1. Introduction

A classic problem in fluid mechanics is the terminal velocity of a spherical particle in an otherwise quiescent viscous liquid. A balance of weight, buoyancy and Stokes drag, which depends on the velocity of the particle, yields the terminal velocity. While the result is affected by nearby particles, adjacent walls, etc., the essence of the problem resides in the force balance on the particle.

In this paper, we consider the analogous problem in granular shear flow and use it to determine the segregation velocity in mixtures of two particle species having different sizes. To do this, we use a force balance of the particle weight, the segregation force and the granular drag force to determine the terminal velocity, or, equivalently, the segregation velocity, of an intruder particle in a granular flow and then extend this to the segregation velocity in mixtures of two particle species. However, the construction of the equivalent ‘granular terminal-velocity’ problem requires a crucial addition compared with the fluid problem. An intruder particle in a granular system will move only if energy, e.g. in the form of vibration or shear, is added to the system. In the case of shear, which is considered here, the local shear profile in the intruder vicinity affects the forces acting on it. Furthermore, the buoyancy force on a particle in a granular medium differs somewhat from that for a particle in a fluid. The forces related to shear and buoyancy can be expressed in terms of a ‘segregation force’ that includes both kinematics- and gravity-dependent terms (Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2021). Last, the relationship between the drag force and the particle velocity in a granular flow has recently been clarified to be Stokesian in character (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022). Thus, a force balance of the particle weight, the segregation force and the granular drag force can be used to determine the segregation velocity for an intruder particle over a wide range of granular flow conditions.

More generally and more significantly, the granular terminal velocity of an intruder particle can be connected to the problem of particle-size segregation in a flowing mixture of small and large particles with arbitrary finite concentrations. In the mixture, small particles fall through interstices between large particles to lower parts of a flowing layer, thereby forcing large particles upward and resulting in the spatial segregation of initially mixed small and large particles (Gray Reference Gray2018; Umbanhowar, Lueptow & Ottino Reference Umbanhowar, Lueptow and Ottino2019). If segregation of two particle species is viewed as one of the two species migrating relative to the other within the bulk flow (Bridgwater, Foo & Stephens Reference Bridgwater, Foo and Stephens1985; Savage & Lun Reference Savage and Lun1988), the segregation velocity of each species can be thought of as a granular terminal-velocity problem. In this case, the segregation-force and drag-force models need to be extended from the single-intruder limit to mixtures of arbitrary species concentrations. Such extensions bridging particle-level forces and continuum models of the segregation velocity are the focus of recent work (Rousseau et al. Reference Rousseau, Chassagne, Chauchat, Maurin and Frey2021; Tripathi et al. Reference Tripathi, Kumar, Nema and Khakhar2021; Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022, Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2024; Sahu et al. Reference Sahu, Kumawat, Agrawal and Tripathi2023), leading to the emergence of a new physics-based approach to segregation-velocity modelling. The present paper aims to complete this new approach and demonstrate its general applicability using a wide range of granular flow configurations.

Modelling particle-size segregation in the continuum framework usually involves solving the spatial and temporal evolution of particle concentration via an advection–diffusion–segregation equation, first suggested by Bridgwater et al. (Reference Bridgwater, Foo and Stephens1985), which differs from a standard advection–diffusion formulation in that a closure relation is needed for the segregation velocity (Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019; Thornton Reference Thornton2021). Therefore, how to model the segregation velocity is the central question of most recent segregation theories. Several different approaches have been used to understand, model and predict the segregation velocity. In one approach, the segregation velocity is determined directly from discrete element method (DEM) simulations (Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019), which empirically connect the local segregation velocity with flow kinematics (shear rate), species concentration and relative particle properties (size ratio and density ratio). Despite the semi-empirical nature of this approach, it has proved effective in capturing segregation fluxes (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015a ; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018), density- or shape-induced segregation (Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016; Zhao et al. Reference Zhao, Xiao, Umbanhowar and Lueptow2018; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2021) and fluid effects in segregation (Cui et al. Reference Cui, Zhou and Jing2022), as well as segregation involving both gravity- and shear-gradient-related driving mechanisms (Fan & Hill Reference Fan and Hill2011a ; Liu et al. Reference Liu, Singh and Henann2023; Singh, Liu & Henann Reference Singh, Liu and Henann2024). The drawback of such empirical segregation-velocity models is the lack of a universal model suitable for a wide range of particle properties and flow configurations.

The segregation velocity can also be extracted from particle-species-specific momentum equations (force balance at the continuum level) in a flowing mixture (Gray Reference Gray2018; Thornton Reference Thornton2021). In this framework, the intrinsic pressure gradient of a particle species drives segregation and is counteracted by interspecies drag and diffusive remixing (Gray & Thornton Reference Gray and Thornton2005; Gray & Chugunov Reference Gray and Chugunov2006; Bancroft & Johnson Reference Bancroft and Johnson2021), which is a departure from mixture theory (Atkin & Craine Reference Atkin and Craine1976). Key to such approaches for segregation-velocity models is the closure relation for pressure partitioning and interspecies drag. Despite progress in kinetic-theory-based segregation models for collisional granular flows (Jenkins & Mancini Reference Jenkins and Mancini1987; Jenkins & Yoon Reference Jenkins and Yoon2002; Larcher & Jenkins Reference Larcher and Jenkins2015; Neveu et al. Reference Neveu, Larcher, Delannay, Jenkins and Valance2022), developing closures from first principles remains challenging for size-bidisperse dense granular flows, where multiple, enduring frictional contacts are common. A variety of approaches and assumptions have been used to account for pressure partitioning and drag in dense granular flows (Gray & Thornton Reference Gray and Thornton2005; Fan & Hill Reference Fan and Hill2011b ; Marks, Rognon & Einav Reference Marks, Rognon and Einav2012; Gajjar & Gray Reference Gajjar and Gray2014; Hill & Tan Reference Hill and Tan2014). Experiments have also been used to directly measure the segregation velocity of single intruder particles and mixtures undergoing shear (van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Trewhela, Ancey & Gray Reference Trewhela, Ancey and Gray2021). Alternatively, a variety of approaches using virtual springs tethered to a single intruder particle or groups of particles have been used to provide insight into the forces on particles (Guillard, Forterre & Pouliquen Reference Guillard, Forterre and Pouliquen2016; Bancroft & Johnson Reference Bancroft and Johnson2021; Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2021; Liu & Müller Reference Liu and Müller2021; Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022, Reference Duan, Peckham, Umbanhowar, Ottino and Lueptow2023, Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2024). In all cases, the challenge is to develop a general closure model for the segregation velocity that is applicable over a broad range of granular flow geometries.

In this paper, we develop such a general closure model for the segregation velocity, exploiting recently established segregation-force and drag-force models at the particle level (Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2020, Reference Jing, Ottino, Lueptow and Umbanhowar2021, Reference Jing, Ottino, Umbanhowar and Lueptow2022) along with their extensions to mixtures of arbitrary concentrations (Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022, Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2024). The approach follows the fluid terminal-velocity analogue by using a force balance of the particle weight, the segregation force and the granular drag force to determine the segregation velocity in mixtures of two particle species. Since the segregation-force and drag-force models are characterised based on particle-resolved simulations (i.e. DEM simulations) with measurable parameters, they serve as first-principle closures for the species momentum-balance equations at the continuum level and produce segregation-velocity predictions matching simulation results for size-bidisperse granular flows across a diverse set of flow geometries.

2. Equations of motion

Several models are combined to extract the segregation velocity. In this section, we outline these models and provide details on how to combine them to estimate the segregation velocity under a wide range of flow and particle conditions.

2.1. Particle force balance in a mixture

Consider an incompressible flow of a size-disperse mixture of two species, such as the simple shear flow shown schematically in figure 1(a). The two particle species have volume concentrations

![]() $c_i$

, where

$c_i$

, where

![]() $i=l,s$

for large and small particles, respectively, and

$i=l,s$

for large and small particles, respectively, and

![]() $c_s+c_l=1$

. We neglect vertical acceleration terms, which is reasonable for the relatively slow segregation observed in many common granular flows including heap, chute and rotating-tumbler flows (Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019), though not necessarily all flows (such as some high-speed geophysical flows).

$c_s+c_l=1$

. We neglect vertical acceleration terms, which is reasonable for the relatively slow segregation observed in many common granular flows including heap, chute and rotating-tumbler flows (Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019), though not necessarily all flows (such as some high-speed geophysical flows).

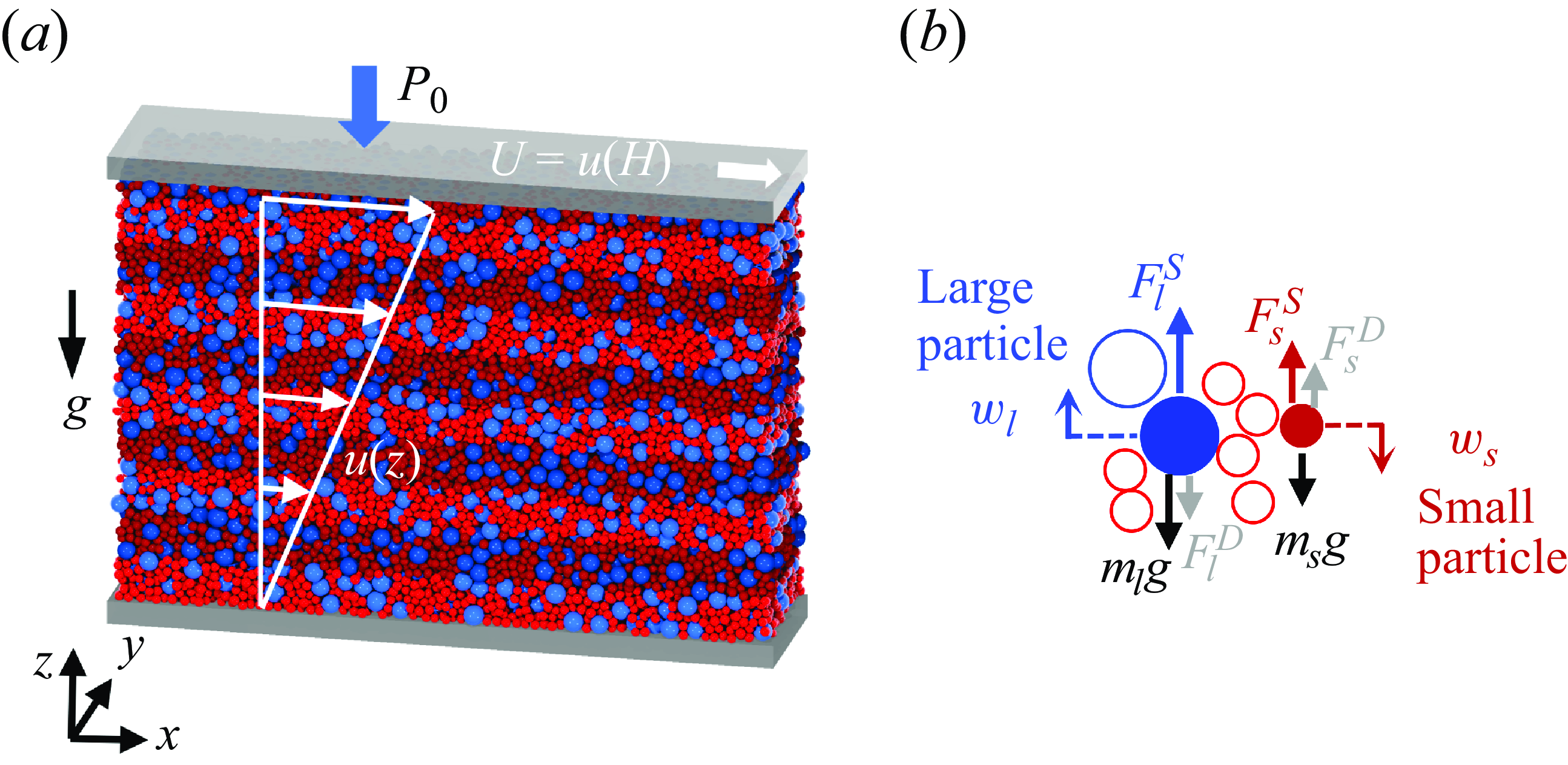

Figure 1. (a) A DEM simulation example of large (4 mm, blue) and small (2 mm, red) spheres in a uniform shear flow with streamwise velocity

![]() $u(z)$

, top wall velocity

$u(z)$

, top wall velocity

![]() $U=u(H)$

where

$U=u(H)$

where

![]() $H$

is the height of the top wall above the stationary bottom wall, overburden pressure

$H$

is the height of the top wall above the stationary bottom wall, overburden pressure

![]() $P_0$

and downward gravity (negative

$P_0$

and downward gravity (negative

![]() $z$

-direction), partitioned into 2.5

$z$

-direction), partitioned into 2.5

![]() $d_l$

high layers (shading) for characterising depth-varying segregation velocity. Here, large particles rise while small particles sink. The segregation direction varies in the different flow configurations analysed later. (b) Force balances on a large particle and a small particle corresponding to (2.1) and species-specific vertical segregation velocities,

$d_l$

high layers (shading) for characterising depth-varying segregation velocity. Here, large particles rise while small particles sink. The segregation direction varies in the different flow configurations analysed later. (b) Force balances on a large particle and a small particle corresponding to (2.1) and species-specific vertical segregation velocities,

![]() $w_i$

.

$w_i$

.

A force balance at the particle level in the vertical (gravitational,

![]() $g$

) direction for an individual non-accelerating particle with mass

$g$

) direction for an individual non-accelerating particle with mass

![]() $m_i$

in the flowing mixture, shown in figure 1(b), includes the segregation force,

$m_i$

in the flowing mixture, shown in figure 1(b), includes the segregation force,

![]() $F^S_i$

, the weight,

$F^S_i$

, the weight,

![]() $m_i g$

, and the drag force,

$m_i g$

, and the drag force,

![]() $F^D_i$

such that (Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022)

$F^D_i$

such that (Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022)

Much like in the analysis of terminal velocity in a fluid, the segregation velocity in granular flows appears in the drag force,

![]() $F^D_i$

, as we will show shortly. Thus, with an appropriate model for the segregation force,

$F^D_i$

, as we will show shortly. Thus, with an appropriate model for the segregation force,

![]() $F^S_i$

, and a model for the dependence of the drag force,

$F^S_i$

, and a model for the dependence of the drag force,

![]() $F^D_i$

, on the segregation velocity, we can use (2.1) to calculate the segregation velocity. The key is having appropriate models for

$F^D_i$

, on the segregation velocity, we can use (2.1) to calculate the segregation velocity. The key is having appropriate models for

![]() $F^S_i$

and

$F^S_i$

and

![]() $F^D_i$

on an individual particle in the flowing mixture, which are described shortly.

$F^D_i$

on an individual particle in the flowing mixture, which are described shortly.

Using force balance at the particle level, i.e. (2.1), differs somewhat from the continuum description of segregation using the mixture theory framework. Within this framework, the momentum balance for each species along the segregation direction (negative

![]() $z$

-direction) in a simple shear flow scenario can be expressed as (Gray & Thornton Reference Gray and Thornton2005; Tunuguntla, Weinhart & Thornton Reference Tunuguntla, Weinhart and Thornton2017)

$z$

-direction) in a simple shear flow scenario can be expressed as (Gray & Thornton Reference Gray and Thornton2005; Tunuguntla, Weinhart & Thornton Reference Tunuguntla, Weinhart and Thornton2017)

Here,

![]() $ -\partial p_i / \partial z= n_i F^S_i$

is the partial pressure gradient, where

$ -\partial p_i / \partial z= n_i F^S_i$

is the partial pressure gradient, where

![]() $p_i$

is the partial pressure of species

$p_i$

is the partial pressure of species

![]() $i$

, and

$i$

, and

![]() $z$

is in the direction of gravity, and

$z$

is in the direction of gravity, and

![]() $\rho _i$

is the density of species

$\rho _i$

is the density of species

![]() $i$

. The interspecies momentum exchange is

$i$

. The interspecies momentum exchange is

![]() $\beta _i=n_i F^D_i$

, where

$\beta _i=n_i F^D_i$

, where

![]() $n_i = c_i \phi /V_i$

represents the particle number density,

$n_i = c_i \phi /V_i$

represents the particle number density,

![]() $\phi$

is the bulk solid volume fraction, and

$\phi$

is the bulk solid volume fraction, and

![]() $V_i$

denotes the individual particle volume of species

$V_i$

denotes the individual particle volume of species

![]() $i$

. Combined with the bulk pressure gradient

$i$

. Combined with the bulk pressure gradient

![]() $\partial p/\partial z = -\phi \rho g$

, where it is assumed that both species have the same density

$\partial p/\partial z = -\phi \rho g$

, where it is assumed that both species have the same density

![]() $\rho$

, the ratio of the pressure contribution of species

$\rho$

, the ratio of the pressure contribution of species

![]() $i$

to the bulk pressure

$i$

to the bulk pressure

![]() $p$

, or normal stress fraction, is

$p$

, or normal stress fraction, is

![]() $f_i=p_i/p= n_i F^S_i/\phi \rho g=c_i F^S_i/m_i g$

in the simplified case where

$f_i=p_i/p= n_i F^S_i/\phi \rho g=c_i F^S_i/m_i g$

in the simplified case where

![]() $F^S_i$

remains constant with depth. Prior studies adopting the momentum-based approach have often assumed a quadratic-dependence or a particle-size or volume-weighted dependence of

$F^S_i$

remains constant with depth. Prior studies adopting the momentum-based approach have often assumed a quadratic-dependence or a particle-size or volume-weighted dependence of

![]() $f_i$

on

$f_i$

on

![]() $c_i$

(Marks et al. Reference Marks, Rognon and Einav2012; Tunuguntla, Bokhove & Thornton Reference Tunuguntla, Bokhove and Thornton2014; Gray & Ancey Reference Gray and Ancey2015; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Rousseau et al. Reference Rousseau, Chassagne, Chauchat, Maurin and Frey2021; Trewhela et al. Reference Trewhela, Ancey and Gray2021), along with a linear drag model (Gray & Thornton Reference Gray and Thornton2005). While these approaches have been proposed for species concentration profiles in specific scenarios, the approach we use here matches direct DEM measurements of

$c_i$

(Marks et al. Reference Marks, Rognon and Einav2012; Tunuguntla, Bokhove & Thornton Reference Tunuguntla, Bokhove and Thornton2014; Gray & Ancey Reference Gray and Ancey2015; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Rousseau et al. Reference Rousseau, Chassagne, Chauchat, Maurin and Frey2021; Trewhela et al. Reference Trewhela, Ancey and Gray2021), along with a linear drag model (Gray & Thornton Reference Gray and Thornton2005). While these approaches have been proposed for species concentration profiles in specific scenarios, the approach we use here matches direct DEM measurements of

![]() $f_i$

(Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022), and using (2.1) allows us to consider the segregation velocity of not only mixtures but also intruders for a wide range of granular flow conditions and geometries.

$f_i$

(Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022), and using (2.1) allows us to consider the segregation velocity of not only mixtures but also intruders for a wide range of granular flow conditions and geometries.

2.2. Segregation force,

$F^S_i$

$F^S_i$

Determining the segregation force

![]() $F^S_i$

at finite concentration starts with the segregation force on a single intruder,

$F^S_i$

at finite concentration starts with the segregation force on a single intruder,

![]() $F^S_{i,0}$

(subscript

$F^S_{i,0}$

(subscript

![]() $0$

indicates the single-intruder limit of species

$0$

indicates the single-intruder limit of species

![]() $i$

,

$i$

,

![]() $c_i \to 0$

). Here,

$c_i \to 0$

). Here,

![]() $F^S_{i,0}$

can be modelled with two additive terms, one related to gravity and the other to flow kinematics. Inspired by the observations of Fan & Hill (Reference Fan and Hill2011a

,Reference Fan and Hill

b

), the flow kinematics term was initially scaled with the shear stress gradient (Guillard et al. Reference Guillard, Forterre and Pouliquen2016) but was later linked to the shear rate gradient (Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2021; Singh et al. Reference Singh, Liu and Henann2024). The segregation force can be expressed as (Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2021)

$F^S_{i,0}$

can be modelled with two additive terms, one related to gravity and the other to flow kinematics. Inspired by the observations of Fan & Hill (Reference Fan and Hill2011a

,Reference Fan and Hill

b

), the flow kinematics term was initially scaled with the shear stress gradient (Guillard et al. Reference Guillard, Forterre and Pouliquen2016) but was later linked to the shear rate gradient (Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2021; Singh et al. Reference Singh, Liu and Henann2024). The segregation force can be expressed as (Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2021)

where superscripts

![]() $g$

and

$g$

and

![]() $k$

indicate gravity- and kinematics-related mechanisms, respectively,

$k$

indicate gravity- and kinematics-related mechanisms, respectively,

![]() $V_i$

is the intruder particle volume,

$V_i$

is the intruder particle volume,

![]() $\dot \gamma$

is the local shear rate, and

$\dot \gamma$

is the local shear rate, and

![]() $\rho$

is the density of both the intruder and the bed particles. The gravity term is buoyancy-like, and the kinematic term depends on the shear rate gradient in the flow. The empirical dimensionless functions

$\rho$

is the density of both the intruder and the bed particles. The gravity term is buoyancy-like, and the kinematic term depends on the shear rate gradient in the flow. The empirical dimensionless functions

![]() $f^g(R_d)$

and

$f^g(R_d)$

and

![]() $f^k(R_d)$

depend on the intruder-to-bed-particle-diameter ratio

$f^k(R_d)$

depend on the intruder-to-bed-particle-diameter ratio

![]() $R_d=d_i/d_j$

(Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2021),

$R_d=d_i/d_j$

(Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2021),

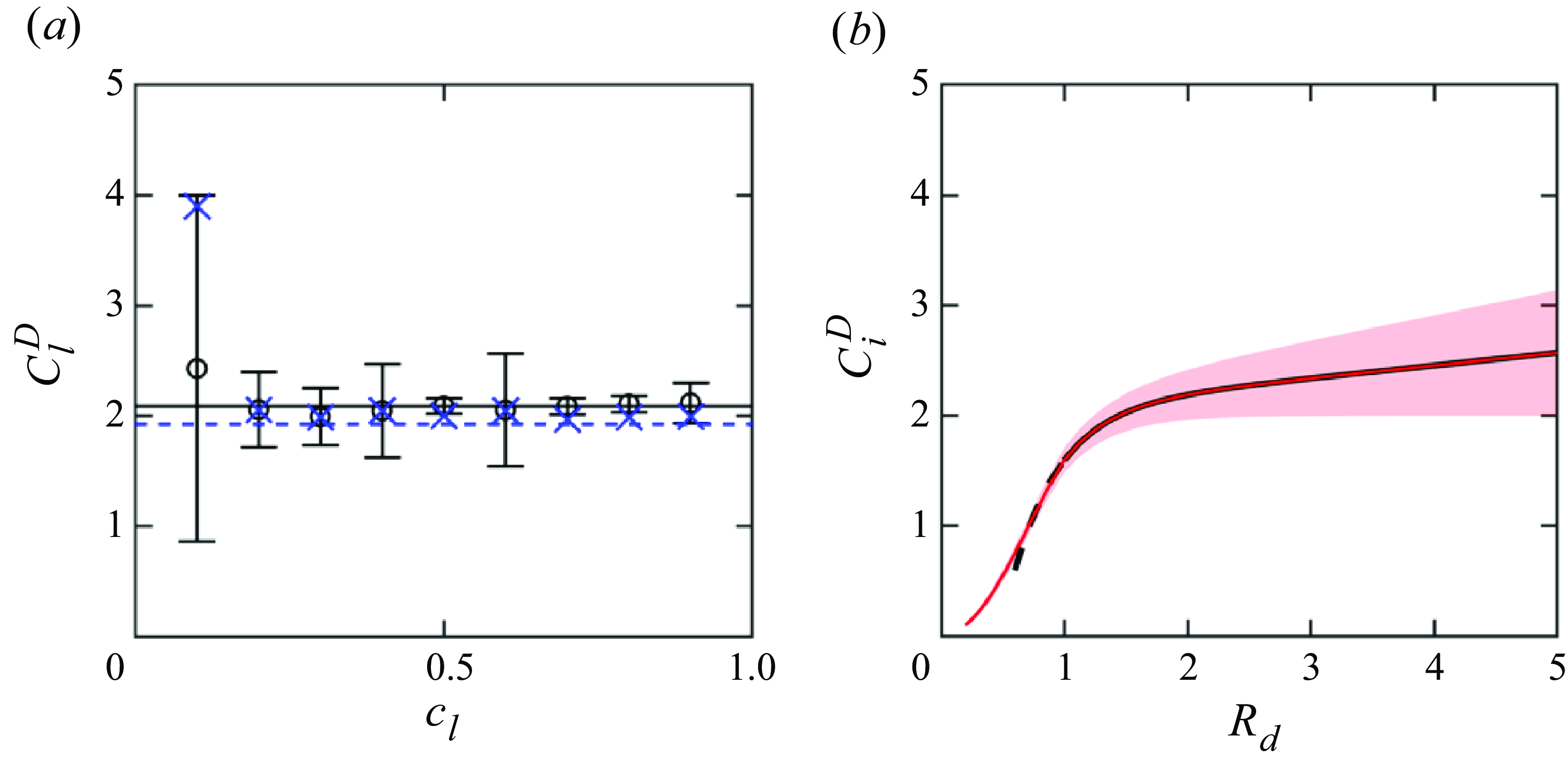

\begin{equation} f^g(R_d)=\left [ 1-c^g_1 \exp \left(-\frac {R_d}{R^g_1}\right) \right] \left [ 1+c^g_2\exp \left(-\frac {R_d}{R^g_2}\right) \right], \end{equation}

\begin{equation} f^g(R_d)=\left [ 1-c^g_1 \exp \left(-\frac {R_d}{R^g_1}\right) \right] \left [ 1+c^g_2\exp \left(-\frac {R_d}{R^g_2}\right) \right], \end{equation}

\begin{equation} f^k(R_d)=f^k_\infty \left [ \tanh {\left(\frac {R_d-1}{R^k_1}\right)} \right] \left [ 1+c^k_2\exp \left(-\frac {R_d}{R^k_2}\right) \right], \end{equation}

\begin{equation} f^k(R_d)=f^k_\infty \left [ \tanh {\left(\frac {R_d-1}{R^k_1}\right)} \right] \left [ 1+c^k_2\exp \left(-\frac {R_d}{R^k_2}\right) \right], \end{equation}

where

![]() $R^g_1=0.92$

,

$R^g_1=0.92$

,

![]() $R^g_2=2.94$

,

$R^g_2=2.94$

,

![]() $c^g_1=1.43$

,

$c^g_1=1.43$

,

![]() $c^g_2=3.55$

,

$c^g_2=3.55$

,

![]() $f^k_\infty =0.19$

,

$f^k_\infty =0.19$

,

![]() $R^k_1=0.59$

,

$R^k_1=0.59$

,

![]() $R^k_2=5.48$

and

$R^k_2=5.48$

and

![]() $c^k_2=3.63$

are fitting parameters appropriate for a range of flow conditions. In applying these functions over a range of concentrations, we need to consider both a large intruder particle surrounded by a bed of small particles and a small intruder particle surrounded by a bed of large particles corresponding to intruder-to-bed particle-size ratios of

$c^k_2=3.63$

are fitting parameters appropriate for a range of flow conditions. In applying these functions over a range of concentrations, we need to consider both a large intruder particle surrounded by a bed of small particles and a small intruder particle surrounded by a bed of large particles corresponding to intruder-to-bed particle-size ratios of

![]() $d_l/d_s$

and

$d_l/d_s$

and

![]() $d_s/d_l$

, respectively.

$d_s/d_l$

, respectively.

To predict the segregation force

![]() $F^S_i$

in mixtures at arbitrary non-zero concentrations, the intruder-segregation-force model in (2.3) is extended using semi-empirical relations for mixtures (rather than an intruder particle) based on DEM simulations (Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022). For large particles in a bidisperse mixture of concentration

$F^S_i$

in mixtures at arbitrary non-zero concentrations, the intruder-segregation-force model in (2.3) is extended using semi-empirical relations for mixtures (rather than an intruder particle) based on DEM simulations (Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022). For large particles in a bidisperse mixture of concentration

![]() $c_l$

(Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2024),

$c_l$

(Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2024),

\begin{equation} F^S_l=m_l g\cos {\theta }+(F_{l,0}^S-m_l g\cos {\theta })\textrm {tanh}\left ( \frac {m_l g\cos {\theta }- F_{s,0}^S }{F_{l,0}^S-m_l g\cos {\theta }}\frac {c_s}{c_l} \right), \end{equation}

\begin{equation} F^S_l=m_l g\cos {\theta }+(F_{l,0}^S-m_l g\cos {\theta })\textrm {tanh}\left ( \frac {m_l g\cos {\theta }- F_{s,0}^S }{F_{l,0}^S-m_l g\cos {\theta }}\frac {c_s}{c_l} \right), \end{equation}

and for small particles,

\begin{equation} F_{s}^S=m_s g\cos {\theta }-(F_{l,0}^S-m_s g\cos {\theta }){\frac {c_l}{c_s}}\textrm {tanh}\left ( \frac {m_s g\cos {\theta }-F_{s,0}^S}{{F}_{l,0}-m_s g\cos {\theta }}\frac {c_s}{c_l} \right), \end{equation}

\begin{equation} F_{s}^S=m_s g\cos {\theta }-(F_{l,0}^S-m_s g\cos {\theta }){\frac {c_l}{c_s}}\textrm {tanh}\left ( \frac {m_s g\cos {\theta }-F_{s,0}^S}{{F}_{l,0}-m_s g\cos {\theta }}\frac {c_s}{c_l} \right), \end{equation}

where

![]() $\theta$

is the angle between gravity and the segregation direction, which is generally normal to the flow.

$\theta$

is the angle between gravity and the segregation direction, which is generally normal to the flow.

Equations (2.5a

) and (2.5b

) can be rewritten in terms of the net forces (

![]() $T_i=F^S_i-m_ig\cos \theta$

) that balance the interspecies drag (2.1) such that

$T_i=F^S_i-m_ig\cos \theta$

) that balance the interspecies drag (2.1) such that

where

![]() $T_{i,0}=F_{i,0}-m_ig\cos \theta$

, and

$T_{i,0}=F_{i,0}-m_ig\cos \theta$

, and

![]() $F_{i,0}$

and

$F_{i,0}$

and

![]() $F_{i}$

denote the segregation forces for a single intruder and for mixtures, respectively. The force balance in (2.1) can be rewritten for a mixture as

$F_{i}$

denote the segregation forces for a single intruder and for mixtures, respectively. The force balance in (2.1) can be rewritten for a mixture as

What remains to be specified is an expression for the drag force in a mixture,

![]() $F^D_i$

, including its dependence on the segregation velocity, which is described next.

$F^D_i$

, including its dependence on the segregation velocity, which is described next.

2.3. Drag force,

$F^D_i$

$F^D_i$

As with the approach for the segregation force, we start with the drag force on a single intruder particle within a monodisperse flow of bed particles,

![]() $F^D_{i,0}$

. A Stokes drag formulation can be employed to express the drag force (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022; He et al. Reference He, Zhang, Ottino, Umbanhowar and Lueptow2025) in terms of the intruder segregation velocity relative to the local bulk flow velocity in the segregation direction,

$F^D_{i,0}$

. A Stokes drag formulation can be employed to express the drag force (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022; He et al. Reference He, Zhang, Ottino, Umbanhowar and Lueptow2025) in terms of the intruder segregation velocity relative to the local bulk flow velocity in the segregation direction,

![]() $w_{i,0}$

, as

$w_{i,0}$

, as

where

![]() $C^D_{i,0}$

is the drag coefficient for a single intruder, and

$C^D_{i,0}$

is the drag coefficient for a single intruder, and

![]() $\eta$

is the effective bulk granular viscosity calculated from the

$\eta$

is the effective bulk granular viscosity calculated from the

![]() $\mu (I)$

rheology as described shortly. For Stokes drag on a spherical particle at low Reynolds number in a viscous fluid,

$\mu (I)$

rheology as described shortly. For Stokes drag on a spherical particle at low Reynolds number in a viscous fluid,

![]() $C^D_{i,0}=3$

. However, the value of

$C^D_{i,0}=3$

. However, the value of

![]() $C^D_{i,0}$

for an intruder in a granular flow is not as simply specified. For a single spherical intruder particle,

$C^D_{i,0}$

for an intruder in a granular flow is not as simply specified. For a single spherical intruder particle,

![]() $C^D_{i,0} \approx 2.1$

for

$C^D_{i,0} \approx 2.1$

for

![]() $1\leqslant R_d \leqslant 5$

, but the precise value depends on the flow conditions (Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022), specifically, the size-bidisperse mixture inertial number (Rognon et al. Reference Rognon, Roux, Naaïm and Chevoir2007; Tripathi & Khakhar Reference Tripathi and Khakhar2011),

$1\leqslant R_d \leqslant 5$

, but the precise value depends on the flow conditions (Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022), specifically, the size-bidisperse mixture inertial number (Rognon et al. Reference Rognon, Roux, Naaïm and Chevoir2007; Tripathi & Khakhar Reference Tripathi and Khakhar2011),

\begin{equation} { I =\dot \gamma \sqrt {\frac {\rho }{p}}\sum _{i=s,l}d_ic_i.} \end{equation}

\begin{equation} { I =\dot \gamma \sqrt {\frac {\rho }{p}}\sum _{i=s,l}d_ic_i.} \end{equation}

For large intruders with

![]() $R_d\geqslant 1$

,

$R_d\geqslant 1$

,

where

![]() $k_1=2$

,

$k_1=2$

,

![]() $k_2=7$

,

$k_2=7$

,

![]() $k_3=2.6$

,

$k_3=2.6$

,

![]() $s_1=0.57$

and

$s_1=0.57$

and

![]() $s_2=0.1$

are fitting parameters determined across a wide range of flow conditions (

$s_2=0.1$

are fitting parameters determined across a wide range of flow conditions (

![]() $0.6\leqslant R_d \leqslant 5$

,

$0.6\leqslant R_d \leqslant 5$

,

![]() $1\leqslant R_{\rho } \leqslant 20$

and

$1\leqslant R_{\rho } \leqslant 20$

and

![]() $I \lesssim 1$

), and

$I \lesssim 1$

), and

![]() $R_\rho$

is the intruder-to-bed-particle density ratio (Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022). The granular viscosity

$R_\rho$

is the intruder-to-bed-particle density ratio (Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022). The granular viscosity

![]() $\eta$

is estimated from the

$\eta$

is estimated from the

![]() $\mu (I)$

rheology (GDR-MiDi 2004) as

$\mu (I)$

rheology (GDR-MiDi 2004) as

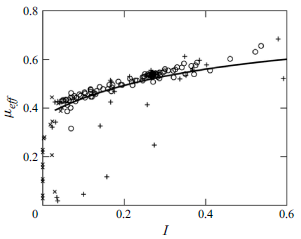

where the effective friction coefficient is

where

![]() $\tau$

is the shear stress and

$\tau$

is the shear stress and

![]() $\mu _s$

,

$\mu _s$

,

![]() $\mu _2$

and

$\mu _2$

and

![]() $I_c$

are granular material specific parameters. The flows simulated in this study generally follow the

$I_c$

are granular material specific parameters. The flows simulated in this study generally follow the

![]() $\mu (I)$

rheology for dense flows with the usual caveats for collisional flow at larger

$\mu (I)$

rheology for dense flows with the usual caveats for collisional flow at larger

![]() $I$

than considered here and for quasi-static flow as

$I$

than considered here and for quasi-static flow as

![]() $I\rightarrow 0$

, see Appendix A.

$I\rightarrow 0$

, see Appendix A.

The drag coefficient,

![]() $C^D_{i,0}$

, in (2.10) is for a single intruder particle in an otherwise homogeneous bed of the other species. Since we are interested in the segregation velocity of particles in a mixture, it is necessary to determine the dependence of the drag force in a mixture,

$C^D_{i,0}$

, in (2.10) is for a single intruder particle in an otherwise homogeneous bed of the other species. Since we are interested in the segregation velocity of particles in a mixture, it is necessary to determine the dependence of the drag force in a mixture,

![]() $F^D_i,$

on species concentration. Previous approaches to determine the mixture

$F^D_i,$

on species concentration. Previous approaches to determine the mixture

![]() $C^D_i$

have focused predominantly on density-bidisperse mixtures where

$C^D_i$

have focused predominantly on density-bidisperse mixtures where

![]() $R_d=1$

(Tripathi & Khakhar Reference Tripathi and Khakhar2013; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020; Bancroft & Johnson Reference Bancroft and Johnson2021) due to the simplicity of estimating the segregation force in terms of buoyancy. Reported values of

$R_d=1$

(Tripathi & Khakhar Reference Tripathi and Khakhar2013; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020; Bancroft & Johnson Reference Bancroft and Johnson2021) due to the simplicity of estimating the segregation force in terms of buoyancy. Reported values of

![]() $C^D_i$

at

$C^D_i$

at

![]() $R_d=1$

based on this approach range from 1.7 to 3.7 depending on the volume fraction, and

$R_d=1$

based on this approach range from 1.7 to 3.7 depending on the volume fraction, and

![]() $C^D_i$

is independent of

$C^D_i$

is independent of

![]() $c_i$

for density-bidisperse mixtures. However, the concentration dependence of

$c_i$

for density-bidisperse mixtures. However, the concentration dependence of

![]() $C^D_i$

in size-bidisperse mixtures (

$C^D_i$

in size-bidisperse mixtures (

![]() $R_d\ne 1$

and density ratio

$R_d\ne 1$

and density ratio

![]() $R_\rho =1$

) has not been considered explicitly, although Bancroft & Johnson (Reference Bancroft and Johnson2021) mention it in passing. We use simulations of controlled shear flow later in this paper (§ 4) to demonstrate that the drag coefficient is nearly independent of the mixture concentration for the conditions we consider here. For now, in order to proceed with the analysis, we simply assume that

$R_\rho =1$

) has not been considered explicitly, although Bancroft & Johnson (Reference Bancroft and Johnson2021) mention it in passing. We use simulations of controlled shear flow later in this paper (§ 4) to demonstrate that the drag coefficient is nearly independent of the mixture concentration for the conditions we consider here. For now, in order to proceed with the analysis, we simply assume that

![]() $C^D_i \approx C^D_{i,0}$

. Hence,

$C^D_i \approx C^D_{i,0}$

. Hence,

where the mixture drag coefficient,

![]() $C^D_i$

, has been substituted for the intruder drag coefficient,

$C^D_i$

, has been substituted for the intruder drag coefficient,

![]() $C^D_{i,0}$

, and the species-specific segregation velocity in the mixture,

$C^D_{i,0}$

, and the species-specific segregation velocity in the mixture,

![]() $w_i$

, for the intruder segregation velocity,

$w_i$

, for the intruder segregation velocity,

![]() $w_{i,0}$

, in (2.8).

$w_{i,0}$

, in (2.8).

2.4. Segregation velocity

The species-specific segregation velocity,

![]() $w_i$

, relative to the local bulk flow velocity in the segregation direction is now easily calculated by substituting the mixture drag force (2.12) and the segregation-force model (2.6) into the force balance (2.7) and solving for the segregation velocities of the large-particle species,

$w_i$

, relative to the local bulk flow velocity in the segregation direction is now easily calculated by substituting the mixture drag force (2.12) and the segregation-force model (2.6) into the force balance (2.7) and solving for the segregation velocities of the large-particle species,

![]() $w_l$

, and small-particle species,

$w_l$

, and small-particle species,

![]() $w_s$

:

$w_s$

:

\begin{equation} w_l=\frac { T_{l,0}\textrm {tanh}\left ( -\dfrac{{T}_{s,0}}{{T}_{l,0} }\dfrac{m_lc_s}{m_sc_l} \right)}{C^D_l \pi \eta d_l} \end{equation}

\begin{equation} w_l=\frac { T_{l,0}\textrm {tanh}\left ( -\dfrac{{T}_{s,0}}{{T}_{l,0} }\dfrac{m_lc_s}{m_sc_l} \right)}{C^D_l \pi \eta d_l} \end{equation}

and

\begin{equation} w_s=-\frac { {T}_{l,0}{\dfrac{m_sc_l}{m_lc_s}}\textrm {tanh}\left ( -\dfrac{{T}_{s,0}}{{T}_{l,0} }\dfrac{m_lc_s}{m_sc_l} \right) }{C^D_s \pi \eta d_s}. \end{equation}

\begin{equation} w_s=-\frac { {T}_{l,0}{\dfrac{m_sc_l}{m_lc_s}}\textrm {tanh}\left ( -\dfrac{{T}_{s,0}}{{T}_{l,0} }\dfrac{m_lc_s}{m_sc_l} \right) }{C^D_s \pi \eta d_s}. \end{equation}

Recall that we assume

![]() $C^D_i \approx C^D_{i,0}$

, independent of species concentration

$C^D_i \approx C^D_{i,0}$

, independent of species concentration

![]() $c_i$

, which we confirm in § 4.

$c_i$

, which we confirm in § 4.

2.5. Effect of diffusion on segregation velocity

A final consideration is the diffusive flux of species driven by collisional diffusion and its effect on the measured segregation velocity. The diffusion contribution is most clearly framed in terms of the advection–diffusion–segregation transport equation based on mass balance that has been successfully used to model segregation in flowing granular media (Bridgwater et al. Reference Bridgwater, Foo and Stephens1985; Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019). Within this continuum framework, the concentration of species

![]() $i$

can be expressed as

$i$

can be expressed as

Here,

![]() $\boldsymbol{u}_i$

is the diffusionless velocity, and the local collisional diffusion coefficient

$\boldsymbol{u}_i$

is the diffusionless velocity, and the local collisional diffusion coefficient

![]() $D$

is a scalar, although in general it is a tensor. This approximation is accurate for flows with a single dominant shear direction (Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019). Note that the diffusionless velocity,

$D$

is a scalar, although in general it is a tensor. This approximation is accurate for flows with a single dominant shear direction (Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019). Note that the diffusionless velocity,

![]() $\boldsymbol{u}_i$

, differs slightly from the overall velocity, which is a combined effect of both advection and diffusion. With the usual assumptions of two-dimensional flow and gradual development in the streamwise direction, (2.14) in the

$\boldsymbol{u}_i$

, differs slightly from the overall velocity, which is a combined effect of both advection and diffusion. With the usual assumptions of two-dimensional flow and gradual development in the streamwise direction, (2.14) in the

![]() $z$

-direction can be written as

$z$

-direction can be written as

or, rearranging, as

where

![]() $w$

is the local vertical velocity of the bulk. Note that

$w$

is the local vertical velocity of the bulk. Note that

![]() $w=0$

in the reference frames associated with the example flows used in this study.

$w=0$

in the reference frames associated with the example flows used in this study.

When the normal component of flux for species

![]() $i$

is measured from DEM simulation, it is the entire quantity within the square brackets of (2.16) that is measured. In other words, the measured normal flux

$i$

is measured from DEM simulation, it is the entire quantity within the square brackets of (2.16) that is measured. In other words, the measured normal flux

![]() $(w_i+w)c_i-D(\partial c_i/\partial z)$

is a combination of both the total segregation flux,

$(w_i+w)c_i-D(\partial c_i/\partial z)$

is a combination of both the total segregation flux,

![]() $(w_i+w)c_i$

, and the diffusion flux,

$(w_i+w)c_i$

, and the diffusion flux,

![]() $-D(\partial c_i/\partial z)$

. To compare the segregation-velocity model predictions developed in this paper with DEM measurements of the segregation velocity, the segregation flux needs to be combined with the diffusion flux, such that the net species velocity is

$-D(\partial c_i/\partial z)$

. To compare the segregation-velocity model predictions developed in this paper with DEM measurements of the segregation velocity, the segregation flux needs to be combined with the diffusion flux, such that the net species velocity is

which can be measured directly in situations where there is a concentration gradient.

Both experimental (Bridgwater Reference Bridgwater1980; Utter & Behringer Reference Utter and Behringer2004) and computational (Fan et al. Reference Fan, Umbanhowar, Ottino and Lueptow2015; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019) studies of dense granular flows suggest that the diffusion coefficient,

![]() $D$

, is proportional to the product of the local shear rate and the square of the local mean particle diameter,

$D$

, is proportional to the product of the local shear rate and the square of the local mean particle diameter,

where

![]() $\bar d = \sum c_i d_i$

and

$\bar d = \sum c_i d_i$

and

![]() $A$

is a constant with reported values in the range 0.01–0.1 (Savage & Dai Reference Savage and Dai1993; Hsiau & Shieh Reference Hsiau and Shieh1999; Utter & Behringer Reference Utter and Behringer2004; Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014, Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2015; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019). In this study,

$A$

is a constant with reported values in the range 0.01–0.1 (Savage & Dai Reference Savage and Dai1993; Hsiau & Shieh Reference Hsiau and Shieh1999; Utter & Behringer Reference Utter and Behringer2004; Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014, Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2015; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019). In this study,

![]() $A=0.046$

based on diffusion coefficient data measured from heap-flow simulations (Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022).

$A=0.046$

based on diffusion coefficient data measured from heap-flow simulations (Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022).

With the exception of demonstrating that the drag coefficient for a mixture is similar to that for an intruder particle, as noted in § 2.3, we now have all of the relationships necessary to calculate the segregation velocity. Before addressing drag in mixtures, it is first necessary to describe the simulation approach that we use.

3. Simulations

An in-house DEM code running on CUDA-enabled NVIDIA GPUs is used to simulate size-bidisperse particle mixtures with species-specific volume concentration

![]() $c_i$

, diameter

$c_i$

, diameter

![]() $d_i$

and density

$d_i$

and density

![]() $\rho _l=\rho _s=1$

g cm

$\rho _l=\rho _s=1$

g cm

![]() $^{-3}$

. Large (

$^{-3}$

. Large (

![]() $d_l=4$

mm) and small (

$d_l=4$

mm) and small (

![]() $d_s$

varied to adjust the size ratio,

$d_s$

varied to adjust the size ratio,

![]() $R_d=d_l/d_s$

) particle species have a

$R_d=d_l/d_s$

) particle species have a

![]() $\pm 10$

% uniform size distribution to minimise layering (Staron & Phillips Reference Staron and Phillips2014) (increasing the diameter variation to

$\pm 10$

% uniform size distribution to minimise layering (Staron & Phillips Reference Staron and Phillips2014) (increasing the diameter variation to

![]() $\pm 20$

% does not alter the results). The mixture is sheared in the streamwise (

$\pm 20$

% does not alter the results). The mixture is sheared in the streamwise (

![]() $x$

) direction (see figure 1). Boundary conditions are periodic in

$x$

) direction (see figure 1). Boundary conditions are periodic in

![]() $x$

and

$x$

and

![]() $y$

with length

$y$

with length

![]() $L=35d_l$

and width

$L=35d_l$

and width

![]() $W=10d_l$

, respectively. The height is

$W=10d_l$

, respectively. The height is

![]() $H=50d_l$

in the

$H=50d_l$

in the

![]() $z$

-direction, which is normal to the flow direction (reducing

$z$

-direction, which is normal to the flow direction (reducing

![]() $H$

to

$H$

to

![]() $25d_l$

does not alter the results). In all cases, particles fall freely under gravity to fill the domain before flow begins. Gravity may be aligned with the

$25d_l$

does not alter the results). In all cases, particles fall freely under gravity to fill the domain before flow begins. Gravity may be aligned with the

![]() $z$

-direction, as shown in figure 1, at an angle

$z$

-direction, as shown in figure 1, at an angle

![]() $\theta$

with respect to

$\theta$

with respect to

![]() $z$

for inclined chute flow, or parallel to the flow aligned with

$z$

for inclined chute flow, or parallel to the flow aligned with

![]() $x$

for vertical chute flow. In some cases, gravity is set to zero; in all other cases we use

$x$

for vertical chute flow. In some cases, gravity is set to zero; in all other cases we use

![]() $g=g_0\equiv 9.81$

m s

$g=g_0\equiv 9.81$

m s

![]() $^{-2}$

.

$^{-2}$

.

The standard linear spring-dashpot model (Cundall & Strack Reference Cundall and Strack1979) is used to resolve particle–particle and particle–wall contacts of spherical particles using a friction coefficient of

![]() $\mu =0.5$

, a restitution coefficient of 0.9, and a binary collision time of 0.15 ms. We have confirmed that our results are relatively insensitive to these values except for very low friction coefficients (

$\mu =0.5$

, a restitution coefficient of 0.9, and a binary collision time of 0.15 ms. We have confirmed that our results are relatively insensitive to these values except for very low friction coefficients (

![]() $\mu \leqslant 0.2$

) (Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020; Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2020). From 26 000 to 150 000 particles are included in each simulation, depending on the size ratio.

$\mu \leqslant 0.2$

) (Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020; Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2020). From 26 000 to 150 000 particles are included in each simulation, depending on the size ratio.

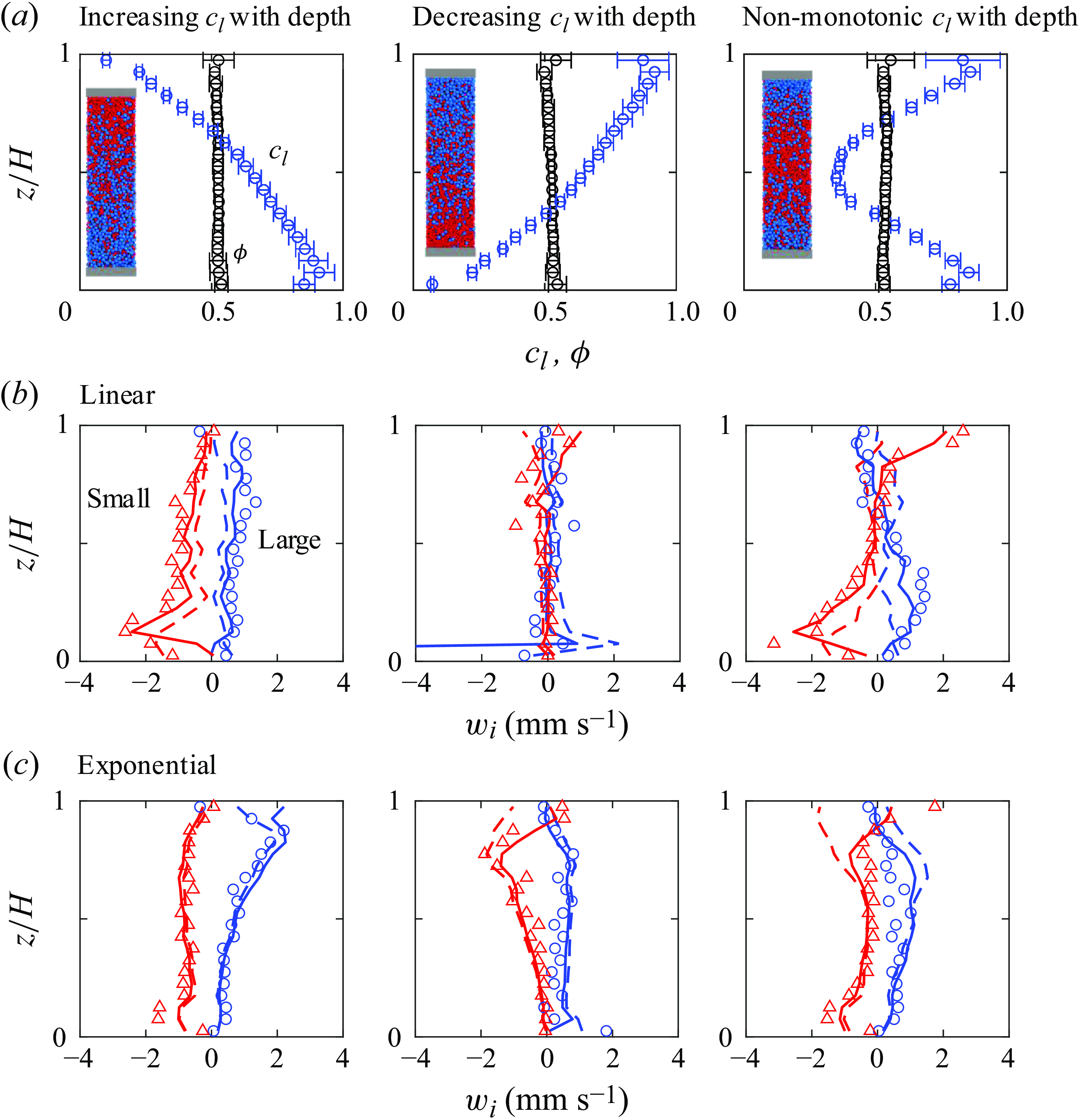

The segregation velocity is measured in a variety of flow configurations, including controlled shear flows and natural uncontrolled flows. These various flow configurations are explained in more detail in a previous paper in which we consider the segregation force (Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2024). The first flow conditions that we consider are controlled shear flows in which the velocity profile is constrained to be of a certain form. The specified velocity profile,

![]() $u(z)$

, is achieved by applying a small streamwise stabilising force

$u(z)$

, is achieved by applying a small streamwise stabilising force

![]() $k_v [\,u(z)-u_p(z_p)]\,$

to each particle at each DEM simulation time step in order to maintain the desired velocity profile, where

$k_v [\,u(z)-u_p(z_p)]\,$

to each particle at each DEM simulation time step in order to maintain the desired velocity profile, where

![]() $u_p$

and

$u_p$

and

![]() $z_p$

are the instantaneous particle velocity and position, respectively, and

$z_p$

are the instantaneous particle velocity and position, respectively, and

![]() $k_v$

is a gain parameter (Lerner, Düring & Wyart Reference Lerner, Düring and Wyart2012; Clark et al. Reference Clark, Thompson, Shattuck, Ouellette and O’Hern2018; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2018; Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2020, Reference Jing, Ottino, Lueptow and Umbanhowar2021, Reference Jing, Ottino, Umbanhowar and Lueptow2022). By prescribing a specific velocity profile, we control the shear rate and shear rate gradient, which play direct roles in determining both the segregation force (2.3) and the drag (2.8) via the viscosity (2.11), and hence influence the segregation velocity (2.13). The presence of gravity results in a pressure gradient in

$k_v$

is a gain parameter (Lerner, Düring & Wyart Reference Lerner, Düring and Wyart2012; Clark et al. Reference Clark, Thompson, Shattuck, Ouellette and O’Hern2018; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2018; Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2020, Reference Jing, Ottino, Lueptow and Umbanhowar2021, Reference Jing, Ottino, Umbanhowar and Lueptow2022). By prescribing a specific velocity profile, we control the shear rate and shear rate gradient, which play direct roles in determining both the segregation force (2.3) and the drag (2.8) via the viscosity (2.11), and hence influence the segregation velocity (2.13). The presence of gravity results in a pressure gradient in

![]() $z$

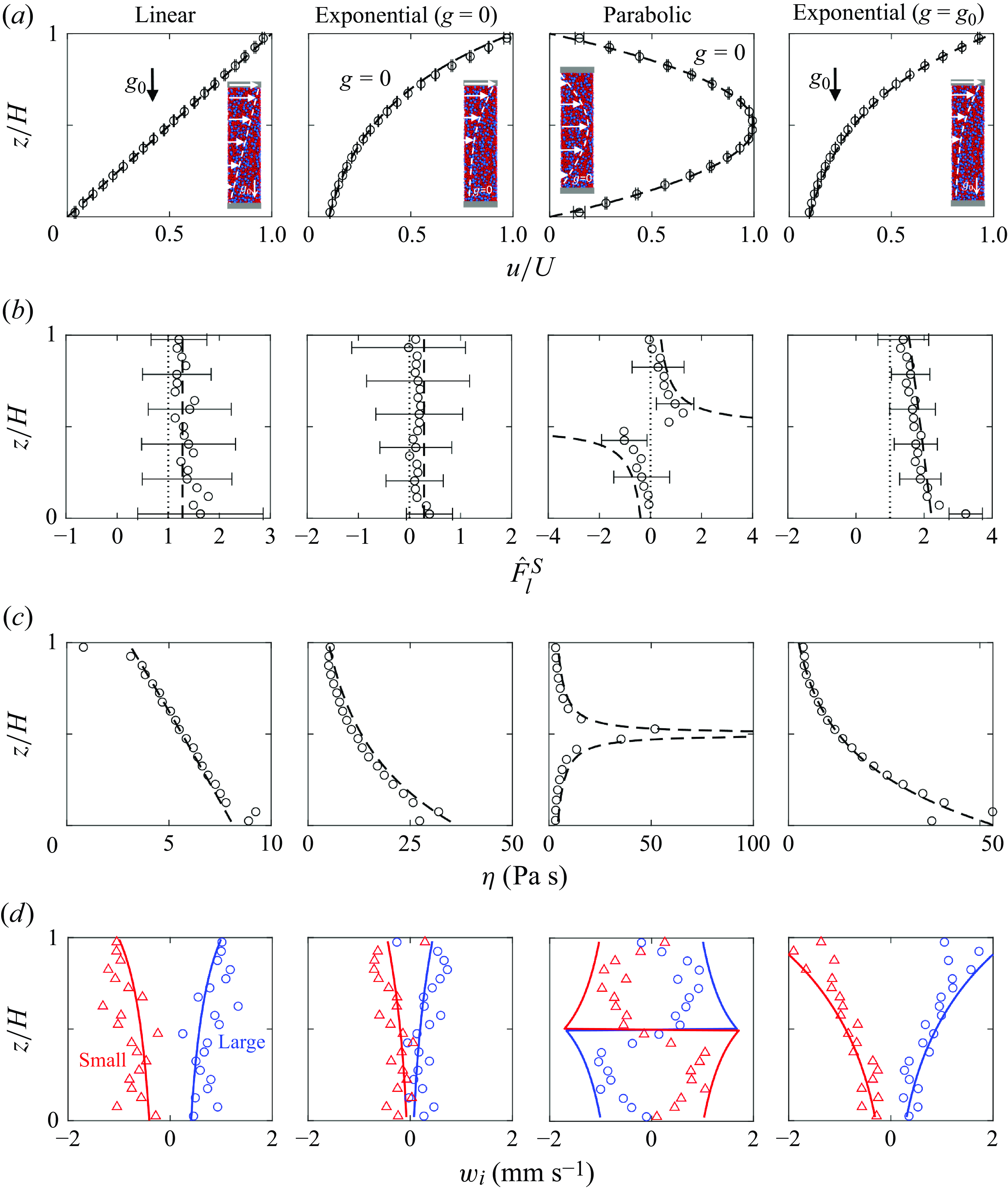

, which also influences the segregation force (2.3). We consider four cases: a linear velocity profile with gravity, an exponential velocity profile without gravity, a parabolic velocity profile without gravity, and an exponential velocity profile with gravity. (For reference, each of these flows is shown schematically later in the paper as insets when the results are discussed, see figure 3

a.) A wide range of inertial numbers,

$z$

, which also influences the segregation force (2.3). We consider four cases: a linear velocity profile with gravity, an exponential velocity profile without gravity, a parabolic velocity profile without gravity, and an exponential velocity profile with gravity. (For reference, each of these flows is shown schematically later in the paper as insets when the results are discussed, see figure 3

a.) A wide range of inertial numbers,

![]() $I$

, is achieved via the variation of the pressure with depth for flows with

$I$

, is achieved via the variation of the pressure with depth for flows with

![]() $g\neq 0$

and by imposing large shear rates, which can lead to wall velocities of

$g\neq 0$

and by imposing large shear rates, which can lead to wall velocities of

![]() $u(H)=U=20$

m s

$u(H)=U=20$

m s

![]() $^{-1}$

in some cases. For the flows with gravity (linear and exponential velocity profiles), a small overburden pressure

$^{-1}$

in some cases. For the flows with gravity (linear and exponential velocity profiles), a small overburden pressure

![]() $P_0$

equal to the pressure at a depth of

$P_0$

equal to the pressure at a depth of

![]() $2.5 d_l$

(i.e.

$2.5 d_l$

(i.e.

![]() $P_0=0.05\rho \phi g_0 H$

, where the bulk solid fraction

$P_0=0.05\rho \phi g_0 H$

, where the bulk solid fraction

![]() $\phi \approx 0.55$

) is imposed on the upper wall, which is free to move vertically, and which fluctuates in height by no more than

$\phi \approx 0.55$

) is imposed on the upper wall, which is free to move vertically, and which fluctuates in height by no more than

![]() $\pm$

0.05 % after an initial rapid dilatation of the particles at flow onset. For the flows without gravity (exponential and parabolic velocity profiles), the top wall is fixed vertically. These different velocity profiles allow us to consider cases with no pressure gradient (when gravity

$\pm$

0.05 % after an initial rapid dilatation of the particles at flow onset. For the flows without gravity (exponential and parabolic velocity profiles), the top wall is fixed vertically. These different velocity profiles allow us to consider cases with no pressure gradient (when gravity

![]() $g=0$

) so that the gravity-related first term of (2.3) is zero, with no shear rate gradient (linear profile) so that the kinematics-related second term of (2.3) is zero, and with combinations of the gravity and shear such that both the gravity and kinematics terms in (2.3) contribute to the segregation velocity.

$g=0$

) so that the gravity-related first term of (2.3) is zero, with no shear rate gradient (linear profile) so that the kinematics-related second term of (2.3) is zero, and with combinations of the gravity and shear such that both the gravity and kinematics terms in (2.3) contribute to the segregation velocity.

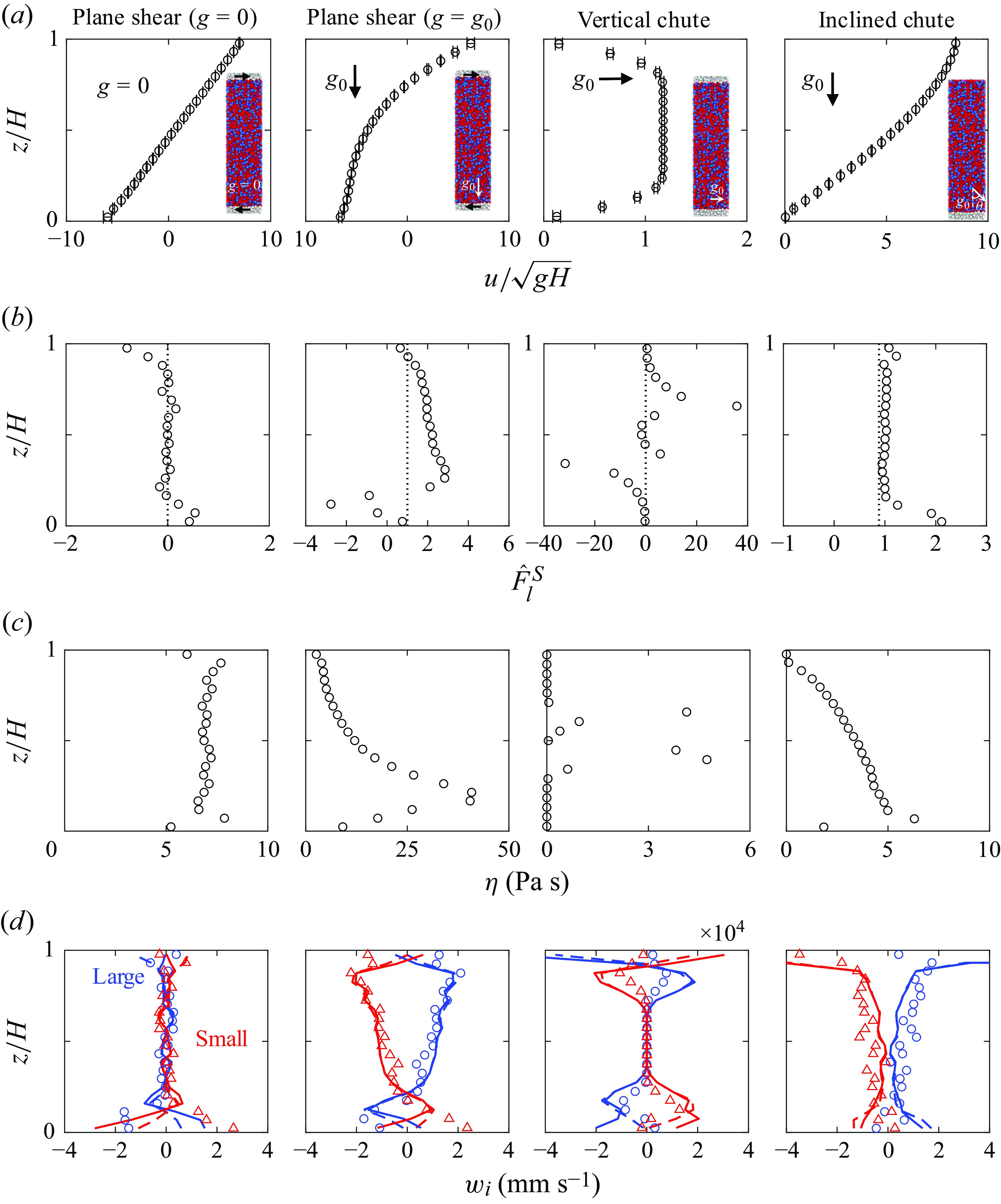

In addition to the controlled shear flows, we also consider four cases where the velocity field is not directly controlled. (For reference, each of these flows are shown schematically later in the paper as insets when the results are discussed, see figure 6). The flow kinematics of these uncontrolled ‘natural flows’ are driven entirely by the combined effects of gravity and boundary conditions. The walls are rough in all cases, formed from a

![]() $2.5d_l$

thick layer of bonded large and small particles that move collectively. For the wall-driven flows, an overburden pressure

$2.5d_l$

thick layer of bonded large and small particles that move collectively. For the wall-driven flows, an overburden pressure

![]() $P_0$

equal to the pressure at a depth of

$P_0$

equal to the pressure at a depth of

![]() $H/2$

(i.e.

$H/2$

(i.e.

![]() $P_0=0.5\rho \phi g_0 H$

) is imposed on the upper wall. When gravity is included for plane shear flow and inclined chute flow, it results in a pressure gradient in

$P_0=0.5\rho \phi g_0 H$

) is imposed on the upper wall. When gravity is included for plane shear flow and inclined chute flow, it results in a pressure gradient in

![]() $z$

. In both wall-driven flows, the upper wall moves at velocity

$z$

. In both wall-driven flows, the upper wall moves at velocity

![]() $u(H) = 10\,$

m s

$u(H) = 10\,$

m s

![]() $^{-1}$

in the

$^{-1}$

in the

![]() $x$

-direction and the lower wall at

$x$

-direction and the lower wall at

![]() $u(0) = -10\,$

m s

$u(0) = -10\,$

m s

![]() $^{-1}$

in the negative

$^{-1}$

in the negative

![]() $x$

-direction. Both cases show little to no slip at either wall. The vertical chute flow is driven by gravity, which is aligned parallel to the rough fixed bounding walls, resulting in a generally uniform velocity at the centre of the channel that goes to zero at the walls. In this case, there is no pressure gradient in

$x$

-direction. Both cases show little to no slip at either wall. The vertical chute flow is driven by gravity, which is aligned parallel to the rough fixed bounding walls, resulting in a generally uniform velocity at the centre of the channel that goes to zero at the walls. In this case, there is no pressure gradient in

![]() $z$

to drive segregation, so any segregation in

$z$

to drive segregation, so any segregation in

![]() $z$

is driven by shear gradients alone. Finally, the inclined chute flow lacks an upper wall (free boundary) so that particles flow due to a streamwise component of gravity. Here the pressure gradient in the segregation direction is

$z$

is driven by shear gradients alone. Finally, the inclined chute flow lacks an upper wall (free boundary) so that particles flow due to a streamwise component of gravity. Here the pressure gradient in the segregation direction is

![]() $g_0 \cos {\theta }$

, where

$g_0 \cos {\theta }$

, where

![]() $\theta$

is the inclination angle of the base (lower wall) relative to

$\theta$

is the inclination angle of the base (lower wall) relative to

![]() $\boldsymbol{g}$

.

$\boldsymbol{g}$

.

To consider segregation for each of these flow conditions, the simulation domain is discretised into horizontal layers, each of thickness

![]() $2.5d_l$

(1 mm) in the

$2.5d_l$

(1 mm) in the

![]() $z$

-direction, for averaging purposes (see figure 1). Decreasing the layer thickness to

$z$

-direction, for averaging purposes (see figure 1). Decreasing the layer thickness to

![]() $1.25d_l$

increases averaging uncertainties but does not alter the mean values of the flow fields. Within each layer, various local variables are measured including the streamwise velocity (

$1.25d_l$

increases averaging uncertainties but does not alter the mean values of the flow fields. Within each layer, various local variables are measured including the streamwise velocity (

![]() $u$

), pressure (

$u$

), pressure (

![]() $p$

), shear rate (

$p$

), shear rate (

![]() $\dot \gamma$

) and species concentration (

$\dot \gamma$

) and species concentration (

![]() $c_i$

). Subsequently, these flow measurements, which are averaged in the

$c_i$

). Subsequently, these flow measurements, which are averaged in the

![]() $x \hbox {-}$

and

$x \hbox {-}$

and

![]() $y \hbox {-}$

directions but vary in the

$y \hbox {-}$

directions but vary in the

![]() $z \hbox {-}$

direction, are used to determine intermediate variables including the net gravity and segregation force acting on each species (

$z \hbox {-}$

direction, are used to determine intermediate variables including the net gravity and segregation force acting on each species (

![]() $T_i$

via (2.3)–(2.6)), the local viscosity of the mixture (

$T_i$

via (2.3)–(2.6)), the local viscosity of the mixture (

![]() $\eta$

via (2.11)), the drag coefficient for each species (

$\eta$

via (2.11)), the drag coefficient for each species (

![]() $C^D_i$

via (2.10)) and the diffusion coefficient (

$C^D_i$

via (2.10)) and the diffusion coefficient (

![]() $D$

via (2.18)). Finally, these computed variables are used to predict the segregation velocity using (2.13) and, where necessary, (2.17).

$D$

via (2.18)). Finally, these computed variables are used to predict the segregation velocity using (2.13) and, where necessary, (2.17).

The predicted segregation velocities based on the model of (2.13) are compared with the segregation velocities measured from the simulations. To characterise the segregation velocity for each layer in figure 1, we assess the average centre of mass height for each species relative to the mean height of all particles over a short measurement window, calculated as

\begin{equation} \bar z_i = \frac {1}{N_i}\sum ^{N_i}_{k\in i}z_k- \frac {1}{N}\sum ^{N}_{k=1}z_k, \end{equation}

\begin{equation} \bar z_i = \frac {1}{N_i}\sum ^{N_i}_{k\in i}z_k- \frac {1}{N}\sum ^{N}_{k=1}z_k, \end{equation}

where

![]() $N_i$

and

$N_i$

and

![]() $N$

are the number of particles of species

$N$

are the number of particles of species

![]() $i$

and the total number of particles in the horizontal averaging layer, respectively. The segregation distance for species

$i$

and the total number of particles in the horizontal averaging layer, respectively. The segregation distance for species

![]() $i$

is the offset of its centre of mass from its initial position,

$i$

is the offset of its centre of mass from its initial position,

![]() $\bar z_i - \bar z_{i,0}$

. The segregation velocity for species

$\bar z_i - \bar z_{i,0}$

. The segregation velocity for species

![]() $i$

is then measured as the rate of this offset,

$i$

is then measured as the rate of this offset,

![]() $(\bar z_i - \bar z_{i,0})/\Delta t$

, where the measurement window is

$(\bar z_i - \bar z_{i,0})/\Delta t$

, where the measurement window is

![]() $\Delta t=1\,s$

, which we have shown previously is sufficiently long to provide statistically meaningful data and short enough to capture temporally local results (Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020).

$\Delta t=1\,s$

, which we have shown previously is sufficiently long to provide statistically meaningful data and short enough to capture temporally local results (Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020).

To mitigate the influence of noise and kinematic acceleration on the measurements, each simulation begins with the initial flow of mixed particles subject to equal and opposite vertical restoring forces applied to particles of each species in each layer in figure 1. This technique maintains the initial uniformly mixed distribution of the two particle species and suppresses segregation while the flow develops, similar to the approach previously employed to measure the mixture segregation force (Duan et al. Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022, Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2024). The flow is allowed to develop for 2 s with the prescribed velocity and concentration profiles and the segregation being suppressed. During the subsequent 1 s measurement window, the restoring forces suppressing the segregation are deactivated while primary flow field parameters, such as streamwise velocity, pressure and particle vertical positions (

![]() $z_k$

) are recorded at intervals of 0.01 s. The species segregation velocity is then measured as

$z_k$

) are recorded at intervals of 0.01 s. The species segregation velocity is then measured as

![]() $w_i=(\bar z_i-\bar z_{i,0})/ \Delta t$

for the ensemble of each particle species in each layer, and the other local variables (

$w_i=(\bar z_i-\bar z_{i,0})/ \Delta t$

for the ensemble of each particle species in each layer, and the other local variables (

![]() $u$

,

$u$

,

![]() $p$

,

$p$

,

![]() $c_i$

) in each layer are averaged over the 1 s measurement window for use in calculating the predicted segregation velocity from (2.13). We have shown previously (Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2018; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020; Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022, Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2024) and confirmed here that the velocity profile is unaffected by the segregation for the short duration of the measurement window. Furthermore, we have confirmed that the concentration profile in the bulk changes by less than 2 % on average over the 1 s measurement window.

$c_i$

) in each layer are averaged over the 1 s measurement window for use in calculating the predicted segregation velocity from (2.13). We have shown previously (Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2018; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020; Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2022, Reference Duan, Jing, Umbanhowar, Ottino and Lueptow2024) and confirmed here that the velocity profile is unaffected by the segregation for the short duration of the measurement window. Furthermore, we have confirmed that the concentration profile in the bulk changes by less than 2 % on average over the 1 s measurement window.

4. Drag force in mixtures

Before considering the segregation velocity, which is the focus of this paper, it is necessary to address the effect of mixture concentration on the drag force, as noted in § 2.3. To extend the intruder drag model of (2.8) and (2.10) to mixtures, we perform a series of simulations using an approach motivated by Bancroft & Johnson (Reference Bancroft and Johnson2021), where opposing forces are applied to particles of each species. Specifically, equal and opposite applied forces are imposed in the segregation direction to particles of each species (negative

![]() $z$

-direction for small particles and positive

$z$

-direction for small particles and positive

![]() $z$

-direction for large particles) in a homogeneous shear flow of a mixture of large and small particles like that shown in figure 1 with

$z$

-direction for large particles) in a homogeneous shear flow of a mixture of large and small particles like that shown in figure 1 with

![]() $g=0$

. The applied force, which is distributed across all particles of a species, drives the particle species to segregate at a rate controlled entirely by the applied force and the drag, which balance each other (Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022). In this way, (2.1) has just two terms, the mixture segregation force,

$g=0$

. The applied force, which is distributed across all particles of a species, drives the particle species to segregate at a rate controlled entirely by the applied force and the drag, which balance each other (Jing et al. Reference Jing, Ottino, Umbanhowar and Lueptow2022). In this way, (2.1) has just two terms, the mixture segregation force,

![]() $F^S_i$

, which is equivalent to the applied force, and the mixture drag force

$F^S_i$

, which is equivalent to the applied force, and the mixture drag force

![]() $F^D_i$

(since

$F^D_i$

(since

![]() $g=0$

). Here,

$g=0$

). Here,

![]() $F^D_i$

is given by (2.12) which is in terms of the effective granular viscosity,

$F^D_i$

is given by (2.12) which is in terms of the effective granular viscosity,

![]() $\eta$

, and the species-specific segregation velocity,

$\eta$

, and the species-specific segregation velocity,

![]() $w_i$

. By tracking the average motion of all of the particles of each species,

$w_i$

. By tracking the average motion of all of the particles of each species,

![]() $w_i$

for species

$w_i$

for species

![]() $i$

is obtained. By calculating the overall normal and shear stresses,

$i$

is obtained. By calculating the overall normal and shear stresses,

![]() $P$

and

$P$

and

![]() $\tau$

, from interparticle collisions (Luding Reference Luding2008),

$\tau$

, from interparticle collisions (Luding Reference Luding2008),

![]() $\eta$

is obtained via (2.11). Using force balance (2.1) with the applied force for

$\eta$

is obtained via (2.11). Using force balance (2.1) with the applied force for

![]() $F^S_i$

, the mixture drag coefficient

$F^S_i$

, the mixture drag coefficient

![]() $C^D_i$

is estimated using (2.12) for

$C^D_i$

is estimated using (2.12) for

![]() $F^D_i$

with the measured

$F^D_i$

with the measured

![]() $w_i$

and calculated

$w_i$

and calculated

![]() $\eta$

. In these simulations, the domain is the same as the controlled shear flows used for measuring segregation velocities. The data are recorded at intervals of 0.01 s over a 1 s window after the flow reaches a steady state.

$\eta$

. In these simulations, the domain is the same as the controlled shear flows used for measuring segregation velocities. The data are recorded at intervals of 0.01 s over a 1 s window after the flow reaches a steady state.

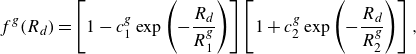

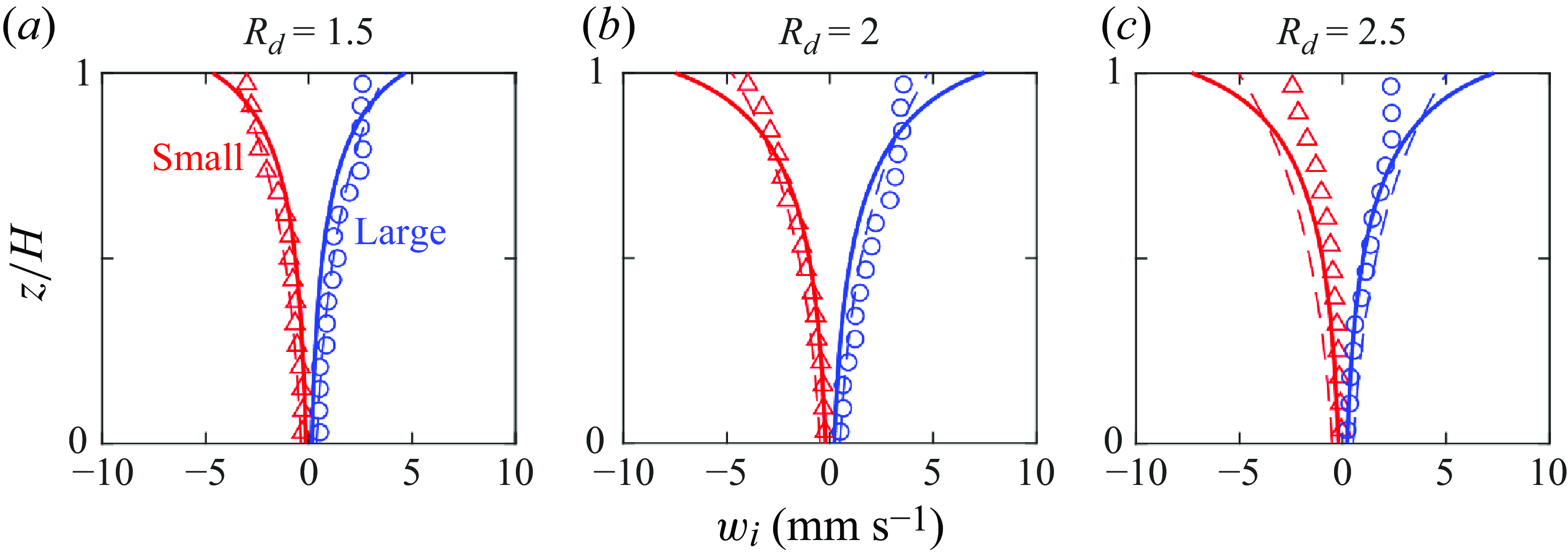

Figure 2. (a) Large-particle drag coefficient,

![]() $C^D_l$

, versus large-particle species concentration,

$C^D_l$

, versus large-particle species concentration,

![]() $c_l$

, in a uniformly sheared flow for size ratios of

$c_l$

, in a uniformly sheared flow for size ratios of

![]() $R_d=1.5$

at

$R_d=1.5$

at

![]() $I\approx 0.08$

(blue crosses) and

$I\approx 0.08$

(blue crosses) and

![]() $R_d=2$

at

$R_d=2$

at

![]() $I\approx 0.12$

(black circles) for

$I\approx 0.12$

(black circles) for

![]() $g=0$

. Error bars show the standard deviation of

$g=0$

. Error bars show the standard deviation of

![]() $C^D_{l}$

over a 1 s window for

$C^D_{l}$

over a 1 s window for

![]() $R_d=2$

; error bars for

$R_d=2$

; error bars for

![]() $R_d=1.5$

are similar but omitted for clarity. Horizontal solid black line corresponds to

$R_d=1.5$

are similar but omitted for clarity. Horizontal solid black line corresponds to

![]() $C^D_{i,0}$

for

$C^D_{i,0}$

for

![]() $R_d=2$

; horizontal dashed blue line corresponds to

$R_d=2$

; horizontal dashed blue line corresponds to

![]() $C^D_{i,0}$

for

$C^D_{i,0}$

for

![]() $R_d=1.5$

. (b) Comparison of

$R_d=1.5$

. (b) Comparison of

![]() $C^D_{i,0}$

with

$C^D_{i,0}$

with

![]() $C^D_i$

for varying size ratio. The single-intruder drag coefficient,

$C^D_i$

for varying size ratio. The single-intruder drag coefficient,

![]() $C^D_{i,0}$

is calculated from (2.10) for large (

$C^D_{i,0}$

is calculated from (2.10) for large (

![]() $i=l$

for

$i=l$

for

![]() $R_d\geqslant 1$

) (solid black curve) and small (

$R_d\geqslant 1$

) (solid black curve) and small (

![]() $i=s$

for

$i=s$

for

![]() $R_d\lt 1$

) (dashed black curve) intruder particles. The mixture drag coefficient,

$R_d\lt 1$

) (dashed black curve) intruder particles. The mixture drag coefficient,

![]() $C^D_i$

, (red curve) is calculated from (2.10) for

$C^D_i$

, (red curve) is calculated from (2.10) for

![]() $R_d\geqslant 1$

and (4.4) for

$R_d\geqslant 1$

and (4.4) for

![]() $R_d\lt 1$

. Both curves represent predictions for

$R_d\lt 1$

. Both curves represent predictions for

![]() $I=0.2$

. Predictions of the mixture model for

$I=0.2$

. Predictions of the mixture model for

![]() $I$

values ranging from 0 (lower bound) to 0.4 (upper bound), which are typical of dense granular flows, are indicated by the shaded band.

$I$

values ranging from 0 (lower bound) to 0.4 (upper bound), which are typical of dense granular flows, are indicated by the shaded band.

Figure 2(a) shows the drag coefficient of large particles measured in mixtures of particles with varying large-particle concentration,

![]() $c_l$

, in uniform shear flows with

$c_l$

, in uniform shear flows with

![]() $R_d=1.5$

and 2, having a constant inertial number in each case. The values for

$R_d=1.5$

and 2, having a constant inertial number in each case. The values for

![]() $C^D_l$

are nearly independent of

$C^D_l$

are nearly independent of

![]() $c_l$

except at very low

$c_l$

except at very low

![]() $c_l$

, approaching the single-intruder limit. Furthermore, the values for

$c_l$

, approaching the single-intruder limit. Furthermore, the values for

![]() $C^D_l$

match the value for

$C^D_l$

match the value for

![]() $C^D_{l,0}$

(horizontal dashed line for

$C^D_{l,0}$

(horizontal dashed line for

![]() $R_d=1.5$

and solid line for

$R_d=1.5$

and solid line for

![]() $R_d=2$

). Hence, the intruder drag model (2.8) for

$R_d=2$

). Hence, the intruder drag model (2.8) for

![]() $C^D_{l,0}$

provides a reasonable estimate of

$C^D_{l,0}$

provides a reasonable estimate of

![]() $C^D_l$

for mixtures at arbitrary non-zero concentrations for the cases considered here, although further study of the dependence of drag on species concentration, size ratio and inertial number is warranted.

$C^D_l$

for mixtures at arbitrary non-zero concentrations for the cases considered here, although further study of the dependence of drag on species concentration, size ratio and inertial number is warranted.

Unlike the intruder drag model (2.8) that treats the drag force on the intruder, whether it is small or large, as if it is in a sea of particles of the other size, the drag forces for a mixture must also satisfy volume conservation when determining the species-specific segregation velocities,

![]() $w_i$

, for a mixture. This requires that the overall drag force for all of the large particles at a given concentration of large particles must be balanced by the drag force for all of the small particles at the corresponding concentration of small particles, while at the same time volume flux must be conserved (in the laboratory reference frame):

$w_i$

, for a mixture. This requires that the overall drag force for all of the large particles at a given concentration of large particles must be balanced by the drag force for all of the small particles at the corresponding concentration of small particles, while at the same time volume flux must be conserved (in the laboratory reference frame):

Consequently, there exists an implicit relation between the drag coefficients for large (

![]() $C^D_l$

) and small (

$C^D_l$

) and small (

![]() $C^D_s$

) particles to assure that volume flux is conserved. Noting from (2.7) that

$C^D_s$

) particles to assure that volume flux is conserved. Noting from (2.7) that

![]() $T_i+F^D_i=0$

, expressions for

$T_i+F^D_i=0$

, expressions for

![]() $w_i$

for each species from (2.12) can be substituted into (4.1) yielding

$w_i$

for each species from (2.12) can be substituted into (4.1) yielding

Using (2.6), this can be expressed as

which can be rearranged as

To satisfy this constraint for size segregation with density ratio

![]() $R_\rho =1$

, we implement the drag model so that the large-particle drag coefficient

$R_\rho =1$

, we implement the drag model so that the large-particle drag coefficient

![]() $C^D_l$

is estimated by (2.10) but the small-particle drag coefficient

$C^D_l$

is estimated by (2.10) but the small-particle drag coefficient

![]() $C^D_s$

is calculated based on the correlation (4.4). The justification for this approach is that (2.10) is valid for

$C^D_s$

is calculated based on the correlation (4.4). The justification for this approach is that (2.10) is valid for

![]() $0.6\leqslant R_d \leqslant 5$

, so we only use it to estimate

$0.6\leqslant R_d \leqslant 5$

, so we only use it to estimate

![]() $C^D_l$

for large particles (

$C^D_l$

for large particles (

![]() $R_d\geqslant 1$

) and use (4.4) to find the corresponding value for

$R_d\geqslant 1$

) and use (4.4) to find the corresponding value for

![]() $C^D_s$

for small particles that assures volume flux conservation. Figure 2(b) compares

$C^D_s$

for small particles that assures volume flux conservation. Figure 2(b) compares

![]() $C^D_i$

predictions by both the original intruder drag model (2.10) and the revised mixture drag model ((2.10) for

$C^D_i$

predictions by both the original intruder drag model (2.10) and the revised mixture drag model ((2.10) for

![]() $R_d\geqslant 1$

and (4.4) for

$R_d\geqslant 1$

and (4.4) for

![]() $R_d\lt 1$

) for

$R_d\lt 1$

) for

![]() $I=0.2$

. The two approaches overlap for

$I=0.2$

. The two approaches overlap for

![]() $R_d\gt 0.6$