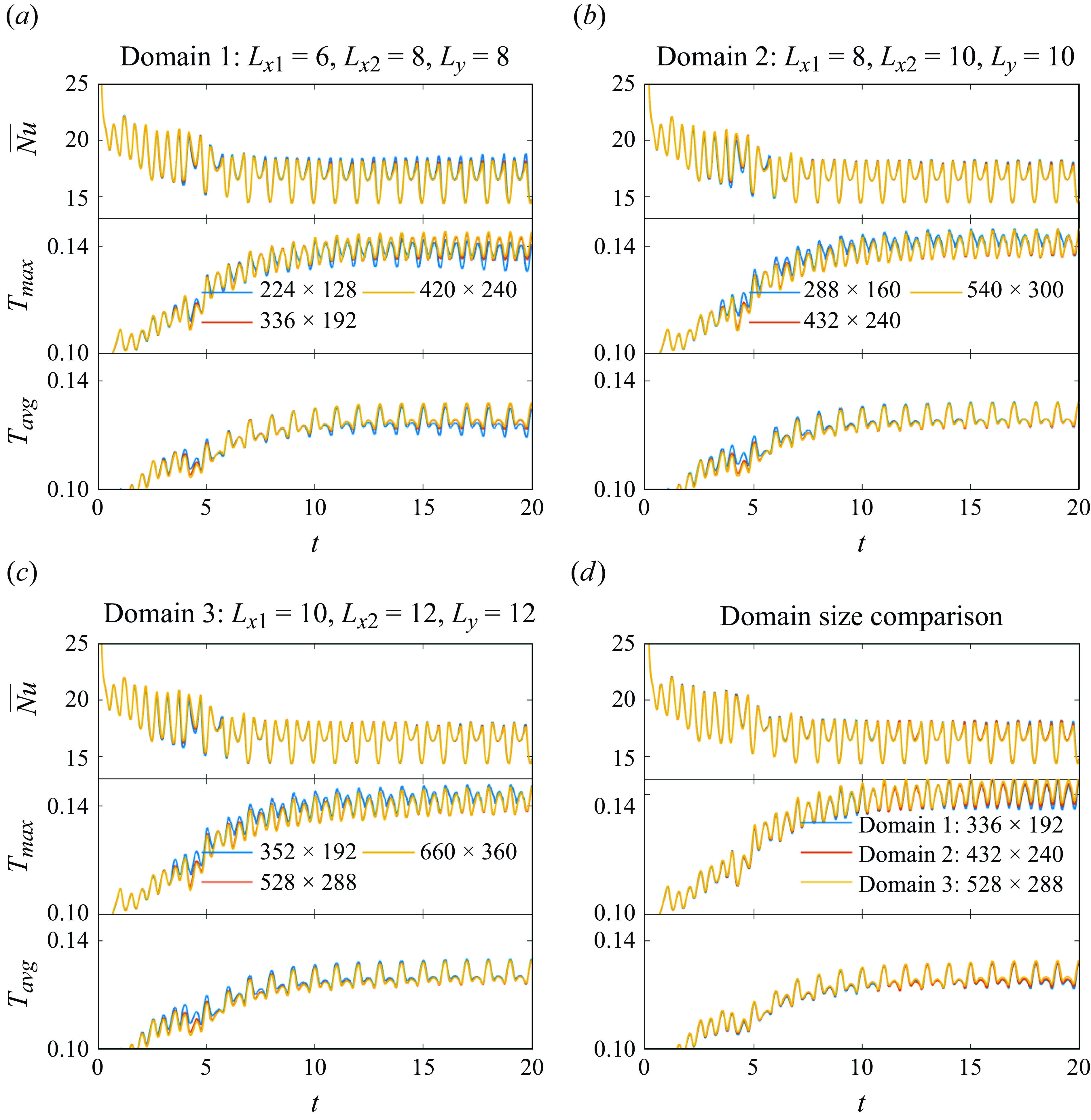

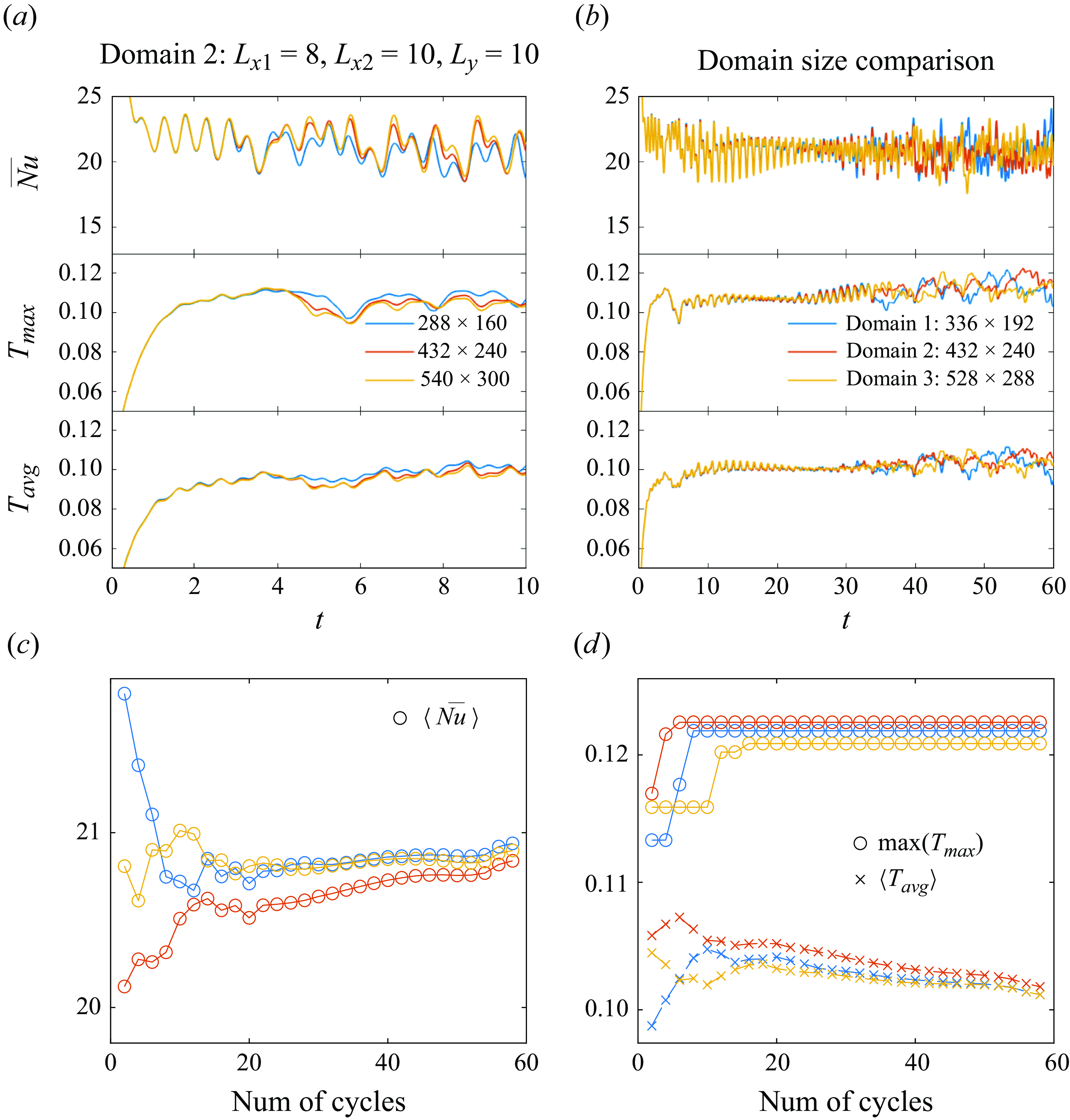

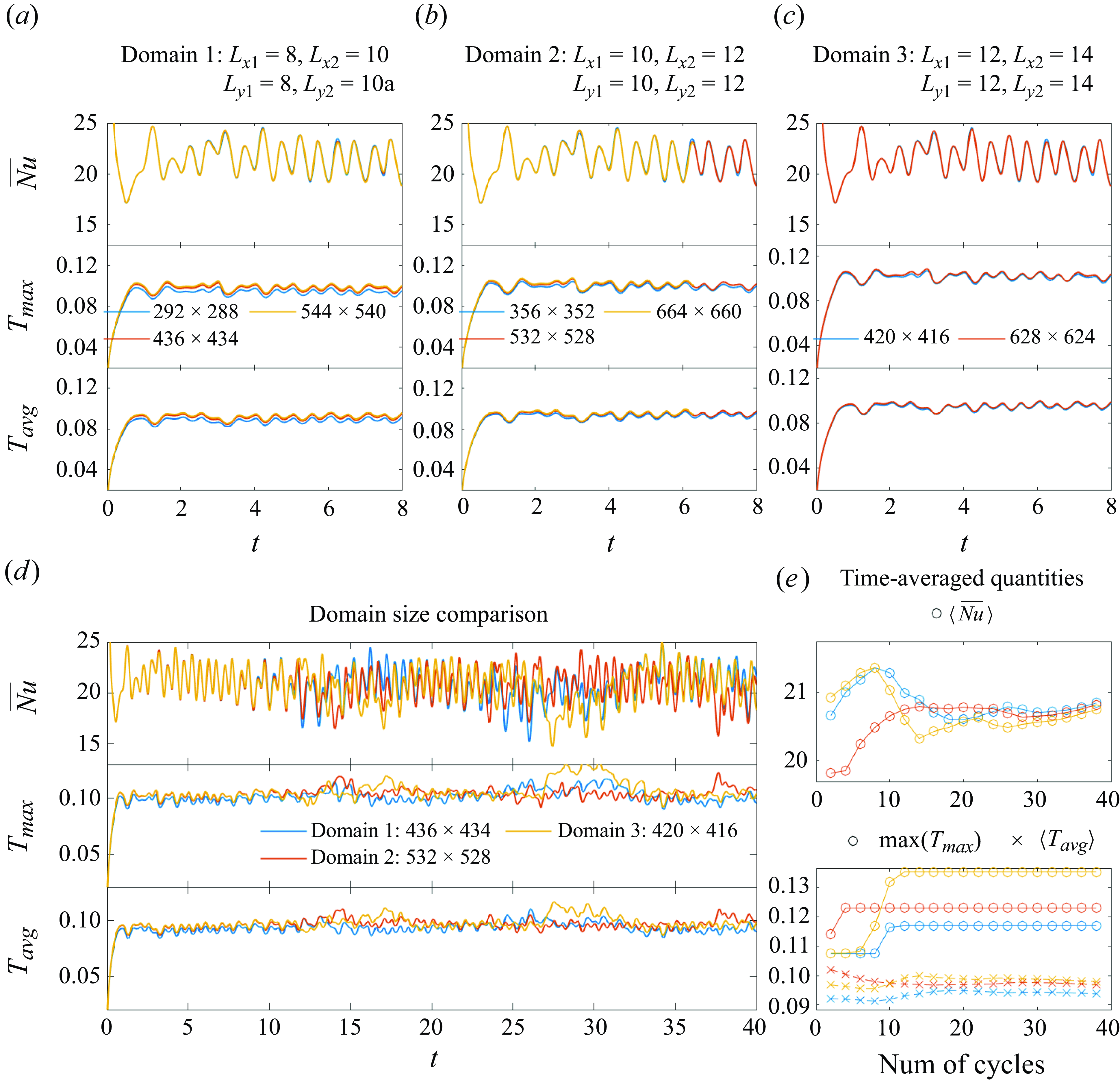

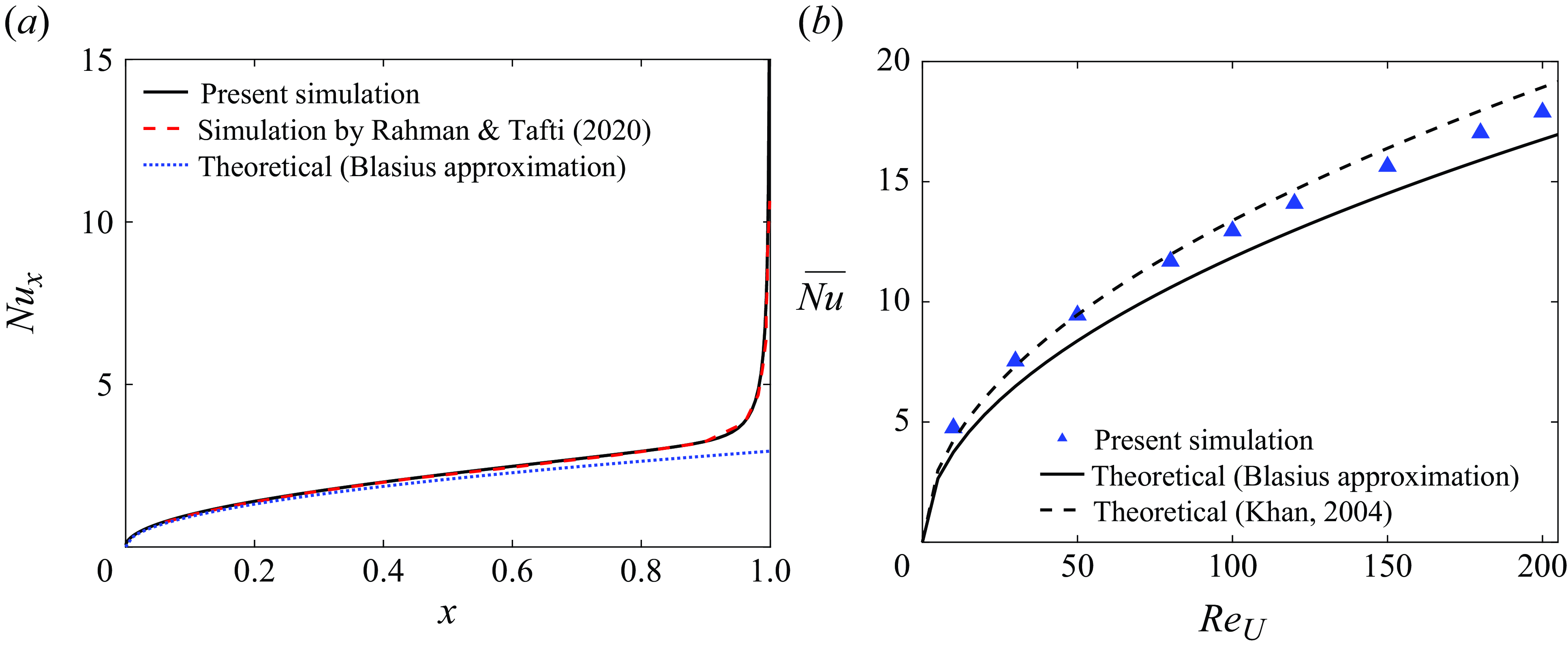

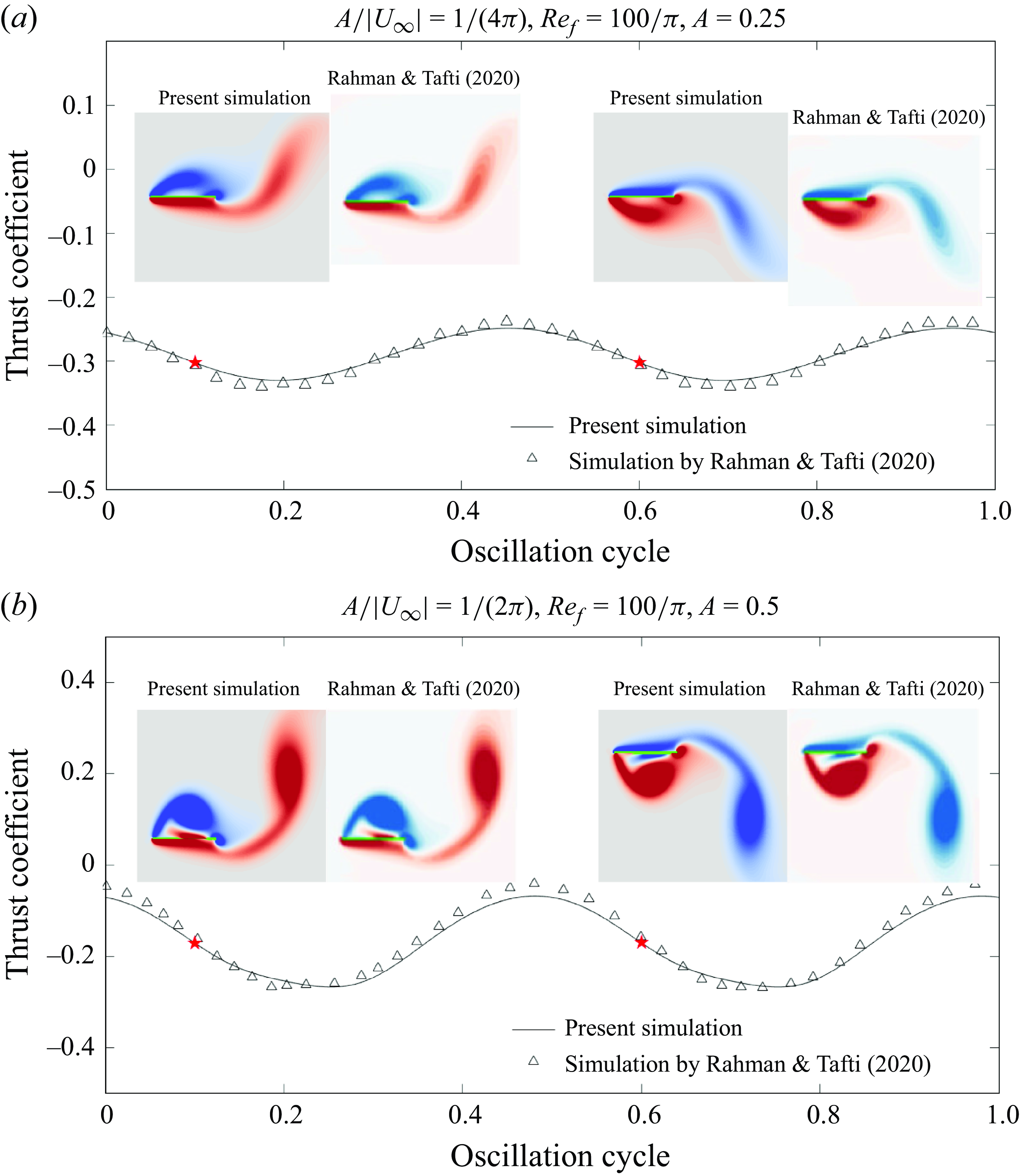

. A comparison of results with different domain and mesh sizes is given in Appendix B. Validations of our numerical method against previous theoretical and computational results are provided in Appendix C.

$T(x,y,0)=0$

. A comparison of results with different domain and mesh sizes is given in Appendix B. Validations of our numerical method against previous theoretical and computational results are provided in Appendix C.

The main heat transfer performance metric in this study is the Nusselt number, the local heat flux relative to the difference between the plate temperature

![]() $T_{{plate}}$

and the far-field fluid temperature

$T_{{plate}}$

and the far-field fluid temperature

![]() $T_\infty$

, set to zero here (Incropera et al. Reference Incropera, DeWitt, Bergman and Lavine2006)

$T_\infty$

, set to zero here (Incropera et al. Reference Incropera, DeWitt, Bergman and Lavine2006)

A larger rate of heat transfer corresponds to larger

![]() $Nu$

. With the fixed-plate-temperature boundary condition, the denominator of (2.7) is fixed at unity while the numerator varies along the plate. We consider two local and one global Nusselt number in this case

$Nu$

. With the fixed-plate-temperature boundary condition, the denominator of (2.7) is fixed at unity while the numerator varies along the plate. We consider two local and one global Nusselt number in this case

\begin{align} &Nu_{{top}}(x, t) = -\left .\frac {\partial T}{\partial y}\right |_{y=0^+}, \quad Nu_{{bot}}(x,t) = \left .\frac {\partial T}{\partial y}\right |_{y=0^-},\nonumber\\& \qquad \overline {Nu}(t) = \displaystyle \int _0^1 -\left .\frac {\partial T}{\partial y}\right |_{y=0^+} + \left .\frac {\partial T}{\partial y}\right |_{y=0^-}\, \textrm{d}x. \end{align}

\begin{align} &Nu_{{top}}(x, t) = -\left .\frac {\partial T}{\partial y}\right |_{y=0^+}, \quad Nu_{{bot}}(x,t) = \left .\frac {\partial T}{\partial y}\right |_{y=0^-},\nonumber\\& \qquad \overline {Nu}(t) = \displaystyle \int _0^1 -\left .\frac {\partial T}{\partial y}\right |_{y=0^+} + \left .\frac {\partial T}{\partial y}\right |_{y=0^-}\, \textrm{d}x. \end{align}

The first two Nusselt numbers are the local heat fluxes from the plate’s top and bottom surfaces, respectively, while the third is the global Nusselt number, the total heat flux from both plate surfaces.

With the fixed-heat-flux boundary condition, the numerator of (2.7) summed over both sides of the plate is fixed at each

![]() $x$

while

$x$

while

![]() $T_{{plate}}$

in the denominator varies with

$T_{{plate}}$

in the denominator varies with

![]() $x$

. In this case

$x$

. In this case

![]() $Nu$

is inversely proportional to

$Nu$

is inversely proportional to

![]() $T_{{plate}}$

, so lower plate temperature corresponds to better heat transfer performance. In this case, instead of

$T_{{plate}}$

, so lower plate temperature corresponds to better heat transfer performance. In this case, instead of

![]() $Nu$

, we use the plate-temperature distribution

$Nu$

, we use the plate-temperature distribution

![]() $T_{{plate}}(x, t)$

, the maximum plate temperature

$T_{{plate}}(x, t)$

, the maximum plate temperature

![]() $T_{max }(t)$

and the spatially averaged plate temperature

$T_{max }(t)$

and the spatially averaged plate temperature

![]() $T_{{avg}}(t)$

as performance metrics

$T_{{avg}}(t)$

as performance metrics

In the following sections, we will also examine the time averages of quantities in equations (2.8) and (2.9), denoted as

![]() $\langle \cdot \rangle$

. In § 4.1 we explain how we choose appropriate time spans for the time averages.

$\langle \cdot \rangle$

. In § 4.1 we explain how we choose appropriate time spans for the time averages.

3. Non-oscillating plate in steady oncoming flows

In figures 4 and 5, we show results for a non-oscillating plate in steady oncoming flows, which can be taken as a reference state for investigating how plate oscillations influence heat transfer. As in the cases with oscillating plates, the Reynolds number of the oncoming flow is fixed at

![]() $Re_U=100$

for different plate orientations. However, since the plate is not oscillating,

$Re_U=100$

for different plate orientations. However, since the plate is not oscillating,

![]() $t$

is non-dimensionalised using

$t$

is non-dimensionalised using

![]() $\ell ^\star /|\boldsymbol{U}^\star _{\infty }|$

instead of

$\ell ^\star /|\boldsymbol{U}^\star _{\infty }|$

instead of

![]() $1/f^\star$

.

$1/f^\star$

.

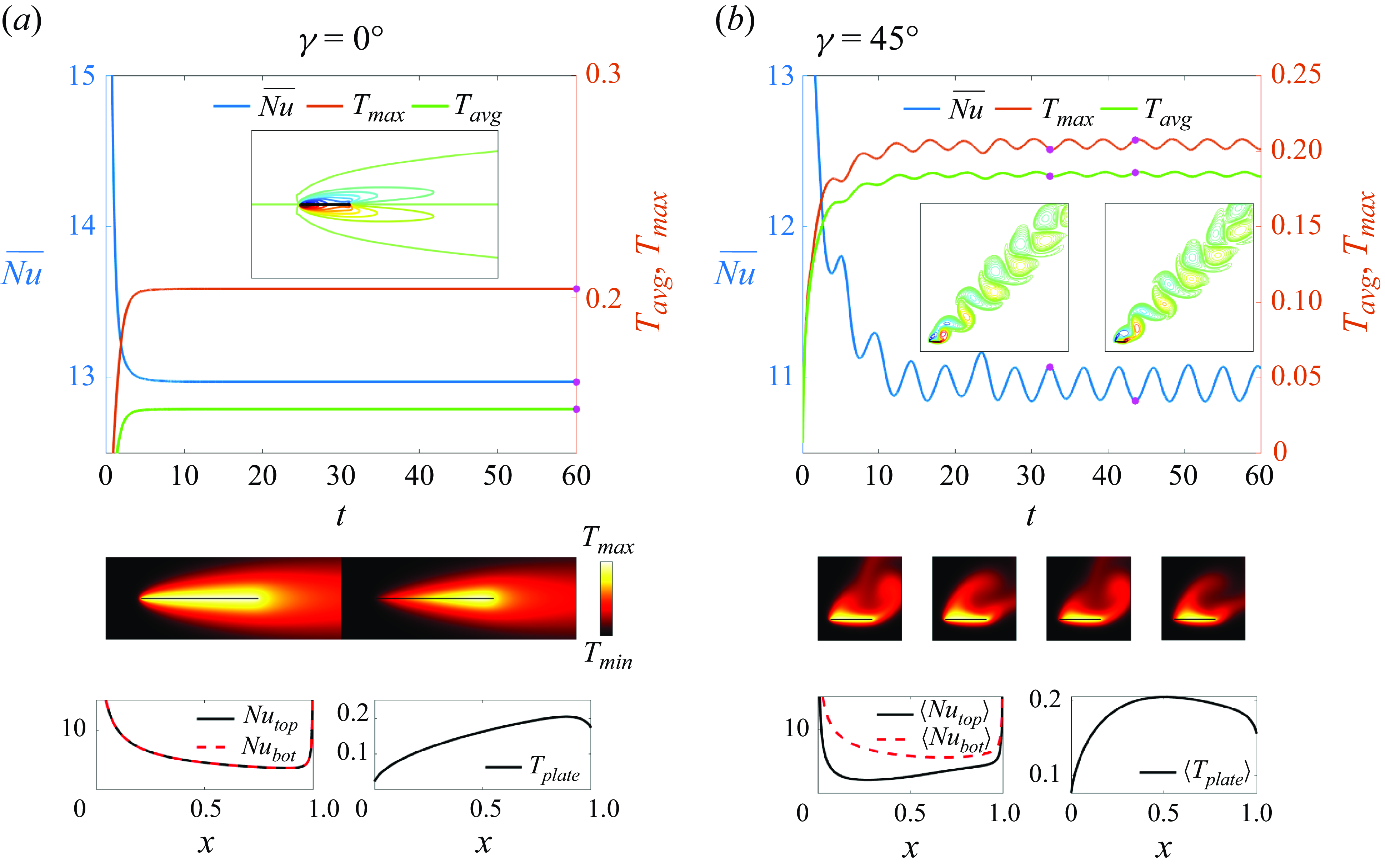

Figure 4. Heat transfer from a non-oscillating plate in steady oncoming flows angled at

![]() $\gamma = 0^\circ$

(panel (a)), and

$\gamma = 0^\circ$

(panel (a)), and

![]() $\gamma = 45^\circ$

(panel (b)). The time series of

$\gamma = 45^\circ$

(panel (b)). The time series of

![]() $\overline {Nu}$

,

$\overline {Nu}$

,

![]() $T_{max }$

and

$T_{max }$

and

![]() $T_{{avg}}$

with selected snapshots of the vorticity field and temperature field (at times marked with pink dots) are shown for each case. In panel (a), the temperature field snapshots show the isothermal-plate and fixed-flux cases on the left and right, respectively. In panel (b) the same quantities are shown but with four temperature snapshots, the leftmost two for the isothermal-plate case, and the rightmost two for the fixed-flux case. At the bottom of each panel, the local

$T_{{avg}}$

with selected snapshots of the vorticity field and temperature field (at times marked with pink dots) are shown for each case. In panel (a), the temperature field snapshots show the isothermal-plate and fixed-flux cases on the left and right, respectively. In panel (b) the same quantities are shown but with four temperature snapshots, the leftmost two for the isothermal-plate case, and the rightmost two for the fixed-flux case. At the bottom of each panel, the local

![]() $Nu$

and plate temperatures are shown, steady in panel (a) and averaged over the last four periods in panel (b).

$Nu$

and plate temperatures are shown, steady in panel (a) and averaged over the last four periods in panel (b).

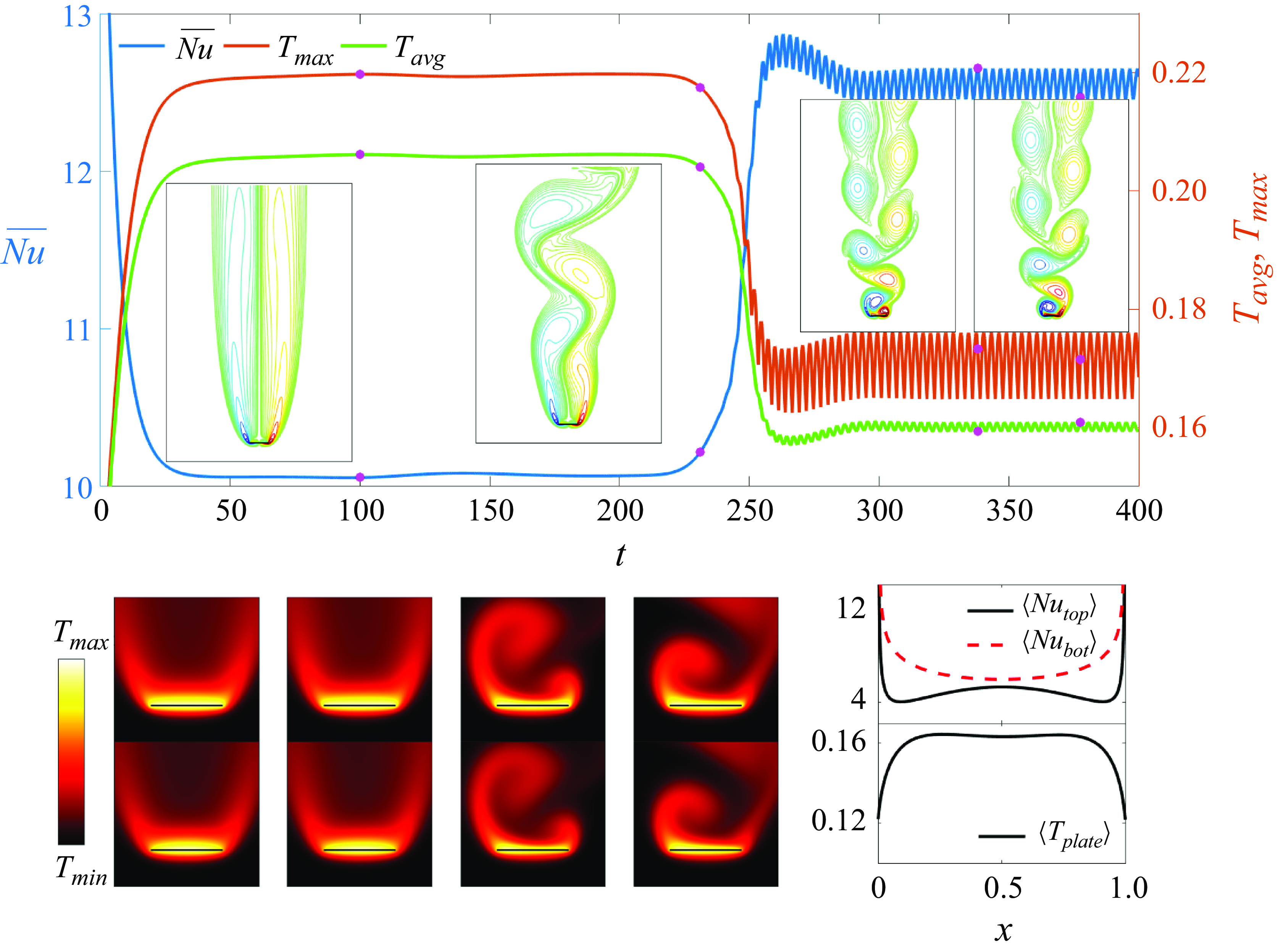

Figure 5. Heat transfer from a non-oscillating plate in a steady oncoming flow angled at

![]() $\gamma = 90^\circ$

. The time series of

$\gamma = 90^\circ$

. The time series of

![]() $\overline {Nu}$

,

$\overline {Nu}$

,

![]() $T_{max }$

and

$T_{max }$

and

![]() $T_{{avg}}$

with selected snapshots of the vorticity field and temperature field (at times marked with pink dots) are shown at the bottom left. The first row of the temperature snapshots is for the isothermal case and the second row is for the fixed-flux case. The local

$T_{{avg}}$

with selected snapshots of the vorticity field and temperature field (at times marked with pink dots) are shown at the bottom left. The first row of the temperature snapshots is for the isothermal case and the second row is for the fixed-flux case. The local

![]() $Nu$

and plate temperature, averaged over the last four periods, are shown at the bottom right.

$Nu$

and plate temperature, averaged over the last four periods, are shown at the bottom right.

In figure 4(a) the plate is aligned with the flow (

![]() $\gamma =0^\circ$

). We have rapid convergence to a steady flow with symmetrical boundary layers along both sides of the plate. The temperature field is also up–down symmetric, and the thickness of the thermal boundary layer increases toward the trailing edge (the right edge). For the isothermal plate (left sides of the bottom rows of panel (a)), the local Nusselt number is equal on the top and bottom surfaces, and larger near the leading edge than the trailing edge. Previous computations show that the local Nusselt number diverges at both edges (Dennis & Smith Reference Dennis and Smith1966; Rahman & Tafti Reference Rahman and Tafti2020a

). When instead the heat flux from the plate is fixed (right sides of the bottom rows of panel (a)), the hottest spot is located slightly upstream of the trailing edge.

$\gamma =0^\circ$

). We have rapid convergence to a steady flow with symmetrical boundary layers along both sides of the plate. The temperature field is also up–down symmetric, and the thickness of the thermal boundary layer increases toward the trailing edge (the right edge). For the isothermal plate (left sides of the bottom rows of panel (a)), the local Nusselt number is equal on the top and bottom surfaces, and larger near the leading edge than the trailing edge. Previous computations show that the local Nusselt number diverges at both edges (Dennis & Smith Reference Dennis and Smith1966; Rahman & Tafti Reference Rahman and Tafti2020a

). When instead the heat flux from the plate is fixed (right sides of the bottom rows of panel (a)), the hottest spot is located slightly upstream of the trailing edge.

In figure 4(b), with an oblique oncoming flow relative to the plate (

![]() $\gamma =45^\circ$

), we observe a periodic flow with a von Kármán vortex street wake instead of the steady flow at

$\gamma =45^\circ$

), we observe a periodic flow with a von Kármán vortex street wake instead of the steady flow at

![]() $\gamma =0^\circ$

. During one complete period, a negative vortex (in blue) and a positive vortex (in red) form and shed at the left and right edges of the top wall alternately. Because the flow is oblique, the negative vortex covers a larger portion of the top wall, shown in the rightmost vorticity snapshot in panel (b). The rotation of the negative vortex sweeps hot fluid along the top surface from the right edge toward the left edge, which makes the thermal boundary layer thicker near the left edge. Therefore, the time-averaged local Nusselt number of the top wall

$\gamma =0^\circ$

. During one complete period, a negative vortex (in blue) and a positive vortex (in red) form and shed at the left and right edges of the top wall alternately. Because the flow is oblique, the negative vortex covers a larger portion of the top wall, shown in the rightmost vorticity snapshot in panel (b). The rotation of the negative vortex sweeps hot fluid along the top surface from the right edge toward the left edge, which makes the thermal boundary layer thicker near the left edge. Therefore, the time-averaged local Nusselt number of the top wall

![]() $\langle Nu_{{top}} \rangle$

(black solid line), which is roughly the inverse of the temperature boundary layer thickness, has a minimum near the left edge. There are no vortices adjacent to the bottom wall, and the thermal boundary layer thickness is more uniform along the bottom wall. The thermal boundary layer is much thinner along the bottom wall, so

$\langle Nu_{{top}} \rangle$

(black solid line), which is roughly the inverse of the temperature boundary layer thickness, has a minimum near the left edge. There are no vortices adjacent to the bottom wall, and the thermal boundary layer thickness is more uniform along the bottom wall. The thermal boundary layer is much thinner along the bottom wall, so

![]() $\langle Nu_{{bot}} \rangle \gt \langle Nu_{{top}} \rangle$

. The temperature fields in the case of fixed heat flux from the plate (two rightmost snapshots) are qualitatively similar to those for the isothermal plate (two leftmost snapshots). The time-averaged plate temperature

$\langle Nu_{{bot}} \rangle \gt \langle Nu_{{top}} \rangle$

. The temperature fields in the case of fixed heat flux from the plate (two rightmost snapshots) are qualitatively similar to those for the isothermal plate (two leftmost snapshots). The time-averaged plate temperature

![]() $\langle T_{{plate}} \rangle$

rises sharply from the left edge to a maximum near the centre, and decreases more gradually on the right side.

$\langle T_{{plate}} \rangle$

rises sharply from the left edge to a maximum near the centre, and decreases more gradually on the right side.

For the vertical oncoming flow (

![]() $\gamma =90^\circ$

) in figure 5, the vortex wake instead has a long transition from a symmetric initial state to the time-periodic alternating-vortex-shedding state. Initially, there is a pair of recirculation bubbles behind the plate, and the corresponding temperature field is symmetric about the middle of the plate, as shown in the first column of the temperature snapshots. The thermal boundary layer thickness is fairly uniform and thinner along the bottom wall, as before. Small asymmetric perturbations (from numerical round-off error) grow exponentially during this time and reach O(1) amplitude at

$\gamma =90^\circ$

) in figure 5, the vortex wake instead has a long transition from a symmetric initial state to the time-periodic alternating-vortex-shedding state. Initially, there is a pair of recirculation bubbles behind the plate, and the corresponding temperature field is symmetric about the middle of the plate, as shown in the first column of the temperature snapshots. The thermal boundary layer thickness is fairly uniform and thinner along the bottom wall, as before. Small asymmetric perturbations (from numerical round-off error) grow exponentially during this time and reach O(1) amplitude at

![]() $t \approx 200$

. During this instability, which has been studied more extensively for circular cylinders than for flat plates (Thompson et al. Reference Thompson, Radi, Rao, Sheridan and Hourigan2014), the long recirculation bubbles become wavy and shed vortices, as shown in the second vorticity field snapshot. However, the corresponding temperature field close to the plate does not change much from the first stage, as shown in the second column of the temperature snapshots, because the flow is still fairly symmetric close to the plate. At

$t \approx 200$

. During this instability, which has been studied more extensively for circular cylinders than for flat plates (Thompson et al. Reference Thompson, Radi, Rao, Sheridan and Hourigan2014), the long recirculation bubbles become wavy and shed vortices, as shown in the second vorticity field snapshot. However, the corresponding temperature field close to the plate does not change much from the first stage, as shown in the second column of the temperature snapshots, because the flow is still fairly symmetric close to the plate. At

![]() $t \approx 300$

, the system reaches a periodic state, with alternating shedding of positive and negative vortices from the edges, giving rise to a von Kármán vortex street. The near-wake flow and temperature fields (third and the fourth columns of the temperature snapshots) are now very asymmetric. The top panel shows jumps in the global Nusselt number

$t \approx 300$

, the system reaches a periodic state, with alternating shedding of positive and negative vortices from the edges, giving rise to a von Kármán vortex street. The near-wake flow and temperature fields (third and the fourth columns of the temperature snapshots) are now very asymmetric. The top panel shows jumps in the global Nusselt number

![]() $\overline {Nu}$

,

$\overline {Nu}$

,

![]() $T_{{avg}}$

and

$T_{{avg}}$

and

![]() $T_{max }$

during the transition at

$T_{max }$

during the transition at

![]() $t \approx 250$

. Similarly to the case of

$t \approx 250$

. Similarly to the case of

![]() $\gamma =45^\circ$

, the vortices behind the plate make the thermal boundary layer thinner along the top wall, increasing heat transfer, although

$\gamma =45^\circ$

, the vortices behind the plate make the thermal boundary layer thinner along the top wall, increasing heat transfer, although

![]() $\langle Nu_{{bot}} \rangle$

is still larger than

$\langle Nu_{{bot}} \rangle$

is still larger than

![]() $\langle Nu_{{top}} \rangle$

. The plots of

$\langle Nu_{{top}} \rangle$

. The plots of

![]() $\langle Nu_{{top}} \rangle$

,

$\langle Nu_{{top}} \rangle$

,

![]() $\langle Nu_{{bot}} \rangle$

and

$\langle Nu_{{bot}} \rangle$

and

![]() $\langle T_{{plate}} \rangle$

are symmetric about the plate centre when

$\langle T_{{plate}} \rangle$

are symmetric about the plate centre when

![]() $\gamma =90^\circ$

, reflecting the symmetry of the plate with respect to the oncoming flow. The vortices at the two edges take the same time to develop and have the same strength. The vortices alternately sweep hot fluid toward the two edges, so the thermal boundary layer is thinnest in the middle of the plate, where

$\gamma =90^\circ$

, reflecting the symmetry of the plate with respect to the oncoming flow. The vortices at the two edges take the same time to develop and have the same strength. The vortices alternately sweep hot fluid toward the two edges, so the thermal boundary layer is thinnest in the middle of the plate, where

![]() $\langle Nu_{{top}} \rangle$

has a local maximum and

$\langle Nu_{{top}} \rangle$

has a local maximum and

![]() $\langle T_{{plate}} \rangle$

has a local minimum. Thompson et al. (Reference Thompson, Radi, Rao, Sheridan and Hourigan2014) studied the transient wake development for elliptical cylinders ranging from a flat plate to a circular cylinder at a Reynolds number of

$\langle T_{{plate}} \rangle$

has a local minimum. Thompson et al. (Reference Thompson, Radi, Rao, Sheridan and Hourigan2014) studied the transient wake development for elliptical cylinders ranging from a flat plate to a circular cylinder at a Reynolds number of

![]() $150$

. Using a much larger domain than we use here, they reported not only the von Kármán street behind the plate but also secondary vortex shedding further downstream. We believe that the secondary vortex shedding has negligible influence on heat transfer as the near wake reported by Thompson et al. (Reference Thompson, Radi, Rao, Sheridan and Hourigan2014) is very similar to what we show in figure 5 and very close to periodic, despite the existence of the secondary vortex shedding.

$150$

. Using a much larger domain than we use here, they reported not only the von Kármán street behind the plate but also secondary vortex shedding further downstream. We believe that the secondary vortex shedding has negligible influence on heat transfer as the near wake reported by Thompson et al. (Reference Thompson, Radi, Rao, Sheridan and Hourigan2014) is very similar to what we show in figure 5 and very close to periodic, despite the existence of the secondary vortex shedding.

Our discussion so far has shown that the local heat transfer is quite different for

![]() $\gamma =0^\circ , 45^\circ$

and

$\gamma =0^\circ , 45^\circ$

and

![]() $90^\circ$

. The time-averaged global heat transfer quantities

$90^\circ$

. The time-averaged global heat transfer quantities

![]() $\langle \overline {Nu} \rangle$

and

$\langle \overline {Nu} \rangle$

and

![]() $\langle T_{{avg}} \rangle$

can be inferred from the graphs in figures 4 and 5 at the latest times (in the final periodic steady state for

$\langle T_{{avg}} \rangle$

can be inferred from the graphs in figures 4 and 5 at the latest times (in the final periodic steady state for

![]() $\gamma =90^\circ$

, after the symmetry breaking). For the isothermal plate,

$\gamma =90^\circ$

, after the symmetry breaking). For the isothermal plate,

![]() $\gamma =0^\circ$

has the best heat transfer i.e. the largest

$\gamma =0^\circ$

has the best heat transfer i.e. the largest

![]() $\langle \overline {Nu} \rangle$

, 13.0, and the smallest

$\langle \overline {Nu} \rangle$

, 13.0, and the smallest

![]() $\langle T_{{avg}} \rangle$

, 0.15. Slightly worse is

$\langle T_{{avg}} \rangle$

, 0.15. Slightly worse is

![]() $\gamma =90^\circ$

, with

$\gamma =90^\circ$

, with

![]() $\langle \overline {Nu} \rangle = 12.6$

and

$\langle \overline {Nu} \rangle = 12.6$

and

![]() $\langle T_{{avg}} \rangle =0.16$

. Third best is

$\langle T_{{avg}} \rangle =0.16$

. Third best is

![]() $\gamma =45^\circ$

with

$\gamma =45^\circ$

with

![]() $\langle \overline {Nu} \rangle = 11.0$

and

$\langle \overline {Nu} \rangle = 11.0$

and

![]() $\langle T_{{avg}} \rangle =0.19$

. At

$\langle T_{{avg}} \rangle =0.19$

. At

![]() $\gamma =45^\circ$

, local heat transfer is decreased particularly at the left edge of the top wall, as shown by

$\gamma =45^\circ$

, local heat transfer is decreased particularly at the left edge of the top wall, as shown by

![]() $\langle Nu_{{top}} \rangle$

and the temperature snapshots in figure 4(b). Considering the possibility of device failure above a temperature threshold (Wen & Yan Reference Wen and Yan2021), it is also important to consider the maximum temperature over space and time,

$\langle Nu_{{top}} \rangle$

and the temperature snapshots in figure 4(b). Considering the possibility of device failure above a temperature threshold (Wen & Yan Reference Wen and Yan2021), it is also important to consider the maximum temperature over space and time,

![]() $\max (T_{max })$

. By this measure

$\max (T_{max })$

. By this measure

![]() $\gamma =90^\circ$

is best with

$\gamma =90^\circ$

is best with

![]() $\max (T_{max }) = 0.18$

. The other cases are close, with

$\max (T_{max }) = 0.18$

. The other cases are close, with

![]() $\max (T_{max })$

0.20 and 0.21 for

$\max (T_{max })$

0.20 and 0.21 for

![]() $\gamma =0^\circ$

and

$\gamma =0^\circ$

and

![]() $45^\circ$

, respectively. The temperature snapshots of figures 4(a) and 4(b) show that the highest temperatures occur near the trailing edge for

$45^\circ$

, respectively. The temperature snapshots of figures 4(a) and 4(b) show that the highest temperatures occur near the trailing edge for

![]() $\gamma =0^\circ$

and near the top left edge for

$\gamma =0^\circ$

and near the top left edge for

![]() $\gamma =45^\circ$

, where the mean flow tends to advect hot fluid in each case. By contrast, the alternating vortex shedding for

$\gamma =45^\circ$

, where the mean flow tends to advect hot fluid in each case. By contrast, the alternating vortex shedding for

![]() $\gamma =90^\circ$

leads to a more uniform temperature distribution, lowering the temperature of the hottest spots, as shown in the last two columns of the temperature snapshots in figure 5.

$\gamma =90^\circ$

leads to a more uniform temperature distribution, lowering the temperature of the hottest spots, as shown in the last two columns of the temperature snapshots in figure 5.

4. Vorticity patterns and their effects on heat transfer

Having quantified heat transfer in the baseline non-oscillating-plate cases at the three

![]() $\gamma$

values, we now examine the same heat transfer quantities with plate oscillation, in the direction

$\gamma$

values, we now examine the same heat transfer quantities with plate oscillation, in the direction

![]() $\alpha$

, at frequency

$\alpha$

, at frequency

![]() $Re_f$

and oscillation velocity

$Re_f$

and oscillation velocity

![]() $A/|\boldsymbol{U}_{\infty }|$

, and at the same three

$A/|\boldsymbol{U}_{\infty }|$

, and at the same three

![]() $\gamma$

(flow orientation) values.

$\gamma$

(flow orientation) values.

For

![]() $\gamma =0^\circ$

and

$\gamma =0^\circ$

and

![]() $90^\circ$

, we consider five

$90^\circ$

, we consider five

![]() $\alpha$

values:

$\alpha$

values:

![]() $0^\circ ,\ 30^\circ ,\ 45^\circ ,\ 60^\circ$

and

$0^\circ ,\ 30^\circ ,\ 45^\circ ,\ 60^\circ$

and

![]() $90^\circ$

. For

$90^\circ$

. For

![]() $\gamma =45^\circ$

, we consider eight

$\gamma =45^\circ$

, we consider eight

![]() $\alpha$

values:

$\alpha$

values:

![]() $0^\circ ,\ 30^\circ ,\ 45^\circ ,\ 60^\circ ,\ 90^\circ ,\ 120^\circ ,\ 135^\circ$

and

$0^\circ ,\ 30^\circ ,\ 45^\circ ,\ 60^\circ ,\ 90^\circ ,\ 120^\circ ,\ 135^\circ$

and

![]() $150^\circ$

. (There is no need to consider

$150^\circ$

. (There is no need to consider

![]() $\alpha \gt 90^\circ$

for

$\alpha \gt 90^\circ$

for

![]() $\gamma =0^\circ$

and

$\gamma =0^\circ$

and

![]() $90^\circ$

since

$90^\circ$

since

![]() $\alpha = \alpha _1$

and

$\alpha = \alpha _1$

and

![]() $\alpha = 180^\circ -\alpha _1$

give the same flows after a reflection.) For each combination of

$\alpha = 180^\circ -\alpha _1$

give the same flows after a reflection.) For each combination of

![]() $\gamma$

and

$\gamma$

and

![]() $\alpha$

, we use two values of the plate’s oscillation velocity

$\alpha$

, we use two values of the plate’s oscillation velocity

![]() $A/|\boldsymbol{U}_{\infty }|$

, 0.2 and

$A/|\boldsymbol{U}_{\infty }|$

, 0.2 and

![]() $0.3$

, and vary

$0.3$

, and vary

![]() $Re_f$

from 50 to 250 in increments of 50. Note that

$Re_f$

from 50 to 250 in increments of 50. Note that

![]() $Re_U=Re_f\times A \times |\boldsymbol{U}_{\infty }|/A$

by (2.3). At a given

$Re_U=Re_f\times A \times |\boldsymbol{U}_{\infty }|/A$

by (2.3). At a given

![]() $A/|\boldsymbol{U}_{\infty }|$

(0.2 or 0.3) and at fixed

$A/|\boldsymbol{U}_{\infty }|$

(0.2 or 0.3) and at fixed

![]() $Re_U$

(always 100), the product of the oscillatory frequency and amplitude

$Re_U$

(always 100), the product of the oscillatory frequency and amplitude

![]() $Re_f \times A$

must be constant. Therefore, at each

$Re_f \times A$

must be constant. Therefore, at each

![]() $A/|\boldsymbol{U}_{\infty }|$

we vary

$A/|\boldsymbol{U}_{\infty }|$

we vary

![]() $Re_f$

with the understanding that simultaneously the amplitude

$Re_f$

with the understanding that simultaneously the amplitude

![]() $A$

is varied inversely.

$A$

is varied inversely.

4.1. Global heat transfer

We investigate the global heat transfer using

![]() $\overline {Nu}(t)$

,

$\overline {Nu}(t)$

,

![]() $T_{{avg}}(t)$

and

$T_{{avg}}(t)$

and

![]() $T_{max }(t)$

from (2.8) and (2.9). Although the plate oscillates periodically, these three quantities are not necessarily time periodic. We use the time series of

$T_{max }(t)$

from (2.8) and (2.9). Although the plate oscillates periodically, these three quantities are not necessarily time periodic. We use the time series of

![]() $\overline {Nu}(t)$

,

$\overline {Nu}(t)$

,

![]() $T_{{avg}}(t)$

and

$T_{{avg}}(t)$

and

![]() $T_{max }(t)$

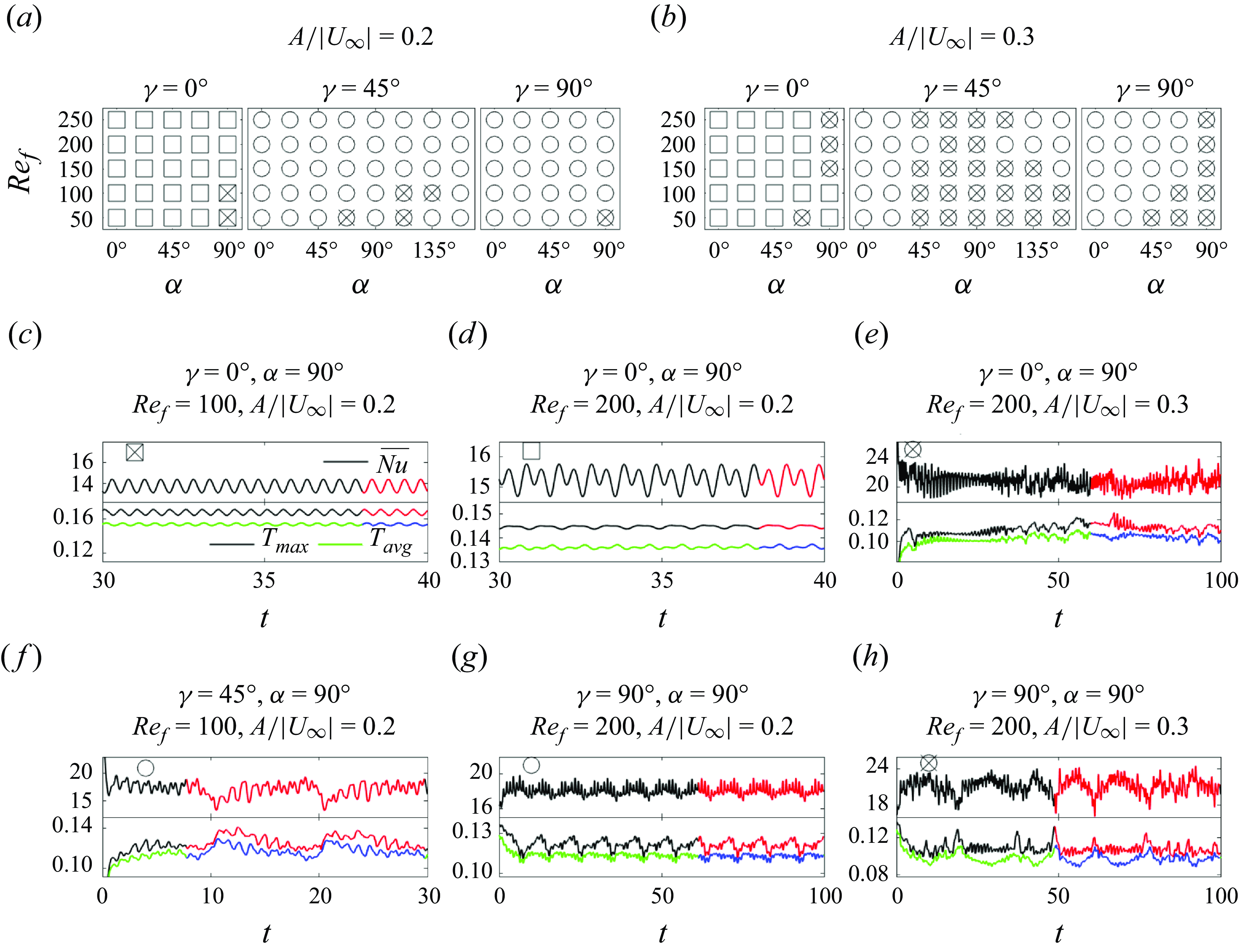

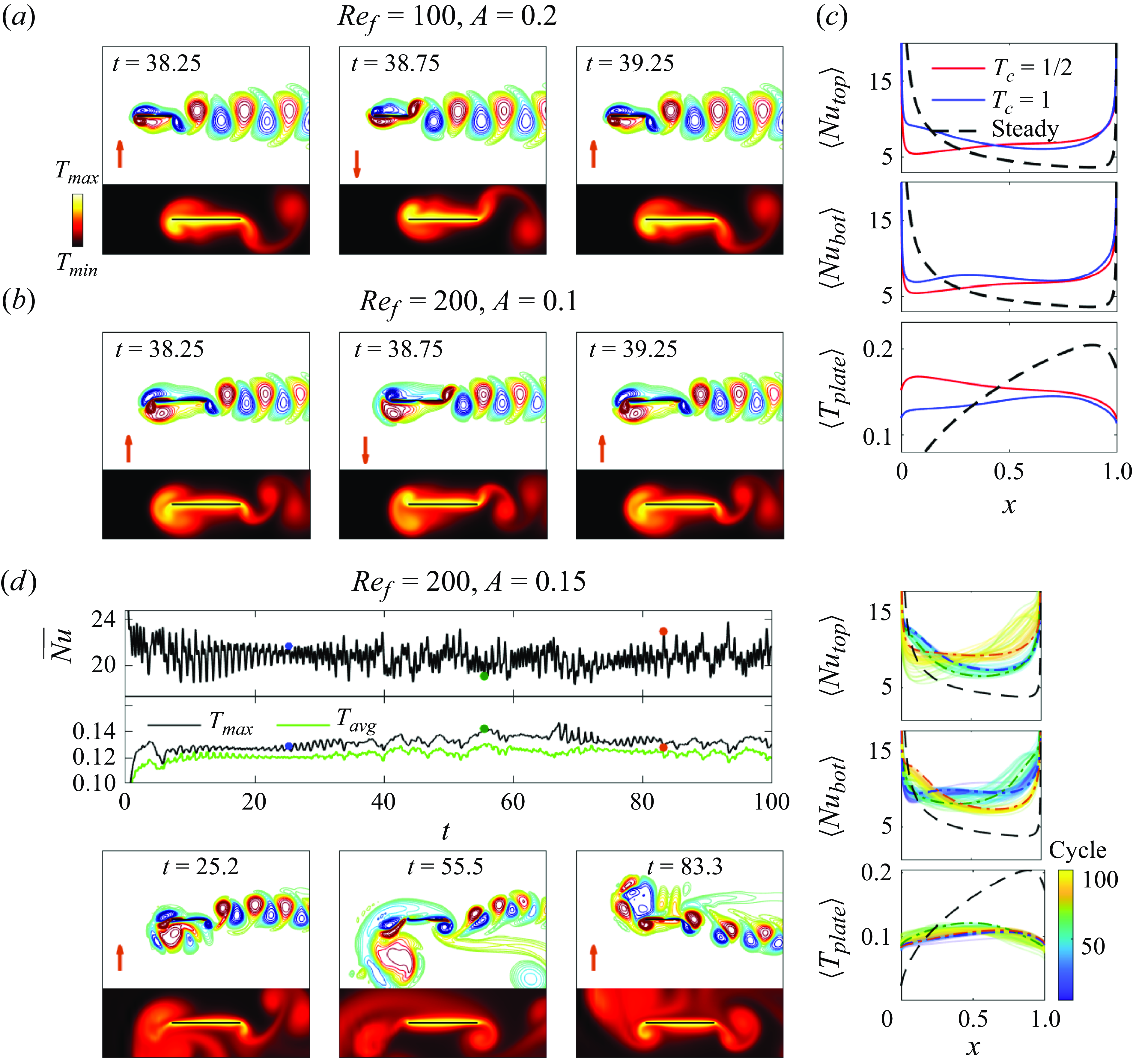

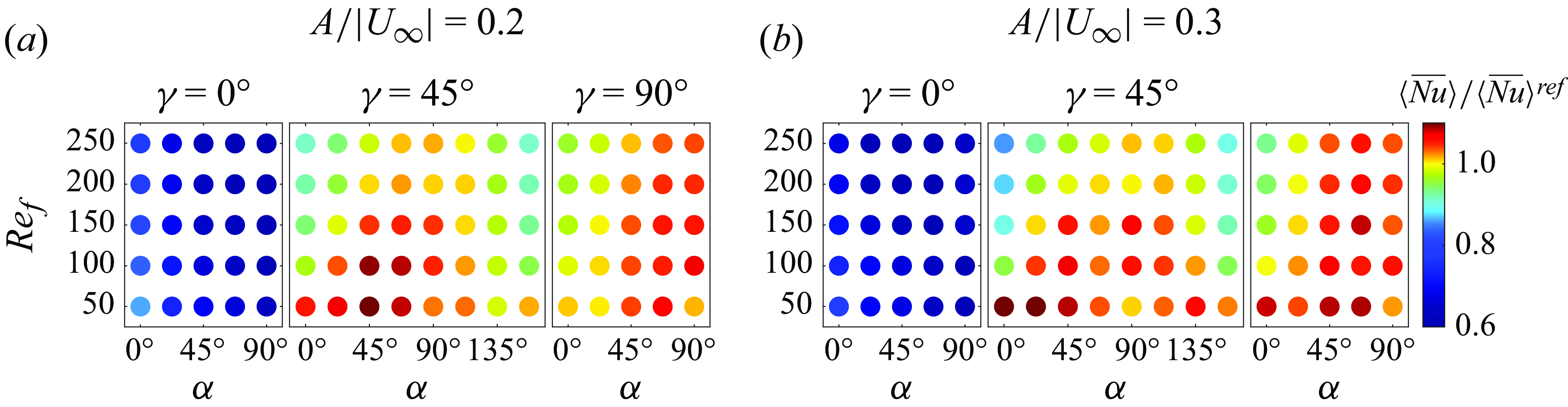

to classify the types of periodic and non-periodic dynamics in figure 6. Panels (a) and (b) give the classifications for

$T_{max }(t)$

to classify the types of periodic and non-periodic dynamics in figure 6. Panels (a) and (b) give the classifications for

![]() $A/|\boldsymbol{U}_{\infty }|=0.2$

and 0.3, respectively. Each panel is divided into three subpanels, one each for

$A/|\boldsymbol{U}_{\infty }|=0.2$

and 0.3, respectively. Each panel is divided into three subpanels, one each for

![]() $\gamma =0^\circ , 45^\circ$

and

$\gamma =0^\circ , 45^\circ$

and

![]() $90^\circ$

. Each subpanel classifies the dynamics in the space of

$90^\circ$

. Each subpanel classifies the dynamics in the space of

![]() $\alpha$

and

$\alpha$

and

![]() $Re_f$

as one of four types using circles and squares, with and without crosses.

$Re_f$

as one of four types using circles and squares, with and without crosses.

Figure 6. The four classes of the time series of

![]() $\overline {Nu}$

,

$\overline {Nu}$

,

![]() $T_{{avg}}$

and

$T_{{avg}}$

and

![]() $T_{max }$

. The three panels in (a) and (b) correspond to

$T_{max }$

. The three panels in (a) and (b) correspond to

![]() $\gamma =0^\circ$

,

$\gamma =0^\circ$

,

![]() $\gamma =45^\circ$

and

$\gamma =45^\circ$

and

![]() $\gamma =90^\circ$

, respectively. The open and filled squares denote period-1 and period-1/2 cases, respectively. The open and filled circles represent almost-periodic and non-periodic cases, respectively, with periods typically

$\gamma =90^\circ$

, respectively. The open and filled squares denote period-1 and period-1/2 cases, respectively. The open and filled circles represent almost-periodic and non-periodic cases, respectively, with periods typically

![]() $\gg 1$

in the almost-periodic cases. Panels (c)–(h) show examples of the four classes, with the class label at the upper left. The portion of the curves in red and blue is used to compute the time average.

$\gg 1$

in the almost-periodic cases. Panels (c)–(h) show examples of the four classes, with the class label at the upper left. The portion of the curves in red and blue is used to compute the time average.

The first major class corresponds to periodic time series, shown with squares. The squares are open for period-1 dynamics and filled with crosses for period-1/2 dynamics. To determine whether a case is periodic, we consider the last four cycles of the plate oscillation and compute the time average of

![]() $\overline {Nu}(t)$

and

$\overline {Nu}(t)$

and

![]() $T_{{avg}}(t)$

every half-cycle. We take the standard deviation of the eight values, normalised by

$T_{{avg}}(t)$

every half-cycle. We take the standard deviation of the eight values, normalised by

![]() ${1}/{4}\int _{t_{{end}}-4}^{t_{{end}}} \overline {Nu}(t) \, \textrm{d}t$

and

${1}/{4}\int _{t_{{end}}-4}^{t_{{end}}} \overline {Nu}(t) \, \textrm{d}t$

and

![]() ${1}/{4}\int _{t_{{end}}-4}^{t_{{end}}} T_{{avg}}(t) \, \textrm{d}t$

, respectively, with

${1}/{4}\int _{t_{{end}}-4}^{t_{{end}}} T_{{avg}}(t) \, \textrm{d}t$

, respectively, with

![]() $t_{{end}}$

the final time of the simulation. If the normalised standard deviation is below 0.1 % we label the case 1/2-periodic. If the case is not 1/2-periodic, we test for 1-periodicity by splitting the eight values into two groups, one for the first half-cycle and the other for the second half-cycle. If the average of the normalised standard deviations of each group is below 0.1 %, we label the case 1-periodic.

$t_{{end}}$

the final time of the simulation. If the normalised standard deviation is below 0.1 % we label the case 1/2-periodic. If the case is not 1/2-periodic, we test for 1-periodicity by splitting the eight values into two groups, one for the first half-cycle and the other for the second half-cycle. If the average of the normalised standard deviations of each group is below 0.1 %, we label the case 1-periodic.

Most cases with

![]() $\gamma =0^\circ$

(left sides of panels (a) and (b)) have period 1, i.e. the period of the plate oscillation. Period 1/2 occurs when the flow is symmetric on the two half-strokes of the plate, and this is possible only when the two half-strokes are symmetric with respect to the oncoming flow, i.e. for

$\gamma =0^\circ$

(left sides of panels (a) and (b)) have period 1, i.e. the period of the plate oscillation. Period 1/2 occurs when the flow is symmetric on the two half-strokes of the plate, and this is possible only when the two half-strokes are symmetric with respect to the oncoming flow, i.e. for

![]() $\alpha =90^\circ$

. Two cases with

$\alpha =90^\circ$

. Two cases with

![]() $\gamma =0^\circ$

,

$\gamma =0^\circ$

,

![]() $\alpha =90^\circ$

and

$\alpha =90^\circ$

and

![]() $A/|\boldsymbol{U}_{\infty }|=0.2$

have period 1/2 (filled squares), and the remainder have period 1.

$A/|\boldsymbol{U}_{\infty }|=0.2$

have period 1/2 (filled squares), and the remainder have period 1.

A period-1/2 example is shown in figure 6(c), and we will show the corresponding up–down symmetry of the vorticity field in § 4.2. Panel (d) shows an example with period 1 but not 1/2. Although the plate motion is up–down symmetric here, the flow is not. For all the periodic cases, we compute time averages using the last two plate oscillation cycles, e.g. the intervals marked in red and blue in panels (c) and (d).

The second major class corresponds to non-periodic time series, labelled with circles. In this class, the aforementioned normalised standard deviations based on the last four cycles of the plate oscillation are far above 0.1 %. All cases with

![]() $\gamma =45^\circ$

and

$\gamma =45^\circ$

and

![]() $90^\circ$

, and several cases with

$90^\circ$

, and several cases with

![]() $\gamma =0^\circ$

at

$\gamma =0^\circ$

at

![]() $A/|\boldsymbol{U}_{\infty }|=0.3$

, belong to this class. Within this class, open circles denote cases that are almost periodic with a period longer than 1. Figures 6(f) and 6(g) show examples of these cases. The time series have a component with the frequency of the plate oscillation and a much lower-frequency component, corresponding to 11 plate oscillations in figure 6(f) and 10 plate oscillations in figure 6(g). The low-frequency component is caused by the vortex grouping dynamics over several plate oscillation cycles, at almost the same location each time. We take time averages using at least two of these longer cycles of vortex grouping, shown in red and blue in panels (f) and (g).

$A/|\boldsymbol{U}_{\infty }|=0.3$

, belong to this class. Within this class, open circles denote cases that are almost periodic with a period longer than 1. Figures 6(f) and 6(g) show examples of these cases. The time series have a component with the frequency of the plate oscillation and a much lower-frequency component, corresponding to 11 plate oscillations in figure 6(f) and 10 plate oscillations in figure 6(g). The low-frequency component is caused by the vortex grouping dynamics over several plate oscillation cycles, at almost the same location each time. We take time averages using at least two of these longer cycles of vortex grouping, shown in red and blue in panels (f) and (g).

To quantitatively determine whether a case is almost periodic, we compare the cycle averages of

![]() $\overline {Nu}(t)$

and

$\overline {Nu}(t)$

and

![]() $T_{{avg}}(t)$

every

$T_{{avg}}(t)$

every

![]() $t_{{low}}$

apart for five consecutive oscillations, with

$t_{{low}}$

apart for five consecutive oscillations, with

![]() $t_{{low}}$

the tentative number of plate oscillations corresponding to the low-frequency component. For example, with

$t_{{low}}$

the tentative number of plate oscillations corresponding to the low-frequency component. For example, with

![]() $t_{{low}}=11$

in figure 6(f), the cycle-averaged

$t_{{low}}=11$

in figure 6(f), the cycle-averaged

![]() $\langle \overline {Nu} \rangle$

and

$\langle \overline {Nu} \rangle$

and

![]() $\langle T_{{avg}} \rangle$

from the 26th to 30th cycle are compared with those from the 15th to 19th cycle, respectively. We compute the standard deviations of the five pairs and then take the average and normalise it by

$\langle T_{{avg}} \rangle$

from the 26th to 30th cycle are compared with those from the 15th to 19th cycle, respectively. We compute the standard deviations of the five pairs and then take the average and normalise it by

![]() ${1}/{t_{{low}}}\int _{t_{{end}}-t_{{low}}}^{t_{{end}}} \overline {Nu}(t) \, \textrm{d}t$

and

${1}/{t_{{low}}}\int _{t_{{end}}-t_{{low}}}^{t_{{end}}} \overline {Nu}(t) \, \textrm{d}t$

and

![]() ${1}/{t_{{low}}}\int _{t_{{end}}-t_{{low}}}^{t_{{end}}} T_{{avg}}(t) \, \textrm{d}t$

, respectively. If the resulting value is

${1}/{t_{{low}}}\int _{t_{{end}}-t_{{low}}}^{t_{{end}}} T_{{avg}}(t) \, \textrm{d}t$

, respectively. If the resulting value is

![]() $\leqslant$

1 %, we label the case ‘almost periodic.’ In figure 6(f),

$\leqslant$

1 %, we label the case ‘almost periodic.’ In figure 6(f),

![]() $t_{{low}}=11$

, and the resulting two normalised average standard deviations are 0.67 % and 0.56 %, respectively. In figure 6(g), we have

$t_{{low}}=11$

, and the resulting two normalised average standard deviations are 0.67 % and 0.56 %, respectively. In figure 6(g), we have

![]() $t_{{low}}=10$

and the values are 0.26 % and 0.17 %. There are subtle but noticeable differences between the longer cycles that make these cases non-periodic: although the vortex configuration near the plate is nearly the same from one long period to the next, the configuration far from the plate differs. For this reason we chose the 1 % threshold for the almost-periodic cases, instead of the 0.1 % threshold for the periodic cases.

$t_{{low}}=10$

and the values are 0.26 % and 0.17 %. There are subtle but noticeable differences between the longer cycles that make these cases non-periodic: although the vortex configuration near the plate is nearly the same from one long period to the next, the configuration far from the plate differs. For this reason we chose the 1 % threshold for the almost-periodic cases, instead of the 0.1 % threshold for the periodic cases.

The last subclass, shown by circles with crosses, corresponds to a strongly non-periodic dynamics. In these cases, vortex grouping still occurs over long cycles, but the long cycles vary in duration, the positions of the groups vary from one long cycle to the next, and the vortex shedding can be irregular. These cases are more prevalent at

![]() $A/|\boldsymbol{U}_{\infty }|=0.3$

than 0.2, and with

$A/|\boldsymbol{U}_{\infty }|=0.3$

than 0.2, and with

![]() $\alpha$

close to

$\alpha$

close to

![]() $90^\circ$

, i.e. with more transverse plate motions. Such cases correspond to stronger vortices with a more complicated dynamics. Example time series are shown in figures 6(e) and 6(h). For this subclass we compute time averages over time intervals that are long enough that further increases give only minor changes, as shown in Appendix B. The beginnings and ends of the intervals are chosen so that the vorticity distributions near the plate approximately match.

$90^\circ$

, i.e. with more transverse plate motions. Such cases correspond to stronger vortices with a more complicated dynamics. Example time series are shown in figures 6(e) and 6(h). For this subclass we compute time averages over time intervals that are long enough that further increases give only minor changes, as shown in Appendix B. The beginnings and ends of the intervals are chosen so that the vorticity distributions near the plate approximately match.

We can interpret the periodic and almost-period cases by considering the frequency of vortex shedding due to the plate oscillation together with the natural wake shedding frequency seen in the steady cases of § 3 at

![]() $\gamma = 45^\circ$

and

$\gamma = 45^\circ$

and

![]() $90^\circ$

. At

$90^\circ$

. At

![]() $\gamma = 0^\circ$

there is no natural wake shedding frequency, so here the dynamics is mostly periodic with the period of the plate oscillation. At

$\gamma = 0^\circ$

there is no natural wake shedding frequency, so here the dynamics is mostly periodic with the period of the plate oscillation. At

![]() $\gamma = 45^\circ$

and

$\gamma = 45^\circ$

and

![]() $90^\circ$

there is the additional wake frequency, but many cases are close to periodic, particularly at

$90^\circ$

there is the additional wake frequency, but many cases are close to periodic, particularly at

![]() $A/|\boldsymbol{U}_{\infty }|$

= 0.2. Such cases resemble frequency locking between the wake and plate oscillation, which has been studied most often for circular cylinders (Koopmann Reference Koopmann1967; Armstrong, Barnes & Grant Reference Armstrong, Barnes and Grant1986; Williamson & Roshko Reference Williamson and Roshko1988; Chen & Fang Reference Chen and Fang1998). In these studies, lock-in was observed when the body was forced at a period within approximately 20 % of the natural wake period. Locking of the flow to a multiple of the period of the oscillating body was found in experiments by Bishop & Hassan (Reference Bishop and Hassan1964) and in computations of an oscillating ellipse that is free to translate horizontally (Alben Reference Alben2008).

$A/|\boldsymbol{U}_{\infty }|$

= 0.2. Such cases resemble frequency locking between the wake and plate oscillation, which has been studied most often for circular cylinders (Koopmann Reference Koopmann1967; Armstrong, Barnes & Grant Reference Armstrong, Barnes and Grant1986; Williamson & Roshko Reference Williamson and Roshko1988; Chen & Fang Reference Chen and Fang1998). In these studies, lock-in was observed when the body was forced at a period within approximately 20 % of the natural wake period. Locking of the flow to a multiple of the period of the oscillating body was found in experiments by Bishop & Hassan (Reference Bishop and Hassan1964) and in computations of an oscillating ellipse that is free to translate horizontally (Alben Reference Alben2008).

Although it might be conjectured that the four classes correspond to completely different heat transfer performances, we do not see a direct mechanism by which one class performs better than the other consistently. In particular, as we will show next, it is not uncommon for different classes to have similar global heat transfer. Thus the classification only indicates the regularity of the vortex dynamics. In the following discussion, we can see that, compared with the regularity of the vortex dynamics, the strength of the shed vorticity is more correlated with heat transfer.

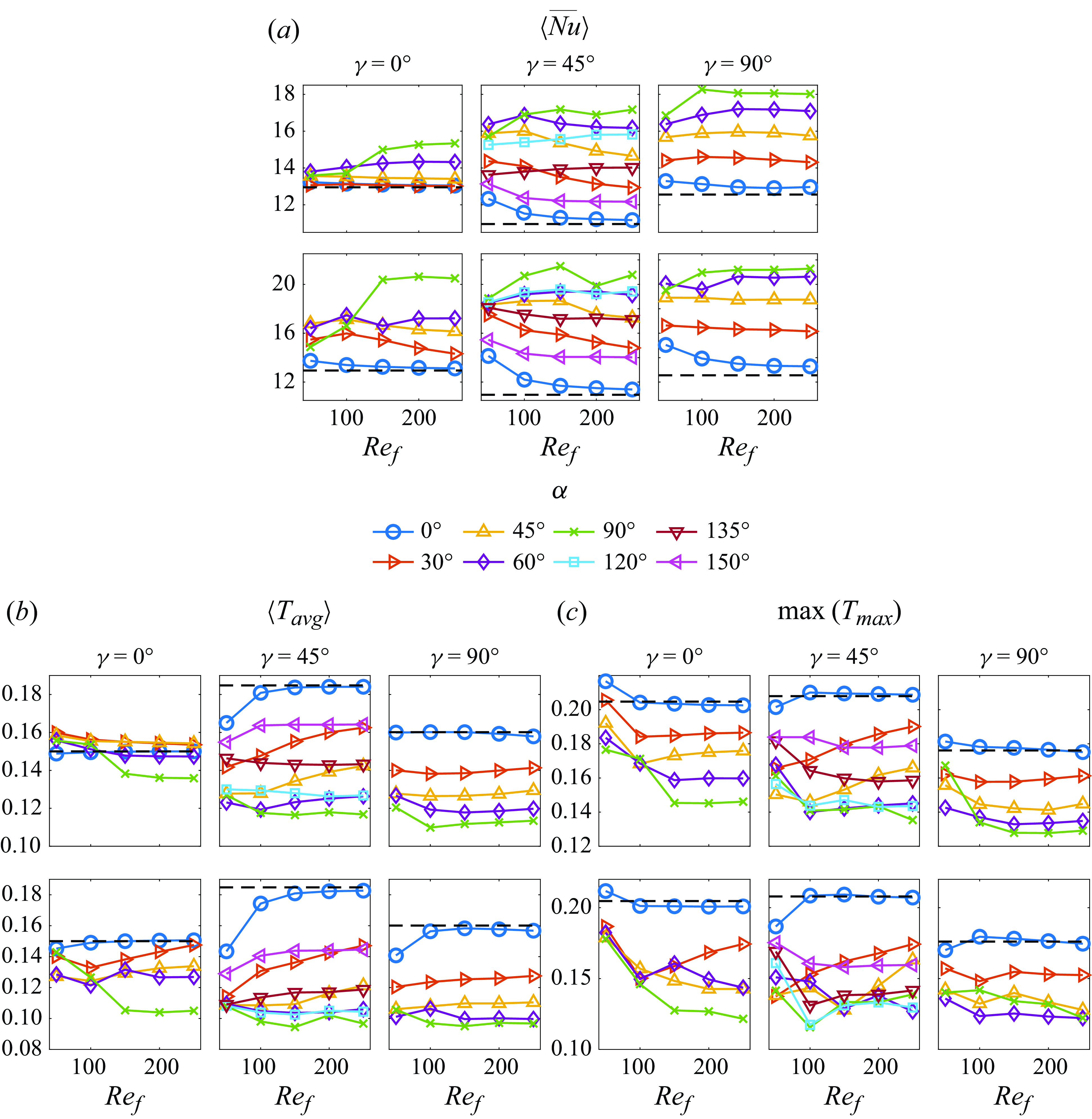

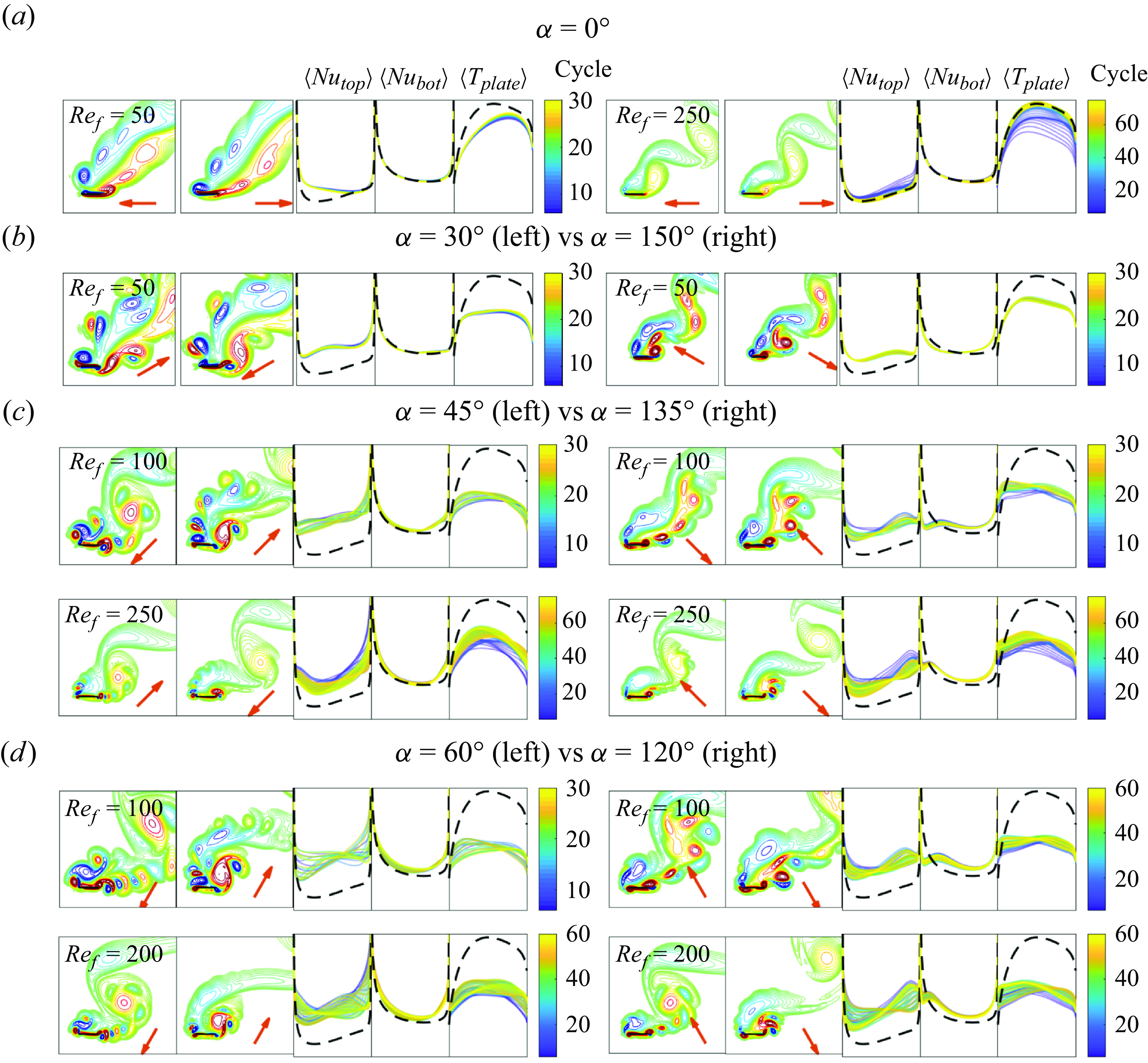

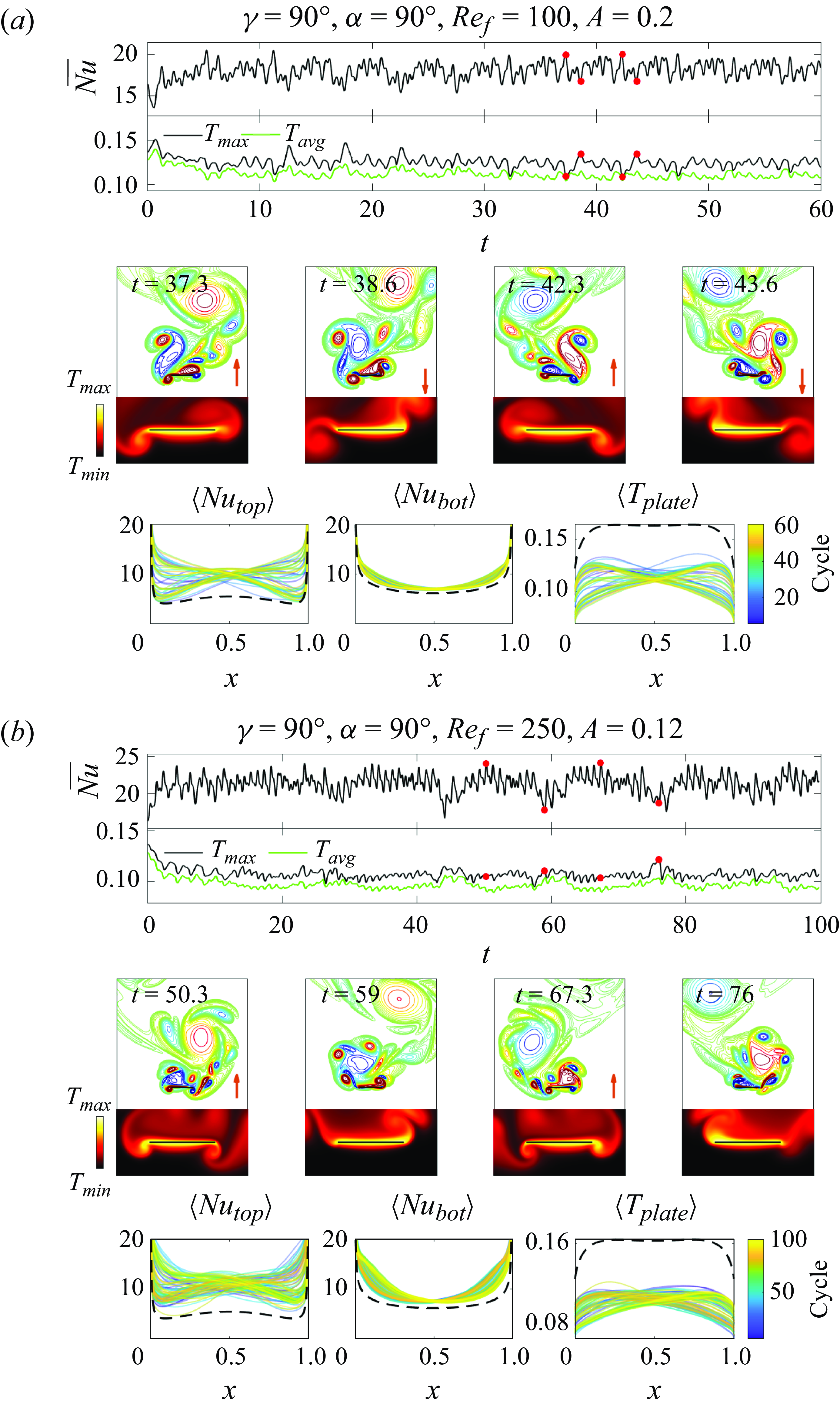

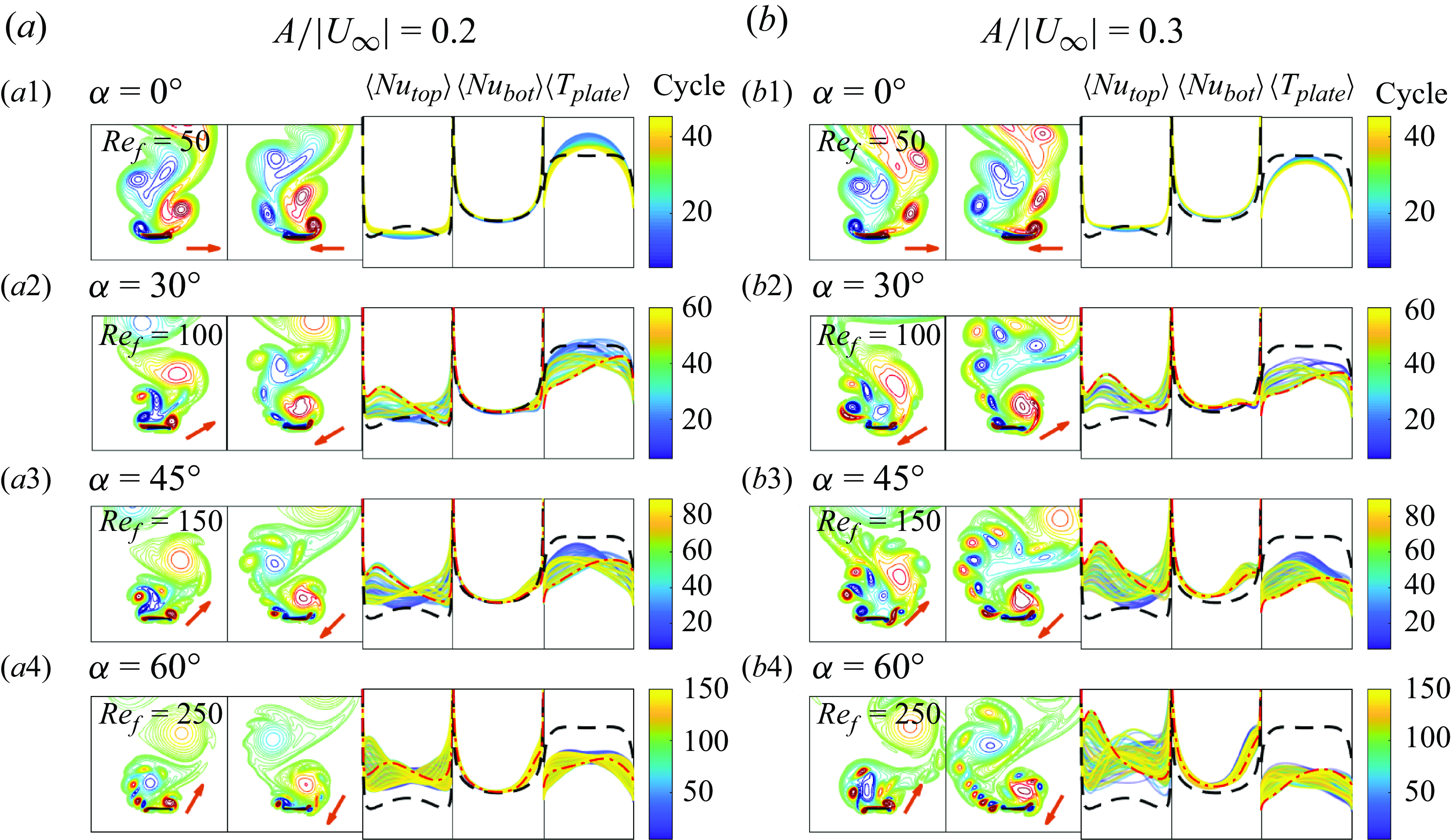

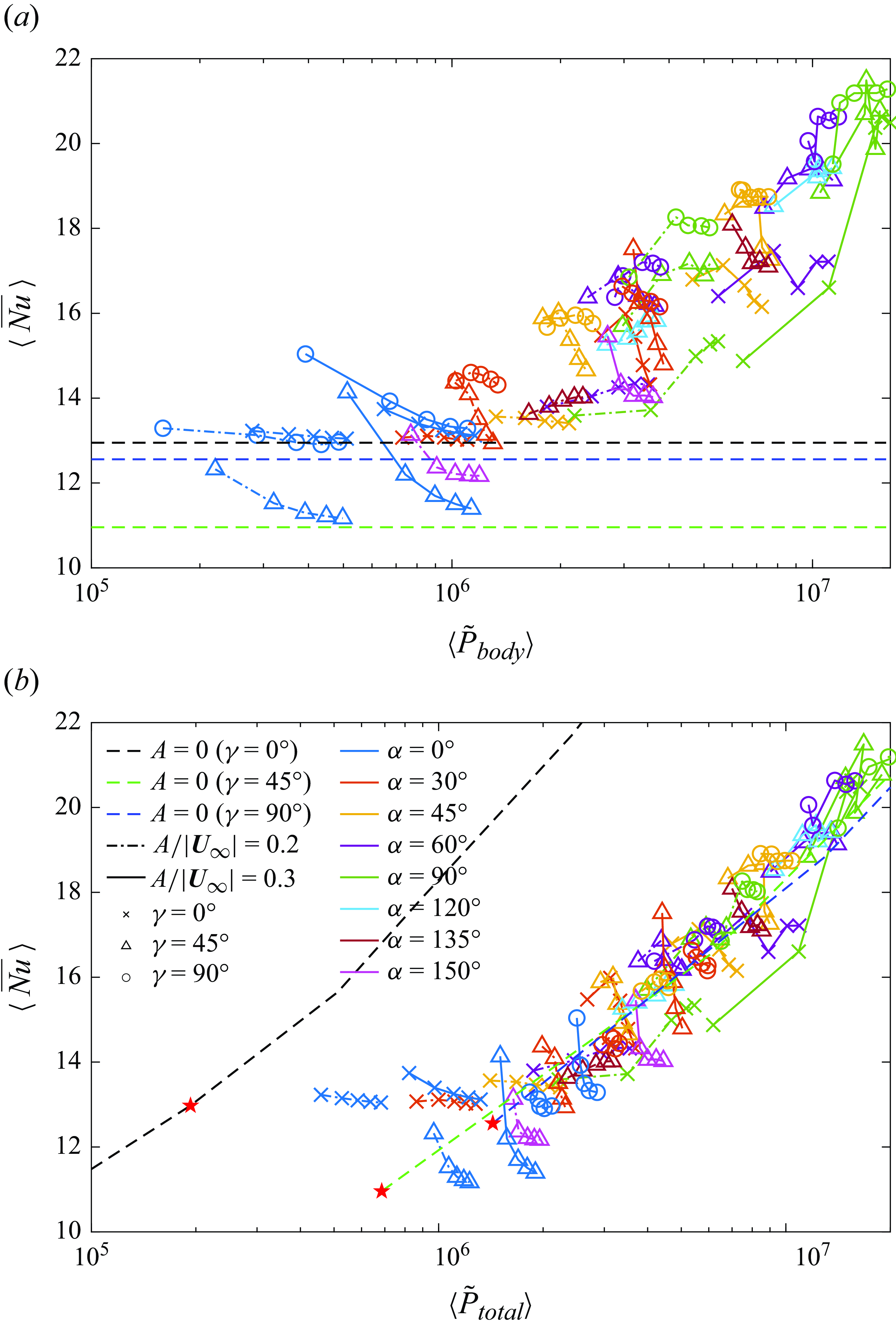

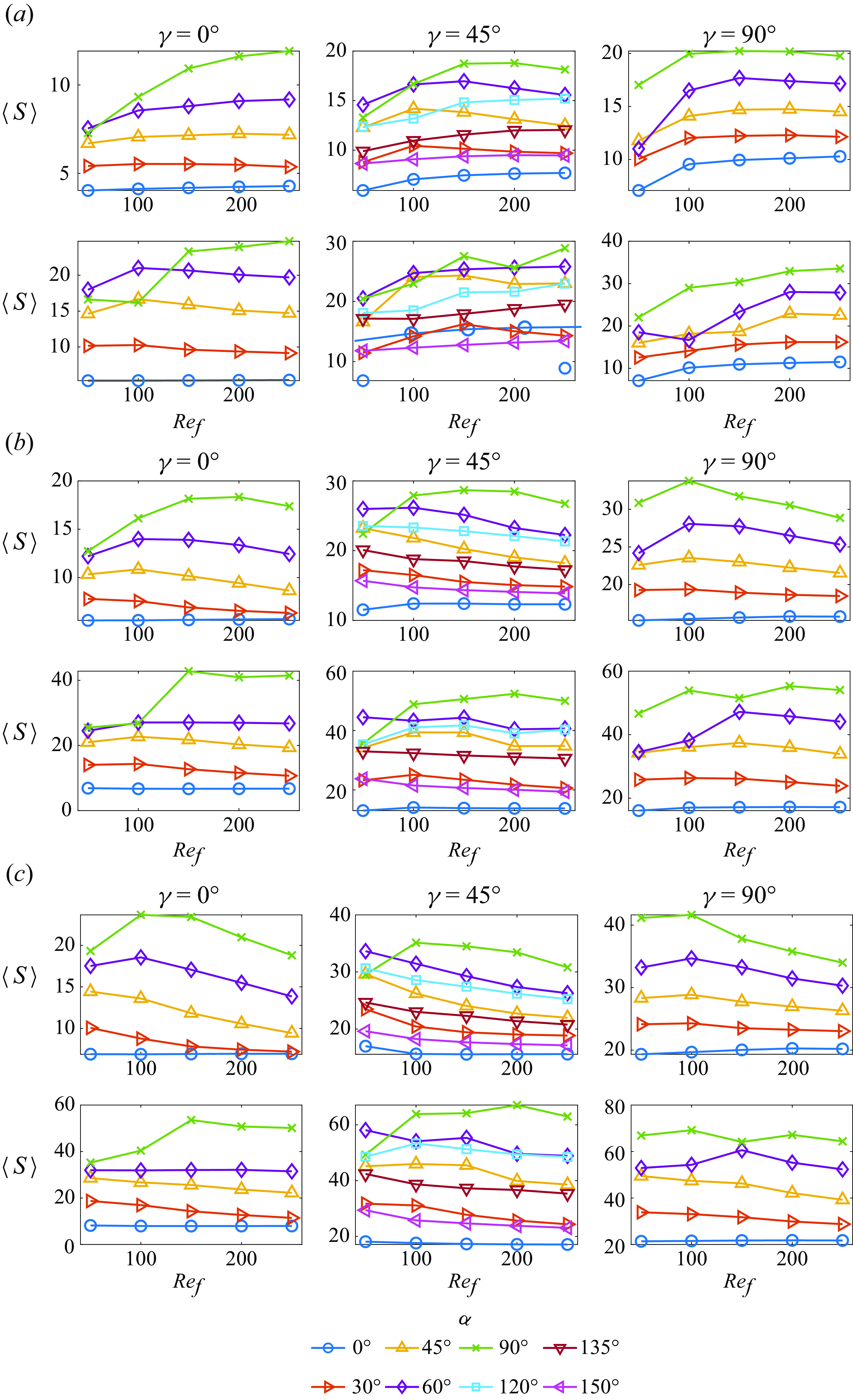

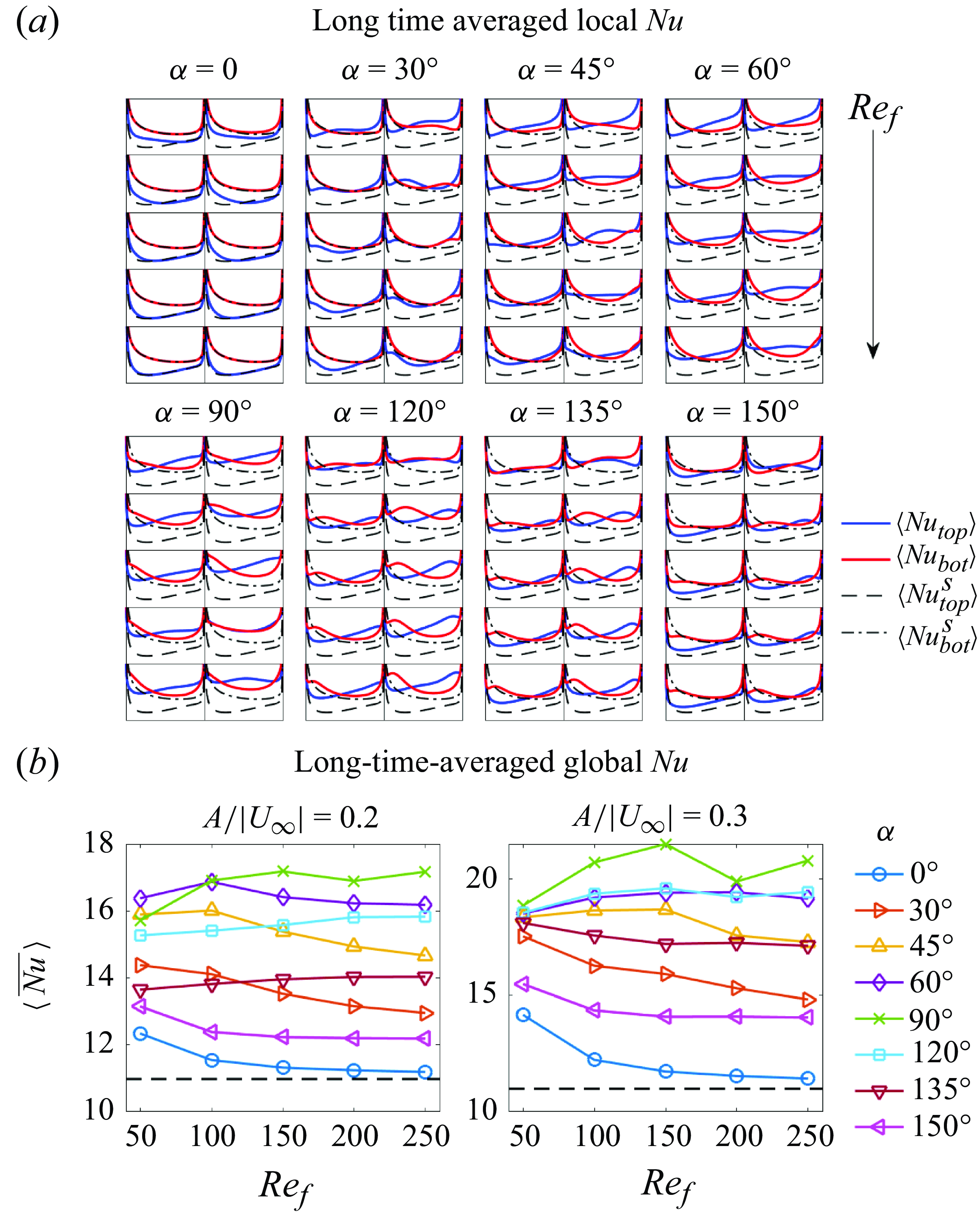

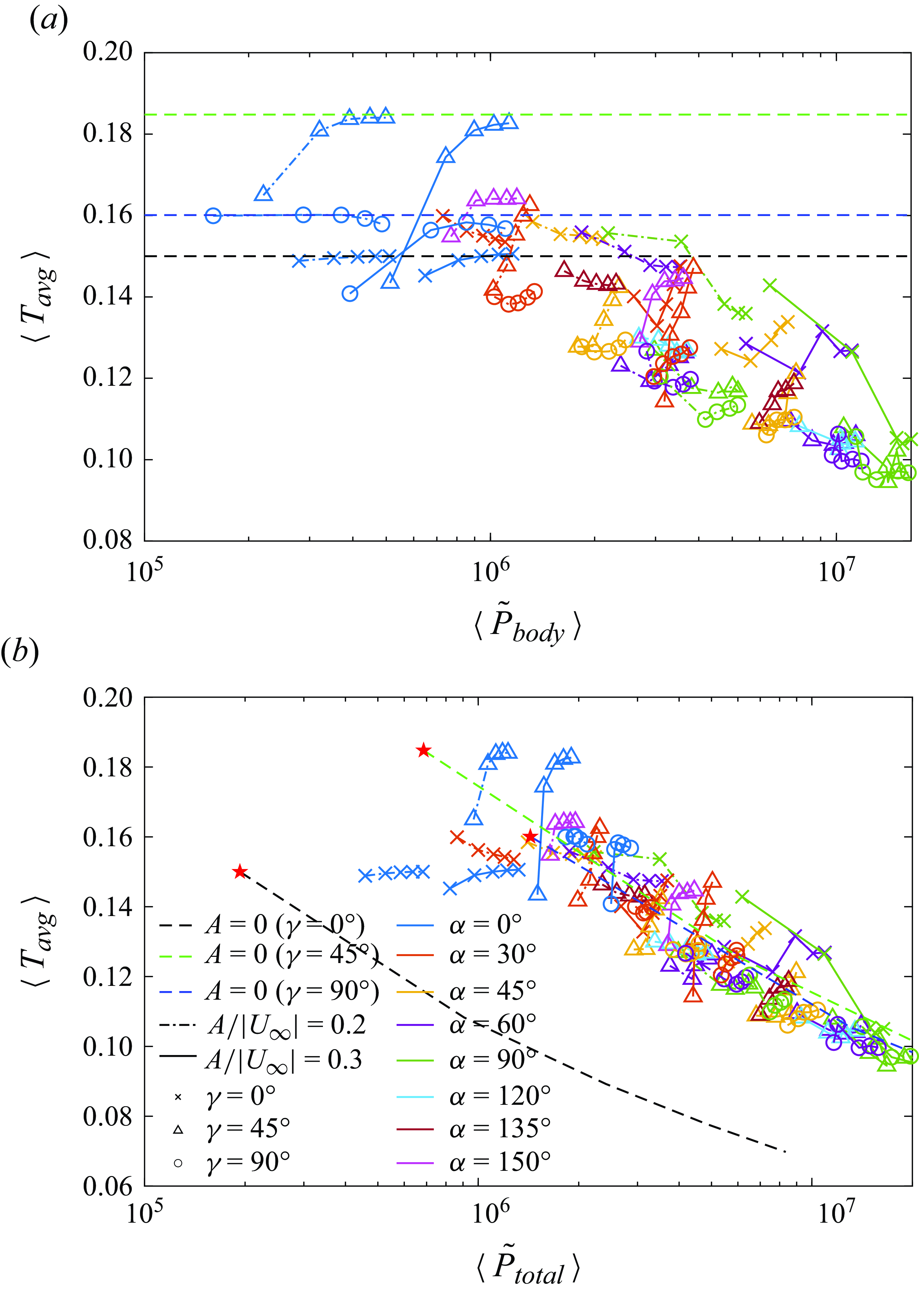

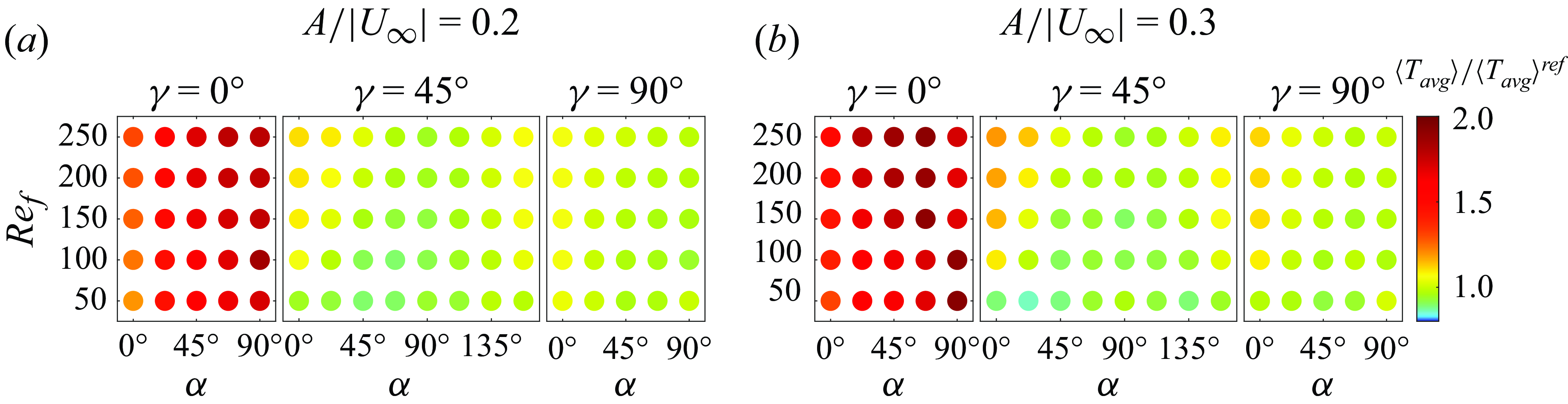

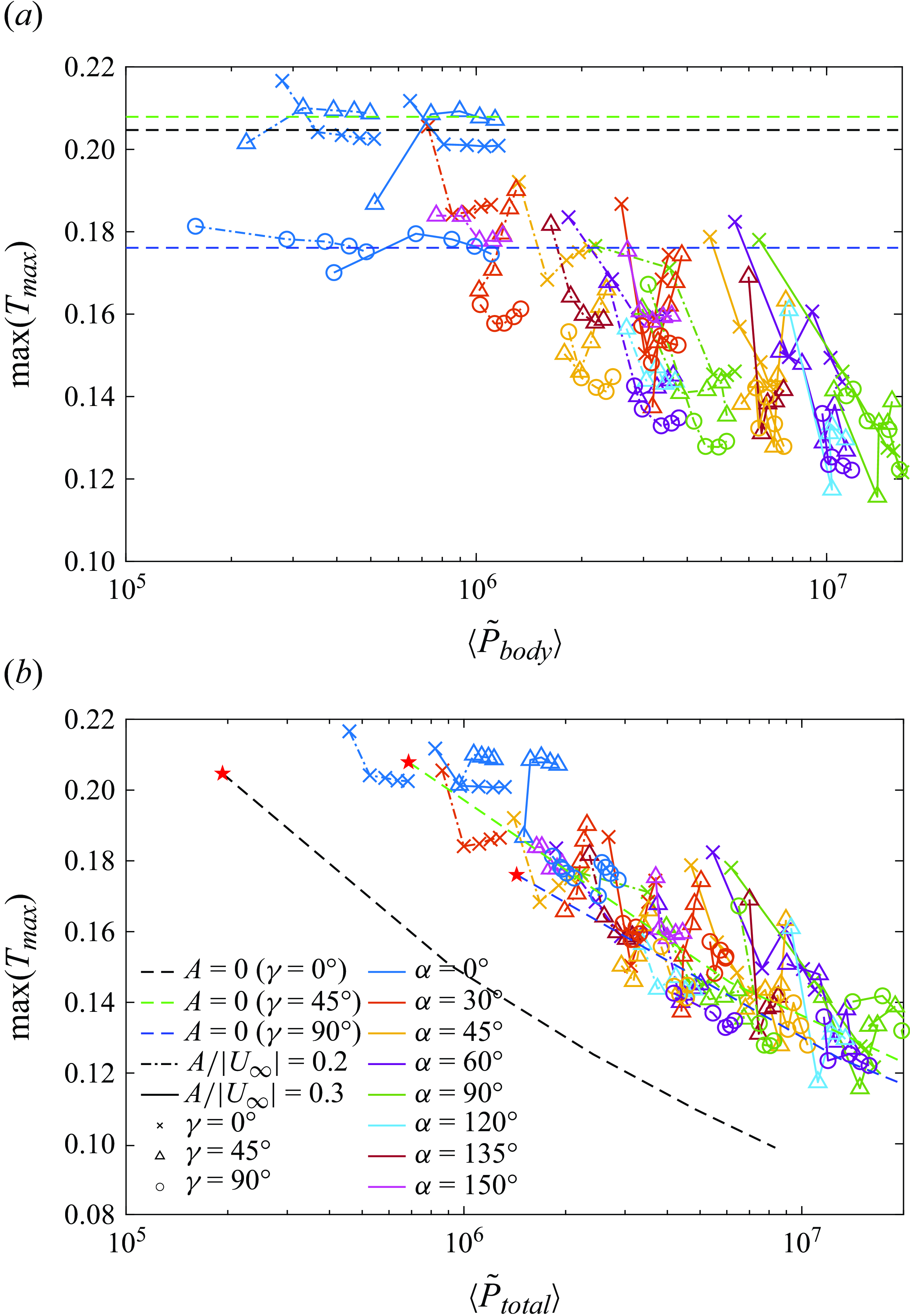

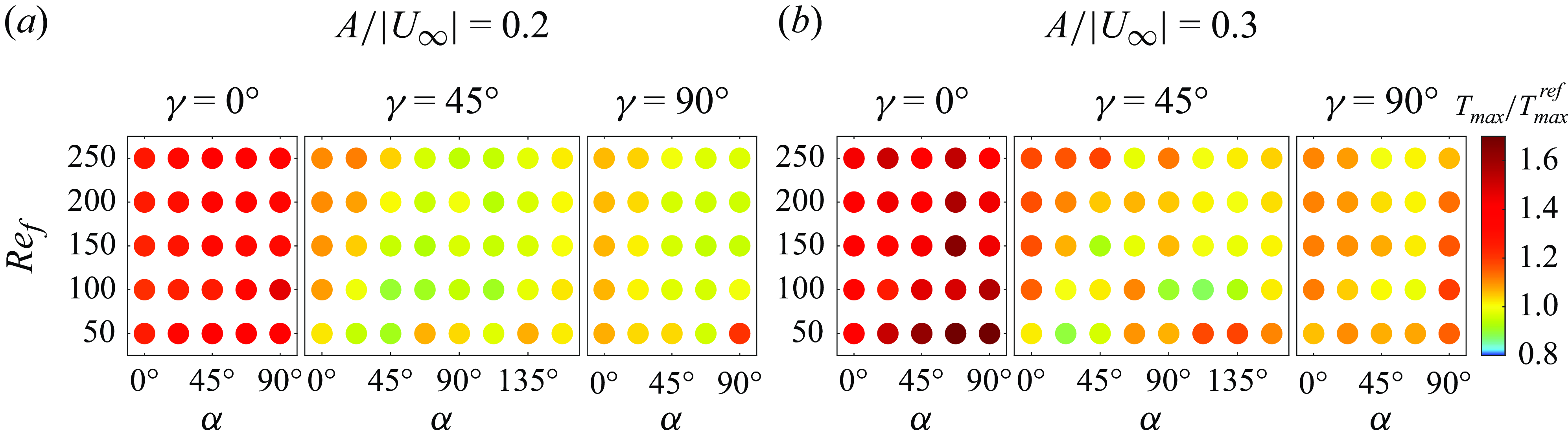

Figure 7. (a) The time-averaged global Nusselt number,

![]() $\langle \overline {Nu}\rangle$

, for the isothermal plate, (b) the time-averaged plate temperature,

$\langle \overline {Nu}\rangle$

, for the isothermal plate, (b) the time-averaged plate temperature,

![]() $\langle T_{{avg}} \rangle$

and (c) the maximum plate temperature,

$\langle T_{{avg}} \rangle$

and (c) the maximum plate temperature,

![]() $\max (T_{max })$

, when the heat flux from the plate is fixed. The first and second rows in each panel correspond to

$\max (T_{max })$

, when the heat flux from the plate is fixed. The first and second rows in each panel correspond to

![]() $A/|\boldsymbol{U}_{\infty }|=0.2$

and 0.3, respectively. The dashed line in each panel gives the values for the non-oscillating plate. The panels in the same row share the same

$A/|\boldsymbol{U}_{\infty }|=0.2$